U.S Navy Commissions USS New Jersey, First Ever Submarine For A Mixed Gender Crew

World’s Largest Hotel-Branded Superyacht Sets Sail For Maiden Voyage

India Establishes Its First Maritime Arbitration Center

Yanmar Unveils Its First Electric Propulsion Product For Emission-Free Sailing

Marine Propeller Shaft – Design And Construction

The heart of any ship lies in the engine room. Powered by large marine engines usually running on diesel oil of HFO, vessels are able to reach speeds of up to 50 kmph.

The components responsible for actually moving the ship are the large multi-blade propellers fit at the back.

So how does power transfer from the engines located deep inside the hull of a vessel to the propellers at the aft?

The answer lies in an integral mechanical component known as the marine shaft or propeller shaft.

Similar to how driveshafts work in cars, the shafts in ships also transfer rotational power from the engines to the propellers, which convert them into translational motion.

In this article, we will look at the marine propeller shaft and its various components, along with their design and construction, we will also study the working mechanism of these shafts.

How Are Ships Propelled?

The propulsion systems onboard ships power the vessel by converting rotational motion into translational motion. This is similar in theory to the famous Archimedes’ Screw mechanism credited to the Greek Mathematician Archimedes in c. 234 BC.

The rotational energy is provided by two to four marine engines located in the engine compartment of a ship. Both two and four-stroke engines are used depending on the size and required use of the vessel.

The marine engines generally run on diesel, although attempts are being made to turn to energy-friendly alternatives.

Inside the engine, pistons combust the fuel through alternating compression and expansion cycles. The combustion is achieved at ignition temperature and forces the crankshaft to make half a rotation under compression. The expansion phase completes the remaining half of the rotation.

The most commonly used type of marine engine is the reciprocating diesel engine that has a higher efficiency compared to other models. These engines can be classified into three types based on their revolutions per minute (rpm).

The three categories- slow, medium, and high speed have their own benefits based upon the type of ship to be powered.

For instance, large ships require a low speed but high torque propulsion system to power them. For such vessels, a low output speed engine can be selected.

The issue with using slow-speed engines is the large space they take up as compared to the other engines. Thus, a space-effective solution would be to install high-speed engines in the ship, and then reduce the torque before it reaches the propellers.

For this, a gearbox is a very useful component that can be used to manipulate rotational torque transfer. It is attached to the marine propeller shaft and reduces the power transmitted to the propeller.

The slow speed engines pose no problem to the transfer of torque and do not require an additional gearbox. The gearbox in the other speed engines is attached in between the intermediary and propeller shafts.

Components of Propeller Shafts

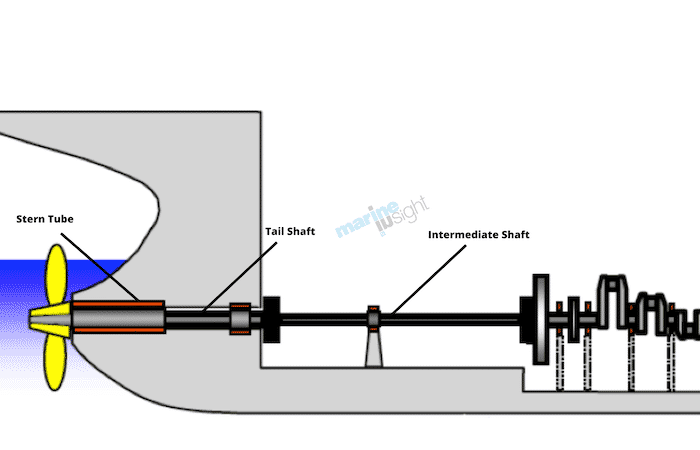

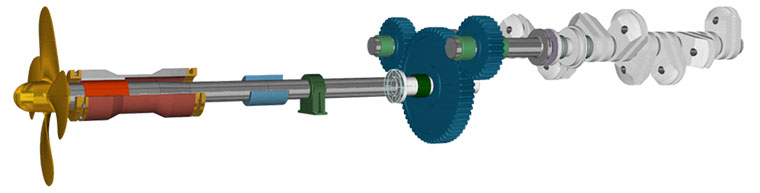

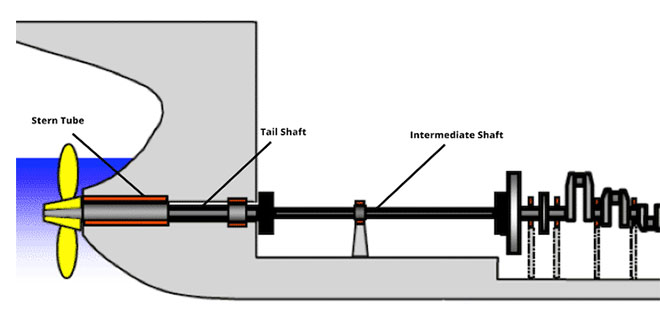

The marine propeller shaft is divided into three main components-

- the thrust shaft,

- intermediate shaft(s), and

The thrust shaft is the primary shaft emerging out of the engine. It directly receives the rotational motion from the crankshaft and rotates at the maximum velocity in high-speed engines.

For high rpm engines, the thrust shaft is further connected to other components that lie further aft.

The next component is the intermediate shaft. There is no specific restriction on the number of intermediary shafts that a ship can have. However, beyond 2 shafts, it can be difficult to service and maintain. The reason for this is the large catenary force acting on the entire propeller shaft. This force tends to deform and damage parts due to their weight.

When coupled with the large vibrational shocks that act on the shafts, there could be permanent damage to the propeller shafts. Thus, a low number of intermediary shafts are preferred. The only reason to have multiple intermediary shafts as if the engines are located far away from the propellers.

The last part is the tail shaft . It is directly connected to the propellers and lies mainly encased in the stern tube . The tail shaft is connected to the intermediate shaft by a gearbox that manipulates torque transfer. The tail shaft is built to withstand a variety of forces that may act at the stern of the ship.

The next component is the coupled bearing that connects two adjacent shafts. The coupling is achieved by virtue of joints that are usually rigid and do not flex. The coupling units are bolted to each other using high strength fasteners that can withstand a large number of vibrational stresses.

Shaft bearings are components that are used to support and bear the load of the shafts. They run along the length of the shaft and ensure smooth rotation. These bearings are constructed differently based on their location.

The last part of the marine propeller shaft system is the thrust blocks. These blocks support the propeller shafts at regular intervals. These blocks play transfer the excess power from the shafts into the hull of the ship.

As the shafts rotate at very high speeds, some amount of vibration occurs. This further leads to jarring shocks that may compromise the structural integrity of the vessel . Thus, using specialized bearings, the shocks can be dispersed over the hull of the ship.

To anchor these thrust blocks to the bed of the ship, a reinforced frame is built. There is a primary thrust block placed aft of the engine crankshaft, that disperses the majority of the shock into the hull girders and structures.

The components discussed above form the large bulk of parts that make up the propeller shafts. In addition, there are a variety of smaller parts such as sealants and bearings that serve different functions.

Design and Construction

The design and construction phase are important as it ensures structural strength. With shaft speeds reaching anywhere between 300 rpm to 1200 rpm, care must be taken to control material fatigue and reduce damages caused to the components of the ship.

The construction of the shaft bearings is important, as this holds the complete weight of the propeller shafts.

There are two main types of bearings- the full case bearing located at the stern, and the half case bearing located at the other positions.

The full casing provides a complete bearing for the weight of the shaft and is an integral part. The reason it is located at the stern is to account for both catenary weight forces, and also to counteract any buckling or reverse thrust forces felt at the aft due to the motion of the propellers. This bearing is also known as the aftmost tunnel bearing, as it encases the shaft just like a tunnel.

The other shafts only account for the weight, and hence do not require an upward casing unit. These bearings must be designed of high strength metals that do not easily buckle or deform under high strains. In addition, low levels of tolerances are expected during the manufacturing stage.

Special bearing pads are fit into slots on the connecting inner face of the bearing, such that it allows for smooth rotation. To lubricate the shaft bearing, an oil dip arrangement is carried out. By coating the rotating surface with oil from an oil thrower ring at regular intervals, a thick coat of lubrication is maintained at all times.

The coolant used to prevent overheating and subsequent damage are water circulated about the shaft bearing. This is stored in specialized tubes that run along the bearing and shaft. Tanks stored above the engine platform house coolant that is circulated around the propulsion machinery and systems.

The thrust blocks are used primarily to dampen and absorb forces from the rotating propeller shafts. These forces are redirected into specialised frames that make up the bed of the engine compartment. The energy in these frames is further distributed into the surfaces of the hull through the hull girders.

The hull girders serve as the framework on which the hull of the ship is constructed. The thrust blocks must be rigidly mounted in place to prevent any form of vibration during the course of the journey. Also, the primary thrust block can either be an independent unit that is built separately or can be integrated into the marine engines itself.

By integrating the block into the engine, it reduces the space requirements and maintenance costs while sailing. However, maintenance, while berthed, can be an issue as it would require opening the engine block casing. The casing that makes up the thrust blocks are built in two parts- an upper half that is detachable, and a lower half that supports the shaft.

The shaft is laid onto the lower block, and the upper half is then bolted into place using specialized fasteners that can absorb shock. To lubricate the rotating shaft, oil is regularly coated on to the rotating surface. This is achieved in a manner similar to that of the shaft bearings.

An oil thrower and deflector are put in place to maintain a constant supply of oil from a storage unit located on the lower half of the thrust block.

The operating temperature is controlled using cooling coils that circulate a chosen type of coolant throughout the block. It also draws coolant from the central propulsion cooling system. To absorb the vibrations and shocks, bearing pads are attached to the blocks.

They can be of two types- tilt pads, or pivotal pads, both of which are held in specialized holders built into the thrust block. The thrust pads transfer energy to the lower half of the casing that is constructed to withstand larger amounts of shock.

A thrust collar is also used to absorb thrust from the propeller shaft. The thrust blocks incorporate integral flanges that primarily help in bolting the block to other surfaces.

For instance, the block can be connected to the gearbox or engine using this flange. It can also be used to connect the engine thrust shaft to the intermediate shafts using these flanges. In case the thrust block is built into the engine block, it is made of the same casing material that the engine base plates are manufactured from.

In addition, they directly use the lubrication and coolant from the engine components itself. The integrated block is similar to the normal thrust blocks in most other features. It is interesting to note that the thrust block is integrated into the engine in most ships, except for the smaller boats that have space constraints.

The shafts themselves must be built from robust materials with high yield strength, and a lower probability of buckling. Each shaft starting from the thrust shaft must be built into small and manageable components that can be disassembled when the need arises.

In addition, seals and stuffing boxes are also built from appropriate materials that can effectively seal the inner working machinery from external water. High-grade materials are a must while manufacturing propeller shafts, as this is very sensitive equipment that needs to handle large forces.

The marine gearbox is an integral component that is attached in between the tail shaft and the intermediary shaft. It is mainly used to manipulate the torque transferred from the engine crankshaft to the propellers located at the stern. It is most commonly used in large vessels that engage a high-speed engine during operations.

The gearbox works just like an automobile gearbox, that uses a system of clutch discs and pads to control torque. Using robust gear arrangements that can withstand large vibrations, the gearbox is an integral part of ships with high-speed engines.

Lubrication is a necessity to prevent friction-related accidents or damage from occurring.

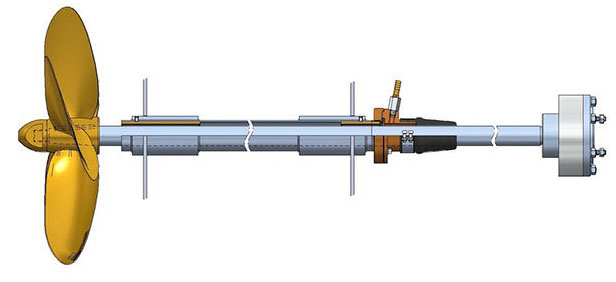

Stern Tube and the Propeller Shafts

Stern tube arrangement refers to the manner in which the tail shaft is borne by the stern tube that is located at the aft of the vessel. The stern tube is a hollow, horizontal tube that serves as the primary connection between the propellers and the rest of the vessel.

Attached to the stern frame , the stern tube acts as a plug at the rear of the vessel. The stern frame is the primary structural member that supports the stern overhang that lies above the propellers and rudder.

The stern tube houses the tail shaft of the marine drive shaft system and serves two main purposes- withstanding load and sealing the entire vessel at the aft portion.

Since the stern tube serves as the primary link between the vessel and the propeller, it must be able to withstand a tremendous amount of force that is exerted by the suspended propellers. In addition, it should provide sufficient room for the propeller hub to actually move without creating friction.

To handle the load, white metal is a commonly used material that can withstand the required loads. Sufficient lubrication is also provided within the stern tube to ensure the smooth functioning of the entire marine propulsion system.

Along with supporting the structural weight and forces of the propeller, the stern tube also needs to be able to effectively seal the vessel. It prevents water from entering through the aft and achieves this by using a combination of seals along its length. The stern tube has two main seals located at its aft and fore regions.

This serves as dual protection against any possible leaks that may occur over long periods of time. These seals can be of three main types- stuffing boxes, lip seals, and radial face seals. Stuffing boxes are built out of a variety of packing materials that are used to plug the stern tube.

Lip seals are gland seals that are used to prevent lubricants from seeping out into the water. They also serve the dual purpose of preventing water from entering the stern tube. Lastly, radial face seals extend radially out from any points of ingress and use a spring system to seal the entire structure. They are composed of two main parts that join to completely seal the rear portion.

The stern tube plays an important role in marine propulsion since it absorbs and dampens a considerable amount of power away from the propeller. In an effort to completely seal the stern section of the ship, it may also hamper the rotational abilities of the propeller shafts.

This would be counterproductive and would create a large amount of stress within the hull of the ship. Thus, being able to effectively seal the aft region without affecting the performance parameters is a major necessity in naval architecture and engineering.

Disclaimer : The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

About Author

Ajay Menon is a graduate of the Indian Institute of Technology, Kharagpur, with an integrated major in Ocean Engineering and Naval Architecture. Besides writing, he balances chess and works out tunes on his keyboard during his free time.

Read More Articles By This Author >

Do you have info to share with us ? Suggest a correction

Daily Maritime News, Straight To Your Inbox

Sign Up To Get Daily Newsletters

Join over 60k+ people who read our daily newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

BE THE FIRST TO COMMENT

Thank you very much for this article. You explained marine propulsion and shaft in a clear manner.

Thank you very much for this information

Leave a Reply

Your email address will not be published. Required fields are marked *

Subscribe to Marine Insight Daily Newsletter

" * " indicates required fields

Marine Engineering

Marine Engine Air Compressor Marine Boiler Oily Water Separator Marine Electrical Ship Generator Ship Stabilizer

Nautical Science

Mooring Bridge Watchkeeping Ship Manoeuvring Nautical Charts Anchoring Nautical Equipment Shipboard Guidelines

Explore

Free Maritime eBooks Premium Maritime eBooks Marine Safety Financial Planning Marine Careers Maritime Law Ship Dry Dock

Shipping News Maritime Reports Videos Maritime Piracy Offshore Safety Of Life At Sea (SOLAS) MARPOL

WAIT! Did You Download 13 FREE Maritime eBooks?

Sign-up and download instantly!

We respect your privacy and take protecting it very seriously. No spam!

- Shopping cart 0 You have no items in your shopping cart.

- Check Order Status

- Inboard Boat Props

- Outboard Boat Props

- Sterndrive Props

- PWC Impellers

- Ski/Wake Props

- Authentic Volvo Duo Props

- Propeller Pullers

- Propeller Guides

- Brass cutless bearings

- Non metallic bearings

- Duramax flanged bearing

- Stave bearings

- Shaft Zinc Anodes

- Rudder Zinc Anodes

- Plate Zinc Anodes

- Shaft Nut Zincs

- Stainless Prop Shafts

- Shaft Seals

- Marine Shaft Logs

- Shaft Packing Boxes

- Shaft Accessories

- Deck Hardware

- Drivetrain Hardware

- Marine Exhaust Fittings

- Hose and Clamps

- Steering Hardware

- Marine Valves

- Plumbing Fittings

- Prop Shafting Accessories

- Marine Strainers

- Miscellaneous Hardware

- Aqualoy 22 Prop Shaft

- Shafts & Seals /

- Stainless Prop Shafts /

Aqualoy A22 inboard propeller and industrial pump shafts undergo more quality controls than any competing brand. These prop shafts are used in a wide variety of applications such as work boats, pleasure craft, naval vessels, and pumps. The Aqualoy® process produces a rounder, straighter, stronger shaft. All of our A22 shafts from 3/4" - 4" diameter are precision machined in our Mazak Nexus 350M CNC turning lathe to insure all machining is within .0005".

Single Tapered A22 Stainless Shafts All single tapered shafts will have a propeller taper machine according to SAE J755 specifications, unless other instructions are given. In addition to the propeller taper machining, a single square keyway will be machined for the coupling end of the shaft. The dimples for the set screws can only be machined with the coupling in place. If you purchase a coupling from us, there will be a $125.00 to fit and face the coupling to the shaft and during this process, the dimples for the set screws will be completed.

Double Tapered A22 Stainless Shafts All double tapered shafts will have a propeller taper machine according to SAE J755 specifications, unless other instructions are given. In order for us to machine the coupling taper, we will require either a drawing of the coupling taper or the following dimensions must be specified(as there is not an SAE standard for coupling tapers and these tapers do vary); length of taper, small end diameter of taper, and length and size of threads.

Your Trusted Source for Stainless Shafting Deep Blue Yacht Supply boasts a full service machine shop, with capabilities allowing for machining of stainless shafts up to 9” in diameter. As a testament to the master skill level of our machinists, many discerning yacht, boat, and facility owners across the globe have their A22 stainless shafts machined at Deep Blue Yacht Supply. Current lead time for the production of new custom stainless shafts is 3-4 business days.

Custom Dimensions Please note that our single-taper machining follows the SAE J755 specification. In addition, our CNC engineers can provide a wide array of custom shaft dimensions. For non-standard dimensions and double-tapered shafts, our engineers will be more than happy to review your dimensions to ensure the proper fit.

For diameters greater than 3", lengths greater than 108", or custom specifications, please feel free to contact our shaft specialists at 1-800-454-6960

Fit and Face Shaft with Coupling A22 (Labor Only)

Customized product, psk100 propeller nuts and keystock, 50mc004100 solid buck algonquin marine motor coupling, x-3 shaft zinc 1" diameter.

- Cutlass Bearings

- Boat Hardware

- 1-800-454-6960

- 1-321-978-0253

- 1-954-444-6259

- [email protected]

- DeepBlueYacht

- Contact Us With Questions

- Shipping and Return Policy

- Privacy Policy

- Conditions of Use

- Company Overview

- Accessories

- Cleaners & Waxes

- Clothing & Gifts

- Cooling Systems

- Discount Dock

- Electrical Systems

- Engine Parts

- Exhaust Systems

- Fuel Systems

- Gauges & Accessories

- Hose & Fittings

- Jet Drives & Accessories

- LS Engine Parts & Accessories

- Oil Systems

- Oil, Lubricants & Paint

- Outdrives & Accessories

- Propeller Accessories

- Safety Equipment

- Sale Specials

- Steering Systems

- Steering Wheels & Adapters

- Superchargers

- Throttles, Shifters & Controls

- Trim Indicators & Accessories

- V-Drive Components

- Shipping Information

- Return Policy

- Privacy Policy

- Security Policy

- Terms & Conditions

- Dealer Information

- Your Account

- Instructions & Guides

- Mercruiser Parts Finder

- Press Release Archive

- Custom Fabrication

- New Products

- OEM Replacement Parts

- Diversified Marine Catalog

- GLM Marine Catalog

- Mallory Marine Catalog

- Mercury Marine Catalog

- SEI Marine Catalog

- U-FLEX Marine Catalog

- 1-877-900-7278

- LS Engine Parts and Accessories

- Oil, Lubricants & Paints

- Outdrives and Accessories

- Tools & Accessories

- Trim Indicators and Accessories

- Cavitation Plate Pads

- Cavitation Plate Turnbuckles

- Pins & Clips

- Prop Shafts

- Safety Collars

- Shaft Couplers

- Stuffing Boxes

- Rudders & Accessories

- Transom Pillow Blocks

- V-Drive Accessories

- Mallory / Sierra Marine Catalog

- Mayfair Marine

- Package Deals

- SEI Marine Products Catalog

- AEM Performance Electronics

- American Turbine

- ARP Fasteners

- Barnegat Light

- Berkeley Jet Drive

- Bluewater Enterprises

- Cometic Gaskets

- Competition Headers

- Corsa Performance

- Custom Marine (CMI)

- Delfino Steering Wheels

- Get Real Products

- Glenwood Marine

- Grant Steering Wheels

- Gussi Steering Wheels

- Hardin Marine

- Hi-Tek Marine

- Holley Marine

- IMCO Marine

- Isotta Steering Wheels

- K&N Engineering

- Lightning Headers

- Livorsi Marine

- Mallory / Sierra

- Marine Design Corp

- Marine Lighting Products

- Max Volt Ignition

- MSD Ignition

- Oliver Racing

- Orca Marine Cooling Systems

- Place Diverter

- Plash Marine Lighting

- Rewarder Custom Headers

- San Juan Engineering

- SEI Marine Products

- Stainless Marine

- The Blower Shop

- XRP Fittings

- Zeiger Steering

Prop Shafts & Accessories - Prop Shafts

- Back to Parent Category

| $7.00 Propeller shaft length is critical and must be measured correctly. To ensure overall shaft length, measure from the V-drive shaft to the back of the strut barrel, and add 5". Different alloys are available differing in strength characteristics ranging from weakest to strongest as follows: 303, 17-4, Aquament 22. The amount of horsepower available should be the determining factor in your selection of the correct alloy. We will be happy to make a recommendation for you in this respect. Just give us a call. For a machined shaft, please purchase the shaft machining option in the related parts section. |

| $11.75 Propeller shaft length is critical and must be measured correctly. To ensure overall shaft length, measure from the V-drive shaft to the back of the strut barrel, and add 5". Different alloys are available differing in strength characteristics ranging from weakest to strongest as follows: 303, 17-4, Aquament 22. The amount of horsepower available should be the determining factor in your selection of the correct alloy. We will be happy to make a recommendation for you in this respect. Just give us a call. For a machined shaft, please purchase the shaft machining option in the related parts section. |

| $14.99 Propeller shaft length is critical and must be measured correctly. To ensure overall shaft length, measure from the V-drive shaft to the back of the strut barrel, and add 5". Different alloys are available differing in strength characteristics ranging from weakest to strongest as follows: 303, 17-4, Aquament 22. The amount of horsepower available should be the determining factor in your selection of the correct alloy. We will be happy to make a recommendation for you in this respect. Just give us a call. For a machined shaft, please purchase the shaft machining option in the related parts section. |

| $34.99 Water lubricated prop shaft bushings. Other sizes available by request. Bushings are 4" long. |

| $61.99 |

| $64.99 |

- About Hardin Marine |

- Privacy Policy |

- © Hardin Marine 2023. All Rights Reserved.

- Noah Marine Services

- Main Engines Spares

- Auxiliary Engine Spares

- Shaft Spares

- Rudder Spares

- Marine Valves

- Marine Pumps

Marine Propeller Shaft

- News & Tech Documents

- Marine Parts NO

Marine propeller shaft transmit mechanical torque, rotation, and power. Driveshafts, driving propeller shafts, Splined, Flanged Propeller Shaft, and Cardan shafts are all names for these shafts.

PDF Download Contact us

Marine propeller shafts are the main spare parts for transmitting mechanical torque, rotation, and power. Driveshafts, prop shafts, tail shafts and Cardan shafts are all names for these shafts.

Marine propeller shafts are used to transmit torque between components that are not directly connected due to distance or the need for relative motion.

Marine propeller shafts are prone to torsional or shear stress as it transmits torque. Therefore, they must be strong enough to withstand the pressure, while avoiding adding too much weight, which would increase their inertia.

3 Types of propeller shafts:

Tapered propeller shaft.

A tapered propeller shaft is part of a wind assembly structure or tool that is attached to the propeller shaft. More precisely, it is the adjustable part of the propeller of a ship or boat that allows for changes in pitch or angle. The shaft works by utilizing a common engine design. The tapered propeller shaft is also the main connecting thread in the propeller hub. At the heart of the TPLS is a constant length helical spring that applies a constant load force.

Splined Propeller Shaft

These types of shafts handle torque transmission. They are the teeth of the drive shaft. Its job is to maintain alignment. Splined propeller shafts are a great way to get the most out of a marine engine. They provide better air volume with a flatter path in the engine, resulting in higher velocity ductility of the combustion air. They also help reduce vibration and unwanted noise.

Flanged Propeller Shaft

A flanged propeller shaft is an elongated cylindrical shaft with one or more flanges or flat circular faces at regular intervals to resist bending. Shafts of this type are commonly used in various manufacturing industries and serve different purposes.

Propeller Shafts Pictures

Marine propeller shaft materials

The material of most marine propeller shafts is mild steel. Aluminum alloys are not suitable for marine propellers because they have the fatigue limit of the rotor. When cyclic stress increases, your aluminum propeller cannot withstand this strength.

Martensitic steels are a good choice because they perform well during cyclic stress. The larger the scale they face, the more capable they are. Most commercial marine and aerospace machining uses Tobin’s bronze or Monel for their propellers because they are primarily non-corrosive. This will ensure zero or minimal leakage.

Components of Propeller Shafts

The marine propeller shaft is divided into three major components:

- Thrust shaft,

- intermediate shaft(s)

The thrust shaft is the main shaft extending out of the engine. It receives rotational motion directly from the crankshaft and rotates at maximum speed in high-speed engines.

For high-revving engines, the thrust shaft is further connected to other components located further aft.

The next component is the intermediate shaft. There is no specific restriction on the number of intermediary shafts that a ship can have. However, beyond 2 shafts, it’s difficult to service and maintain. The reason for this is the large catenary force acting on the entire propeller shaft. This force deforms and damages parts because of their weight.

When coupled with the large vibrational shocks that act on the shafts, there could be permanent damage to the propeller shafts. Thus, a low number of intermediary shafts is preferred. The only reason to have multiple intermediary shafts is if the engines are far away from the propellers.

The last part is the tail shaft . It is directly connected to the propellers and lies mainly encased in the stern tube. The tail shaft is connected to the intermediate shaft by a gearbox that manipulates torque transfer. The tail shaft is built to withstand a variety of forces that may act at the stern of the ship.

We are propeller shaft manufacturers

Engine Exhaust Valve

- Marine Check Valves

Marine Diesel Engine Piston

Engine Main Bearing

- Marine Engine Connecting Rods: The Ultimate Guide

- “Smooth Sailing: The Benefits of Marine Butterfly Valves for Safe and Efficient Boat Operations”

- Marine Rudder Pintle

- Maximizing Marine Cylinder Liner Lifespan

- Cylinder Liner S60MC S50MC S42MC S35MC S26MC Spare Parts

We are the world leading Marine Parts Supplier, and a marine engine system accessories service provider integrating ship engine technical consultation, maintenance, spare parts supply…

Click Here To View: Our Products

- Tingting: +86-15967061188 Peter Ye: +86-13777748833

- [email protected] [email protected]

- Monday - Friday, 8am - 6 pm;

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sails and Rigging

- Maintenance

- Sailing Totem

- Sailor & Galley

- Living Aboard

- Destinations

- Gear & Electronics

- Charter Resources

- Ultimate Boating Giveaway

Sailboat Propeller-Shaft Couplings

- By Steve D'Antonio

- Updated: June 19, 2019

If you’ve ever aligned your propeller shaft and engine, then you’ve handled the hardware that connects these two components together: the shaft coupling. While simple in form, couplings play a critical role in drivetrain reliability. If they are not properly installed, they can lead to vibration or worse — the separation of the shaft from the engine.

There are three primary types of couplings: straight, split and tapered, with the first two being the most common for smaller sailboat auxiliaries.

While straight-bore couplings are common, they lack the grip required for larger engines and props, which can place significant strain on the shaft-to-coupling interface. The challenge is getting the interference fit between shaft and coupling bore just right. If it’s too tight, driving the coupling onto the shaft may be very difficult, and if it gets stuck before it’s fully inserted, that can present a challenge. If it’s too loose, the shaft may begin to shift in the coupling with each forward-neutral-reverse shift evolution, which in turn will gall the key, allowing for more and more movement.

This scenario often ends with a sheared key and set screws, with the shaft and prop sliding out the shaft log, at which point they either screw their way into the ocean depths or strike — and jam — the rudder. If the shaft parts from the stuffing box altogether, a fire-hose-like geyser will erupt, after which the bilge pumps will be tested, and not in a good way. Installing a clamp ring on the shaft to prevent this scenario makes good sense as a safety backup. Better still, set up your shaft and coupling properly, and you’ll never have to test the clamp ring.

Split couplings are easily identified by their bifurcated design. While this coupling is really made up of one part, its aft end is divided into two sections that are clamped against the shaft using two or more machine screws. With this arrangement, the coupling can apply clamping action to the shaft. The split coupling offers one advantage over other coupling types, as it enables easy removal of the shaft by driving a pair of steel wedges or cold chisels into the gap between the two split halves.

Beyond this, there is no other benefit to using a split coupling, and I’d argue that rather than making it easy to remove, the primary mission of a coupling is to securely retain the shaft. Additionally, because it is split, and therefore moves or distorts each time a shaft is inserted or removed, the coupling face may not remain perpendicular to the shaft, which will affect the ability of the shaft to be aligned to the engine/transmission output coupling. In addition, it is possible to make a mistake during installation — for example, not torqueing pinch bolts in proper sequence, or pinching against a set screw — which leads to the coupler being off perpendicular, which can lead to a serious vibration. It’s worth reiterating, the only attribute of a split coupling is the ease of shaft removal.

Tapered couplings are popular on large horsepower applications and are the undisputed Cadillac of shaft-connection methods. Relying on the same principal used for the propeller-to-shaft interface, a cone-shaped hole in the coupling mates with a precisely machined cone-shaped male taper on the end of the prop shaft. Once the two are properly connected, and the retention nut tightened, they are very difficult to separate, which is exactly the goal. Separation, when intended, typically requires a puller — or a drift (a socket often works well) and longer coupling fasteners, which are used as jacking screws. Unlike the split coupling, a tapered shaft and coupling fit together the same way every time they’re assembled, so there’s no issue with retaining perpendicularity between the shaft and the coupling face, thereby ensuring proper alignment can be accomplished.

Next month, I’ll discuss coupling keys, keyways, pilot bushings, fastener and set screw selection, drift, roll, and taper pins.

Steve D’Antonio offers services for boat owners and buyers through Steve D’Antonio Marine Consulting .

- More: engine , Hands-On Sailor , How To , monthly maintenance , prop

- More How To

Surviving the Storm: A Sailor’s Tale of Hurricane Lee

Best Practices for Boat-Show Shopping

Grease the Wheels of Your Boat: A Guide to Proper Lubrication

A Bowsprit Reborn: A DIY Renovation Story

Savoring Superior: A Great Lakes Cruise To Remember

Point Your Compass Due South, Bitter End Yacht Club Reopens October 23rd.

Pre-Owned: 1988 Hylas 47

- Digital Edition

- Customer Service

- Privacy Policy

- Terms of Use

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

We Ship Worldwide.

- Testimonial

- Create an Account

Boat Propeller Shafts, Struts and Seals

Need a new boat propeller part? We've got lots! Great Lakes Skipper adds thousands of discount boat parts every month, including boat propeller shafts, marine prop seals, and propeller struts made by Bombardier Johnson Evinrude OMC, Four Winns, Mercury Marine, Suzuki, Wellcraft, Larson, Cruisers Yachts, Carver Yachts, and more top-notch marine manufacturers. Shop our site and save big!

Shop Products

Items 1 - 12 of 139

- You're currently reading page 1

- Privacy Policy

- Terms of Use

- My account Close My account Log out

- Compare products list

You have no items in your shopping cart.

- Inboard Propellers

- Outboard Propellers

- Stern drive boat props

- PWC Impellers

- Ski Wake Boat Props

- Volvo Duo Props

- Prop Pullers

Prop Guide & Sizings

- Brass cutless bearings

- Non Metallic

- Flanged bearings

- Stave bearings

- Shaft Zincs for sale

- Rudder Boat Zincs

- Plate Zincs

- Stainless Steel Shafts

Shaft Seals

- Packing Boxes

- Shaft Accessories

- Deck Hardware

- Drivetrain Hardware

- Exhaust Fittings

- Hose and Clamps

- Steering Hardware

- Plumbing Fittings

- Shafting Accessories

- Miscellaneous Hardware

- Michigan Wheel

- Zimar Zinc Anodes

- Tides Marine

- SOLAS boat propellers

- ACME Marine

- Volvo Penta Duo Props

- Buck Algonquin Marine Hardware

Cutless Bearings

Boat hardware, boss 1-1/2" x 2" x 6" bearing, pyi pss dripless 02034112 shaft seal, r-3 3-11/16" zimar rudder zinc, acme 1235 14.50 x 14.25 x .105 cup w/ 1-1/8" bore lh prop, solas rubex aluminum 13-1/2 x 15 rh 9411-135-15 prop, propeller guide, inboard propeller sizing analysis, solas rubex aluminum 14-1/2 x 19 rh 9511-145-19 prop, solas rubex aluminum 14-4/5 x 17 rh 9511-148-17 prop, michigan wheel xhs 203 hub kit, solas rubex aluminum 15 x 15 rh 9511-150-15 prop, solas rubex 102 hub kit, solas rubex aluminum 14-1/2 x 17 rh 9513-145-17 prop, solas rubex aluminum 13-1/4 x 17 rh 9411-133-17 prop, michigan vortex 15" x 17 rh 992003 propeller, michigan vortex 14-1/2" x 19 rh 992004 propeller.

- Get in Touch

- Shipping and Return Policy

- Privacy Notice

- Conditions of Use

- Customer info

- Shopping cart

Payment options

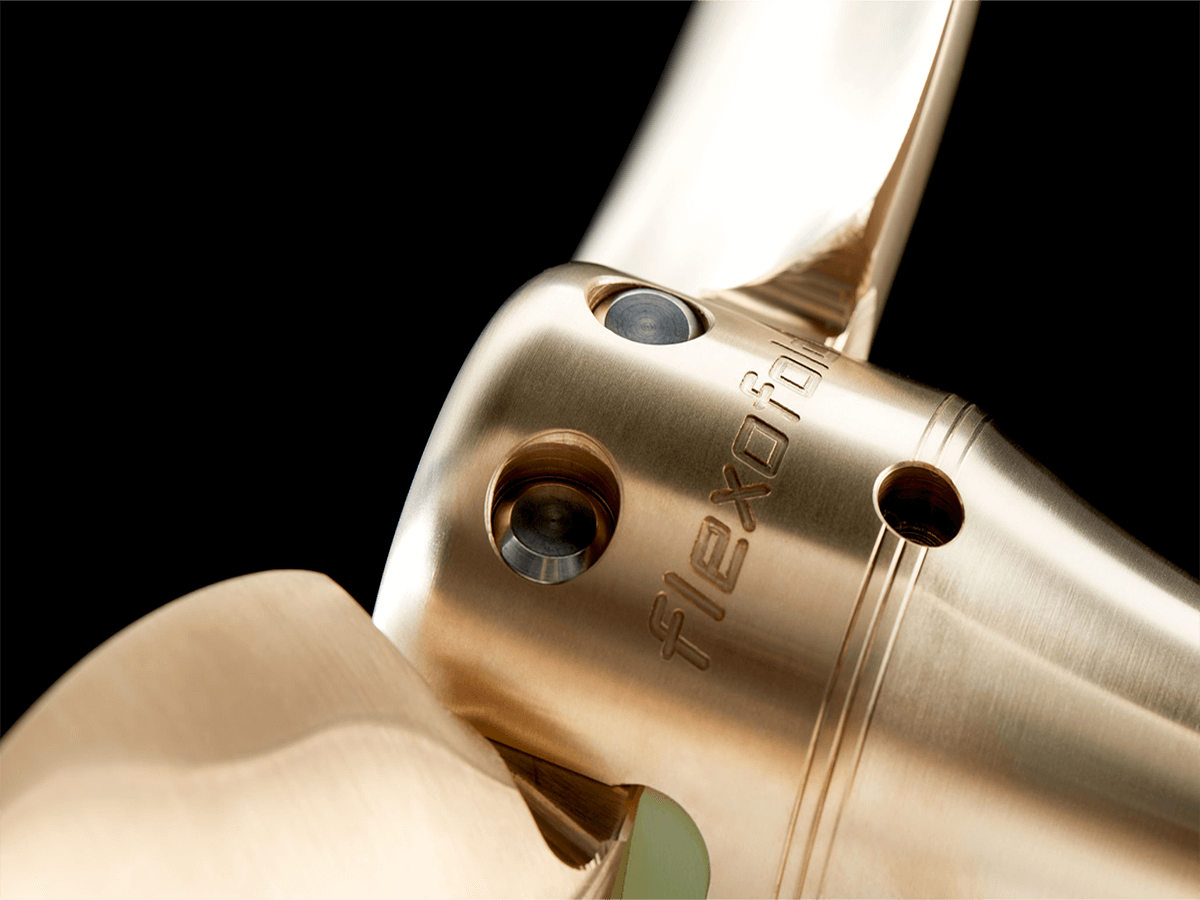

Flexible shaft couplings for sailboats

Sigmadrive flexible propeller shaft coupling.

SigmaDrive is a flexible propeller shaft coupling that is effective noise and vibration suppression for most sailboats up to 1300 hp. SigmaDrives is unique as it is able to absorb thrust when installed as a standalone propeller coupling directly from the shaft to the output flange on the transmission. SigmaDrive solves issues due to imperfect engine alignment between the propeller shaft and the engine, compensating for up to 3 degrees in all directions.

Installation

SigmaDrive is quick and easy to fit, usually without the need to haul out the vessel. The unit is compact and does not need any modifications to the propeller shaft as it uses a taper lock system to grip the shaft securely.

SigmaDrive eliminates the need for costly precision alignments. SigmaDrive gives flexibility to the shaft line allowing the engine to operate at a maximum 3 degree offset (6 degree full sweep) without transferring any harmful side loads.

Build Quality

Your content goes here.

SigmaDrive is manufactured using a sturdy marine grade Bronze housing and all metal interior. The lack of rubber parts used by competing brands gives SigmaDrive and incredibly long and maintenance free life.

SigmaDrive uses and internal rotating sphere to absorb a thrust load and a bearing system to absorb the torque load. This gives SigmaDrive a unique ability to take thrust without the need for additional thrust bulkheads making it extremely compact.

Manufactured from a special bronze alloy, SigmaDrives require virtually no maintenance and containing no bearings or rubber in their construction. The knock on effect of using a SigmaDrive shaft coupling is that the forces typically generated from misalignment will not be transferred to the engine or transmission extending their life significantly.

Unlike existing shaft couplings SigmaDrive does not use rubber to dampen the vibrations or take out misalignment. SigmaDrive shaft couplings are special constant velocity joints that are able to resist the propeller thrust without the need for thrust bearings in most applications. They are extremely compact and able to transmit higher torque than other propeller shaft couplings with similar dimensions. In addition, as they do not use rubber as a vibration suppression device, they are an exceptionally long wearing marine coupling, with minimal maintenance needed.

Why does a SigmaDrive work so well? Because SigmaDrive is a constant velocity joint which allows the propeller shaft to rotate without transmitting the engines movements and vibrations. Other attempts at solving these solutions rely on rubber couplings or Cardan units. The SigmaDrive requires none of these, is compact and easy to fit, usually without slipping the vessel or requiring modifications to the shaft line. It’ s a premium product manufactured from a special bronze alloy that is maintenance free and its internal components are hard wearing and long lived.

Looking at the image on top of the schematic you can see the usual method of connecting an engine with a propeller. The three fixed points, consisting of the propeller mount, the mechanical seal and the engine / gearbox, are individually or collectively capable of creating the two potential causes of noise and vibration. Firstly, any imperfect alignment of the three points can create vibration and noise. Secondly those vibrations and the associated noise are then transmitted directly through to the hull of the vessel and thence throughout the boat.

The simple solution is to fit a SigmaDrive coupling in the place of the standard one. The whole system from gearbox to propeller instantly becomes much more flexible, with the coupling able to correct imperfect co-axial alignment between the prop shaft and the gearbox of as much as 6 degrees. As can be seen in the lower schematic with the SigmaDrive in place the reduction in the rigidity of the whole propulsion system means that the engine vibrations are significantly reduced or eliminated completely, and the prop-shaft can rotate naturally with no vibrations or noise to transmit to the hull.

For most sailboat applications SigmaDrive is a simple effective solution for noise and vibration issues that are caused by misalignment. SigmaDrive reduces and even eliminates vibrations that originate from an imperfect alignment between the propeller shaft and the engine by adding flexibility to the shaft line. Thrust taken up on the engine from the propeller invariably changes the angle of the shaft line, particularly when the engine uses soft rubber mounts. Using a single SigmaDrive coupling will ensure the shaft is correctly aligned at all times, especially under high load. The result, reductions in many cases of around 50% in noise and vibration.

The SigmaDrive coupling is able to resist propeller thrust when installed as a standalone coupling directly from the shaft to the output flange on the engine’s transmission. The SigmaDrive coupling is manufactured from a special bronze alloy and is virtually maintenance free. The internal components are hard-wearing with a long service life. No rubber is used in the construction of the SigmaDrive and its unique design compensates for the movement of the engine when under load from the propeller shaft.

The flexible SigmaDrive coupling is a direct replacement for a hard coupling such as Buck Algonquin, or flexible couplings such as R&D and Polyflex. The coupling uses a keyless taper lock system to grip the shaft so no modifications are needed to install the unit.

SigmaDrive couplings are available for shaft torques of 185 ft-lbs to 4425 ft-lbs with a range of shaft diameters.

| Model | Max. Torque | Shaft Type | Shaft Dia. (A) | Min. shaft depth | Flange Dia |

|---|---|---|---|---|---|

| SD55 | 550 Nm | Parallel ended V-Drive | 22-35mm, 1-1.5" | A + 5mm | 4" |

| SD100 | 1000 Nm | Parallel ended V-Drive | 30-45mm, 1.5-1.75" | A + 5mm | 5" |

| SD150 | 1500 Nm | Parallel ended V-Drive | 45-50mm, 1.75-2" | A + 5mm | 5" |

| SD225 | 2250 Nm | Parallel ended V-Drive | 50-60mm, 2-2.25" | A + 5mm | 5" |

| SD300 | 3000 Nm | Parallel ended V-Drive | 50-70mm, 2-2.5" | A + 5mm | 5.75" |

| SD600 | 6000 Nm | Tapered with keyway | 70-90mm | N/A | 7-8" |

SigmaDrive removes the need for expensive precision alignment of the shaft line

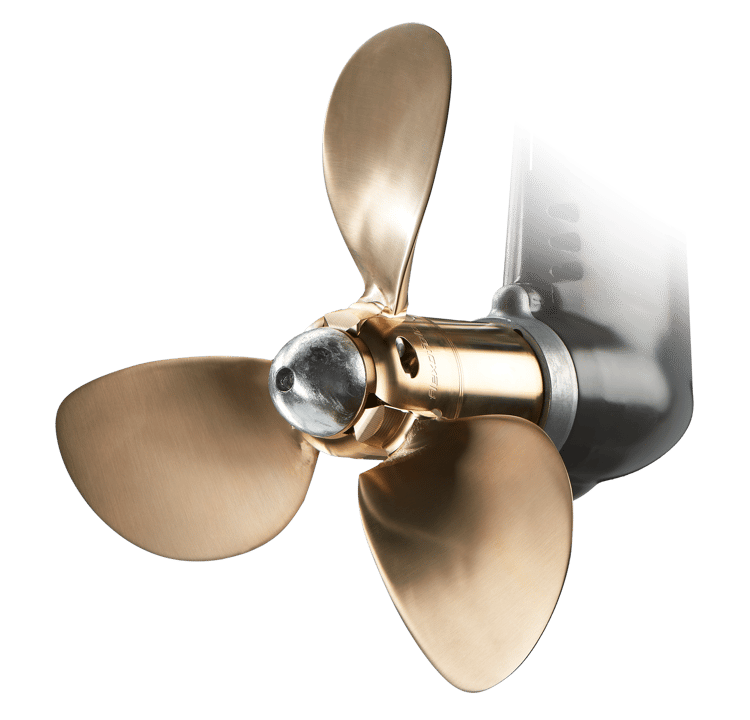

FIND YOUR NEXT FLEXOFOLD FOLDING PROPELLER

Flexofold develops, manufactures,, and sells the most efficient folding, propellers for sailboats and, multihull yachts on the market..

Get a specified propeller recommendation for your sailboat

Our folding propellers are available as 2-bladed, 3-bladed, and 4-bladed in multiple sizes and pitches. All delivered for both shaft- and saildrive installation.

100 % FIT ON ALL COMMON SAILDRIVES

The Flexofold propellers fit perfectly on all common saildrives and are widely used by most of the recognised boatyards worldwide – including Beneteau, Jeanneau, Lagoon, Elan, Hanse Yacht, Dehler, Saffier Yacths, Halberg-Rassy and many more!

100% fit on all common shafts

The Flexofold propellers are designed to fit perfectly on all common shafts following the ISO; SAE and IMP standards, and are widely used by most of the recognized boat yards worldwide.

.png)

Worldwide delivery

Flexofold propellers are delivered all over the world directly from our factory in Vejle, Denmark. No matter where you live or where your boat is located, we ship your new propeller by UPS courier service – directly to your address at very competitive costs. In most cases, we ship your new propeller within 3-5 working days from placing the order / receiving payment.

Our experience - your guarantee!

We pride ourselves in direct contact and dialogue with our customers, shipyards, and dedicated sailors from all around the world. This is why we can ensure that you get the right guidance and the best possible propeller for your sailboat!

Saildrive Propellers

Flexofold folding propellers for Saildrive installation

Shaft Propellers

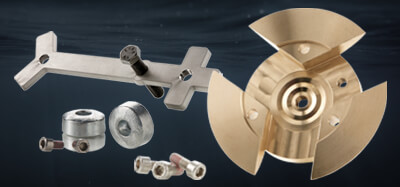

Flexofold folding propellers for mounting on Shaft

Spare Parts

Find spare parts for your propeller here

The best test for a propeller is the one carried out by the sailor himself!

Find the answers to the most frequently asked questions about folding propellers

Enjoy the performance and safety benefits that our foldable propellers provide

CUSTOMER REFERENCES

The Flexofold 3-Blade 17x13-3L/R propeller went on after the first attempt. The motors—2x Yanmar 3JH5—come to a nominal speed of 3000 RPM and the Outstar 48 goes at the speed of 9.5kn

Andreas Bock

The new outstar 48 with twin flexofold - germany.

.png?width=150&height=150&name=quote2%20(1).png)

Adding the 3 bladed Flexofold was the best thing ever. Should have done it years ago. Better performance under sail and power. Cut fuel consumption in half!

Mark Schneider

Smarter charter ltd. - usa, buy directly from the flexofold factory.

Get an offer for a Flexofold folding propeller.

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Reverse or Neutral

- Thread starter jrocheleau

- Start date Sep 17, 2008

- Oday Owner Forums

- Ask An Oday Owner

I've heard conflicting views on what to do with your transmission when under sail. Should it be kept in neutral or reverse when sailing?

What I've been told is to put it in reverse when under sail. This came from the best diesel mechanic in our area. He's the guy that works on most of the boats including the ferry and cruise boats here. I don't know if the make and model make a difference. Ours is a Universal M25. Hope this helps!

Capt Jim24025

Depends on your engine and tranny Check with the engine manufacturer. My VolvoPenta w/saildrive says to use Reverse but my Perkins 107 manual says to use forward. In lieu of that, try them both and find out which one stops the prop from turning. You want to stop the shaft from turning to prevent excessive wear on the transmission and packing bearing. I've also been told that a stationary prop has less drag than a moving prop (but that seems counter-intuitive to me). Capt. Cook

My spin... Right on, Cap'n... I have a Volvo/Perkins MD2030 hooked up to a Volvo MS25S saildrive. Manual states when under sail, place shifter momentarily in reverse to stop prop and then place in neutral. Cheers, Bob

Hello All! Do you know right position of the Paragon reverse gear (Atomic engine) under sail? I didn't find it at the operation manual.

Konstantin said: Do you know right position of the Paragon reverse gear (Atomic engine) under sail? I didn't find it at the operation manual. Click to expand

Thanks a lot! Hello Rad! My name is Konstantin. I'm from Russia and I've bought the same boat (O'Day 32)! I see that it is really rare boat and there is not a lot of information. How long you own your boat?

Attachments

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

Advertisement

Choice of the material for production of a ship propeller shaft

- Science for Production

- Published: November 1985

- Volume 20 , pages 586–589, ( 1985 )

Cite this article

- Ya. M. Sirak 1 ,

- G. N. Filimonov 1 &

- T. G. Tsvetaeva 1

125 Accesses

Explore all metrics

This is a preview of subscription content, log in via an institution to check access.

Access this article

Subscribe and save.

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Literature cited

G. V. Karpenko, The Strength of Steel in a Corrosive Medium [in Russian], Mashgiz, Moscow Moscow (1963).

Google Scholar

A. V. Ryabchenkov, Corrosion Fatigue Strength [in Russian], Mashgiz, Moscow (1953).

A. M. Vaingarten, G. M. Goman, and I. V. Mendel'son, “The corrosion fatigue strength and corrosion resistance of 35 steel specimens in relation to the hardening method,” Tfkh. Sudostr., No. 3, 54–57 (1973).

R. G. Pogoretskii, M. M. Matseiko, Ya. M. Sirak, et al., “A method of fatigue testing of specimens with press fits in sea water,” Fiz.-Khim. Mekh. Mater., No. 2, 231–234 (1968).

G. V. Karpenko, R. G. Pogoretskii, and Ya. M. Sirak, “The influence of surface hardening by burnishing on the fatigue resistance of shafts with press fits in a corrosive medium,” in: The Protection of Metals from Corrosion-Mechanical Damages [in Russian], Profizdat, Moscow (1970), pp. 113–115.

Download references

Author information

Authors and affiliations.

G. V. Karpenko Physicotaechanical Institute, Academy of Sciences of the Ukrainian SSR, Lvov

Ya. M. Sirak, G. N. Filimonov & T. G. Tsvetaeva

You can also search for this author in PubMed Google Scholar

Additional information

Translated from Fiziko-Khimicheskaya Mekhanika Materialov, Vol. 20, No. 6, pp. 84–87, November–December, 1984.

Rights and permissions

Reprints and permissions

About this article

Sirak, Y.M., Filimonov, G.N. & Tsvetaeva, T.G. Choice of the material for production of a ship propeller shaft. Mater Sci 20 , 586–589 (1985). https://doi.org/10.1007/BF00723561

Download citation

Received : 29 November 1983

Issue Date : November 1985

DOI : https://doi.org/10.1007/BF00723561

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Propeller Shaft

- Ship Propeller

- Find a journal

- Publish with us

- Track your research

Dyna-Ski Boats custom builds outboard powered water ski boats for recreational skiers and show ski clubs. We have customers all over the world including Malaysia, the Caribbean, Moscow, Russia, the Cayman Islands and Canada. This blog is used to keep readers informed about what is going on at Dyna-Ski and answers questions that are frequently asked. You can also visit www.dyna-ski.com for more information about our boats. Contact Dyna-Ski at [email protected] or call 715-854-7501.

Tuesday, July 2, 2019

Update on things and how to buy a dyna-ski boat, no comments:, post a comment.

COMMENTS

The Aqualoy process produces a rounder, straighter, stronger shaft. Aqualoy stainless shafts are available in A17, A19, and A22. Our stainless steel inboard propeller shafts from 3/4" - 4" diameter are precision machined in our Mazak Nexus 350M CNC turning lathe to insure all machining is within .0005". All propeller tapers are precisionally ...

Precision CNC marine inboard boat shafts. AQ17, AQ19 and AQ22 marine alloys. discounted price, quick delivery. General Propeller Company is one of the leading boat shaft manufacturers in the US. We are an OEM supplier to numerous boat builders, including Sea Ray, Regal, Hunter, Correct Craft - Nautique, Bertram, Wellcraft, Catalina, Sea Force ...

Marine Propeller Shaft - Design And Construction. The heart of any ship lies in the engine room. Powered by large marine engines usually running on diesel oil of HFO, vessels are able to reach speeds of up to 50 kmph. The components responsible for actually moving the ship are the large multi-blade propellers fit at the back.

4.293. This free propeller shaft size calculator helps you determine the proper propeller shaft diameter for your boat. The calculator determines a safety factor (design coefficient) based on shaft diameter, max engine RPM, shaft horsepower, gear ratio, and torsion strength of the shaft material used. The calculator utilizes the following ...

Individual propeller blades stem from a central hub, which in turn attaches to the sailboat's prop shaft or saildrive. Depending on the manufacturer, these blades typically are pitched in a way that propels the boat forward or backward when the transmission is engaged. The term "pitch" refers to how far forward or reverse a propeller will ...

These prop shafts are used in a wide variety of applications such as work boats, pleasure craft, naval vessels, and pumps. The Aqualoy® process produces a rounder, straighter, stronger shaft. All of our A22 shafts from 3/4" - 4" diameter are precision machined in our Mazak Nexus 350M CNC turning lathe to insure all machining is within .0005".

Stainless Steel Shafts. Propeller Depot is known throughout the marine and pump industry as producing the best stainless shafts; at the best possible pricing, with the best quality. Our stainless shafts come in A17, A19, and A22; and can be shipped across the globe. Order your inboard prop shaft today and save hundreds to thousands.

145-ST3221. Aquamet 22 1-1/8" Diameter (Priced Per Inch) Propeller shaft length is critical and must be measured correctly. To ensure overall shaft length, measure from the V-drive shaft to the back of the strut barrel, and add 5". Different alloys are available differing in strength characteristics ranging from weakest to strongest as follows ...

RE Thomas Marine Hardware maintains a large inventory of Aqualoy 22 propeller shafts in sizes from 7/8″ up to 3″ diameters. We also offer double tapered shafts precision machined to mate with our exclusive tapered coupling system. Give us a call today for quote at 207-422-6532. We are proud to be the OEM propeller shaft supplier to many of ...

3 Types of propeller shafts: Tapered propeller shaft; A tapered propeller shaft is part of a wind assembly structure or tool that is attached to the propeller shaft. More precisely, it is the adjustable part of the propeller of a ship or boat that allows for changes in pitch or angle. The shaft works by utilizing a common engine design.

Ironically, because manufacturers have developed a variety of efficient sailboat propellers designed to maximize thrust under power while minimizing drag under sail, selecting the right prop for a sailboat can be even more complex than it is for a power vessel. ... in turn, is connected to the propeller shaft in traditional drive trains, or to ...

Updated: June 19, 2019. The shaft of this straight coupling has been knurled to improve the interface between the two. The wire in the set screw should be neater and tighter. Steve D'Antonio. If you've ever aligned your propeller shaft and engine, then you've handled the hardware that connects these two components together: the shaft ...

The cost increases as the complexity of the propeller goes up. The folding propellers are the least expensive of the sailboat propellers; the feathering propellers typically the most expensive and Autoprop is slightly behind the feathering propellers. These prices are based on 2024 18″ diameter shaft drive propellers. $

21629136. $1,300.00 $1,040.00. Add to Cart. 2 Blade & 3 Blade bronze inboard propellers, Sail Drive, Folding Shaft & Saildrive, Michigan Wheel and Volvo Penta, In Stock, Fast Delivery.

Boat Propeller Shafts, Struts and Seals. Need a new boat propeller part? We've got lots! Great Lakes Skipper adds thousands of discount boat parts every month, including boat propeller shafts, marine prop seals, and propeller struts made by Bombardier Johnson Evinrude OMC, Four Winns, Mercury Marine, Suzuki, Wellcraft, Larson, Cruisers Yachts, Carver Yachts, and more top-notch marine ...

One stop shop for boat props, stainless shafts, zinc anodes, shaft seals, cutlass bearings and more. Menu. Search. Personal menu. ... ACME 1235 14.50 x 14.25 x .105 cup 1-1/8" bore left hand four blade boat prop. $873.00 $712.99. Compare Add to wishlist. SOLAS Rubex Aluminum 13-1/2 x 15 RH 9411-135-15 prop.

SigmaDrive is a flexible propeller shaft coupling that is effective noise and vibration suppression for most sailboats up to 1300 hp. SigmaDrives is unique as it is able to absorb thrust when installed as a standalone propeller coupling directly from the shaft to the output flange on the transmission. SigmaDrive solves issues due to imperfect ...

Find shaft and saildrive folding propellers with 2, 3 or 4 blades here. See more. Skip to the main content. ... Get a specified propeller recommendation for your sailboat. Our folding propellers are available as 2-bladed, 3-bladed, and 4-bladed in multiple sizes and pitches. All delivered for both shaft- and saildrive installation.

In lieu of that, try them both and find out which one stops the prop from turning. You want to stop the shaft from turning to prevent excessive wear on the transmission and packing bearing. I've also been told that a stationary prop has less drag than a moving prop (but that seems counter-intuitive to me). Capt. Cook

shift it into gear, rotate either prop shaft or input shaft til the clutch locks up and compare revolutions between the prop shaft and input shaft. a 1.36, the input shaft rotates a littler over one and a third of a rotation to 1 prop shaft rotation. 1.5 : is one and a half input shaft rotations to one prop shaft rotation.

G. V. Karpenko, R. G. Pogoretskii, and Ya. M. Sirak, "The influence of surface hardening by burnishing on the fatigue resistance of shafts with press fits in a corrosive medium," in: The Protection of Metals from Corrosion-Mechanical Damages [in Russian], Profizdat, Moscow (1970), pp. 113-115.

Here is what you need to know to shop motors for a Dyna-Ski. 20" shaft motor. A recessed control is the preferred style by customers. 3" GPS Speedometer is almost a must have. 3" tachometer, 2" fuel & 2" trim/tilt gauges are good. I like a 2" water pressure gauge and many people like a 2" depth gauge. All in one screens are not popular on water ...

Russia's Kirov-class battlecruiser's propulsion possesses two nuclear reactors, two steam turbines, four propellers, and 140,000 shaft horsepower. ... the boat was renamed ...