Types of Cleats On A Sailboat

- July 18, 2023

Table of Contents

Cleats are essential fixtures on a sailboat used to secure lines (ropes) and control sail trim. They come in various designs and are strategically placed throughout the boat to provide convenient and secure attachment points. Here, I will describe the different types of cleats found on a sailboat in detail:

Sailboat Cleat Types

The horn cleat is the most common and recognizable type of cleat. It features one or more protruding horns or arms that provide multiple options for securing lines. The line is wrapped around the horns in a figure-eight pattern to create a secure hold. Horn cleats come in different sizes and are used for various applications throughout the boat, including halyards, sheets, and control lines.

Recommended Horn Cleats:

Ronstan Horn Cleat Nylon 76MM (3″)

Schaefer Mid-Rail Chock and Cleat Mounts on 1-1/4 x 3/16-Inch T-Track fits Up to 5/8-Inch/16mm Line

Cam cleats are designed with a spring-loaded cam mechanism that clamps down on the line when it is under tension. The cam grips the line securely and holds it in place until released. Cam cleats are popular for applications where quick and easy adjustment is required, such as controlling jib or spinnaker sheets. They are commonly found on sailboats with high-performance or racing-oriented setups.

Recommended Cam Cleats:

Jam cleats, also known as jamming cleats or rope clutches, are designed to hold a line firmly under load. They feature a set of ridges or teeth that grip the line when it is tensioned. Jam cleats provide a secure hold and are often used for halyards, control lines, and other high-load applications. To release the line, it needs to be pulled at a specific angle to disengage the teeth.

Recommended Jam Cleats:

Clam cleats consist of two interlocking jaws that close around the line. As the line is pulled, the jaws grip it tightly, creating a secure hold. Clam cleats are often used for smaller lines, such as control lines on dinghies or small sailboats. They provide quick and easy adjustment and are commonly found on boats where weight and simplicity are crucial.

Recommended Clam Cleats:

Osculati Clamcleat

V cleats, as the name suggests, have a V-shaped groove that runs along the top surface of the cleat. The line is inserted into the groove, and the V-shaped design holds it securely in place. V cleats are primarily used for smaller-diameter lines or control lines. They are commonly found on dinghies and small sailboats where space and weight are at a premium.

Recommended V Cleats:

Nautos 91061 – V Jam Cleat – Sailboat Hardware

Jammers are similar to jam cleats but offer a more sophisticated and mechanical gripping mechanism. They consist of one or more jaws that grip the line under tension using a cam or lever system. Jammers provide a strong and secure hold and are commonly used for halyards, control lines, and sheets on larger sailboats or racing-oriented setups.

Recommended Jammers:

Spinlock Mobile Jammer for securing Loaded Lines 10-14mm

Rope Clutch

Rope clutches are heavy-duty cleats often used on larger sailboats. They consist of multiple jaws or disks that can be engaged or disengaged to secure or release a line. Rope clutches are designed to handle high loads and are commonly used for controlling halyards, sheets, and other lines that require precise adjustment and secure holding power.

Recommended Rope Clutches:

Deck cleats, also known as mooring cleats, are larger cleats that are permanently mounted to the deck or cockpit of a sailboat. They provide a secure attachment point for dock lines, fenders, and other lines used for docking or securing the boat. Deck cleats are usually made of durable materials such as stainless steel or aluminum and are designed to handle significant loads.

Recommended Deck Cleats:

Fairlead Cleat

Fairlead cleats combine the functionality of a cleat with that of a fairlead, which helps guide lines to the appropriate cleating position. They feature an integrated fairlead or a combination of a fairlead and a cleat. Fairlead cleats are commonly used for jib or genoa sheet control lines, where it is important to guide the line for optimal sail trim and secure it quickly.

Recommended Fairlead Cleats:

HARKEN Micro Carbo-Cam Cleat Kit w/Wire Fairlead

Jamming Block with Cleat

This type of cleat is a combination of a jammer or a cam cleat with a pulley or block. It allows the line to be redirected and creates a mechanical advantage when trimming sails. Jamming blocks with cleats are commonly used for applications that require increased purchase or control, such as mainsheet systems or complex control line setups.

Recommended Jamming Block Cleats:

It’s important to note that the specific cleat types and their placement on a sailboat can vary depending on the boat’s design, rigging setup, and intended use. Sailboat owners and manufacturers may also develop unique variations or combinations of cleats to suit their specific needs. Proper installation, sizing, and maintenance of cleats are essential for safe and efficient sail handling.

The Sailor’s Marketplace for Sailboats and Sails.

Sell Your Sailboat

Sailboats for sale.

- New Sailboats

- Used Sailboats

- Cruising Sailboats

- Racing Sailboats

Sell Your Sails

Sails for sail, sail manufacturers.

- North Sails

- Quantum Sails

- Doyle Sails

- UK Sailmakers

Sailing Reviews

- Sailing Line

- Safety Equipment

- Sailing Accesories

As an Amazon Associate SailTrader earns from qualifying purchases.

This website uses cookies to ensure you get the best experience possible.

Your cart is empty

Use this bar to show information about your cookie policy.

The Ultimate Guide to Boat Cleats: Choosing, Installing, and Using Them Effectively

Whether you are just starting your nautical journey or are a seasoned sailor, we believe it is always beneficial to brush up on essential boating knowledge.

Today, we steer the conversation to an often overlooked, but vital component of boating safety and functionality - boat cleats. In this guide, we'll take a deep dive into the world of boat cleats, providing you with everything you need to know to make informed decisions when choosing, installing, and using them effectively.

A Cleat Introduction: Why Are Boat Cleats Necessary?

Boat cleats serve as the anchoring point on your boat or dock, allowing you to secure lines for a variety of purposes including mooring, anchoring, or towing. Having the right cleat installed not only ensures the safety of your vessel but also prolongs the lifespan of your marine equipment. Understanding the intrinsic role of cleats can pave the way for a seamless and enjoyable boating experience. As a side note: make sure you never leave your boat unattended for long periods of time without being properly secured .

Choose Wisely: Picking the Right Cleat for Your Needs

Material matters.

When it comes to selecting the right cleat, material should be your first consideration. The common materials are:

- Galvanized Steel Cleats: Galvanized steel cleats are cost-effective options that offer resistance against corrosion, suitable for both fresh and saltwater setups.

- Nylon Cleats: Ideal for small and medium-sized boats; they are lightweight, durable, and resist corrosion extremely well. Tommy Docks offers a variety of nylon cleats from traditional horn cleats to foldable cleats.

- Aluminum Cleats: Light yet durable, offering resistance to corrosion, making them a top choice for freshwater environments.

Shape and Style

Next, consider the shape and style of the cleat which determines its functionality. The popular types are:

- Horn Cleats: Traditional and versatile, boat horn cleats are commonly found on most boats and docks.

- Foldable Dock Cleats: Foldable dock cleats are best for smaller boats, they can be quickly and easily folded away so as to give more walkable space on your dock without the worry of stubbing a toe!

- S-Shape Cleats: With a unique design, they prevent lines from slipping off, providing an additional layer of safety.

Size Considerations

Choosing the right size is crucial to ensure proper functionality. A general rule of thumb is to opt for a cleat that is approximately one inch in length for every 1/16 inch diameter of the rope used.

Installing Cleats: Securing Your Peace of Mind

A well-installed cleat can be the difference between a secured boat and a drifting vessel. Here are some steps to install cleats like a pro:

- Select an Appropriate Location: Choose a spot that allows easy access while avoiding potential tripping hazards.

- Mark the Holes : Once you have identified the right spot, mark the holes using a marker.

- Drilling the Hol es: Use a drill to make holes at the marked points, ensuring they are slightly larger than the bolts to be used.

- Fixing the Cleat: Position the cleat over the holes and secure it using appropriate bolts, adding a washer and nut underneath.

- Sealing the Deal: Apply a marine sealant around the bolts to prevent water from seeping in, thereby avoiding potential corrosion.

Using Cleats Effectively: Mastering the Art

Using a cleat effectively is an art that mariners should master to ensure safety and efficiency. Here’s how you can do it:

- Making a Cleat Hitch: Learn to tie a cleat hitch correctly. Start by making a loop around the base, followed by a figure-eight pattern around the horns, securing it with a hitch on the final turn.

- Proper Line Handling: Ensure that the lines are not frayed or damaged, as this could compromise the safety of your boat.

- Regular Inspection: Periodically inspect the cleats for signs of wear and tear, and replace them as necessary to maintain optimal functionality.

If you want a more in-depth guide on how to tie your boat to a dock, check out this guide by Tommy Docks .

Sailing Ahead: Final Thoughts and Recommendations

Remember, the heart of a secure and functional docking system lies in its smallest details. By investing in quality boat cleats and using them correctly, you not only safeguard your vessel but also ensure a delightful and worry-free boating experience.

At Tommy Docks, we are committed to providing you with top-notch prefab dock kits and equipment (including boat cleats!) that stand the test of time. For more guidance and expert advice, feel free to sail into our world, where quality meets innovation.

Get the latest news, updates and exclusive offers.

Tommy Docks Podcast

Listen along as Tommy Dock's Owner Owen Jones explores the meaning of living on the water. Dive deeper into conversation with industry experts on everything outdoors. Don't be a stranger, grab a beer and join us on the dock.

Listen Here

Featured products

Happy Customers

Over 750+ 5-Star Reviews and counting.

Customer Service

Have questions? Contact us by chat, email, phone.

Warranty Support

Sometimes the unexpected happens. View Policy

- Opens in a new window.

- Destination Information

- Sailing routes

- Boat owners

- Tips & Inspiration

- Sustainable Sailing

- Featured Posts: The Latest News

- Nautical Knowledge

The Sailboat Cleat: A guide to types and uses

- 24 March 2023

- 4 minute read

Alice Martin

Share the post "The Sailboat Cleat: A guide to types and uses"

If you’re a sailing enthusiast or just interested in learning more about sailboats, then Click&Boat has got your covered! Today, we’re going to explore the humble Sailboat Cleat – a small but mighty component that is essential for smooth sailing. So, batten down the hatches, and let’s set sail!

What is a Sailbo at Cleat?

It is a small metal or plastic fitting that is attached to the sailboat’s deck. This nifty device helps to secure ropes or lines that are attached to the sails or other parts of the boat. The Sailboat Cleat has two horns or arms, and ropes are wrapped around these arms to hold them in place.

What is a Sailboat Cleat made of?

Manufacturers typically use a range of materials, such as metal, plastic, and wood, to make sailboat cleats. Metal cleats, made from stainless steel, brass or aluminium and sailors consider them more durable. Plastic cleats, often made from nylon or other synthetic materials, are lightweight and affordable, but might not withstand heavy loads as well as their metal counterparts. Wooden cleats, on the other hand, add a touch of traditional charm and can be found on classic or vintage boats. The choice of material depends on factors like cost, strength, and aesthetic preferences.

Why is a Sailboat Cleat So Important?

Sailboat Cleats are essential for sailing because they allow sailors to control the sails and other parts of the boat safely. By securing lines to these, sailors can adjust the sails’ angle and tension, which affects the boat’s speed and direction. Without them, sailors would have to hold onto the lines continuously, which would be tiring and inefficient.

They also play a crucial role in the boat’s safety. By securely holding the lines, they prevent the sails from accidentally unfurling or becoming tangled, which could cause the boat to capsize or become unmanageable.

What are the different types of Sailboat Cleats?

Now lets explore some of the different types of cleats out there. There are different types of cleats, from traditional horn cleats to high-tech cam cleats that sailors can use depending on their sailing style. Lets take a look!

Horn Cleats

These are the most traditional type of Cleat and are still popular today. Horn Cleats have two upward curving arms that sailors use to hold the rope securely in place. In addition to traditional Horn Cleats, sailors can use rope clutches or shaped slots on larger boats to secure control lines.

Cam cleats use a spring-loaded cam mechanism to grip the rope tightly when sailors push it down. These are popular for racing sailboats, where quick and easy release is essential.

Clam Cleats

Similar to Cam Cleats, clam cleats use a spring-loaded mechanism to hold the rope in place. However, the rope is held between two jaws rather than a cam, which can provide a more secure grip.

These cleats are designed specifically for the jib sheets and are often found near the front of the boat. They are typically smaller than other cleats and can hold thinner ropes.

Deck Cleats

Deck cleats hold larger ropes and lines and can be made of metal, plastic or other materials, and sailors use them for docking and anchoring.

How Does a Sailboat Cleat Work?

Cleats hold ropes or lines securely in place while still allowing them to be released quickly and easily when necessary. They work by providing a secure anchor point for the rope, which can then be wrapped around the cleat’s arms multiple times to increase the holding power.

When the rope is wrapped around, it’s important to ensure that it’s done correctly that the line is held securely. The rope should be wrapped around the cleat at least three times, with each wrap crossing over the previous one. This ensures that the line is held securely, and the wraps don’t slip when the rope is under tension.

How to tie a Cleat knot

Tying a cleat knot is a useful skill to have for securing a boat or tying down a load. To tie a cleat knot, sailors start by wrapping the rope around the base of the cleat in a figure-eight pattern. Then, cross the rope over itself and loop it under the opposite horn of the cleat. Bring the rope back over the top of the cleat and create another figure-eight wrap around the opposite horn. Finally, cross the rope over itself once more and tuck the end under the last wrap. Pull the knot tight and it should be secure. With a little practice, tying a cleat knot can become a quick and easy task.

So, now that you are familiar with all the moving parts, you can appreciate just how important they are for a safe and enjoyable sailing experience. From small keel boats to larger vessels, these pieces of sailing hardware are important. So, next time you’re out on the water, give your cleats a little nod of appreciation. After all, they’re the unsung heroes of the sailing world!

50 Essential Sailing Terms For Every Sailor

- 20 March 2023

- Kate Fitzgerald

- Inspiration

Family Boating: The Ultimate Guide

- 31 March 2023

- Clara Chambers

You May Also Like

Your City Break Holidays to Barcelona During the America’s Cup

- 21 August 2024

What you need to know for a boat safety certificate in the United States

- 7 July 2024

Budgeting for your daily boat hire

- 6 July 2024

For your next motorboat trip: A skippered or a bareboat charter?

- 3 July 2024

What to bring aboard a motorboat: your boating checklist

- 1 July 2024

First time renting with Click&Boat? Here’s What You Need to Know!

- 30 June 2024

- About Click&Boat

Click&Boat’s guide to using a boat licence abroad

- 29 June 2024

All you need to know about a daily boat hire

- 28 June 2024

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

This site uses Akismet to reduce spam. Learn how your comment data is processed .

Input your search keywords and press Enter.

Yachting Monthly

- Digital edition

Cleats, clutches and jammers: which to use and when?

- Graham Snook

- July 29, 2022

A variety of deck hardware devices will hold a line fast, but when should one be used and not another? Graham Snook explains

Sailing would be nothing without rope, but rope would be of little use if there was no way to fix, belay or secure it. Early sailors must have quickly realised holding rope for long periods was no fun – something many yacht racers have yet to understand – and making off sheets and halyards freed their hands to do other things. With the advent of rope, came rope-holding technologies.

There may be some who abhor the thought of Yachting Monthly referring to lines as rope, or you may have sailed with someone who proclaims ‘there are no ropes on a boat’. Ignoring the bell rope, bolt rope and foot rope there is rope. Lines are rope, as are halyards, sheets and warps. When we talk about rope-holding technology, we are securing the product ‘rope’ , not a specific line.

While we’re righting misnomers, many people, including me, will have been calling clutches ‘jammers’, but a clutch can be released under load while a jammer cannot. That said, many Australian sailors, including gear manufacturer Ronstan, also refer to clutches as jammers, and Karver’s KJ jammer can be used as a clutch!

Cam cleats and constrictor clutches are used to control all lines on IMOCA 60 Hugo Boss

Simple cleats

For lightly loaded control lines (up to 150kg) used without winches, it’s possible to use clam cleats, jam cleats or cam cleats if they are up to the job.

As the loads increase, and unless you have a winch for each line, you’ll need a rope clutch or jammer ahead of the winch to hold the load of one line while you winch in another.

The mechanisms used to secure the ropes vary between manufacturers and even between ranges – depending on the loads involved. But they all operate by gripping the line as much as possible while minimising damage to the rope.

A line passing through the device in the ‘open’ position can travel in and out. Once the mechanism is closed or locked, the line can be pulled in but will not go out. Once the clutch or jammer is locked it’s always best to ease the load on the winch gradually until you know the line is secured – poorly adjusted clutches can fail to secure the line.

When pulling a line in through a clutch, while it’s usually possible to do so with a closed clutch, having the clutch open will reduce wear on the gripping surface, saving the jaws of the clutch and the fibres in the rope and making it significantly easier to pull the line through.

Before a jammer can be released, the load has to be taken off it by winching the line taut. A clutch, on the other hand, can be released under load – handy for a speedy spinnaker takedown. But, as James Hall from Spinlock explained, ‘just because you can do it, it doesn’t mean you should. Our XXC Powerclutch can release at over 2,300kg but repeatedly releasing a rope with over two tons of load is not good for boat, rope or crew.’

The lead from the clutch to the winch should be as close to straight as possible, unlike in this picture

Clutch vs Jammer

Most boats from 7.5-11m (25-40ft) will have a range of different-sized clutches depending on the loads and the rope diameters in use. As boats get bigger you start to see more jammers to take the larger loads. Choosing between a clutch and a jammer will mostly depend on the working load it will experience, your line thickness, and its purpose. For very high-load applications and lines you don’t want to be released unexpectedly, a jammer is the best choice.

There is less risk of damage, and a high-loaded line cannot be accidentally released, but you rarely see these loads on sub 40ft yachts so most will opt for a clutch, and caution.

Lines become thinner under load and with age, so if you have an 8mm line and the choice of a clutch that takes 6-8mm or 8-10mm opt for the smaller clutch if its maximum load is up to the job – it will grip the line better. Also, if you need to replace a clutch that’s on a continuous line (such as a furling line for an in-mast furling system) look for clutches for endless lines. These have split fittings that can be fitted without parting and re-splicing the line. Some designs allow the clutch to be side-mounted which is handy if the clutch is to be mounted to an upright surface such as the side of a coachroof or coaming.

Clutches allow for many lines to be taken to a single winch, giving you all the lines at your fingertips

The layout of your deck needs to be considered when fitting a new clutch or jammer. Clutches are available individually or in clusters of two, three, four or five. The lines have to enter the body of the device as straight as possible. Likewise, the exit angle to the starboard side of the winch drum must be as fair as possible too. If there is upwards or sideways loading this should be taken by a deck tidy or fairlead/bullseye, not the clutch or jammer itself.

Some clutches and jammers offer the option of operating remotely using thinner control lines. The advantages of this are the length of the highly loaded line is shorter; so less stretch and the ability to locate the hardware in an inaccessible location such as a mast top jammer for a racing yacht’s main halyard.

For the low-load applications any suitable-sized A4 stainless steel bolts will do, but for mid- to high-load use, many devices will come with suitable fixings for the maximum load.

threaded metal backing plates will take loads of the clutches rather than the cored deck

It’s very important that wherever you attach the clutches or jammers, the deck needs to be able to withstand the combined load of all the jammers and should have suitable backing plates inside. Most boats have a cored or sandwich deck that will need cutting away and sealing inside to accommodate the backing pad. See our recommended method for doing this on p83.

Maintenance

Jammers and clutches don’t need a lot of maintenance, just a hose down after use will help rid the clutch of rope fibres, debris the rope has picked up, plus any grit or salt. When you service your winches annually (which of course you do) it’s worth inspecting your clutches and lightly greasing any bearing surfaces, all of which will be identified in the manual.

Finally, if you plan to upgrade or replace your lines, bear in mind your poor rope clutches – they might not be designed for the thinner line diameter, higher loads or the fancy slippery outer braid on the rope. Luckily, spare parts or upgrades are easy to come by, so if the jaws get worn, polished or lose their grip they can usually be replaced.

Enjoyed reading this?

A subscription to Yachting Monthly magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

YM is packed with information to help you get the most from your time on the water.

- Take your seamanship to the next level with tips, advice and skills from our experts

- Impartial in-depth reviews of the latest yachts and equipment

- Cruising guides to help you reach those dream destinations

Follow us on Facebook , Twitter and Instagram.

What is a Sailboat Cleat?

Last Updated by

Daniel Wade

June 15, 2022

A cleat is a tie-down point or securing device mounted to the deck of a sailboat. Cleats secure lines for rigging and docking.

Cleats are an iconic piece of maritime technology that's not limited to sailboats. However, one could argue that cleats are more important on sailboats than any other kind of vessel. There are two types of cleats found on sailboats, and they serve different purposes.

Table of contents

What do Sailboat Cleats Do?

Sailboat cleats are used to secure sections of rope and keep them from moving. Cleats are better than loops for this purpose, as they allow you to tie off a rope without creating an impossibly tight knot. All kinds of cleats can be secured and loosened rapidly regardless of how tight you tie them.

Sailboat cleats perform a seemingly endless list of tasks. Cleats secure sheets, bumpers, docking lines, halyards, blocks, anchors, and much more. You'll find cleats inside and outside of your sailboat and littered all over the cockpit.

The Cleat Knot

The cleat knot is a must-know maritime knot. It's essential for all boat owners (sailing and otherwise) to learn how to tie a cleat knot as it's the only acceptable and proper way to secure a boat to the dock.

Tying a cleat knot is relatively easy. Start by wrapping the line one full loop around the base of the cleat. But instead of winding it underneath on the last fourth of the turn, bring the rope over and across one of the two extensions.

Loop the line underneath the extended part of the cleat, then bring it back and on top again. Next, repeat the loop on the other end to create an "X" shape on top of the cleat. Finally, make a loop and twist it, so the end of the line is on the underside.

Place the loop over the end of the cleat and pull it tight. The result should still resemble an "X" or a figure-eight, with two sections of rope going one direction and a single section on top. If you end up without a figure-eight and a parallel length on one side, remove the final loop and twist it the opposite way.

Cleats for Docking

When docking, secure one end of a rope to a cleat on your bow. Do the same for a cleat on the stern. Then, pull your boat in tight and tie each line to a cleat on the dock. Don't forget to secure your bumpers and hang them over the side.

Types of Sailboat Cleats

There are two primary types of cleats aboard a typical sailboat. The first is a traditional fixed cleat, which is the same type you find on docks, powerboats, and flagpoles. You may even have one for your bedroom blinds.

Fixed Cleat

The fixed cleat has no moving parts, and it's often used for parts of the rigging that aren't adjusted often. The primary exception to this is on older sailboats that predate modern cleats.

Folding Cleat

The folding cleat is a slick version of the classic fixed cleat. These low-profile cleats fold into a stainless steel or brass deck plate. They're not as durable as standard fixed cleats, but they're difficult to trip on and ideal for areas where people frequently walk.

The cam cleat is one of the best gifts to sailors since the winch. Cam cleats don't resemble traditional marine cleats at all. Instead, these small deck hardware components utilize two slatted jaws and a set of springs.

Cam cleats are essentially one-way check valves for rope. They're incredibly easy to engage and disengage. Cam cleats are primarily used for sheets, halyards, and other lines that need to be adjusted frequently.

To use a cam cleat, simply place your line inside it. That's it—there's nothing to it. Releasing the line is just as easy and only requires you to pull up on the line and slide it out of the jaws.

Advantages and Disadvantages of Cleats

Fixed cleats are strong and proven, and they're inexpensive to install. They require no maintenance, and they have no moving parts to fail. However, they're larger than cam cleats, and they take much more effort to use. They also aren't as easily adjustable.

Cam cleats are highly convenient and most reliable, though low-quality cam cleats are prone to failure and corrosion. Cam cleats are smaller than traditional cleats, and they're often found all over a sailboat . Unfortunately, cam cleats can't be used for docking, as the rope slips out too easily.

How to Strengthen a Cleat

Sometimes deck material alone isn't strong enough to ensure a secure cleat foundation. If you're worried about your cleat breaking off, consider installing it like a chainplate. Use a reinforcing steel plate on the underside of the mounting surface to sandwich the deck between the bolts.

Cleat Material

Choosing the right material for your cleats is quite important. Marine hardware has little room for failure. Brass is a tried and tested hardware material, as it doesn't rust and stands up to weather well. However, it's not as strong as steel, and stainless steel offers similar benefits.

Many sailboats use plastic cam cleats. Plastic works well for light-duty operations and doesn't corrode like metal. That said, the sun is a serious adversary for plastic. UV damage can weaken plastic cam cleats over time, leading to binding and failure. However, the cost to replace a plastic cam cleat is much lower than brass or steel.

Galvanic Corrosion

We've talked about galvanic corrosion before, and cleats are certainly not safe from it. Galvanic corrosion is a silent killer of certain metals, and it's rarely obvious like rust. This form of corrosion occurs when metals like aluminum and stainless steel come into contact with each other and saltwater.

Galvanic corrosion is an electrochemical process that rapidly turns aluminum and stainless steel to dust. Saltwater is an electrolyte, so it speeds up the process further.

How to Prevent Cleat Corrosion

Cleats often fall victim to galvanic corrosion when they're bolted to the deck with a dissimilar metal. Here's a few examples of what happens all the time on boats.

- Brass cleat mounted onto the deck with steel screws. In this case, the brass is the problem, and the steel will corrode.

- Aluminum cleat mounted to the deck with stainless steel screws. In this case, the stainless steel will cause the aluminum to corrode.

Galvanic corrosion can be avoided by simply installing cleats with screws made from the same material. If your brass cleat comes with steel screws, throw them away and buy brass screws. The same goes for aluminum, which corrodes violently when in contact with stainless steel.

How to Choose a High-Quality Cleat

Installing high-quality hardware is a great way to take pride in your sailboat. Cleats are an excellent way to present a high level of fit and finish and increase the value of your boat.

The benefits of splurging on cleats aren't all aesthetic. A set of high-quality cleats can last a lifetime. Cam cleats that are designed and manufactured properly can also prevent your lines from fraying or coming loose.

Cleat Prices

Everyone knows that marine hardware often costs a fortune, and cleats are no exception. The price of a well-made cleat ranges from $40 to well over $100, with cam cleats topping the price scale. Even with cleats, you get what you pay for. A $10 cam cleat will give you $10 worth of service life, which will likely be very disappointing.

Where to Find the Best Cleats

The finest marine hardware generally comes from factories in the United States, Japan, and the United Kingdom. But many established brands produce high-quality products elsewhere.

Shopping for vintage marine hardware is an excellent way to save money on cleats. Vintage cleats are often made with superior materials and free from cost-cutting and unexpected corrosive metals. With a bit of polishing, a set of used cleats can serve your sailboat for decades to come.

Related Articles

I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing.

by this author

Sailboat Parts

Learn About Sailboats

Most Recent

What Does "Sailing By The Lee" Mean?

October 3, 2023

The Best Sailing Schools And Programs: Reviews & Ratings

September 26, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

Affordable Sailboats You Can Build at Home

September 13, 2023

Best Small Sailboat Ornaments

September 12, 2023

Discover the Magic of Hydrofoil Sailboats

December 11, 2023

Popular Posts

Best Liveaboard Catamaran Sailboats

December 28, 2023

Can a Novice Sail Around the World?

Elizabeth O'Malley

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Get the best sailing content.

Top Rated Posts

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies. (866) 342-SAIL

© 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy

Free Shipping *

Premium Quality

No-Hassle Returns

844-524-7627

How to Choose Boat Cleats for Your Boat

If you have a boat, you're going to need to tie it up. Boat and dock cleats provide convenient locations to secure lines quickly and easily. There are many different types and arrangements of boat cleats available to customize your mooring experience. We will look at a selection of these and provide some advice along the way. At the end of the article we'll provide a brief guide on properly tying your boat to a cleat with a cleat hitch. Let's get started!

Boat cleats are made from a wide range of materials:

- galvanized steel

- stainless steel

Choosing a material largely depends on the purpose of the cleat; a small wooden cleat may look nice as an accent, but would likely be appropriate only to hang a fender from, while a sturdy steel cleat with a backing plate would be suitable for main bow or stern dock lines. Get a cleat strong enough for the job, and with the variety out there, you'll not likely have to compromise on looks either; a stainless steel cleat, for example, is very strong and looks great just about anywhere!

Here’s a list for you: dock cleat, deck cleat, portable cleat, jam cleat, cam cleat, flip-up cleat, pop-up cleat, pull-up cleat, solar light cleat, Samson post, mooring bollard, zamak cleat – oh my! All of these are tackle used for securing lines of one kind or another. Most boaters will be familiar with at least some of these, especially the typical two-horned deck or dock cleat, which is suitable for just about any situation.

Size and Placement

Sizing a boat cleat is not too difficult if we follow a short chain of dependencies: the size of cleat you should use depends on the size of line you use; the size of line you use depends on the size of boat you have. The general rule is fairly simple:

- Cleat length from tip to tip should be 1" for every 1/16" of line diameter and dock lines should be 1/8" of diameter for every 9 feet of boat length

Let's consider a brief example. If your boat is 40' in length, it requires 1/2" dock lines. Using 1/2" dock lines means that your cleats need to be 8" long to accommodate. That wasn't too hard right?

It is important to note that the above calculation results in a minimum size, and, as with most things in boating, bigger is better! What if you need to add an extra line to that cleat? It sure would be nice to have extra room. Consider this when buying your cleats.

Placement location:

- Place at regular intervals along the port and starboard of your boat

- At minimum use three per side: stern, amidships (for spring lines), and bow

- The more cleats you can reasonably install, the better

The Cleat Hitch: A Guide

| It's important to wrap the dock line first around the farther cleat horn (in this case the right), then around the closer horn (on the left) before crossing over the cleat and beginning the figure 8. | |

| After making the first cross of the cleat with the line and going around the horn (on the right) a second time in a figure-8, make a half-hitch (or just flip the line) so the cleat is crossed again. Note the two parallel lines in the center and that the half-hitch continues the figure-8. | |

| Tighten as shown. The working end of the line (right) comes away from the cleat in the opposite direction from which it began. | |

| Any remaining length of line should be "flemished" so that it won’t trip anyone walking on the dock or tangle when leaving the dock. The same holds true if the cleat is onboard. | |

Conclusions

Mooring is a core component of boating; therefore, it is important to have tackle you can depend on when it is time to tie up.

- Get boat cleats that are strong enough for the load they will take

- Seriously consider updating standard cleats with safety cleats, especially if your boat is designed with port and starboard passageways

- Bigger is better and more is better; get larger cleats than you need and more of them

- Use your cleats properly; tie up the right way using the guide above

Contact us with any other questions you may have. Happy boating!

Published May 08, 2018

Recent Posts

Windlass problems common issues and how to fix them.

Let's look at common issues with windlasses and how to address them: 1) Windlass Won’t Run in Either Direction 2) Solenoid Clicks, but Windlass Won’t Move 3) Windlass Lacks Power to Haul the Anchor 4) Rode Gets Jammed or Doesn’t Come In

Our history: a 20 year journey

Boat Cleaning Tips for Anglers: Keeping Your Vessel Spotless and Pristine

Avast, Ye Mariners! Master the Art of Docking: A Swashbuckling Guide for Boaters

Top Reasons to Keep a Boating Maintenance Log

4 Top Tips for Buying a New-to-you Used Boat

Bent Boat Anchor Shank: Common Causes and Prevention Tips

Prepare Your Boat For An Above Average Hurricane Season

Best Methods For Anchoring Your Jet Ski in Deep or Shallow Water

Best Options For Connecting Your Boat To WiFi Internet

Information

About Us Terms & Conditions Privacy Policy Product Manuals & Instructions Shipping Info

Anchors Anchor Lines Biminis Covers Dock Lines Fenders Galleyware Windlasses

Customer Service

Contact Us FAQs Returns & Warranty Wholesale Inquiries

Anchoring Help

Browse all products >, stay updated.

© 2024 TH Marine. All Rights Reserved. Anchoring.com ™ • Norestar™ • Komo Covers®

Boating Basics Online is reader-supported. When you buy via our links, we may earn a commission at no cost to you. Learn more

What is a Cleat on a Boat and Its Functions

Written by J. Harvey / Fact checked by S. Numbers

With the number of boating fittings any vessel may have, it’s easy to get lost figuring out the function of each one. “What is a cleat on a boat?” is but one of the many questions first-time boat owners or simple boating enthusiasts ask.

A boat cleat is a fixture used to secure lines of rope on the vessel itself. Mounted on the gunwale, its horns serve as tying-off points for the lines. Variations allow it to fulfill more than one purpose.

Table of Contents

Overview of a Cleat on a Boat

Importance of boat cleats, 1. horn cleat, 2. cam and clam cleat, 3. open base and closed base cleat, 4. folding cleats, 5. pop-up cleats, common usage scenarios, cleat materials, how does a cleat work, pros and cons, choosing cleat placement, proper installation techniques, cleaning and polishing, common issues and troubleshooting tips, how to choose the right boat cleats, cleat accessories and additional considerations, frequently asked questions.

Boat cleats are highly practical implements that allow you to have a sturdy point from which you can tie vital lines of ropes. This is so you can have optimal line management and mooring, which is a more secure way to dock as it involves tying your vessel to it.

Where is the cleat on a boat? Boat builders typically mount boat cleats on the upper sides of the vessels (aka the gunwale) with a specified distance and interval.

Incidentally, cleats on boats should not be confused with a dock cleat, which is attached to a dock or marina. It serves the same purpose as a horn cleat on a boat, though.

Based on the definition, we can already see why installing cleats is a must. To further add to that, I’ve gone ahead and listed down every advantage:

- They’re specifically designed to keep your boat from drifting off while docked.

- They provide the necessary tensile strength, especially those made from stainless steel, that can handle continuous pressure, which may result from changing weather and water conditions while moored.

- They help to manage your lines easier, whether they’re dock lines, fender lines, or anchor lines.

- Their configuration makes it easier to adjust their lines’ tension and quickly untie and tie knots when necessary.

- You never know when you’ll need a safe point from which to tie a strong line of rope during emergency situations.

Different Types of Boat Cleats

The following are the different types of boat cleats with their distinct designs and characteristics.

The classical cleat is characterized by its two horns either protruding straightly from side to side or curing a bit upward.

Both are cleats mainly used to control the sails of sailboats. Cam cleats rely on a spring-loaded cam mechanism for gripping and releasing in seconds, while the latter uses jaws with a firmer grip.

These are differentiated by the presence (open base) or absence (closed base) of an opening on the cleat’s base. Either one usually determines the knot you should use and how sleek and neat it would look.

These are usually designed as open-base cleats that you can lock down or retract if you don’t need them. Some designs allow you to re-engage the cleat by simply pushing a button.

These are similar to folding cleats, but you have to push them down to retract them instead. A locking mechanism will engage to keep them in place. The pop-up is also triggered by a button.

Here are a few situations where the boat cleats are extremely handy:

- For securing vessels of various sizes to the dock.

- In the context of sailboats, cleats play a much more crucial role in helping the operator control their sails. For example, with a clam cleat, they can freely adjust their forestays’ tension, and it’s also equipped with a jaw that keeps the line securely in place.

- Powerboat owners love to modernize their vessels by installing pop-up cleats, which not only provide a sleeker, cleaner look but heighten safety as well. After all, traditional horn cleats can be quite the tripping hazard and may cause ropes to be entangled or snagged.

There are a number of materials modern-day boat cleats are made of.

Plastic-based cleats tend to be cheaper, don’t rust, and are naturally resistant to corrosion and the elements. The downside is that they may not be as sturdy as metal cleats.

Preferred for its lightweight, aluminum is also highly resistant to corrosion, ideal for lighter boats and loads, and can last a lifetime.

- Chrome-plated Zinc

The chrome plating adds to overall wear and tear resistance while canceling its brittleness by using zinc, which has high strength, as its base metal.

- Stainless Steel

According to tests, stainless steel cleats have been found to withstand the most load, making them the most recommended for sturdiness. Added bonuses include the ability to withstand harsh marine conditions, excellent corrosion resistance, and superb strength.

Highly resistant to corrosion, bronze also imparts a unique aesthetic touch that fits a boat with a more classic motif.

Made of an alloy composed of aluminum, magnesium, titanium, beryllium, and certain other metals, marinium cleats have been found to be second only to stainless steel cleats in bearing the most load and total tensile strength. It also doesn’t tarnish easily.

Explaining Boat Cleat Functionality

How to use a cleat? Given its purpose of solely securing lines, using this tool is mostly about learning how to properly tie the boat to the cleat and the dock.

There are a number of knots worth knowing, but one that’s worth knowing by any boat operator is a basic but ever-reliable cleat knot called a Cleat Hitch.

It works well with a closed-base cleat and is fairly easy to master. Here’s a video demo of how to do it:

Once a line has been securely tied, the cleat works by being a fixture that holds the rope in place. It creates the right tension that prevents the rope from coming loose.

The horns on a horn cleat are designed as such so that they’ll be able to provide a secure hold or anchoring point, even if you don’t tie a rope in a knot around them.

- Helps to keep you and your watercraft secure

- Adds a stylish touch to your boat

- Requires minimal to no maintenance once installed

- Easy to get the hang of

- Some cleats may not offer enough adjustability

- May fail at certain loads depending on material and installation

Placement and Installation of Cleats

Cleat placement is important to make sure that it can effectively handle the lines attached to it. Here are the most important factors to consider when deciding boat cleat placement:

- There should be a set interval in the distance of the cleats on both sides of the boat.

- Although at least three cleats on both the port and starboard will do, it doesn’t hurt to have more for better flexibility.

It’s always best to follow the manufacturer’s instructions when installing any cleat hook for your boat. Here are some general tips apply to make sure the cleat will stay in place and optimally fulfill its functionality:

- Assuming there’s adequate access, consider back-plating the cleats. You can attach a solid board behind the mounting area to distribute the load and boost durability.

- Reinforce the plates using bolts, then pair them with nuts and washers to prevent them from coming loose. This will boost its strength.

- Be mindful of holes you create for access. Ensure a water-tight installation by using pie plates to cover them.

Maintenance and Care for Cleats

- Flitz has been recommended to me by other boaters and works exceptionally as an all-around cleaner for rust protection.

- Most metal cleaners and polishes are straightforward to apply. Just don’t go overboard and use only as much as necessary.

Stainless steel cleats are subject to rusting. Once you encounter this issue, you can use proven products like Bon Ami or other rust removers available to you.

- Getting ripped out or coming loose

Crazy storms and a janky installation often result in this problem. There’s no other way around it than to ensure you’re correctly installing your cleats and doing everything possible so that they’re firmly in place.

- Line jamming

This may happen if you use the wrong knot and the load ends up getting jammed. This could spell trouble, as you essentially no longer have control over the line.

Choosing the right boat cleats is essential for ensuring secure mooring and docking of your boat. Here are some tips to help you choose the perfect boat cleats:

- Boat Size and Type: This dictates the size and strength of the cleats you need. Larger boats or those subjected to heavier loads will require more robust cleats than smaller vessels.

- Determine the Material: Boat cleats can be made of various materials. Scroll up to find the material that best suits your needs and preferences.

- Cleat Design: Cleats come in various designs, and each has its strength. Horn cleats are popular for versatility, flat-tops reduce the risk of tripping hazards and folding cleats can be folded down when not in use to create an unobtrusive deck surface.

- Number of Cleats: Determine the number of cleats you need. We recommend installing multiple cleats distributed evenly on both sides of the boat to achieve optimal balance and secure attachment points.

- Installation Considerations: Some cleats require through-bolting, while others can be secured with screws or specific mounting systems. Choose the one compatible with your boat’s deck or hull structure.

- Quality and Durability: Go for the best-quality cleats within your budget. The marine environment is harsh. Having durable cleats and accessories means less maintenance and more aquatic fun.

If you still struggle finding cleats suitable for your boat, consult an expert. Ask marine professionals, boat dealers, or experienced boaters for guidance.

- Consider cleat covers to protect you and your passengers from possible cleat-based injuries while onboard.

- Extenders can boost the line accessibility and flexibility of every cleat.

How do I know the right size of cleats for my boat?

It depends on the boat’s size and the line’s size. You don’t need a size chart to determine which one to use. Just follow this guideline:

- Increase your cleat length by 1 inch for every 1/16-inch diameter of line and ⅛-inch diameter for every 9 feet of boat length.

Are there any safety considerations when using boat cleats?

Improperly used and if issues arise, they may cause injury and even death of passengers directly and indirectly. Always beware of sharp edges, use the proper knots, and make sure there’s still ample space for movement once your lines are up.

Can boat cleats be used for purposes other than docking?

Yes, besides rigging sailboats and mooring, they can also be used for towing, anchoring, and for managing fenders.

Considering everything there is to know with regard to what is a cleat on a boat, it’s safe to say that it’s every boater’s best friend. We all want to keep our prized vessels free from damage and safe in their respective slips.

It’s hard to imagine making that possible without this simple yet versatile device. The fact that it’s this flexible and comes in various materials, types, and sizes only proves that point.

“My intention from the first day establishing Boating Basics Online is to provide as much help as possible for boaters who want to experience a first safe and convenient trip. So feel free to join us and share your beautiful journeys to the sea!”

Types of Boat Cleats: Choosing the Right Cleat for Your Vessel

If you’re a boating enthusiast, you know that having the right equipment is essential for a smooth sailing experience. One important component of any boat is the cleat. Boat cleats are used to secure ropes and lines, and they come in various types to suit different needs. In this article, we’ll explore the different types of boat cleats available and their specific uses, so you can choose the best one for your vessel.

You can make an informed decision when choosing which ones will work best for your boating needs. Remember to consider factors such as size, material, durability, and ease of installation when making your selection. Whether you’re docking at a marina or anchoring in open waters, having reliable boat cleats will give you peace of mind knowing that your vessel is securely tied down.

Table of Contents

Different Types of Boat Cleats

Boat cleats are an essential component of any vessel, providing a secure point to tie ropes and anchor your boat. There are several different types of boat cleats available, each with its own unique design and functionality. In this section, we’ll explore some of the most common types of boat cleats and their uses.

1. Horn Cleat

The horn cleat is one of the most traditional and widely used types of boat cleats. Its distinctive shape resembles two curved horns facing upwards. This design allows for easy tying and securing of ropes at various angles. Horn cleats are commonly found on both powerboats and sailboats.

2. Flat Cleat

As the name suggests, flat cleats have a flat surface with two or more mounting points for securing ropes or lines. They are often seen on smaller boats or where space is limited since they can be easily mounted flush against surfaces like gunwales or swim platforms.

3. Folding Cleat

Folding cleats offer a practical solution when it comes to safety and aesthetics. These cleverly designed cleats fold down flush against the deck when not in use, minimizing potential hazards while maintaining a sleek appearance.

4. Dock Cleat

Dock cleats are specifically designed for securing boats to docks or piers temporarily. They typically have a sturdy construction with multiple attachment points to ensure stability during mooring.

5. Rope Clutch

Rope clutches provide a convenient way to secure multiple lines without the need for tying knots manually each time you dock your boat. These self-locking devices can handle high loads and are commonly used on larger sailboats or yachts.

6. Cam Cleat

Cam cleats utilize a spring-loaded cam mechanism that grips the rope firmly when loaded but releases quickly under tension or by hand pressure alone, making them ideal for quick adjustments during sailing maneuvers.

Choosing the right boat cleat for your vessel depends on various factors such as the size of your boat, intended use, and personal preference. It’s important to ensure that the cleats you select are appropriate for the loads they will bear and properly installed to maintain their integrity.

Remember, safety should always be a top priority when it comes to securing your boat. Regularly inspect your cleats for any signs of wear or damage and replace them if necessary. Properly maintained and correctly chosen cleats will provide peace of mind while out on the water, knowing that your boat is securely moored.

Read Also: Types of Sailboats: Find Your Ideal Vessel

Fixed Cleats – Types of Boat Cleats

Fixed cleats are a commonly used type of boat cleat that provide secure attachment points for ropes and lines. They are designed to be permanently mounted onto the deck or other parts of the boat, ensuring stability and reliability in various boating activities. Here’s a closer look at fixed cleats and their features:

1. Material

Fixed cleats can be made from different materials such as stainless steel, aluminum, or nylon. Stainless steel is highly preferred due to its durability and resistance to corrosion, making it suitable for both freshwater and saltwater environments.

Fixed cleats come in various designs, including open-base cleats, closed-base cleats, horn-shaped cleats, and low-profile cleats. Each design offers unique advantages depending on the specific needs of the boat.

3. Installation

Installing fixed cleats requires drilling holes into the boat’s deck or hull and securing them with bolts or screws. It’s essential to ensure proper installation to maintain the integrity of the boat structure.

4. Use Cases

Fixed cleats are versatile and can be used in different applications on a boat. Some common uses include tying off dock lines when mooring or docking, securing fenders for protection against impacts, anchoring your boat securely during rough weather conditions.

5. Size Considerations

The size of a fixed cleat is an important factor to consider when choosing one for your boat. Larger boats typically require larger-sized fixed cleats capable of handling heavier loads.

In summary, fixed cleats provide reliable attachment points for ropes and lines on your boat deck or hull. They come in various designs and are made from durable materials like stainless steel to withstand harsh marine conditions. Proper installation ensures their effectiveness in securing your vessel during different boating activities.

Remember to choose a size that suits your boat’s requirements and always follow manufacturer guidelines for installation best practices.

Folding Cleats: Convenient and Space-Saving

When it comes to boat cleats, one type that stands out for its practicality and space-saving design is the folding cleat. These cleverly engineered cleats offer a range of benefits that make them a popular choice among boaters.

1. Compact Design

Folding cleats are designed to fold flat when not in use, making them extremely compact. This feature is especially useful for boats with limited deck space or when you want to avoid any protrusions that could cause accidents or damage.

2. Easy Installation

Installing folding cleats is a straightforward process, typically requiring just a few screws and basic tools. Their simple design makes them accessible to both experienced boaters and beginners alike.

3. Versatile Application

Folding cleats can be used in various settings on your boat, such as bow, stern, or even along the sides of your vessel. This versatility allows you to place them wherever they provide the most convenience for docking, anchoring, or securing lines.

4. Secure Anchoring

Despite their compact size, folding cleats are built with durability in mind. They are constructed from robust materials like stainless steel or aluminum, ensuring reliable anchoring and secure mooring even in challenging conditions.

5. Aesthetically Pleasing

In addition to their functional advantages, folding cleats also contribute to the overall aesthetics of your boat’s deck area. When folded down, they create a sleek and streamlined appearance that enhances the visual appeal of your vessel.

If you’re considering installing folding cleats on your boat, keep in mind that their size may limit their load-bearing capacity compared to larger traditional cleat designs. It’s important to check their specifications and ensure they meet your specific needs before making a purchase decision.

In conclusion, folding cleats offer an ideal solution for boaters seeking convenience without sacrificing functionality or aesthetics. With their compact design, easy installation, and versatility, these cleats provide a practical and space-saving option for securing your boat.

Types of Boat Cleats: Pop-Up Cleats

Pop-up cleats are a type of boat cleat that offers a sleek and convenient solution for securing lines on your vessel. These cleverly designed cleats can be recessed into the deck when not in use, providing a smooth surface that won’t snag ropes or pose a tripping hazard. When you need to tie off your boat or secure it at the dock, simply push down on the top of the cleat, and it pops up to provide a secure attachment point.

Features and Design

One of the key advantages of pop-up cleats is their ability to maintain a clean and unobstructed deck surface. Traditional fixed cleats can protrude above the deck, creating potential hazards and interfering with foot traffic. With pop-up cleats, you can enjoy a clutter-free deck that allows for safe and easy movement around your boat.

Benefits and Applications

Another benefit of pop-up cleats is their versatility. They come in various sizes and materials to accommodate different types of boats and applications. Whether you have a small recreational craft or a larger yacht, there’s likely a pop-up cleat that will suit your needs. Additionally, they can be installed on both horizontal and vertical surfaces, giving you flexibility in where you choose to mount them.

When it comes to installation, pop-up cleats are relatively straightforward to fit onto your boat. Many models feature an adjustable base plate that allows for easy alignment with existing mounting holes or structural supports. This means you won’t have to drill new holes in your deck, minimizing any potential damage or modifications required.

Maintenance Tips

In terms of performance, pop-up cleats offer reliable strength and durability. They are typically made from corrosion-resistant materials such as stainless steel or aluminum alloys, ensuring they can withstand exposure to saltwater environments without rusting or deteriorating over time.

Overall, if you’re looking for an aesthetically pleasing and functional alternative to traditional fixed cleats, considering installing pop-up cleats on your boat. They provide a clean deck surface, versatility in mounting options, and a secure attachment point when you need it. Upgrade your vessel with these innovative cleats for a seamless boating experience.

Types of Boat Cleats: Horn Cleats

Horn cleats are a popular type of boat cleat commonly used for securing lines on boats. These sturdy and reliable cleats are named after their distinctive shape, resembling the horns of a bull or ram. In this section, we’ll explore the features and benefits of horn cleats, as well as their various applications in boating.

One of the key features of horn cleats is their unique shape, which provides multiple points for securing lines. This design allows for better distribution of load and enhances the overall strength and stability of the cleat. Horn cleats are typically made from durable materials such as stainless steel or aluminum to withstand harsh marine environments.

Horn cleats offer several advantages that make them an excellent choice for boaters:

- Secure Line Holding: The multiple horns provide secure attachment points for ropes and lines, preventing accidental slippage even under heavy loads or rough conditions.

- Versatility: Horn cleats can accommodate a wide range of line sizes, making them suitable for various applications such as docking, anchoring, or securing fenders.

- Ease of Use: With their simple design, horn cleats are easy to use and require no specialized knowledge or skills to operate effectively.

- Aesthetics: Many boaters appreciate the classic look of horn cleats, which can add a touch of traditional charm to any boat’s appearance.

To ensure optimum performance and longevity from your horn cleat:

- Regularly inspect the hardware for signs of wear or corrosion.

- Clean with fresh water after each outing to remove salt residue.

- Apply lubricant to moving parts periodically to prevent friction damage.

- Replace any damaged or worn-out components promptly.

In summary, horn cleats offer secure line holding capabilities along with versatility in different boating scenarios. Their robust construction and timeless design make them a popular choice among boaters. By following proper maintenance practices, you can ensure that your horn cleats serve you well for years to come.

Types of Boat Cleats: Choosing the Right Boat Cleat for Your Needs

When it comes to selecting the perfect boat cleat for your needs, there are a few key factors to consider. The right choice will depend on various aspects such as the size and type of your boat, the specific application, and personal preference. Here are some important points to keep in mind:

1. Types of Boat Cleats Material

Boat cleats are commonly made from stainless steel, aluminum, or nylon. Each material has its own advantages and considerations. Stainless steel offers excellent durability and corrosion resistance, making it ideal for saltwater applications. Aluminum is lightweight yet sturdy, while nylon is more affordable and resistant to rust.

2. Types of Boat Cleats Size

The size of the cleat should be proportionate to the size of your vessel. A general rule of thumb is that larger boats require bigger cleats to ensure secure mooring. Consider both the length and width of your boat when determining the appropriate size.

3. Types of Boat Cleats Style

Boat cleats come in various styles including open base, closed base, horn-shaped, and folding options. Open base cleats are versatile and easy to use but may not provide as much strength as closed base or horn-shaped ones. Folding cleats offer a space-saving solution when not in use.

4. Types of Boat Cleats Mounting Options

Cleats can be mounted through-bolted or with surface-mounted studs depending on your installation preferences and requirements.

5. Types of Boat Cleats Load Capacity

It’s crucial to choose a boat cleat with sufficient load capacity for your intended use. Consider factors such as wind conditions, docking situations, and potential stress on the lines.

6. Types of Boat Cleats Maintenance Requirements

Different materials may have varying maintenance needs – stainless steel requires regular cleaning to prevent tarnish while aluminum may need occasional waxing or polishing.

Remember that selecting the right boat cleat involves balancing functionality with aesthetics and budgetary considerations. By considering these factors carefully you can ensure that you make the right choice for your boat.

In the next section, we’ll explore some common types of boat cleats to further assist you in finding the perfect option for your vessel.

Now that you have explored the different types of boat cleats, you are equipped with the knowledge to choose the right one for your boating needs. Let’s summarize what we’ve learned:

| Cleat Type | Best Use |

|---|---|

| Dock Cleats | Securing boat to dock |

| Mooring Cleats | Tying up boat in mooring |

| Clamshell Cleats | Flush-mounted option, sailboats |

| Deck Cleats | Attaching fenders or accessories on deck |

| Cam Cleats | Racing or high-performance sailing boats |

Remember, safety should always be your top priority when using boat cleats. Make sure they are properly secured and regularly inspected for any signs of wear or damage.

By understanding the different types of boat cleats available and their respective purposes, you can confidently select the right cleats for your boating adventures. Enjoy your time on the water and happy sailing!

APS Expert Advice: Sailboat Cleat Options Explained. VIDEO

Sailboat cleats are fittings to which a line is secured, either temporarily or permanently. In this video the Annapolis Performance Sailing expert is going to explain the seven main sailboat cleat types found on sailboats, and some of their uses:

- Horn Cleats

- Self-Jamming Horn Cleats

- Double Cam Cam Cleats

- Clam Cleats

- Lance Cleats

10 Sailing Tips Essentials to Make You a Better Sailor!

Kiteboarding the south pacific – marc jacobs drone action video, sailing nandji ep 356 preparing to cross oceans | replacing our standing rigging…, vallon launches sustainable sailing eyewear: ‘malizia’, live your passion, subscribe to our mailing list.

Feet Don't Fail Me Now!

Foundation findings #16 - circa 1990, you've heard the expression, "only as strong as the weakest link." and so it is with cleats. whether you're using a cleat for docking, mooring, towing a dinghy, or securing a halyard, it's important to think of the cleat as only a single part of an entire system (and not necessarily the most important part of the system)..

The entire system consists of the cleat, the fasteners-including nuts, bolts and washers, the deck or other mounting platform, backing plates-and the line. You rely on that system to keep your boat secure, even in conditions like storms or towing that subject the system to tremendous stress and shock loads.

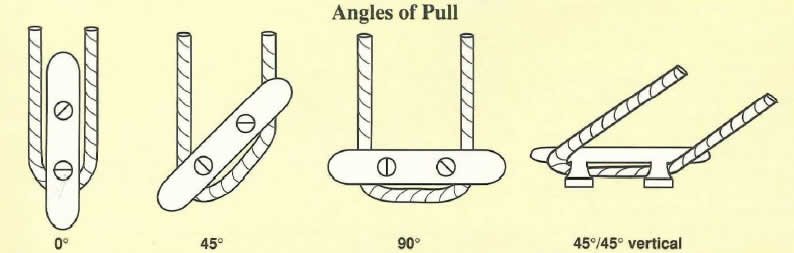

In this test, the BoatUS Foundation wanted to examine one of the most critical links in the system: cleats. Working in conjunction with the University of Virginia School of Engineering, we set up laboratory testing apparatus to simulate the loads placed on cleats of different design configurations and materials. Our goal was to determine the direction and magnitude of the smallest force required to deform or break a cleat fixed to a rigid surface with mounting hardware specified by the manufacturer.

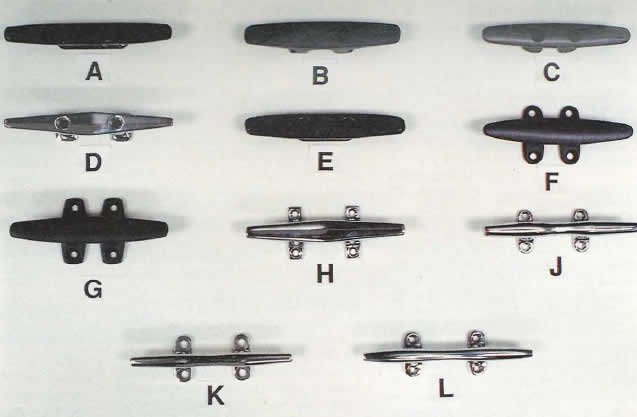

Cleat Types & Failure Loads

| Test Cleat | Cleat Material | Fasteners | 0° | 45° | 90° | 45°/45° | Average Load Sustained | List Price (circa 1990) |

|---|---|---|---|---|---|---|---|---|

| A | Nylon | 2 - #10-32 | 2780 | 1390 | 1590 | 2380 | 2035 | $4.25 |

| B | Aluminum | 2 -1/4-20 | 3780 | 3860 | 3800 | 4000 | 3860 | $16.95 |

| C | Aluminum | 2 - 1/4-20 | 2500 | 3890 | 3700 | 4770 | 3715 | $36.35 |

| D | Zinc | 2 - 1/4-20 | 3580 | 3380 | 3970 | 4760 | 3928 | $21.00/pr. |

| E | Aluminum | 2 - 1/4-20 | 4970 | 3780 | 4170 | 5360 | 4570 | $19.25 |

| F | Aluminum | 4 - 1/4-20 | 4170 | 1190 | 1790 | 4770 | 2980 | $31.95 |

| G | Marinium | 4 - 1/4-20 | 7160 | 6760 | 6720 | 5370 | 6503 | $17.95 |

| H | Zamac | 4 - #10-32 | 3380 | 2920 | 2380 | 3180 | 2965 | $15.00/pr |

| J | Zinc | 4 - #10-32 | 3180 | 2780 | 2880 | 3970 | 3202 | $10.45 |

| K | Stainless | 4 - 1/4-20 | 6660 | 6800 | 7550 | 6560 | 6893 | $10.09 |

| L | Bronze | 4 - #10-32 | 3180 | 3990 | 3970 | 4570 | 3928 | $12.69 |

| Fasteners Failed | Leg Failed | Feet Failed | Body Failed | |||||

Test Procedures

The Foundation tested 11 six inch cleats made of nylon, aluminum, marinium (a magnesium-aluminum- titanium-beryllium alloy), chrome-plated zinc, bronze, stainless steel, and Zamac (a high-grade die-cast zinc alloy). Five of the cleats were two-hole; six were four-hole. The cleats were mounted on a 3/8- 6 inch thick steel plate in a tensile test machine. Admittedly, the steel plate is not the same as a deck mounting on a boat, but it prevents the fasteners from pulling out, and it eliminates different boat decking materials as a variable, so that only the cleat itself is being tested. To ensure uniformity, the cleats were mounted to the steel plate using manufacturer recommended sizes of flathead stainless steel bolts, nuts and washers, all tightened to precisely the same torque. The tensile strength of the bolts was also tested; they fell consistently within the manufacturer-listed range of 80,000 psi ( +/-10%).

Using a 3/8-inch diameter plastic- coated steel cable around each cleat, we pulled at four angles, as shown in the diagram below. (Plastic- coated cable was used to ensure that the cause of a failure would not be the rope or a weak point caused by wire abrading the cleat.) The first three pulls were parallel to the base, at 0°, 45° and 90° relative to the cleat's axis. The fourth pull was an upward 45°/45° pull, with the cable around both legs, pulling at 45° vertical and 45° forward.

The test was conducted under strictly controlled laboratory conditions. We suspect, however, that different tests might produce slightly different results, because the failure figures in each pull are dependent on so many variables.

For example, the seating of the fasteners relative to the exact center of the holes in the feet has a direct effect on load distribution and consequently the amount of stress placed on any given part of the cleat. Similarly, using a larger size line may produce different results, because larger line exerts more force on the bottom of the horn and less on the top of the leg. It is reassuring, however, that the results of this test coincide in most respects with those of a similar cleat test conducted by a manufacturer several years ago.

Test Results

The cleat assemblies withstood simple tension loads of between 1,190 and 7,500 lbs. before a failure occurred. The lower figure is roughly equivalent to the load a 40-ft. boat exerts on its working anchor under normal conditions. The cleat assemblies failed in one of four ways: fasteners, feet, legs, or the body of the cleat. The vast majority of failures, (57%) were fastener failures. Feet failure, exclusive to four-hole cleats, and to zinc and aluminum cleats in particular, was second at 23%. Bodies failed 14% of the time, and legs failed only 9%.

Fastener failures occurred with equal frequency at all three angles of pull parallel to the base (0°, 45° and 90°). By contrast, at the 45°/45° vertical angle pull, fastener failures accounted for less than half; the body of the cleat or its feet were more likely to fail first when pulled forward and up. However, in general the cleats withstood greater loads at this 45° upward pull than under straight pulls (the only two exceptions were the stainless steel cleat and the marinium cleat). Because fastener failure predominated, it may be inaccurate to assess cleat strength based solely on the loads applied. When the four loads each assembly withstood before failure are averaged, the stainless steel cleat assembly withstood the greatest loads, followed by the four-hole hollow marinium cleat. Not surprisingly, the nylon cleat ranked last, but it was stronger than we expected — it took a respectable 2,380 lbs. at 45° to cause the body to fail.

Two Holes or Four?

The test revealed that cleat design is at least as important as cleat material in affecting what breaks, and at what loads. Four-hole cleats were more likely to suffer failure of the feet, legs or body, while two-hole cleats suffered fastener failures 19 out of 20 times. We believe this is because the bolts in two-hole cleats are fastened directly through the center of the cleat, adding strength to the entire assembly. It seems the load applied perpendicular to the axis of the bolts in two-hole cleats causes the fasteners to shear off at the base.

With four-hole cleats, feet failed 10 times in 24 pulls (42%). The feet failed consistently on half the four hole cleats, and they failed under smaller loads than every other cleat except the nylon. Of these three four hole cleats with consistent foot failures, one was aluminum, one zinc and one Zamac. Since these three metals have identical tensile strengths and held their own in the two-hole category, there had to be another explanation. We found the answer in foot surface area: the three cleats with consistently failing feet had the three smallest foot surface areas of the six four-hole cleats we tested.

We took a closer look at the effect of foot surface area by comparing the very similar aluminum and marini urn four hole cleats (see · cleats F and G at right). The feet on the aluminum-a big, beefy cleat failed on all four pulls. The marinium cleat had no feet failures. It had twice the foot surface area of the aluminum cleat (0.13 inches 2 vs. 0.07 inches 2 ), and withstood more than twice the load of the aluminum cleat.So, we deduced, the design of the feet , particularly their surface area, is critical. Ironically, the weak-footed aluminum cleat was the most expensive of the 11 cleats we tested.

Conclusions

Although stainless steel has the greatest tensile strength of a ll the cleat materials we tested (double the tensile strength of aluminum, zinc, Zamac and marinium), it is nowhere near the most expensive cleat material, nor does it necessarily produce the strongest cleat in a given application. This is because, as mentioned earlier, a cleat is only one part of a system, and that system is only as strong as its weakest link.

Line is another part of the system. Generally, manufacturers recommend just slightly under one inch of cleat for every 1/16-inch of line diameter , which means you need a six-inch cleat for 3/8-inch line, an eight-inch cleat for 1/2-inch line, and a 10-inch cleat for 5/8-inch line. Using larger cleats for larger lines adds both weight and expense, but what would be the point of using 3/8-inch nylon line, with a breaking strength ocleat you attach it to can't withstand the same or greater load?

Chafe plays a vital role in the security of any cleat system. You can reduce chafe by using larger cleats, or cleats with smooth, round legs and no sharp angles, since the strength of a line is reduced by bending fatigue when it has to turn sharp corners or make tight bends. Mount your chocks as close to the cleats as possible, and avoid changing the direction of the rope along its path through the chock to the cleat.

As a rule, you should buy the largest size cleat your pocketbook and the deck space can handle. Choose one made of a high tensile strength material, like stainless steel , bronze, aluminum or marinium. Examine the feet to make sure they are large relative to the size of the cleat, sturdy, and have an ample thickness of metal around the fastener holes.