A Complete Guide to Teak Maintenance on Your Sailboat

By Joshua Bremmerer, CEO at Komodo Covers Teak surfaces are divisive in the boating world—loved by some for their sparkling appearance and perfect grip, loathed by others for the perceived difficulty of teak maintenance. The reality is that teak is nothing to be afraid of, as long as you follow some essential tips to take care of the material properly, minimizing costs in the process.

Teak is famed for its various grains of hard and softwood, making it naturally adhesive and anti-slip in practically any weather condition. Furthermore, it maintains a relatively cool temperature , insulating a boat to avoid engine overheating. Due to the several types of wood, different teak maintenance methods can drastically affect its ability to last.

So, it’s crucial to take the following steps into account to make sure you don’t mark the surface and keep your boat in excellent condition.

Cleaning is king

First things first, whatever you do, don’t use high-pressure cleaners on your teak because they will destroy the softer wooden elements, leaving ridges and areas that can quickly rot. Additionally, hard brushes or powerful cleaning detergents will cause a similar effect, damaging the vulnerable soft sections.

Instead, it’s much better to do regular cleaning—weekly if possible—with a very soft brush or Brite pad. You will see good results from lightly brushing against the grain with a mild detergent. If you see mildew or just want to make your sailboat sparkle, you could consider using a tiny amount of bleach, but do it with caution.

Smooth sailing with sanding

Most boaters with a teak deck consider it a standard practice to sand the surface once a year before the start of a season. Sandpapers come in various grits—for a teak deck, between 80 and 120-grit is the ideal level. The higher the number of grit, the more slippery the deck will be, so a medium level is suitable for teak as it will maintain the characteristic non-slip.

Seal the deal

Once you have cleaned and sanded the teak evenly, you can be forgiven for clapping your hands together and proclaiming a “job well done.” But you are still missing one last step—and it is a crucial one. A teak sealer will prolong the natural appearance of the wood for years to come while maintaining the pristine condition. Depending on the type of seal, some can contain biocides and even UV inhibitors which go that extra step in terms of preservation.

Aside from sealers, you can also consider using teak oil products, but be careful on how much you apply as sometimes overapplication of oil can promote mildew growth. If your boat isn’t going to be used regularly, this may not be the best course of action. The other issue with teak oil is that it doesn’t last particularly long, usually 4-12 weeks, depending on how well you have applied it.

Following these tips will put you in a great position to get your boat ready for a season on the water. If you choose the right cleaning products, sand your deck appropriately, and seal it with a good sealer, you should be able to maintain your sailboat deck for longer than you had ever imagined!

About Josh Bremmerer

Josh Bremmerer is an innate navigator, an experienced leader in the boating industry with over a decade of experience in management and company development and a lifelong passion for boating. As the manager of Glacier Ski Shop, Josh grew the small Shop into a nationally recognized business and increased profits by 400%. With that background, it’s no wonder Josh started his own business in the boating industry: Komodo Covers .

10 Sailing Tips Essentials to Make You a Better Sailor!

Vallon launches sustainable sailing eyewear: ‘malizia’, 5 tips for anchoring your sailboat, from stainless steel to dyneema: a lifeline upgrade story, live your passion, subscribe to our mailing list.

Proudly Made in the U.S.A.

PLASDECK ECO SERIES: A Revolutionary New Boat Decking Product

Three Ways to Get PlasDECK Decking on Your Boat:

- 1. Send us a template and order easy-to-install custom panels - Available in over 20 colors.

- 2. Find a PlasDECK installer in your area to do all of the work for you.

- 3. If you're pretty handy, use our rolls of DIY shiplap material - Available in the classic teak color.

- You can also add custom inlays to personalize your deck!

- Award-winning new product! Learn more about PLASDECK ECO SERIES.

PlasDECK Colors

PlasDECK is committed to bringing you quality boat and yacht decking that looks like real teak but without the maintenance!

Sample Packs

You can see and feel PlasDECK by ordering a sample pack!

Synthetic Boat Deck, Yacht Decking, Marine Teak Decking

PlasDECK is a patented synthetic teak boat decking option that provides the elegant look of a teak deck without any of the time-consuming and costly maintenance associated with natural wood teak. Made out of flexible PVC, this material is easy to work with and maintain. It’s the perfect option to upgrade your boat and replace the dingy old carpet. PlasDECK will hold up to the sun and marine environment for years while you enjoy more of your free time.

PlasDECK is specially formulated with ingredients that will prevent the material from drying out or cracking over time. It also has the highest possible UV protection to prevent fading, antifungal inhibitors, superior adhesion… and PlasDECK is proud to say that we offer the only synthetic teak decking option that’s made in the USA! With over 20 colors to choose from, PlasDECK is the most customizable boat decking option on the market.

Support & Customer Service

- Customer Service

- Find a PlasDECK Installer

- International Orders

- Boat Decking Installation Guides

- PlasDECK Installation & Repair Videos

- Returns & Refunds

- Shipping Information

- Boat Decking In-Store Pickup

Research & Information

- PlasDECK Cleaning Guide

- Boats on File

- Boat Decking FAQs

- How Shiplap Works

- Synthetic Teak Deck Specifications/SDS Sheets

- The PlasDECK Synthetic Decking Difference

- PlasDECK Boat Deck Weathering Study

- PlasDECK 5 year Warranty

- Synthetic Teak Boat Decking Repair

Select a Language

- Boat Supply , Boat Tests , News

What’s the best synthetic teak? The comparative test

- Luca D'Ambrosio

- August 5, 2019

Comparative test for the three leaders of synthetic teak decking

The use of synthetic teak in marine decking is quickly and successfully replacing that of the natural wood.

There are many companies producing this material today but only three are the most popular and the most widespread ones. We therefore decided to compare the best of the current production in a no-holds-barred test.

This way, we had the opportunity to test and compare, in a very simple way, the features that most affect the choice of synthetic teak (all our staff was involved in the test and everyone was asked to express his own opinion).

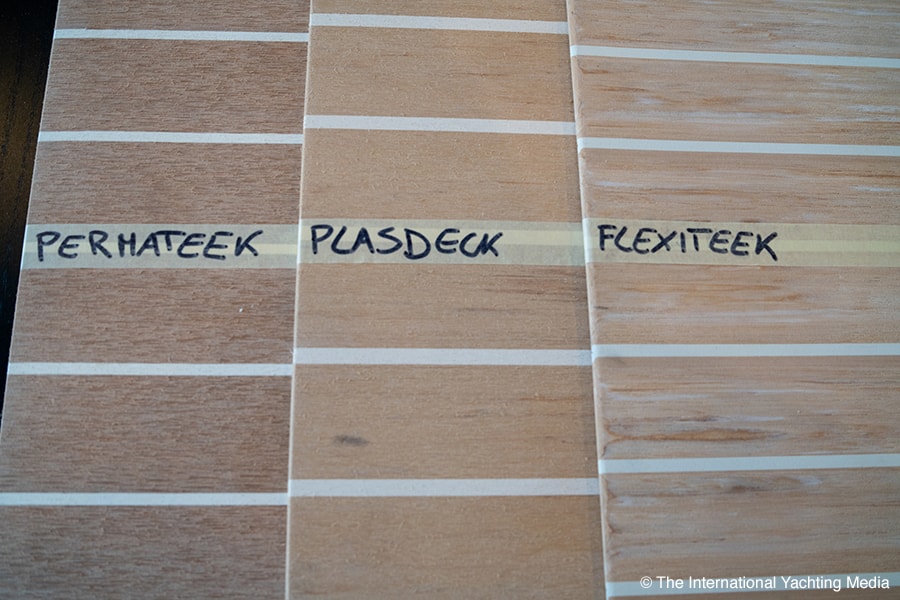

The synthetic teak we tested is, in alphabetical order, the Flexiteek, the Permateek and the Plasdeck.

Here’s what we found out:

Synthetic teak : aesthetics and touch feeling

First of all, we decided to analyze the aesthetic appearance and therefore the element that makes both boat owners and their guests fall in love at first sight.

Of course, it’s a subjective yet important choice since, once chosen, the synthetic teak has the implicit characteristic of maintening the same appearance over years.

More specifically, Flexiteek shows veins and shades that make it, in a natural way, very similar to real wood. Its colour is light biscuit.

The Permateek Classic, instead, is very different from the others since its darker colour makes it more similar to aged or oil-processed wood. However, t he typical nuances of wood are absent. The veins in relief, reproduced during the processing phase, are instead very marked and visible throughout the panel. But they don’t seem natural at all.

Another difference between the three products concerns the width of slats and seams. Flexiteek’s ones are narrower, slimmer and more elegant while the other two are wider.

As for the tactile sensation, we noticed that there’s a big difference between the three products. Permateek is made of harder and rougher plastic, Flexiteek is softer while Plasdeck is somewhere in between.

In our opinion, this test concludes with the following ranking: 1 Flexiteek – 2 Plasdeck – 3 Permateek

Sun exposure

After more than one hour of sun exposure, our teak synthetic panels reached the maximum temperature peak. The Permateek was the hottest one, with a temperature of 60.8 degrees, followed by the Flexiteek with a temperature of 57.3 degres and the Plasdeck with 53.5 degrees.

The other two panels, instead, turned cold more quickly and, after having remained in shadow for one hour and despite the difference in their peak, they reached the same temperature of 34.8 degrees.

In addition to thermometric measurements, we also tested the sensation of warmth transmitted by the materials, walking barefoot on the different teak panels. This step resulted in a further confirmation and a surprise.

The Permateek was the hottest and the contact with the sole of our foot confirmed that. Moreover, the sensation of warmth remained on the foot for some minutes, which confirmed the excellent warmth retention capacity of the material.

Flexiteek, instead, while not registering the lowest surface temperature, when it came into a prolonged contact with our foot, proved to have the lowest warmth retention capacity . This suggests that the material composition (Flexiteek G2 patent) ensures greater heat dispersion.

In conclusion, this second test concludes with Plasdeck and Flexiteek coming joint first and Permateek in last place.

We calculated the weight of our panels on a m2 basis. This time, Flexiteek proved to be the best product. This is an important aspect to take into account when dealing with a boat. The following table shows the overall weight of teak decking on a 13-meter sailboat.

| Sample | cm | cm | cm² | m² | weight in kg | kg in total | |||

| 40 | 40.2 | 1,608 | 0.1608 | 0.721 | 30 | 134.515 | Flexiteek | ||

| 39.5 | 40 | 1,580 | 0.158 | 0.848 | 30 | 161.013 | Permateek | ||

| 41 | 41.5 | 1,701.5 | 0.17015 | 1.003 | 30 | 176.844 | Plasdeck |

Let’s take into consideration a sailboat, especially a performing one. A lower weight on the deck not only contributes to reduce the overall weight but also and above all reduces the weight positioned above the waterline. This way, the centre of gravity of the boat remains lower, which contributes to reduce heeling when sailing while improving performance.

This is also true for motorboats that, as you know, have wider decks and therefore need more square meters of synthetic teak. On these yachts, the main difference lies in comfort and not in performance. Especially if these boats are equipped with a flybridge: a lower weight on this means lower rolling for the yacht itself.

Ranking: 1 Flexiteek – 2 Permateek – 3 Plasdeck

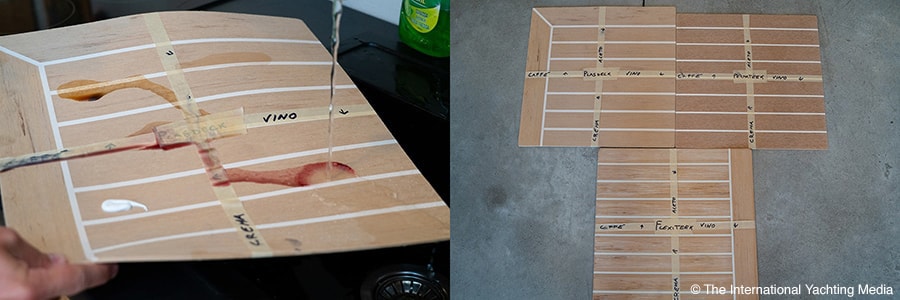

Resistance to dirt

For the first part of our test, we spilled some staining substances and we left them on the teak surface for about one minute; then, we removed everything with what is the most used method on each boat, ie water.

The result is the same for all the three products: stains were removed with a simple cleaning carried out with the hands under the flowing water.

Damage resistance

Things changed when we tried to pierce the panels with our scissors and screwdrivers in order to simulate the most common deck accidents. This time, no sample passed the test: all of them let themselves be pierced ( the Permateek with a little bit of difficulty). This is maybe inevitable with a plastic material that, after all, is not so different from natural wood that, unlike synthetic teak, cannot be repaired if not with a long work.

To the touch, the Permateek proved to be the roughest material, capable of the best grip thanks to its more market veins.

Ranking: 1 Permateek – pari merito Flexiteek e Plasdeck

The back of panels, predisposition to gluing

Flexiteek is highly processed and shows a series of grooves (another patent of the company) that facilitate gluing without bubbles and “slipping” effects. Permateek has a micro-perforated bottom while Plasdeck is the smoothest one.

For obvious reasons of simplicity and installation quality, this chapter concludes with this final ranking: 1 Flexiteek – 2 Permateek – 3 Plasdeck

Conclusions

Rankings speak for themselves and, even if individual differences are not big, Flexiteek is undoubtedly the absolute winner.

It proved to be multi-purpose, highly efficient in all respects and even the most similar one to natural wood.

However, it is also true that boat owners, or better their personal tastes, have the final say. These synthetic teak panels are offered for sale in many colour options, so you can choose the colour combination you like the most or that best matches your boat.

We thank all three manufacturers that, as proof of their good faith, accepted the test without hesitation.

Below you will find their contact details.

Teknoteak SRL

Via guidetti 45, 40052 Passo Segni (BO)

Phone: +39 338 3422028

Refit Style SRL

Via Foscolo 8, 34131 Trieste

Phone: +39 040 2453942

Euroservice Sas – Synteak

Via Graz 12, 38121 Trento

Phone: +39 366 4078168

15 Responses

Thanks for this article, very interesting! any chance to add to the test a piece of real teak? Also, quite important, particularly on racing boats, the abrasion test. Ropes and sailbags dragged on the foredeck could leave marks…

As a certified synthetic teak installer that has installed all three products and watched them weather over several years, Permateek looks newer longer. It is slightly heavier and stiffer but goes down straighter. Flexiteek is challenging to keep the lines straight upon installation. I have found the 2G has a tendency to mold on the surface where the others do not. The grooved back of Flexiteek is only good on paper! When installed over aggressive non-skid, the grooved back may allow for water penetration. This can damage the gel coat and allow moisture to enter the coring. Your test only showed the appearance and Temperature concerns while there are many aspects to consider. If Permateek submitted a similar color to the others, the temperature difference is insignificant. All surfaces are sanded when manufactured. And again when fabricated. The texture can be anything from smooth to “hairy”. Don DRB Marine USA

DRB Marine used to dabble in Flexiteek before switching over to Dek-King, which had excellent feedback all over the US and beyond. They have now been acquired by Flexiteek, which is a compliment on the standard of quality manufacturing performed at their U.K. location. Indeed, Flexiteek is now produced fully at this factory with glowing success! As my Company handles the Importing for the Americas, let’s remember that DRB chose ‘not’ to go with an existing factory that had worked well for the last three years, and continues to increase the quality control levels in order to maintain the #1 status. Don produces excellent work, just a shame he chose to jump ship for reasons not related to the quality!

Hi. I am in search for a synthetic deck manufacturer who has already templates for FP Lavezzi 40… Please email me at [email protected] if you happen to know one. Thank you!

Hi. I am in search for a synthetic deck manufacturer who already has templates for the Leopard 50… Please email me at [email protected] if you happen to know one. Thank you!

Hi I am in search for a synthetic teak deck manufacturer that has templates for Princess 92 55′ with Flybridge. Thank you

I am looking for a template for my 37 ft 1989 Pearson Sail boat

Template for a 78 ft Choey Lee motorsailor?

I would not use Permateek. I had a bad experience on my 66 foot boat. The Permateek was installed by Permateek. The deck developed hundreds of blisters. It has been 6 months and Permateek has not done anything except write emails trying to figure out a way to not honor thier warranty. The product is not as represented. The installers are not qualified. They do not honor their warranty. So far I am out $22,000.

Just an update, there were issues with this boat as we attempted to cover the decking surface which was not fibreglass in the hope that the underdeck was not porous. Unfortunately, this was not successful and blisters did occur. As a company, we always honour our warranty and having made extensive investigation into what went wrong, we assess that fitting synthetic decking over this surface was not going to work out. As a result, Mr Tomlinson was fully refunded.

As a company, we have fitted thousands of decks without issue and we are very proud of the work we carry out.

You missed one main thing. Leave some dirt or whatever on flexiteek for 5-6 hours and then try to wash it, you will be suprised. Flexiteek will alow dirt to go all the way down and you cant remove that or sand it out but with permateek and pladeck is different story. Flexiteek is on the last place just because of that sucking failure. I know what I talking about because I was working with flexiteek and permateek.

The author of the article forgot another major brand: xxxxx that is sold …..

HI Denis, it was a pleasure to read your comment, unfortunately I had to remove the brand and the rest of the text becacuse it was ADV.

Your product was not included in the test because probably at the time of the test it either did not yet exist or was too “young” to be considered.

However, we are more than willing to include your product in the article if of course you are able to send us a sample of the product. The other manufacturers at the time sent us a sample of about 40 centimeters per side, as you can see from the pictures.

The sample will then be examined, measured, weighed, exposed to the sun to measure surface temperature, dirtied and washed, in the same manner as we did with the others and the results, since we are no longer in possession of the old samples, will be displayed at the end of the article.

Just send an email with your contact details and we’ll organize.

Best regards

We are also a supplier of pvc material in UK. Since the material can be sanded any of the 3 could come top of this grouping depending on which material was sanded the coarser. The materials are similiar with the best quality beng 100% virgin pvc. This applies across most reputable brands except one that has some additives that reduces weight and makes the welds less durable and apparently more susceptible to staining.

Hello, if possible, we would like to know if they will last for years and in average experience, how many?

Pictures actually installed on boats from one to as many years as possible would be appreciated.

Thanks in advance.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Language switcher

Browse categories.

You might be interested in

Quick Group at September boat shows with great innovations for the superyacht segment

Sailboat charter: 8 considerations before booking

Guide to RIB Tubes Maintenance

Luna Rossa Prada Pirelli leads the Louis Vuitton Cup standings undefeated

© 2021 – THE INTERNATIONAL YACHTING MEDIA Designed by BLive Communication

ABOUT YACHTINGNEWS.COM

Yachting News is an interactive multimedia magazine dedicated to the world of boating.

The International Yachting Media is the worlds most widely read boating magazines network. Whit its portal It broadcast its original contents in five languages and in more than 200 countries developing 950,000 views a week. Our web portals are the main source of information for yacht and boat owners, the place where they can find anything about their boating passion.

THEINTERNATIONALYACHTINGMEDIA.COM | SUPERYACHTS.NEWS | YACHT DIGEST

VIRTUAL BOAT SHOW | TUTTTOBARCHE | TOUSLESBATEAUX | TODOSLOSBARCOS

BOATING NEWS FREE APP

To provide the best experiences, we and our partners use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us and our partners to process personal data such as browsing behavior or unique IDs on this site and show (non-) personalized ads. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Click below to consent to the above or make granular choices. Your choices will be applied to this site only. You can change your settings at any time, including withdrawing your consent, by using the toggles on the Cookie Policy, or by clicking on the manage consent button at the bottom of the screen.

Subscribe For Latest Updates

Sign up to receive the best of Yachting News, sea trials, boat review and world premieres .

The only ADVERTISING FREE newsletter

Installing a new teak deck on your boat

A new teak deck enhances the value and aesthetics of your boat, while providing a non-slip surface and long-lasting durability. Learn how to install one with our comprehensive guide.

Installing a New Teak Deck on Your Boat

As you embark on your sailing adventure, one of the most important aspects of your boat is its deck. A well-maintained and aesthetically pleasing deck not only adds value to your boat but also enhances your overall sailing experience. Teak has long been the preferred choice for boat decks due to its durability, natural non-slip properties, and timeless beauty. In this comprehensive guide, we will walk you through the process of installing a new teak deck on your boat, covering everything from materials and tools to step-by-step instructions and maintenance tips.

Table of Contents

Why choose teak for your boat deck, materials and tools needed, preparing your boat for teak deck installation, installing the teak deck, finishing touches and maintenance.

Teak is a tropical hardwood that has been used for centuries in shipbuilding and marine applications. Its natural oils and silica content make it resistant to rot, decay, and insects, while its tight grain and minimal shrinkage provide excellent dimensional stability. Here are some of the key benefits of choosing teak for your boat deck:

- Durability : Teak is one of the most durable hardwoods available, with a life expectancy of 30-50 years when properly maintained.

- Non-slip surface : The natural texture of teak provides excellent traction, even when wet, making it a safe choice for boat decks.

- Aesthetics : Teak’s golden-brown color and attractive grain pattern add a touch of elegance and warmth to your boat.

- Low maintenance : Teak requires minimal maintenance compared to other decking materials, such as synthetic or composite options.

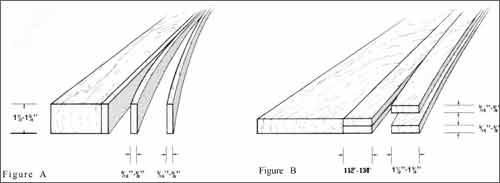

Before you begin the process of installing a new teak deck, it’s essential to gather all the necessary materials and tools. Here’s a list of what you’ll need:

- Teak decking : Choose high-quality, quarter-sawn teak planks or pre-manufactured teak decking panels.

- Adhesive : A marine-grade, flexible polyurethane adhesive is recommended for bonding the teak to your boat’s deck.

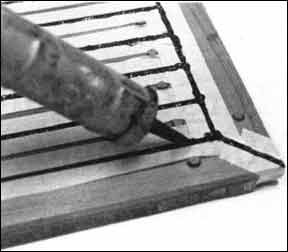

- Sealant : A high-quality, marine-grade sealant is required for sealing the seams between the teak planks.

- Backing material : A thin layer of closed-cell foam or EVA foam is often used as a backing material to provide cushioning and sound insulation.

- Tools : You’ll need a variety of tools, including a circular saw, jigsaw, router, drill, caulking gun, notched trowel, straightedge, clamps, and sanding equipment.

Before you can install your new teak deck, you’ll need to prepare your boat’s existing deck surface. This involves several steps:

Remove any existing decking : If your boat has an old teak deck or another type of decking material, you’ll need to remove it completely. This may involve unscrewing or prying up the old planks, scraping off any remaining adhesive, and cleaning the surface thoroughly.

Inspect and repair the deck : Once the old decking has been removed, inspect your boat’s deck for any damage, such as cracks, soft spots, or delamination. Repair any issues before proceeding with the teak deck installation.

Level the deck surface : It’s essential to have a level and smooth surface for your teak deck to adhere to properly. Sand the deck surface to remove any high spots or imperfections, and fill any low spots with a marine-grade filler.

Create a template : Measure your boat’s deck and create a template using heavy-duty paper or cardboard. This will help you accurately cut your teak planks or panels to fit the deck’s shape and contours.

With your boat’s deck prepared, it’s time to install your new teak deck. Follow these steps for a successful installation:

Dry-fit the teak planks or panels : Lay out your teak planks or panels on the deck, using your template as a guide. Make any necessary cuts or adjustments to ensure a proper fit. Leave a small gap (approximately 1/8 inch) between each plank for the sealant.

Apply the adhesive : Using a notched trowel, spread a layer of marine-grade polyurethane adhesive onto the deck surface. Be sure to cover the entire area where the teak will be installed.

Install the backing material (if applicable) : If you’re using a backing material, such as closed-cell foam or EVA foam, lay it down on top of the adhesive, ensuring it’s properly aligned with the teak planks or panels.

Lay the teak planks or panels : Press the teak planks or panels firmly into the adhesive, ensuring they’re properly aligned and spaced. Use clamps or weights to hold the teak in place while the adhesive cures.

Secure the teak with screws (optional) : Some boat owners choose to secure their teak decks with screws in addition to the adhesive. If you opt for this method, pre-drill holes through the teak planks or panels and into the deck, then insert stainless steel screws and countersink them slightly below the teak surface.

Allow the adhesive to cure : Follow the manufacturer’s instructions for the adhesive’s curing time, which may range from 24 to 48 hours.

Once your teak deck is installed and the adhesive has cured, you’ll need to complete a few finishing touches and establish a maintenance routine to keep your deck looking its best:

Seal the seams : Apply a marine-grade sealant to the seams between the teak planks, using a caulking gun. Smooth the sealant with a plastic spatula or your finger, ensuring it’s level with the teak surface. Allow the sealant to cure according to the manufacturer’s instructions.

Sand the deck : Lightly sand the entire teak deck with a fine-grit sandpaper to remove any rough spots and create a smooth, even surface.

Clean the deck : Regularly clean your teak deck with a soft brush and mild, soapy water to remove dirt, salt, and other debris. Avoid using harsh chemicals or high-pressure washers, as these can damage the teak’s natural oils and fibers.

Apply a teak protector (optional) : Some boat owners choose to apply a teak protector product to help maintain the wood’s color and prevent graying. Follow the manufacturer’s instructions for application and reapplication frequency.

Installing a new teak deck on your boat is a rewarding project that can significantly enhance your sailing experience and your boat’s value. By following this comprehensive guide and using high-quality materials and tools, you’ll be well on your way to enjoying the beauty and functionality of a teak deck for years to come. Remember to establish a regular maintenance routine to keep your deck looking its best and to prolong its lifespan. Fair winds and smooth sailing!

- Teak Decks: Navigating the World of Boat Decking

When you picture a luxurious yacht or a classic sailboat, what's one common feature that instantly comes to mind? Teak decks! These stunning wood surfaces have been a hallmark of marine craftsmanship for decades. In this comprehensive guide, we'll set sail through the world of teak decks, exploring everything from their history and allure to the various options available in the market today. So, fasten your lifejacket , and let's dive into the world of teak decking for boats.

The Rich History of Teak Decks

Teak, scientifically known as Tectona grandis, is a hardwood native to Southeast Asia. Its use in boat building can be traced back centuries. We'll journey through time to uncover the rich history of teak decks and why they have stood the test of time.

Defining Teak: A Wood of Distinction

Before we proceed, let's define teak wood and its exceptional qualities that make it a prized material for boat decking. We'll explore its natural characteristics and why it's highly sought after in the marine industry.

Read more useful sailing tips:

The allure of teak decks, the aesthetic appeal.

Teak decks are renowned for their breathtaking aesthetics. We'll discuss how the warm, golden hue of teak wood enhances the visual appeal of boats, adding a touch of elegance and luxury.

Unmatched Durability

Teak wood's natural oils and density make it exceptionally durable in the harsh marine environment. We'll delve into the longevity and robustness of teak decking, explaining why it's a preferred choice for boat owners.

Comfort Underfoot

The comfort of teak underfoot is often praised by sailors. We'll discuss how teak decks provide a non-slip surface and a comfortable feel, even in the most challenging sea conditions.

Types of Teak Decking

Traditional teak decking.

Traditional teak decking involves individual teak planks assembled on the boat's deck. We'll explore the craftsmanship involved and its classic appeal.

Synthetic Teak Decking

For those seeking a low-maintenance alternative, synthetic teak decking is gaining popularity. We'll discuss the benefits and drawbacks of this modern solution.

Teak Deck Systems

Teak deck systems offer innovative installation methods. We'll explain the different systems available and their advantages.

Maintenance and Care

Preserving the beauty.

Teak decks require proper maintenance to keep their beauty intact. We'll provide tips on cleaning, sealing, and preserving your teak decking.

Restoring Weathered Teak

Over time, teak can weather and lose its luster. We'll explore the process of restoring weathered teak to its former glory.

Read our top notch articles on topics such as sailing, sailing tips and destinations in our Magazine.

Navigating the Market

Teak decking for boats in the uk.

If you're a boat owner in the UK, we've got you covered. We'll guide you through the options available for teak decking for boats in the United Kingdom.

Teak Yacht Decking

Yachts demand the utmost in elegance. We'll discuss teak yacht decking and how it caters to the discerning tastes of yacht owners.

In conclusion, teak decks are not just a functional element of a boat; they are a symbol of timeless elegance and craftsmanship. Whether you're a boat owner looking for a classic touch or a modern solution, the world of teak decking offers a variety of options to suit your needs. So, set sail with teak, and elevate your boating experience with its allure and durability.

So what are you waiting for? Take a look at our range of charter boats and head to some of our favourite sailing destinations .

Teak Deck Company - Teak Decking, Maintenance, Flooring & Furniture

Teak Deck Company™ fabricates and sells ready to install teak decking and flooring products for boat manufacturers, boat owners and professional contractors. In business since 1996, we install teak decks in the United States and on mega-yachts worldwide.

All our teak decking panels are of the highest quality – a result of years of experience in boat carpentry and woodwork. We constantly invest in product development, because “this is how it was done before” doesn’t mean there isn’t a better way. We only promote new products after they have passed the toughest testing by Mother Nature.

Our prefab teak decking system was developed for production boat builders and provides great advantage for private customers and professional installers.

Fine Teak Furniture

Teak Deck Company is the U.S. distributor of fine teak furniture by EuroDesign of Sweden. Eco-friendly and FSC certified, our line of furniture is in-stock and ready to ship from our Florida warehouse. CLICK HERE to find out more.

BIG SALE – 10% off all Table Tops & Select Chairs

Teak deck company products include.

FREE SHIPPING!

Slatted Marstrand Table & Fredrik Chair Set

Teak Folding Marstrand Chair w Slats

Teak Table, Square, Star Inlay

Teak Table, Folding, Star Inlay, Rectangular

Click Here to Contact Us

Or call 561.575.3732.

IMAGES

VIDEO

COMMENTS

Our standard deck thicknesses are 1/4", 3/8" and 1/2". Other deck thicknesses are also available upon request. MARITIME Custom Teak Decks and Teak Deck Panels eliminate the need to tediously hand lay a deck plank by plank. They represent a major savings in on-site skilled labor hours and fabrication materials waste.

Removing the deck hardware; virtually everything was bolted through the deck. Removing the old teak and preparing the deck for bonding new teak. Cutting, bonding, and caulking the new teak. Re-installing the deck hardware. Removing the deck hardware took eight days with two people working 12 hour days.

Explore premium teak and composite decking for yachts and boats. Teakdecking Systems offers durable, eco-friendly, innovative marine decking solutions worldwide

Smooth sailing with sanding. Most boaters with a teak deck consider it a standard practice to sand the surface once a year before the start of a season. Sandpapers come in various grits—for a teak deck, between 80 and 120-grit is the ideal level. The higher the number of grit, the more slippery the deck will be, so a medium level is suitable ...

PlasDECK is a patented synthetic teak boat decking option that provides the elegant look of a teak deck without any of the time-consuming and costly maintenance associated with natural wood teak. Made out of flexible PVC, this material is easy to work with and maintain. It's the perfect option to upgrade your boat and replace the dingy old ...

The following table shows the overall weight of teak decking on a 13-meter sailboat. ... As a company, we have fitted thousands of decks without issue and we are very proud of the work we carry out. Reply. Mladen says: May 9, 2024 at 2:53 pm. You missed one main thing. Leave some dirt or whatever on flexiteek for 5-6 hours and then try to wash ...

A curved teak sailing yacht deck is more technically challenging to build than a straight-laid teak motor yacht deck. Our fabrication system remains unique in the marine industry after 40 years, using adjustable jigs under vacuum pressure to ensure the curved teak battens hold their shape during assembly. Complete water tightness is critical ...

With your boat's deck prepared, it's time to install your new teak deck. Follow these steps for a successful installation: Dry-fit the teak planks or panels: Lay out your teak planks or panels on the deck, using your template as a guide. Make any necessary cuts or adjustments to ensure a proper fit. Leave a small gap (approximately 1/8 inch ...

In conclusion, teak decks are not just a functional element of a boat; they are a symbol of timeless elegance and craftsmanship. Whether you're a boat owner looking for a classic touch or a modern solution, the world of teak decking offers a variety of options to suit your needs. So, set sail with teak, and elevate your boating experience with ...

Teak Deck Company™ fabricates and sells ready to install teak decking and flooring products for boat manufacturers, boat owners and professional contractors. In business since 1996, we install teak decks in the United States and on mega-yachts worldwide. All our teak decking panels are of the highest quality - a result of years of experience in boat carpentry and woodwork.

Resisting the urge to use bleach will benefit your deck in the long run. However, if the urge proves too strong, mix 1 cup of bleach in 1/2 bucket of water and apply it to the areas in need. Thoroughly rinse the solution away before the decks dry. Oiling Teak. Boat owners striving to maintain the warm gold of fresh-cut teak will often reach for ...

The alternative is to put the boat in a shed somewhere. Anything is possible but it always costs. Replacing a teak deck is a massive job. To replace the decks on a 9m (30ft) boat is six weeks' work - three months for a 15m (50-footer). We are talking about many thousands of pounds and your boat out of action for a while.

Tye Conway of UK-based decking specialist Elite-Teak says that typical installed prices in the UK are often lower than elsewhere in northern Europe, with many jobs falling into the following price ...

For the typical production boat up to about 35′ the teak can be about 5/16″ thick, 3/8″ at the most. At this thickness the weight of the decking is about 112 lbs per square foot, not so much that it should seriously decrease stability. The problem with laying a deck this thin is that fastening is a problem.

We are the North American leader in the manufacture of production boat teak and composite decking, and component parts for a wide variety of cruising and fishing boats, boatyards and private owners. Our service includes design and consultation assistance, templating, installation training and process review. Turnaround times are fast and we ...

Flexiteek. With over two decades of expert product development, Flexiteek is the patented, synthetic teak decking alternative to real teak. And it looks every bit as beautiful. Available in stylish, contemporary colours, it can be customised with lettering and logos. It's been developed to be safe and comfortable in extreme conditions and to ...

Sep 10, 2016. Since the advent of fiberglass boat production, sailors have had a love-hate relationship with teak decks. On the one hand, they provide a good nonskid surface and add a feeling of warmth to a boat's appearance. On the other, teak is expensive and time-consuming to maintain. By contrast, synthetic teak decking can be installed ...

After curing, the deck is then ready to be sanded. The entire deck is sanded with 36 grit to remove excess caulking, followed by 60 and 80 grit to enhance the look of the deck. We use the finest legally sourced teak. For new builds or refits, our expert team handles design, templating, manufacturing, and installation for perfect decks.

Welcome to Maritime Wood Products, the premium manufacturer of custom teak decks and the supplier of finest quality wood products for yacht building and restoration. We are specialists in wood and its application, and we look forward to the opportunity to serve you.

Reduced Weight. Weighing just 4.5kg per m², Flexiteek is up to 35% lighter than rival synthetic decking systems. This makes it particularly attractive for high performance multihulls, power and sailing boats. Importantly, it reduces the weight positioned above the waterline, as well as the overall boat weight.

When it comes to boat deck material, teak wood is the undisputed king. It's been used by boat builders for over 2,000 years, and is still considered the finest material for boat decks. This is hardly surprising considering how eye-catching teak decks are, but those good looks require regular maintenance to preserve.

Many boat owners like the silver patina. However, those who do not like the color will sand the teak deck to restore it to the original golden brown color. After sanding, the teak will be like new. Frequent sanding accelerates the reduction in thickness and decreases the deck's life . A healthy teak deck has a light silver color and clean wood.

PERFORM ANNUAL LIGHT SAND-OUT to EXTEND DECK LIFE. In addition to proper cleaning, perform an annual light sand-out (best performed by a highly experienced carpenter). A well-done sand-out will remove a thin layer of teak refreshing the surface and make it smooth. The teak's natural oil is brought back to the surface.