- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Blue Jacket 40 Used Boat Review

Catalina 270 vs. The Beneteau First 265 Used Boat Match-Up

Ericson 41 Used Boat Review

Mason 33 Used Boat Review

How to Create a Bullet-Proof VHF/SSB Backup

Tips From A First “Sail” on the ICW

Tillerpilot Tips and Safety Cautions

Best Crimpers and Strippers for Fixing Marine Electrical Connectors

Polyester vs. Nylon Rode

Getting the Most Out of Older Sails

How (Not) to Tie Your Boat to a Dock

Stopping Mainsheet Twist

Fuel Lift Pump: Easy DIY Diesel Fuel System Diagnostic and Repair

Ensuring Safe Shorepower

Sinking? Check Your Stuffing Box

What Do You Do With Old Fiberglass Boats?

Boat Repairs for the Technically Illiterate

Boat Maintenance for the Technically Illiterate

Whats the Best Way to Restore Clear Plastic Windows?

Stopping Holding-tank Odors

Giving Bugs the Big Goodbye

Galley Gadgets for the Cruising Sailor

The Rain Catcher’s Guide

Sailing Gear for Kids

What’s the Best Sunscreen?

UV Clothing: Is It Worth the Hype?

Preparing Yourself for Solo Sailing

R. Tucker Thompson Tall Ship Youth Voyage

On Watch: This 60-Year-Old Hinckley Pilot 35 is Also a Working…

On Watch: America’s Cup

On Watch: All Eyes on Europe Sail Racing

Dear Readers

- Systems & Propulsion

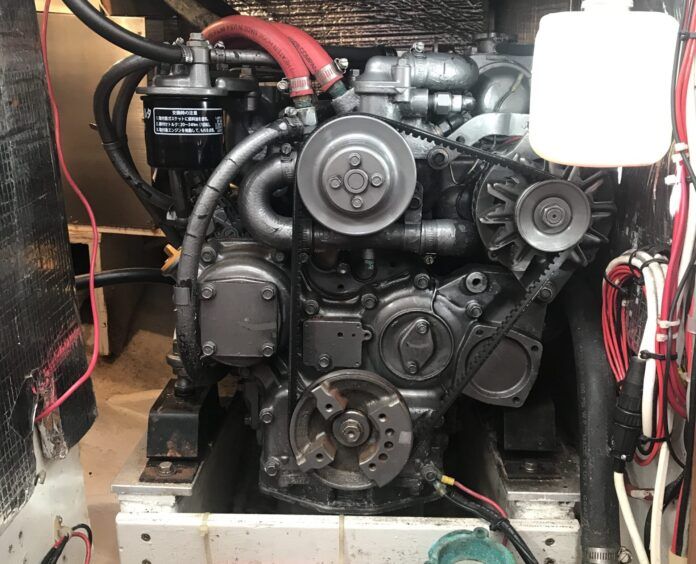

Breaking Point: What Can Go Wrong With Your Yanmar?

These auxiliaries are an industry workhorse, but stay on top of that exhaust elbow..

If you want to know more about the little Yanmar chugging away in your sailboat, it helps to learn about this iconic engine maker’s lowly but ubiquitous GM series. This noisy, cantankerous, yet well-regarded machine will nonetheless take you anywhere you want to go. You just have to know how to treat it right—with respect, but a firm hand.

It is built to be simple, reliable and easy to repair, even in remote locations. Sailors who venture far from help and resources can literally rebuild this engine in the cockpit of their sailboat, as it doesn’t require any hard-to-access specialty tools, and is rather forgiving when it comes to assembly missteps or poor maintenance.

It is the “Toyota” of the industry, and it’s extremely tolerant of corrosive conditions, owner neglect, and poor operating practices.

As a marine mechanic, I have found that sailboat engines take some of the worst abuse an engine can withstand, from lack of maintenance, to simply not running the engine hard enough, which can wreak havoc on a small diesel. And yet, I have seen many Yanmar GM series engines still running with cracked pistons, saltwater in their cylinders, sludged oil in their passageways, and many other hideous conditions where any other engine would’ve failed. How is this possible? What is so special about Yanmar’s tough-as-nails, gnarly little GM?

SOME COMPANY BACKGROUND

Whether you are an experienced sailor, or you are getting ready to purchase your first sailboat, you are likely familiar with the Yanmar brand name. It should be familiar, as a Yanmar diesel engine is installed in approximately 50% or more of today’s recreational sailboats and powerboats. You can barely walk down the dock at a marina without passing one or more boats with a Yanmar engine installed. That said, why are they such a popular engine choice in the recreational boating world? Are they as reliable as everyone says they are? Are they always so on a “cool” day like everyone says? What’s their secret, and why is there such a following?

Yanmar has been in the business of building engines for more than a hundred years, and was the first engine manufacturer to successfully downsize a diesel engine in 1933 before entering the marine market in 1947. Not only do they build some of the world’s largest marine diesel engines, they also build the world’s smallest. The Yanmar GM is one of the United States’ most popular sailboat engines, and includes the 1GM10, 2GM20F, 3GM30F to name a few.

Like its earlier HM and YSM predecessors of the 60s and 70s, Yanmar’s GM series is a compression-dependent engine. Unlike equivalently sized engines from other makers that use glowplugs and intake grid heaters, however, the GM series engines have a much higher compression ratio. This means the engine can create its own heat within its cylinders in a significantly shorter time frame than, say, a Universal/Westerbeke, which has a significantly lower compression ratio, and thus requires glowplugs to get started. Without a lot of compression and heat inside the cylinder, diesel fuel doesn’t like to combust. A diesel engine needs fresh air, clean fuel, and good compression (creating lots of heat!) in order to start and run! This means a Yanmar can start in the coldest conditions without glowplugs, which eliminates a potential failure point. This also gives a Yanmar owner a unique perspective on the internal health of his or her engine. It will start relatively easily in the cold when new, but if you notice it getting harder and harder to start, even on warm days, that’s a sign compression may be dwindling. Thanks to the salty and damp environments these engines live in, I see many Yanmar compression-based engines struggle to start due to corroded valve seats. Why? While Yanmar succeeded in building a simple, reliable engine, they failed royally with their exhaust elbow design. Yanmar’s original equipment elbows, especially the mild steel L-style and cast iron U-bend style elbows, can fail in a variety of ways and is one of the reasons I sometimes wind up pulling off cylinder heads. Bad exhaust elbows means water intrusion and wet exhaust, weakened valve seats and finally, weak compression. As Yanmars age, weakening compression afflicts older Yanmars more than any other issue.

The faulty exhaust-elbow topic is likely a broken record for those of you who are aware of it. But take note of this problem if you own any Yanmar (including newer models) or are looking to buy a boat equipped with a Yanmar.

While we are on the subject of Yanmar exhaust elbow, let’s take the time to have a little introduction to corrosion and metallurgy. First, exhaust gases are extremely corrosive. Mix several hundred hot/cold heat cycles. Then, because of that bad exhaust elbow, add to the stew backed-up freshwater or even saltwater! If you think that mild steel or cast iron can withstand all that – think again. Yanmar’s OEM elbows tend to corrode terribly from the inside out, where you can’t see the damage until it’s too late. This is usually when the elbow finally breaks apart or water starts going backwards into the exhaust manifold. Eventually, raw water makes it into the cylinders. Remember what I mentioned about corroded valve seats leading to poor compression and starting issues? I have seen Yanmars running with water in their cylinders, the number one reason valves and piston/rings fail. The source? Water intrusion from a failed exhaust elbow. The U-shaped iron elbow is notorious for this, but it doesn’t stop there. The elbow is technically water jacketed, but the water jacket actually cuts the dry exhaust stream in half, reducing the engine’s ability to clear its own exhaust, and leading to power loss when the elbow becomes clogged with soot and carbon deposits. It will become clogged, that’s a guarantee. While Yanmar isn’t the only manufacturer with this issue, their factory-designed elbows are the worst.

WHAT CAN A YANMAR OWNER DO?

Luckily, there are some decent options to prevent catastrophic failure. If you are running an OEM mild-steel or iron elbow, every year or two it is critical to remove the elbow from the engine and inspect for signs of internal corrosion. This also gives you an opportunity to clear out any carbon buildup so the engine can breathe and not lose power. One solution is to replace a cast exhaust elbow with a stainless steel version. While Yanmar doesn’t offer stainless-steel elbows, a great resource for high-quality 316-grade cast stainless exhaust elbows (that actually cost a lot less and last significantly longer) is HDI Marine in Vancouver, WA. HDI Marine is a great resource for a variety of quality OEM-style elbows for Yanmar, Volvo, Detroit Diesel, and many more.

Another notable Yanmar quirk includes the air cleaner/silencer side of the engine. This is a common fault on many small marine diesels of the 70s-90s era, where many manufacturers never installed an actual air filter on their engines, thinking incorrectly the engine on a sailboat couldn’t possibly suck up any dirt or other crud during operation. Yanmar’s air cleaners consist of a mild steel screen with a foam “filter” installed underneath a steel housing. This filter is not resistant to oil or fuel. Yanmar and other diesel manufacturers route their crankcase vent hoses into the air cleaner. Routing the vent hose this way prevents an oily mess from oil vapor condensing and dripping down the side of the engine—just like they did in the ‘olden days’. But what happens when the foam filter and engine oil mix? The foam disintegrates, breaks apart, then gets sucked into the engine. I have found many engines with only the metal screen left, the foam long gone. Now if that isn’t a good way to encourage some premature wear and tear on the engine, I don’t know what is! If you’re checking out a Yanmar onboard a potential boat to buy – pop open the air cleaner and check. If the filter is gone, you’ll get a good idea as to the maintenance habits of the previous owner! If you are currently an owner of one of these Yanmars, get in the habit of checking/replacing it every 100 hours or every oil change to keep it in tip-top condition. This will keep it out of your engine’s piston rings!

Finally, two things I commonly hear from owners: Complaints about Yanmar’s notorious noise and vibration. Earlier Yanmars (HM, YSM, and GM Series) are particularly loud, as they have a notable “fuel knock” when running. When I first heard one of these engines, I honestly thought it was about to throw a connecting rod. Little did I know, the design of the pre-combustion chamber and the injector nozzle itself make for a very noisy injection event when fuel is squirted into the chamber and fires almost immediately. This is normal, and something many of us have gotten used to on our own boats. However, if you value hearing any conversation over this engine, consider a more modern (and quieter!) Yanmar YM series. Another gripe: Yanmar’s older-style motor mounts get regular complaints, but they’re not only found on older models. They are still used on brand-new engines of every model in the Yanmar line. The problem? Yanmar’s OEM motor mounts are particularly soft, allowing the engine lots of movement as a result, even if all other vibration sources have been tamed. These mounts are also notorious for delamination from their steel supports because the rubber can degrade when it makes contact with oil/diesel fuel. This causes vibration to get worse as time goes on. The original mount brackets are also built of mild steel, which will corrode over time. Aftermarket companies such as PYI Inc. and Oceanic Innovations sell higher-quality OEM mounts that perform better than the originals. Many clients who choose a stiffer engine mount have been pleased with the results.

Even though I have noted the GM series’ water-intrusion problems, I believe Yanmar does pay attention to corrosion resistance in most components. Yanmar has built their marine line of engines to withstand damp, wet and salty environments, and they have certainly demonstrated that ability with high-quality construction in engine blocks, engine paint, heat exchanger tube bundles, and other parts. Unlike some other small-engine manufacturers (apart from Volvo), Yanmar designs and builds its product line exclusively for the marine environment. Other manufacturers might marinize a tractor engine block for sale to boaters. Yanmar also built raw-water engines equivalent to their fresh-water (or coolant) cooled counterparts as a cheaper alternative to the cost of a new engine. While these engines were considered “disposable”, many of them have lasted 40+ years and some are still running to this day. Yanmar’s raw-water engines are quite unique in the fact that the water jackets inside the engine block are porcelain/ceramic coated to protect the iron block from excessive corrosion and damage, particularly in saltwater. While most everything will corrode over time, these blocks far exceed the longevity of a raw-water cooled Universal M15 engine block, for instance, which was initially designed for use in an excavator far removed from any salt water. Another notable fact: Yanmar took special care to design its heat exchanger cores and housing end caps to withstand years of corrosion without protection from a zinc anode. Unlike many of Yanmar’s competitors, who use copper and aluminum heat exchangers, Yanmar uses silicon bronze end caps and a cupronickel tube bundle that is nearly perfectly resistant to corrosion over long periods of time. These tube bundles can last 20+ years as opposed to 5 or so years with a cheaper heat exchanger, which often results in raw-water coolant contamination.

A common question I get as a diesel mechanic working with a lot of different engines is whether or not I would recommend a Yanmar and why. Short answer: I absolutely would. While many manufacturers on the recreational engine front build reliable engines, Yanmar’s attention to detail and continued support is what keeps me onboard as a mechanic, but also as a customer. While all engines have their quirks, as we’ve discussed here, Yanmars enjoy good construction, good design, and a well-supported network that keeps parts available. Many of the GM series I work on today are 20-30+ years old and still perform beautifully, especially if well-maintained. I know the attention to detail paid to the GM line is indicative of Yanmar’s philosophy throughout the line. Yanmar has built its own empire over the last 100 years, and it continues to improve its design, efficiency and reliability. While some may consider the GM series obsolete, they are out there doing the job and owners need to know how they tick.

In future issues of Practical Sailor, I’ll be back to discuss the care and feeding of your diesel auxiliary, which, like a good dog, only wants to please. Your job is to treat it right.

RELATED ARTICLES MORE FROM AUTHOR

11 comments.

I think I have solved the dissolving air filter problem K&N makes several styles of clamp on cylindrical air filters that end in a short length of essentially rubber hose, that can be clamped around the end of the nozzle of the air filter housing with a hose clamp. A K&N RD–0450 fit on mine. If I recall correctly it cost about $50 from Amazon, but there are many sources. I left the oil breather setup as Yanmar designed it. I orient the nozzle vertically so that none of the oil can drip into the filter. And the filter is easily seen to monitor for the need to replace it. I’d love to send a photo of the filter on the engine, but the boat is put away right now – not handy. Works fine. I’ve put several hundred hours on the engine since installing the K&N.

What Yanmar engine do you use the K&N RD–0450?

Great article! Thank you

Love it! Great article. I just picked up a used 3GM30F for a repower in my Ericson 35, so this is extremely pertinent.

A really thoughtful article, with new information and explanations. I repowered to a 3YM20 in my Atlantic City Catboat, and it is a “rock crusher”. Have had it since new about 15 years now. Routine maintenance each season, and it has never failed me. I was aware of the exhaust elbow issue, so I did replace it-but found it to be in fine condition anyway. I think following Yanmar’s operation guidelines regarding high max revs for 10 minutes at the end of a longer motoring session does extend the life of the entire exhaust system. This engine does have glow plugs, which might be helpful below 50 F, but I have never had to use them. Engine starts every time in a nano-second. Highly recommend this engine. It is quiet, and no vibe when above idle. Design has no dissimilar metals, so no anodes required. Thanks for the info!!

This is one of the best series to come to PS! Will you be continuing with other engines like Westerbeke? BTW, I had no idea Yanmars were so well designed.

A second on the K&N line of filters! Found a height & circumference that would work for my 2GM & ‘modified’ the rubber capped side; positioned over the intake port it works wonderfully! No more disappearing foam & easy to clean & re-oil the filter. Wish I had not lost the box or I would post the K&N model #… IF anybody has the info PLEASE post it up!!

As I said, a K&N RD-0450 fit clamped on the air cleaner nozzle of my 3HM34F Yanmar. And I’m pretty sure the air cleaner housings are universal among the smaller older Yanmars. Plus, when I was researching a K&N filter, the staff at K&N was helpful in identifying which of their clamp-on filters would fit. Hope this helps.

Great Article. I rebuilt a 3QM30 in 2015 for under $2k. The QMs are even more a beast weighing almost twice that of the GM equivalent and loud as hell but sounds great when sailing… See svjohannarose dot blogspot dot com/search/label/EngineWork.

Thanks for your informative article. I have a 1984 3GMF. What do you know about the number of hours before overhaul for a well-maintained engine? Also, do you have a list of the components that are likely to fail so should be replaced? I replaced the gear cover gasket and understand that is a common wear item. Thanks, Tom

Very interesting article! I’m looking forward to your follow-up article on routine maintenance. I’d appreciate it you would expand it to cover larger Yanmar’s. I have twin 100 HP Turbo Yanmar’s (YJH3-HTE) on my PDQ Power Catamaran.

LEAVE A REPLY Cancel reply

Log in to leave a comment

Latest Videos

Cabo Rico 34 Boat Review

Super Shallow Draft Sailboat: The Leeboard Sharpie

Hans Christian 41T – Boat Review

Seven dead after superyacht sinks off Sicily. Was the crew at...

Latest sailboat review.

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

Yachting Monthly

- Digital edition

Best marine diesel engines: a buyer’s guide

- Sam Fortescue

- September 24, 2021

Modern marine diesel engines may look very similar to the large, noisy, oily chunks of iron of yesteryear, but a lot has changed under the bonnet, says Sam Fortescue

An inboard engine is a critical part of any boat, whether you're a purist who only motors when safety demands, or if you'd rather get into harbour in time for last orders. The chances are you also rely on the engine for battery charging. Credit: WorldFoto/Alamy Stock Photo

Best marine diesel engines: the new tech making inboard engines cleaner, more efficient, lighter and more reliable

Once referred to as the ‘auxiliary’ engine , your boat’s inboard diesel is now so much more than just a helping hand.

Not only is it central to your boat’s ability to manoeuvre safely into tight marina berths, it also allows you to keep up average speeds and make the tidal gate before it closes, charges the batteries that run the ever-expanding suite of entertainment and navigational tools aboard, and keeps the beers cold and showers warm.

Despite visual similarities to the noisy models of yesteryear, modern marine diesel engines are cleaner and more efficient, lighter and more reliable. And they are increasingly interactive.

If you’re considering re-powering your boat, here are some of the key features to look out for.

Marine Diesel Engines: Emissions

Tighter regulation in Europe has been forcing engine manufacturers to reduce the harmful emissions generated by their equipment.

In the marine sector, that means complying with the 2013 Recreational Craft Directive, known as RCD 2, and often with the EPA Tier 3 requirements in the USA.

Though most manufacturers anticipate further tightening in the future, there is nothing yet on the cards for marine diesel engines in the leisure sailing sector.

The focus on reducing emissions has resulted in a better understanding of the combustion process inside the cylinder.

A key pollutant, nitrous oxide, is formed at higher combustion temperatures, so one advance has been to reduce those temperatures.

A mechanical system, like this Beta Marine engine, offers ease of maintenance. You don’t need a laptop to reset the electronics

Increasing the swept volume of the cylinder theoretically creates more power, because there is room to burn more fuel each cycle, but if you keep fuel consumption the same, the diesel generates less heat in combustion.

Another area of development has been around the fuel injection system.

A lot has been written about the desirability and reliability of so-called common rail versus mechanical injection for marine diesels.

As Andrew Growcoot, CEO of Beta Marine puts it: ‘The benefits of a mechanical system [are] simplicity and ease of maintenance. One doesn’t need a laptop to reset the electronics ; a mechanical system is safe and will not power down at the wrong time.’

Beta Marine is a British marine diesel engine supplier that uses a Kubota block, and has no intention of introducing the technology any time soon on sub-100hp engines.

The same is true of France’s Nanni and Spain’s Solé, who both supply good, reliable diesel marine engines to the sailing market.

Hedley Beavis of Solé distributor Engines Plus says research to find a common rail injection system has been delayed by COVID-19.

‘It is not an easy task finding a reliable common rail engine but also at a reasonable price for the marine market,’ he adds.

But while common rail injection makes your engine reliant on an electronic control unit for precise high-pressure fuel injection and makes it more susceptible to poor quality fuel, this widely used technology can also offer significant benefits in terms of power and fuel consumption.

Continues below…

Diagnose and fix marine diesel engine problems

Tim Bartlett explains how you can diagnose some common marine diesel engine problems, and fix most of them

White diesel: is it worth converting from red?

Duncan Kent examines the implications of switching from red to white diesel and what you can do to avoid fuel…

How to: troubleshoot your marine diesel fuel system

One of the most common causes of a marine diesel engine not starting is a fuel problem. If you have…

How to avoid diesel bug

Diesel bug can clog filters, wreck engines, corrode fuel tanks, and leave you powerless at sea. Ben Sutcliffe explains how…

Plus, it’s quieter and produces less vibration.

That’s because the diesel is injected as a huge number of tiny droplets, greatly increasing the surface area for better combustion.

Common rail injection is usually found on more powerful engines – Volvo Penta uses the system in its D3 engine and above, which starts at 110hp.

But Yanmar took a bold step in 2018 when it launched a new 40hp unit with electronic fuel injection. The 3JH40 is still the smallest marine diesel engine with this technology.

‘Through common rail technology, the 3JH40 offers minimal fuel consumption and exceptionally low noise and emission levels, exceeding EPA Tier 3 and EU RCD Tier 2 emission regulations for virtually smoke- and odour-free operation,’ says marketing manager Sander Gesink.

‘People don’t want to have the smell of diesel onboard making them seasick.’

The demand for more plentiful electrical power on board boats has led engine manufacturers to increase the output of their alternator systems.

Where a typical alternator on a 30hp engine might have been around 50A two decades ago, they are now often in excess of 100A.

So, for example, even Volvo Penta’s entry-level D1-13 engine packs a meaty 115A alternator with its own built-in charging regulator, for optimal battery charging.

The 50hp D2-50 offers the same alternator, as well as the option of expanding output with a pulley take-off for a second alternator.

Even Volvo Penta’s entry-level D1-13 engine packs a meaty 115-amp alternator with a built-in charging regulator

Beta Marine’s 43hp engine comes with a 70A alternator as standard, but can accommodate upgrades to 120A or 175A alternators, as well as a second 175A alternator for really hefty charging.

It is worth noting, however, that many of these alternators remain fairly basic bits of kit with an inflexible charging regime.

That’s one reason that Yanmar has worked with Mastervolt on its 150hp-plus 4LV engines to develop a secondary charging option in addition to the on-board 130A unit.

Using the Alpha III charge regulator, that alternator will put exactly the right charge into the battery bank on a three-step regime that works regardless of the RPM by varying the field current going into the alternator.

Units on smaller, older marine diesel engines can easily be retrofitted with a regulator, such as Sterling Power’s Pro Reg.

Interactive marine diesel engines

It used to be that marine diesel engines would buzz along in the background unless they overheated, in which case you were treated to an ear-splitting alarm from the control panel.

They still do sport their own dedicated warning lights which ping on if oil pressure drops or the temperature rises above a safe 80-90ºC.

But with the growth of instrumentation on board, and the development of fast, bi-directional networks, engine manufacturers have had to up their game.

That means enabling the engine to put data into your NMEA2000 instrument network about its speed, temperature and oil pressure, as well as many other potential parameters on more complex systems.

‘Captains just want to see their engine performance and details on their MFDs,’ says Yanmar’s Gesink.

Steyr’s unique monoblock marine diesel engine starts at 75hp. The MO 4-CYL uses a two-stage unit injection system with the benefits of high-pressure fuel without the requirement for electronic control

As a common rail injection engine, Yanmar’s 3JH40 already has the electronics necessary to connect directly to the boat’s NMEA2000 instrument network, as well as the VC10 electronic throttles and other controls via a J1939 CAN bus.

These include the YD42 smart panel display, which will toggle through engine data such as load percentage and engine hours, as well as standard navigational data like depth and wind speed.

‘Direct connectivity to NMEA and J1939 CAN-bus networks has been purpose engineered into the 4LV range, allowing future-proofed integration to any multifunction bridge display. Same counts for the 3JH40 and the rest of our common rail engine range,’ adds Gesink.

While 110hp-plus Volvo Penta marine diesel engines – the D3 upwards – have been built since 2006 with a proprietary Electronic Vessel Control system, its smaller D1 and D2 marine diesel engines were given a hybrid solution.

This Mechanical Diesel Interface (MDI) is a black box fitted to the side of the exhaust manifold, where heat and vibration have made it somewhat temperamental.

Without the MDI, the engine simply won’t run, although it is quite straightforward to bypass.

Volvo sells an Easy Connect adapter that plugs into the J1939 socket on the MDI and feeds its data out onto a NMEA 2000 instrument network, allowing it to be visualised on the plotter or other displays.

Volvo’s Easy Connect app allows you to monitor engine-specific data over Bluetooth on smart devices

Other manufacturers also offer products that can do this.

Volvo offers dedicated instruments to show fuel level, temperature and voltage if you want it.

It also produces its own glass bridge touchscreen displays from 7in to 24in, although this will mainly appeal to the powerboat market.

More interesting for sailors is Volvo’s Easy Connect app available for smart devices, which allows you to monitor engine-specific data over Bluetooth thanks to the Easy Connect adapter.

Other engine manufacturers have adopted a more agricultural approach.

Beta Marine, for instance, has worked with market-leading sensor firm Actisense to build a module that plugs into the wiring loom that runs between the engine and the control panel, and feeds data into the NMEA 2000 network.

It only works with one of Beta’s more expensive C and CW Deluxe control panels, and requires a bit of splicing in of wires.

Solé also offers an NMEA 2000 converter to get analogue data from the engine into your digital instrument network.

You still need a dedicated control panel, but the SDC2000 kit even allows the engine’s alarms to be transferred to your MFD.

It is compatible with all Solé diesel engines since 2008.

France’s Nanni uses a similar NMEA adapter, but also offers a dedicated interactive display to enhance its control panel – available for all engines above 21hp.

There is a small 4in model, and larger 7in and 9in display built around Raymarine technology, with charting, radar and CHIRP sonar support.

The choice is yours

Every owner will make up their own mind on common rail injection.

It looks like the way of the future, judging by the automotive sector, but critics point out that poor quality fuel and the need for maintenance in out-of-the-way places weigh in favour of mechanical fuel systems.

It depends whether you’ve got far-flung cruising in mind, or whether you plan to stick to home waters.

Weigh up your priorities. The Yanmar’s fuel consumption is certainly better than the competition.

But the Beta offers one of the best torque curves, equating to more usable power at cruising revs.

Thinking about going electric? Click here

Either way, don’t be tempted to overpower the boat, as marine diesel engines are most efficient at around 80% of their revs.

If you want the engine to feed data onto the network, it’s best to know from the outset, so the engineer can hook the whole thing up.

That said, it’s hardly a complex job, although the necessary kit amounts to several hundred pounds in the aftermarket.

If you’re looking to re-power, the key criteria will always be the space available, and access to filters, impellers and freshwater systems for maintenance .

While there’s broad consensus about hydrogen being the fuel of the future, the path to fuel-cell propulsion is distinctly unclear.

In the meantime, alternative fuels may play an increasing part in the energy mix for combustion engines: methanol or ammonia can be stored as liquids and mixed with diesel in a combustion engine.

There are challenges to overcome, not least the nitrous oxides produced when ammonia burns, but there is research time going into just that.

Shipbuilder CMB is working with manufacturers of bigger engines to make the design tweaks to run on dual fuels; focused on the injection system.

A more immediate possibility is the use of hydrogenated vegetable oil ( HVO ) or gas-to-liquids (GLT).

HVO is essentially biodiesel and can be made from waste cooking oil, while GLT is made from natural gas and is said to burn more cleanly than diesel.

‘The advantage of mechanical injection systems is that the engine can take advantage of using low- emission alternative fuels, such as HVO and GLT, without alterations to the engine,’ adds Beta Marine CEO Andrew Growcoot.

Marine Diesel Engines: A buyer’s guide

Volvo penta d2-50.

Volvo Penta D2-50: Easy to get NMEA data from the engine

Volvo has an odd gap in its engine line-up between the 28hp D1 and the 50hp D2, which exist in both shaft and saildrive formats.

The D2 marine diesel engines run at 3,000rpm, which is pretty standard for this power rating.

In general, slower rotation makes for less noise and vibration. Both series use inline injection and feature the MDI electronic interface which has suffered from reliability problems in the past.

On the plus side, the interface makes it easy to get NMEA data out of the engine and onto your instrument network. It also opens up a good range of snazzy remote displays.

Volvo’s ergonomic electronic controls won’t work with the D2 engine, however. They are only compatible with the EVC marine diesel engines that run on common rail injection.

Volvo has excellent, if expensive, global support.

- Power: 51hp (37.5kW) crankshaft

- Cylinders: 4

- Displacement: 2,200cc

- Fuel consumption at max rpm: 11.5lt/hr

- Dry weight: 249kg

- D2-50: £9,360

- Dealers: www.volspec.co.uk ; www.goldenarrow.co.uk

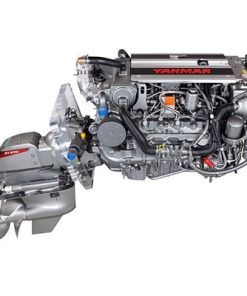

Yanmar 3JH40

Yanmar 3JH40: An award-winning 40ho engine

With a power output rated at 40hp, this hugely successful, award-winning engine was launched in 2018.

Its key feature is the common rail injection system which Yanmar has introduced with claims that it reduces smoke and odour to nearly nil.

This is due to the more complete combustion of the diesel fuel when injected under high pressure.

It also operates at a relatively low 3,000rpm, which makes it quieter than faster-spinning engines, and reduces vibration.

Yanmar has developed a series of digital controls for its engines. The VC10 and VC20 electronic throttles make data such as engine loading available on the network.

There are also dedicated displays like the YD42, which has a full-colour screen. Otherwise, a £350 analogue-to-digital converter will get your engine data onto the NMEA 2000 network.

There’s a saildrive option, which costs some £2,500 more than the shaft alternative.

Yanmar engines are also very well supported with servicing.

- Power: 40hp (29.4kW)

- Cylinders: 3

- Displacement: 1,642cc

- Fuel consumption at max RPM: 8.8lt/hr

- Dry weight: 192kg

- www.barrus.co.uk

Beta 43: Excellent, mid-range torque for its rating

Beta Marine diesel engines are based on the solid Kubota block, and represent good value, no-frills performance.

Painted a distinctive red colour, they offer flexible installation thanks to a good range of options.

This makes them well suited to repowering in tight corners.

Though the design is constantly being improved, this is a traditional mechanical engine with the minimum of electronic gimmickry.

It offers excellent mid-range torque for its rating.

The standard control panels are steadfastly analogue, although a NMEA2000 converter is available to get limited engine data onto the network.

A new digital display panel is now available, with a standard loom input and a NMEA 2000 output.

Reliable and well supported with spares, and readily serviced, these are good engines that are sold worldwide.

- Power: 43hp

- Displacement: 1,999cc

- Fuel consumption at max RPM: 9.3lt/hr

- Dry weight: 238kg

- www.betamarine.co.uk

Nanni N4.43

Nanni N4.43: Low rpm makes for a quieter unit

Nanni, a French-Italian brand, is well represented in the UK by AR Peachment. These distinctive blue marine diesel engines have helped make Nanni the world’s third largest marine engine supplier.

The engines are fairly traditional, with indirect mechanical fuel injection, natural aspiration and water-cooled exhaust manifold. Relatively low RPM makes for a quieter unit.

The N4.43 is in fact a de-rated version of the larger 50hp unit.

Being a mechanical engine, the N4.43 relies on an NMEA adapter to get engine data onto the network.

Though controls remain analogue, the N4.43 is compatible with a series of Nanni digital displays which start at 4in.

Support at the leisure end is not as widespread as bigger brands, but as it’s based on a Kubota engine block, it should be easy to find a competent mechanic.

- Power: 43hp (29.4kW)

- Displacement: 2,197cc

- Fuel consumption at max RPM: 10.3lt/hr

- Dry weight: 228kg

- www.peachment.co.uk

Solé Mini-44

Solé Mini-44: Decent torque at mid range

Spain’s Solé produces a very wide range of diesel marine engines, and the Mini-44 is aimed at yachts in the 10-12m LOA range.

Sam Fortescue is a freelance marine journalist and former magazine editor who sails a Sadler 34, which has taken his family from the Caribbean to the Baltic

It looks cheaper than the competition, but Solé’s model is to quote a fixed price and not engage in the inevitable discounting of the other brands.

This is the smallest four-cylinder unit the company builds, giving quieter running but greater fuel consumption at top speed.

Though rated 42hp, it has a smaller capacity and has to work harder to achieve it.

For that reason it compares better against 38hp models.

A purely mechanical engine, it relies on cam-driven indirect fuel injection and produces decent if not outstanding torque at the mid range.

Available with an impressive range of gearboxes, including saildrive fittings, the Mini-44 is a very flexible engine with lots of options.

A very expensive converter (SDC2000 – £800) is available to transfer the engine’s analogue data into digital signals for your NMEA 2000 network.

But the control panel options, although very attractively styled, remain resolutely analogue.

Solé has decent global support, naturally focused on Europe and the Spanish-speaking world.

- Power: 42hp (30.9kW)

- Displacement: 1,758cc

- Fuel consumption at max RPM: 10.4lt/hr

- Dry weight: 175kg (w/o gearbox)

- www.enginesplus.co.uk

Enjoyed reading Best marine diesel engines: a buyer’s guide?

A subscription to Yachting Monthly magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

YM is packed with information to help you get the most from your time on the water.

- Take your seamanship to the next level with tips, advice and skills from our experts

- Impartial in-depth reviews of the latest yachts and equipment

- Cruising guides to help you reach those dream destinations

Follow us on Facebook , Twitter and Instagram.

Yanmar Marine Diesel Engines

Sailboat, power boat, and commercial marine diesel engines..

Bobtail and Saildrive Options

14 HP - 29 HP

40 HP - 110 HP

Bobtail Engines

150 HP - 250 HP

320 HP - 370 HP

400 HP - 440 HP

485 HP - 550 HP

Commercial Bobtail Engines

650 HP - 800 HP

Join our mailing list.

Stay up to date with the latest news, announcements, and articles.

© Mack Boring & Parts Co. All rights reserved Powered by ONE18MEDIA

- Customer Support

- Career Opportunities

- Privacy Policy

- Call: 908-964-0700

- Email: [email protected]

- Location: 245 Belmont Drive Somerset, NJ 08873

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

- OUTBOARD MOTORS FOR SALE - Yamaha | mercury | honda | tohatsu | evinrude | suzuki |

- Testimonials

- Track Order

Sign up for Newsletter

Signup for our newsletter to get notified about sales and new products. Add any text here or remove it.

- All AB INFLATABLE BOATS ACHILLES INFLATABLE BOATS ATVs INVENTORY AVON BOATS BARLETTA BOATS DIRTBIKES INVENTORY Engine Drives Evinrude Outboard Motors EVINRUDE OUTBOARDS FLEXBOAT Generators, Marine Generators GOLF CARTS INVENTORY Honda Outboard Motors HONDA OUTBOARDS Inboard and Sterndrives, Inboard Diesel Engines Inboard and Sterndrives, Sterndrives MERCURY BOATS Mercury Outboard Motors MERCURY OUTBOARDS MIG Welders Mixed Outboard Motors Motorcycle / Scooter Nissan Outboard Motors NITRO BOATS OTHERS RANGER BOATS REFLEX BOATS REGENCY BOATS SIDE BY SIDES INVENTORY Snow Blowers SNOWMOBILE INVENTORY Stick Welders SUN TRACKER BOATS Suzuki Outboard Motors SUZUKI OUTBOARDS TAHOE BOATS TIG Welders Tohatsu Outboard Motors TOHATSU OUTBOARDS TORQEEDO OUTBOARDS Utility Vehicle WATERCRAFT INVENTORY Welding Yamaha Outboard Motors YAMAHA OUTBOARDS Search for:

No products in the cart.

- Refunds Policy

- 08:00 - 17:00

- +1 786 296-0841

Yanmar 6LY440 Inboard Diesel Engine

$ 16,720

- Description

New Yanmar 6LY440 Inboard Diesel Engine for sale 6 Cylinder, 5.8-liter diesel engine, Turbocharged, Gears – KMH61A2 / KMH61V2 / ZF280. The new 6LY takes the all the attributes of its foreruers and adds major engineering advances. The beating heart of the engine remains the international powerboat race-wiing compact 5.8 -litre in-line six-cylinder YANMAR engine block that over three decades has cemented its popularity with boat designers, builders and owners who laud its performance, fuel efficiency, reliability and smooth and quiet operation.This latest incarnation has taken the engine into a new era of mechanical and digital sophistication. We have completely re-engineered the fuel induction and aspiration systems – all functions now being managed by state-of-the-art electronic precision for even better all-round performance.

Yanmar 6LY440 Inboard Diesel Engine Specifications:

Rated Output : 324 kW / 440 mhpnRated Speed : 3300 rpmnDisplacement : 5.813 L / 354 cu. iNo. of cylinders : 6 cylindersnCylinder Bore x Stroke : 106 mm x 110 mm / 4.17 in x 4.33 iCombustion system : Direct Injection, Denso Common Rail SystemnAspiration : Turbocharged & IntercoolednAlternator : 12V – 125AnDry weight without gear : 585 kg / 1290 lbsnDimensions : 1440 mm x 748.5 mm x 773.8 mmnControls : ElectronicnCertifications : RCD 2, IMO Tier 2, EPA Tier 3, EPA Tier 3C, BSO II, EMC, SOLAS

Standard Engine Package

– Exhaust mixing elbow [L-type]n- Alternator 12V – 120An- VC10 Vessel Control Systemn- Fresh water expansion tank

Optional Accessories

– High-riser mixing elbow [instead of L-elbow]n- Flexible mounts Barryn- Flexible mounts Bridgestonen- Secondary alternator 12V – 120A or 24V – 45An- Extension harness [3m, 5m, 10m]n- Second statio- JC20 Inboard Joystickn- NMEA2000 Engine monitoring systemn- SOLAS including Certificate [factory fit only]n- Hot water kitn- Water separatorn- Lube oil drain pumpn- Bilge pump [12V]

Warranty Information

Related products.

Inboard and Sterndrives, Inboard Diesel Engines

Yanmar 4JH57 Inboard Diesel Engine

Yanmar 4JH5E Inboard Diesel Engine

Yanmar 4LV170 Inboard Diesel Engine

Yanmar 8LV320 Inboard Diesel Engine

Yanmar 6LY2A STP Inboard Diesel Engine

Yanmar 4LV195 Inboard Diesel Engine

Yanmar 6LF550 Inboard Diesel Engine

Yanmar 4JH80 Inboard Diesel Engine

Username or email address *

Password *

Remember me Log in

Lost your password?

Are Yanmar Engines Any Good?

Spend any time around boat owners, boatyards or pontoons and you’ll soon hear the question, “Are Yanmar marine diesel engines any good?” Well – do you remember the series of “I’m a Mac – I’m a PC” adverts from the late 2000s? Sometimes the sailboat owners can appear just like the characters in those adverts. Users of a particular brand of engine seem quietly confident that their technology is superior in every way to all alternatives.

Confirmation Bias is the phenomenon where we seek information to confirm how we already feel and ignore information that contradicts that opinion. Sometimes we just want to hear the engine powering our pride and joy is the long-standing holder of the world’s best ever engine, ever title.

So let’s get back to that question: “Are Yanmar marine diesel engines any good?” To be clear; all engines require a full schedule of maintenance to remain at their best and every manufacturer will have had, down through the years, their hits and their misses. But generally speaking, marine diesel engines from any mainstream manufacturer tend to be reliable .

That said, Yanmar are widely considered to produce very reliable and long-lasting marine diesel engines. Provided that the boat owner is conscientious about regular maintenance; changing filters, impellers and hoses as specified in the manual; cleaning the fuel if and when required and changing the oil on a regular schedule, a Yanmar marine diesel engine should last you 30 years and run happily for 10,000 hours.

Both sailboat owners and marine diesel mechanics alike are tremendously fond of Yanmar diesel engines, especially the older naturally aspirated versions. Without the complication of common-rail injection and turbos, they are trusted workhorses which, if treated well, will just keep going and going. They are easy to work on and most of the common service parts are available in non-OEM variants saving money on maintenance.

Who Manufactures Yanmar Marine Diesel Engines?

Yanmar Co., Ltd. is a Japanese diesel engine manufacturer. They were founded in Osaka, Japan in 1912 where they still design and manufacture their own engines. Since 2000 their main manufacturing plant has been at “Tsukaguchi Factory” in Osaka. Yanmar designs engines for a wide range of applications, including seagoing vessels, pleasure boats, construction equipment, agricultural equipment and generator sets. It also manufactures and sells agricultural equipment, construction equipment, climate control systems, aqua-farming systems, in addition to providing a range of remote monitoring services.

Notably, in 1933 Yanmar produced the world’s first practical, small diesel engine and in 1992 they produced their 10 millionth diesel engine. Yanmar’s small marine diesel engines, like those used in countless sailboats around the globe, are not simply marinized versions of industrial engines. They have been designed specifically for the application down to the choice of casting materials optimized for use in a salt-water environment.

What is Yanmar’s After Sales Service like?

Yanmar is a large multi-national organisation. In order to distribute their engines around the world, they have a huge network of local distributors . So, if you purchase a Yanmar engine you will be dealing with your local distributor rather than with Yanmar directly. Yanmar is set up that these local distributors are basically an arm of Yanmar. They have to meet required standards and are certified. All after-sales is also provided by these local distributors, whether or not they supplied the engine originally. While some owners have reported issues, specifically when dealing with service technicians who didn’t supply their engine or in out-of-warranty disputes, the vast majority of feedback is that Yanmar’s after-sales service is excellent and they quickly and efficiently sort out issues that arise within the warranty period. The standard warranty lasts for two years with a free three year extension for most small marine models. See here for details .

Are Yanmar Spare Parts Expensive?

There are a couple of things that we must consider before diving in to the cost of parts. Firstly, small marine Yanmar’s are very easy to work on and very reliable. Servicing costs will be low or, even better, services will carried out by the owner. Many of the service parts are available as OEM replacements and therefore very cost effective. Yanmar service parts such as gaskets that are not available as OEM replacements are generally not too expensive. Then there is the reliability – the reality is that many owners will never need a non-service part throughout their ownership of the engine. Careful maintenance makes this even more true. Parts such as starter motors can generally be found cheap as they are common to industrial Yanmar engines. Exhaust elbows can be bought as OEM.

So that all said, all marine diesel are expensive to repair. Some brands price their parts way more than others and many owners and mechanics would consider Yanmar parts right in the middle of the price range. Many Yanmar owners would put it this way; they are not as expensive as Volvo Penta parts.

Are Yanmar Spare Parts Easy to Find?

Yanmar have a global network of dealers with many sailors reporting that they have easily found suppliers for Yanmar OEM parts in far flung cruising grounds around the Caribbean, the Mediterranean and much further afield. These days, all parts can be found on the internet and shipped globally. All older engines are well supported and many parts such as alternators and injectors can often be rebuilt. Cylinders can reportedly be easily sleeved if necessary.

Are Yanmar Engines Fuel Efficient?

Marine Diesel engines tend to be designed less for fuel efficiency and more for reliability and longevity which is sensible given their operating environment. Automotive engines have gained impressive levels of efficiency by utilizing turbos, common rail injection and very high operating temperatures. None of these is essential in a small marine diesel for propelling a medium sized family sailboat.

Yet, despite not being designed for maximum efficiency, it is quite easy to get your sailboat up to hull speed . After all, the sails can do it in relatively low winds. Therefore, you shouldn’t expect to use too much fuel. A common rule of thumb for marine diesels is twenty horsepower-hours from a gallon of diesel.

If this was accurate, and you were running your Yanmar 2GM20 (with a 20 HP maximum output at 3000 rpm) at 75% power (2250 rpm), then you could expect to use ¾ gallon of fuel (2.8 Litres) per hour. Users report that this engine uses about 30% less than that. So, empirical evidence would suggest that Yanmars are above average for fuel efficiency.

What is the Life Expectancy of a Yanmar Marine Diesel Engine?

Many sources state that the average life expectancy of a small marine diesel engine is approximately 5000 hours. This figure, however, may vary based on the regularity and quality of usage, and how well and how often the user maintains the engine. If well maintained and revved properly throughout the engine’s life, a Yanmar Marine Diesel should last well in excess of 8,000 to 10,000 hours. Many owners of the Yanmar GM series and, particularly, the 4JH series engines remain convinced that their engines will last forever.

Are Yanmar Engines Quiet?

There is certainly a balance in diesel engines between quiet sophistication and dogged reliability. Foe many years, Yanmar fell decidedly on the side of reliability. The GM series engines, for example, were hand crank-able and therefore the compression ratio was lower than equivalent engines from other stables. This led to a noisy reliability that some owners love. Others, perhaps with better hearing, found them too noisy. The newer YM series engines don’t suffer the same but the fact that Yanmar kept hand crank-able engines on the go for so long, and their cement mixer heritage would suggest that quietly purring engines are not their top priority.

What Common Issues Do I Need to Look Out for?

Every marine diesel engine manufacturer has their foibles. So what do you need to keep a lookout for in Yanmar diesels? The first thing that springs to mind is the exhaust elbows. Yanmar have gone through waves of fabricating these out of mild steel (which rusts), stainless steel (which causes galvanic corrosion) and aluminium. Whichever is on your engine deserves at least an annual inspection and you should expect to replace them every five or so years.

Many of Yanmar’s engines have raw-water cooling. This is not necessarily a negative as it means that the cast iron head and block tend to be made from the best ore available but the internal anodes must be replaced regularly.

Finally, Yanmar have a reputation for using soft metal bolts when building their engines. They may have a good reason for doing this, but there are countless stories of folk shearing bolts when removing parts and heads. So much so, in fact, that many people say;

Yanmar make great engines cleverly held together with chocolate fastenings Anon.

So are small Yanmar Marine Diesel engines any good? No engine, or engine producer, is perfect but users and engineers find Yanmar Engines to be reliable, long-lasting and fuel-efficient. They have an excellent network of accredited dealers and service centers with knowledgeable staff, they’re easy to service and parts are readily available and averagely priced. Aside from a few foibles, yes, Yanmar Diesels are excellent.

A smart skipper learns from the lessons of others.

In our Yanmar GM Series Almanac section, we have a series of previous questions and queries from Yanmar GM owners along with answers. Many of these have been adapted from discussions on the “Yanmar Marine Engine Owner’s Group – Repair and Discussion” Facebook group which is a fantastic resource for getting help.

- White Smoke & Black Water from a Yanmar 2GM20

- KM2P Transmission Oil level question – please can someone help?

- Yanmar 1GM won’t go over 2700 RPM

- This Yanmar 2GM20 only started with one decompression lever engaged

Do you want to get future Yanmar GM Series Almanac articles straight to your inbox? Sign up to our Yanmar GM Series Owners’ Group today and we’ll make sure that you’re first to see them. And we definitely won’t share your email address with anyone else.

Which Yanmar GM Series Engine do you own? 1GM or 1GM10 2GM or 2GM20 3GM or 3GM30

Boat make and model

Where is your boat located?

No products in the cart.

- [email protected]

- 250-716-9065

New Yanmar engines

As an approved central island dealer for all Yanmar engines (and Kohler generators), we are proud to offer engines, drive systems and accessories for all types of boats, from runabouts to sailboats and from cruisers to mega yachts. Yanmar engines go further as they work harder and harder, year after year. Yanmar diesel engines are renowned for their rugged reliability, with a worldwide reputation that is second to none.

Yanmar diesel engines are also the lightest and toughest solutions available for sailboat inboard power. Smooth and quiet, innovative and built to last, the great reputation of these engines is well-deserved. Yanmar has been building diesel engines for nearly 100 years, always with the philosophy of developing more power for less weight. Yanmar has been the power of choice for sail boaters since the 1960’s

Yanmar warrants to the original retail purchaser that it will make any repairs or replacements necessary to correct defects in material and / or workmanship of Yanmar Marine Products for the Limited Warranty Period. This Limited Warranty gives you certain legal rights. You may have other rights that vary from state to state and country to country. This Limited Warranty covers Yanmar Marine Products operating anywhere in the world where Yanmar approved service is available.

GREAT FINANCING IS AVAILABLE ON PURCHASING A NEW ENGINE FROM US!

- Shipping of online purchases

- Refund and Returns Policy

- Boatyard Rules/Practices

- Privacy Policy

- Cookie Policy

U.S Navy Commissions USS New Jersey, First Ever Submarine For A Mixed Gender Crew

World’s Largest Hotel-Branded Superyacht Sets Sail For Maiden Voyage

India Establishes Its First Maritime Arbitration Center

Watch: U.S. Coast Guard Airlifts Injured Crew Member From Oil Tanker Off Texas Coast

Yanmar Unveils Its First Electric Propulsion Product For Emission-Free Sailing

Yanmar Marine International, a leading marine engine manufacturer, has launched its first-ever electric propulsion product, the E-Saildrive, for emission-free sailing.

The product was introduced globally at the Cannes Yachting Festival and the Newport International Boat Show to make electric boating more accessible to sailing enthusiasts.

The E-Saildrive is designed with a plug-and-play platform for easy installation and connection, avoiding the need for complex hull modifications.

The product features a cooling system, an integrated gear, a motor, and a motor controller, allowing a smooth transition to 100% electric sailing.

The global launch introduces the three models of the E-Saildrive: the SDe7, SDe 10, and SDe 15, each capable of producing up to 15kW of power for sailboats under 40 feet, depending on the vessel’s application and displacement.

The E-Saildrive is a direct replacement for Yanmar’s YM engine, one of the most widely used engines in sailboats. This allows boatbuilders to offer both electric and combustion engines.

Customers who want to refit their sailboats with the E-Saildrive can do so without making any hull modifications.

Regarding user experience, YANMAR has equipped the system with a modern control design, including a 4.3″ optically bonded TFT display with an IPX7 waterproof rating and anti-fog coating. Control heads are available on both side and top mounts, ensuring flexible installation.

YANMAR is known for the reliability and efficiency of its HVO-approved combustion engines. The E-Saildrive series upholds this engineering standard with lower maintenance requirements than traditional combustion engines.

Boaters will also benefit from YANMAR’s extensive global support network, which comprises over 2,000 distributors and dealers in 130 countries.

Floris Lettinga, Director of Sales and Marketing at YANMAR Marine International, highlighted the importance of the E-Saildrive’s launch, saying it represents an important step in decreasing the environmental impact of sailing.

Lettinga said that YANMAR’s new electric propulsion system is packed with innovative features to help boaters easily switch to emission-free sailing and that the company’s dealer and distributor network would provide worldwide technical support.

Reference: Yanmar

Marine Insight Academy

Online courses for the Maritime industry!

Enroll For Maritime Courses

- 100 + Free & Premium Courses

- Learn at your own speed

- Earn certificates on completing Premium Courses

- Quizes to evaluate your knowledge

- Interactive videos

Related Posts

- What Are Accommodation Barges?

- Watch: World’s Largest Cruise Ship – Harmony Of The Seas Hits Water

- British Crew Dies In Tragic Electrocution Incident Aboard Super Yacht In The Caribbean

- ICS To Push For Rapid Action On Further CO2 Reduction By International Shipping

- What Are Vessel’s Particulars?

Disclaimer : The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Do you have info to share with us ? Suggest a correction

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

Read More Articles By This Author >

Daily Maritime News, Straight To Your Inbox

Sign Up To Get Daily Newsletters

Join over 60k+ people who read our daily newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

BE THE FIRST TO COMMENT

Leave a reply.

Your email address will not be published. Required fields are marked *

Subscribe to Marine Insight Daily Newsletter

" * " indicates required fields

Marine Engineering

Marine Engine Air Compressor Marine Boiler Oily Water Separator Marine Electrical Ship Generator Ship Stabilizer

Nautical Science

Mooring Bridge Watchkeeping Ship Manoeuvring Nautical Charts Anchoring Nautical Equipment Shipboard Guidelines

Explore

Free Maritime eBooks Premium Maritime eBooks Marine Safety Financial Planning Marine Careers Maritime Law Ship Dry Dock

Shipping News Maritime Reports Videos Maritime Piracy Offshore Safety Of Life At Sea (SOLAS) MARPOL

WAIT! Did You Download 13 FREE Maritime eBooks?

Sign-up and download instantly!

We respect your privacy and take protecting it very seriously. No spam!

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

What RPM for Yanmar in continuous operation ?

- Thread starter Delawaredave

- Start date Jun 2, 2013

- Hunter Owner Forums

- Ask A Hunter Owner

Delawaredave

Hi Dave, I have a 1GM in my Hunter 27. I usually run between 2800 and 3000 rpm. 3000 is about max when transiting under power. The only time I can get it above 3000 is when I am dockside.

First thing to do is to check your tachometer .(Use a digital sort of like this http://www.harborfreight.com/digital-photo-sensor-tachometer-66632.html .) The Yanmar supplied tachometers are notoriously geframitzed.. Then once you know what the tach means when it reads a number, use 2400-3000 (real RPM) or someplace in there to keep it happy.. Find a sweet spot and use it.. Too slow and you'll carbon up the elbow

On the top of you engine is a plate. It will indicate what your continuous and maximum RPMS should be. If it says your continuous is 3400 then you can run 3400. The Yanmar rep said you should run at or near your continuous rating as much as possible. Now, your fuel economy will be less at the continuous rating so you might run at lower speeds at times if you are interested in economy. Frankly most people run their engines too slow. If in doubt call a Yanmar engine representative.

http://yanmarhelp.com/operate.htm If you are not getting the proper speed at the recommended RPM's you may need to have your prop checked. We have heard many complaints about lower speeds and it is usually an incorrect prop, assuming your engine is operating properly.

Industry standard 'rule of thumb' to result in longest service life of most diesel engines is to operate at 75% of max. rpm / or the '1 hour rating output'. In this case 3600 rpm X .75 = ~2700 rpm .... your typical 'best' cruising rpm (assuming a 'properly pitched' prop).

RichH said: Industry standard 'rule of thumb' to result in longest service life of most diesel engines is to operate at 75% of max. rpm / or the '1 hour rating output'. In this case 3600 rpm X .75 = ~2700 rpm .... your typical 'best' cruising rpm (assuming a 'properly pitched' prop). Click to expand

The manufacturer has NO input on the 'loading' thats placed on an IC engine ... and thats why you dont want to run an engine at its 'peak' on the HP vs. rpm curve that the engine manufacturer (can) supplies. This curve/plot will insure that the engine is operating at a relative minimum combustion chamber pressure and ensures or will indicate that the engine is not 'lugging' (too slow rpm vs. HP 'demand') - 'lugging' will result in extreme cylinder wall, connecting rod bearing, etc. wear.

Info from the GM operations manual Attached is the relevant page from the Yanmar GM operations manual.

Attachments

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

REPOWER WITH

Benefits of Repowering

Installing a new, technologically advanced YANMAR engine will instantly breathe new life into your boat.

With the right system, you will benefit from:

- Improved acceleration, power, and responsiveness

- Lower running costs and increased uptime

- Enhanced fuel efficiency and lower environmental impact

- Upgrade to the latest electronics, controls, and diagnostics with interconnectivity to modern multi-function displays

- An overall smoother, quieter, and more pleasurable boating experience

When to Consider Repowering

YANMAR marine engines are renowned for their durability and long lifespan. The point at which your YANMAR or other diesel system will need repowering cannot be determined based on the number of operational hours alone. An engine’s longevity is often subject to how regularly and consistently you run your system.

You should consider repowering if:

- Your existing engine is becoming increasingly unreliable

- You are losing horsepower

- The engine is consuming too much fuel

- Maintenance costs and downtime are rising

Depending on the complexity of the project, replacing an inboard engine can take between one to four weeks once it arrives at the yard. However, the more time and consideration that can be put into planning the repowering project beforehand will pay dividends when the installation starts.

This includes:

- Choosing your installation center

- Selecting your new engine

- Choosing new accessories/technology you may wish to include

- Allocating delivery time for all needed materials

- Identifying any additional work that might be required

Download Our Full Repower Guide

What engine do i need.

When determining the engine best suited to your repowering needs, there will be a number of things to consider, centered around the type of boat you own, what you are looking to gain, and your engine room space and current engine footprint.

Displacement hull vessels will normally require a like-for-like power output while planing hull boats, more sensitive to weight, may benefit from the improved power to weight ratio offered by modern diesel engines.

With the advances in technology and materials used in YANMAR’s modern engines, it is often possible to achieve the same or higher power output with a smaller and lighter engine, boosting both acceleration and top speed. However, keep in mind that a more powerful engine may require a different marine gear, stronger engine beds, larger prop shafts and propellers, additional fuel tank capacity, and reworking of the existing intake air and exhaust system.

It is best to consult with a certified YANMAR dealer to determine the right propulsion system for your needs.

Choosing the Right Installer

A successful repowering project relies on two key aspects: selecting the correct engine for your boat and commissioning a qualified YANMAR installer.

Finding a technician with the right level of expertise and skill will help achieve a great outcome. The following tips are a guide to how you can make this selection process as smooth as possible.

- Only commission an installer who has visited and inspected your vessel.

- A competent installer should ask relevant questions about your boat and how you operate it.

- Look for an installer who has repowered vessels and/or completed projects of a similar scale.

- Ask for references that you can visit or speak with, as well as research the overall reputation of the yard.

- Make sure that an installer’s work conforms to all relevant regulations and legislation.

- Ensure that you receive a detailed quotation and a full breakdown of technical costs. On occasion, certain costs may be difficult to define upfront, such as converting a gasoline tank to diesel. However, these should be discussed in detail before work commences.

Rebuild vs. Repower

Rebuilding an existing engine(s) is an alternative option to repowering. This route is commonly perceived to be an easier and less costly choice. However, this may not always be the case, and if it is, these may only be short-term benefits.

Many existing parts are often not replaced during a rebuild. These parts can include, but are not limited to, the alternator, starter, and water pump. The remaining life expectancy of these parts cannot be predicted and could require further maintenance, downtime, and expense. Rebuilding an engine could also take more time and could present additional, unexpected costs.

By contrast, the installation of a new YANMAR engine guarantees that all of the components are new and the system is covered by our extensive manufacturer’s warranty. It will also likely incorporate the latest state-of-the-art technology, which will deliver rewards on both an economic and performance level.

Ultimately, the decision between the two options relies on individual circumstances and requirements. Consider this: if a rebuild is going to cost about 40% or more than the amount to install a new engine, then repowering may be a sounder investment.

Cost vs. Value

Repower your boat because you plan to keep it and reap the benefits of the new engine yourself. The value of your boat will certainly increase with a new engine, but rarely enough to recoup the costs immediately if you are only repowering with the intent to sell. The same is generally true if you convert from gas to diesel. The boat’s value will increase, but not likely enough to fully pay for the conversion.

Repower Because of Engine Failure

When an engine goes down, you need to repower your vessel regardless of choice. Whether your boat is used for recreation or for light duty commercial purposes, our goal is to get you back on the water as quickly as possible.

- What if I have multiple engines and only one goes down? If one engine fails and needs repowering, consider the remaining life expectancy of the other engine. If the other engine is nearing its end of lifespan, it is best to replace both engines at the same time. When replacing both engines, we recommend upgrading to the latest engines to benefit from the performance and efficiency gained by the latest advances in technology. If the other engine still has about 50% or more life expectancy, replacing only the down engine might be the best choice.

Emissions Compliance

If your boat has an engine(s) not currently compliant with the latest emissions regulations, there are several things to consider when repowering.

Is there a current emission compliant engine model that fits the power requirements and space needs of your boat?

- If yes, it is highly recommended by the emissions governing authorities to repower with engines meeting current emissions regulations. There are some cases where exceptions can be made. Please contact your regional dealer or distributor to inquire.

- If there is not a current emission compliant engine that fits your boat without significant modifications, then you might qualify for a non-compliant replacement engine.

Advantages to repowering with an emissions-compliant engine:

- Enjoy the benefits of a significantly more fuel-efficient system.

- Advances in performance and efficiency from the latest common rail technology provide a cleaner, smoother, quieter, and more powerful engine experience.

- See YANMAR engine data and real time diagnostic troubleshooting codes at a glance with advanced electronic controls and displays that come standard, or as an option, with all current YANMAR compliant engines.

Why Choose YANMAR?

YANMAR marine engines set the global standard in performance, efficiency, and endurance.

YANMAR’s reliable engines are well known to have a low total cost of ownership.

YANMAR has the largest sales and service network in the marine industry, covering over 130 countries worldwide.

YANMAR is the only manufacturer to bring the benefits of common rail technology to smaller vessels, providing 5x Best in Class standards – Clean, Interconnective, Quiet, Powerful, & Fuel Efficient.

YANMAR is the inventor of the modern diesel engine and is continuing to innovate solutions that push the boundaries of marine propulsion into the next century. Meeting the demands of the evolving, modern consumer by providing advanced and sustainable technologies is proudly at the forefront of development at YANMAR Marine International.

Ready to Get Started?

Find your local authorized YANMAR distributor or service center here.

YANMAR Repower Guide

Download our guide to repowering, which includes a useful checklist of what to plan for when approaching a repowering project

Repower with YANMAR 6LFs

Certified YANMAR dealer Motonáutica Balear, Mallorca, completes the installation of two YANMAR 6LF530 diesel engines on Magnum Marine 40 motorboat Adriana to raise performance to a new level.

Elige tu idioma

Choisissez votre langue, velg ditt språk.

Nederlandsk

Portugisisk

Välj ditt språk

Portugisiska

IMAGES

VIDEO

COMMENTS

500, 580, 640, MHP. Expanding YANMAR's renowned common rail range up to an output high of 640 mhp, the 6LT is a compact and light-weight diesel engine that is an ideal solution for planing and semi-planing hulls, and fast boats, with inboard propulsion systems, suiting a range of recreational and light-duty commercial applications.

The Yanmar GM is one of the United States' most popular sailboat engines, and includes the 1GM10, 2GM20F, 3GM30F to name a few. Like its earlier HM and YSM predecessors of the 60s and 70s, Yanmar's GM series is a compression-dependent engine.

Best marine diesel engines: the new tech making inboard engines cleaner, more efficient, lighter and more reliable. Once referred to as the 'auxiliary' engine, your boat's inboard diesel is now so much more than just a helping hand. Not only is it central to your boat's ability to manoeuvre safely into tight marina berths, it also allows you to keep up average speeds and make the tidal ...

Yanmar distributor for marine diesel engines from 10hp to 800hp. Engines for sailboats, powerboats, Light Duty & Heavy Duty commercial boats. ... Sailboat, Power Boat, and Commercial Marine Diesel Engines. YM Series. Bobtail and Saildrive Options. 14 HP - 29 HP. Visit Page . JH Series. Bobtail and Saildrive Options. 40 HP - 110 HP.

Mechanical. Certifications. RCD 2 EPA Tier 3 EPA Tier 3C BSO II EMC. NOTE: 1 kW = 1.3596 mhp = 1.34102 bhp. Fuel condition: density at 15°C = 0.842 g/cm³. Technical data is according to (ISO 8665) / (ISO 3046) Fuel temperature 40°C at the inlet of the fuel injection pump (ISO 8665) Length includes KM2P-1 marine gear & height includes U-type ...

Yanmar 1GM10. Configuration. 4-stroke, vertical, raw water-cooled diesel engine. Maximum output at crankshaft. 6.7 kW@3600 rpm. 9 mhp@3600 rpm. at a fuel temperature of 25° C. Displacement. 0.318 litres.

Yanmar 6LY440 Inboard Diesel Engine. $ 16,720. Add to cart. SKU: b7a6cad17ccb Category: Inboard and Sterndrives, Inboard Diesel Engines. Description. New Yanmar 6LY440 Inboard Diesel Engine for sale 6 Cylinder, 5.8-liter diesel engine, Turbocharged, Gears - KMH61A2 / KMH61V2 / ZF280. The new 6LY takes the all the attributes of its foreruers ...

Diesel engines for sailboat and small craft engines. To provide a better shopping experience, our website uses cookies. ... Yanmar sailboat engines 13 Products . Sort & Filter . Narrow By . 2YM15 14HP . 3YM20 21HP . 3YM30AE 29HP . 3JH40 40HP . 4JH45 45HP . 4JH57 57HP . 4JH80 80HP . 4JH110 110HP . 1GM10 10HP ...

Feb 16, 2018. #7. Larry Borland (Sic) of Mack Boring told us in his course that the current (7 years ago) Yanmar diesels have a serviceable life of 20,000 hours. He went on to say that the reason it is that "short" is that Yanmar has to include emissions as part of the life cycle. Otherwise it would be much longer.

A good Yanmar mechanic could do an evaluation for 300-500 dollars for things like compression and oil pressure and condition of the fuel injectors and the high pressure pump.. Remember that you have sails in the event the engine fails.. A new Beta Marine engine would be in the vicinity of $7000 to $8000 to $10000.. B.