- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sails and Rigging

- Maintenance

- Sailing Totem

- Sailor & Galley

- Living Aboard

- Destinations

- Gear & Electronics

- Charter Resources

- Ultimate Boat Giveaway

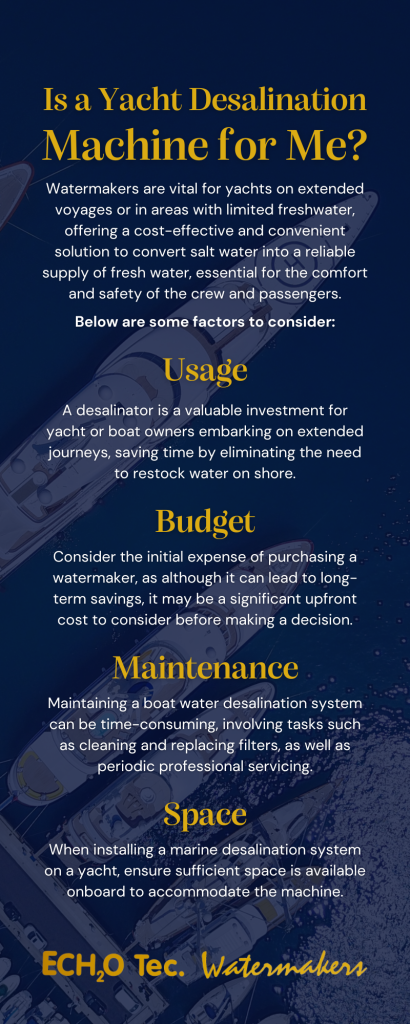

Do You Need a Watermaker for Your Sailboat?

- By Jen Brett

- Updated: October 2, 2019

I remember, in the not too distant past, when having a watermaker aboard a cruising boat seemed to be the ultimate luxury. Plenty of sailors considered them too expensive and complicated. Fortunately times have changed. With improved technology and a range of price points on the market, now even average cruising boats of modest means carry a reverse-osmosis system. And really, is there anything that feels better after a day spent sailing and swimming than a hot shower? The freedom and security that come with full water tanks are also a nice bonus, particularly if you’re cruising in an area where fresh water is difficult to come by and pricey when you do.

Choosing a Watermaker

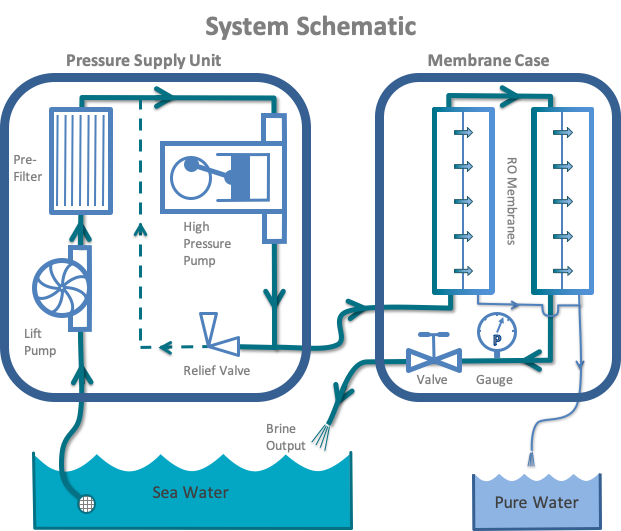

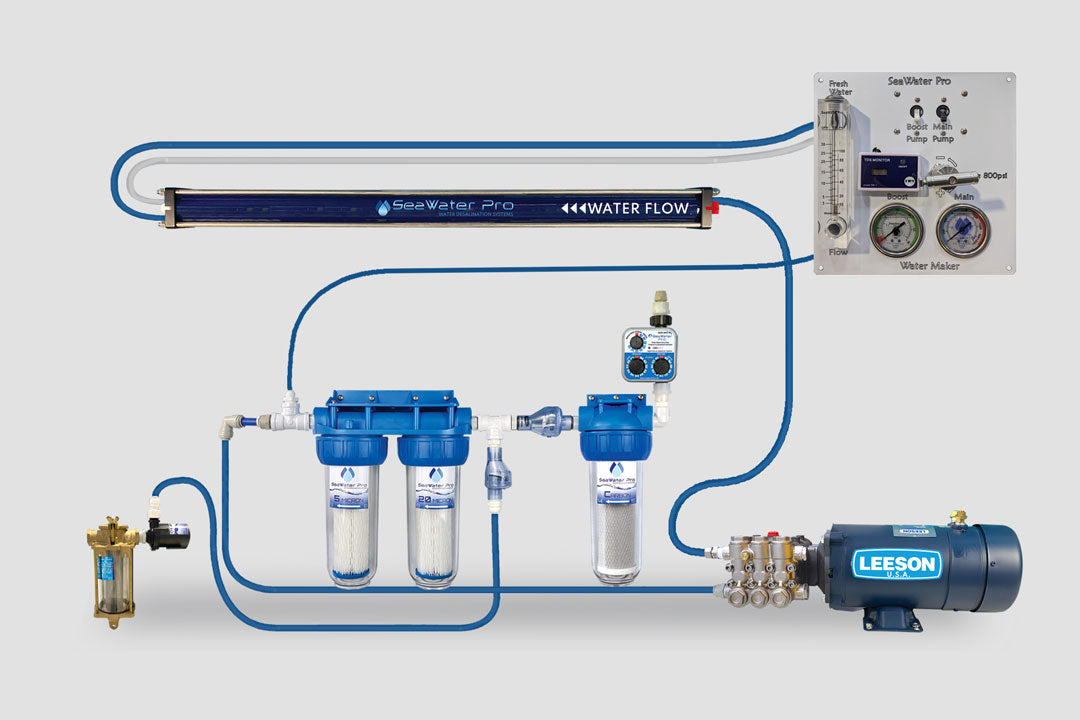

As with any major system, there are many factors to consider when you choose a watermaker. You’ll need to figure out your freshwater needs, the space you have available for the system and how you’re going to power it . Generally speaking, in a reverse-osmosis desalination system the raw water is run through a series of pre-filters, and then a high-pressure pump moves the water through one or more membrane housings. The wastewater, or brine, is released overboard and the product water goes into your water tanks.

Since all of the watermakers that are currently available for cruising sailboats use this process for desalination, the major differences between the systems are how you power the high-pressure pump and the user interface. Powering options include 120/220-volt AC, 12- or 24-volt DC and engine/belt driven. All have their pros and cons.

“The first question I ask a potential customer is ‘Will your boat have a ship’s generator?’” said Rich Boren of Cruise RO Water. “If they plan to have a generator, then the decision to go with a 120-volt high-output watermaker seems natural. While running the generator for battery charging and other loads two to three times per week, they can keep their water tanks full without having to make generator runs just to make water.”

A 12-volt system, such as the Spectra Catalina 300 Mk II or the Horizon Reverse Osmosis Seafari Quest, makes a lot of sense for smaller cruising boats since they don’t need a generator to run and have fairly miserly power consumption. On a breezy, sunny day, a solar panel and/or a wind generator will likely keep up with the demand. “The only difference between 12-volt DC low-output and 120-volt AC high-output watermakers is how the high-pressure pump brings seawater up to the 800 psi needed to drive fresh water through the reverse-osmosis membrane,” Boren said. “The membrane and support equipment, like pre-filtering and plumbing, are the same.”

These systems typically produce anywhere from about 6 to 16 gallons per hour, and some units can do so for about a 1-amp-per-gallon power draw.

“Many smaller sailboats, under 45 feet or so, often utilize solar panels,” said Berkeley Andrews of Parker Hannifin, which produces Sea Recovery, Horizon Reverse Osmosis and Village Marine watermaker systems. “Their entire electrical backbone consists of 12-volt or 24-volt. So they must have a watermaker that can operate on low voltage. These customers have limited amp hours on their batteries, so all of their equipment must be suited to handling this.”

In choosing a watermaker, Bill Edinger, owner of Spectra Watermakers, said to be realistic about water needs. “When helping customers decide which system is right for them, first we like to determine their approximate water usage with questions like ‘How many people are aboard normally? Are you going to be living on the boat full time? Do you have a washing machine? Any children? Are you going to be cruising full time or leaving the boat for extended periods?”

A common error people make is choosing a watermaker that is too small for their needs. “The most common mistake I see cruisers making in their watermaker purchase decision is underestimating how much water it will take them to cruise comfortably,” Boren says. “I’m not talking about the minimal amount of water it takes for the crew to stay alive, because there is a big difference between staying alive and comfort. Selecting a watermaker that will only meet their minimal drinking-water needs but not keep up with the comfort needs of the crew can lead to crew tensions and feeling like camping rather than cruising.”

Remember that “watermakers are rated in gallons of production in a 24-hour period,” Edinger said. “So a 300-gallon-per-day watermaker system sounds like a lot of water. The important thing is that it produces about 12 gallons per hour. Normally a system like this will be run three to four hours per day if power is not a critical issue, in this case producing 36 to 48 gallons of water. It’s better for a system to run for a few hours every few days than an hour every day.”

Watermakers for Small Boats

If space is at a premium, consider purchasing a modular system instead of an enclosed one. In a modular system, the components, such as the membranes and filters, can be mounted separately. Another power source for the high-pressure pump is the boat’s diesel engine. In these engine-driven setups , the pump and an additional pulley are mounted on a custom bracket next to the engine. The watermaker can then be run while motoring or using the engine to charge the batteries.

While engine-driven watermakers can produce a large amount of water, 20 or more gallons an hour on average, the downside is that the installation can be more complex than for other systems. “Unlike the 12-volt DC or 120-volt AC watermakers, where you simply bolt the high-pressure pump down and then run the wires and plumbing hoses, the hardest installation aspect of an engine-driven watermaker is finding space. Some boats simply have no room in the engine compartment to mount the 5-pound pump with a 7-inch pulley on the engine while still leaving access to other engine parts that need to remain serviceable,” Boren says.

A relative newcomer to the marine market, the portable watermaker is a good solution for cruisers who want the convenience of a watermaker but don’t want to permanently install one. The Rainman is one such system that is available as a self-contained unit driven by a gasoline-powered Honda motor, or as a 115-volt AC-powered unit. “The bulk of our gasoline-powered system customers are sailing yachts between 30 and 50 feet,” said Ron Schroeder of Rainman Desalination. “Our customers seem to prefer to have a simple and somewhat manual system over one that relies on control panels, software and solenoid valves. We are also attractive to those customers who have had bad experiences with the installation process of an installed system.”

The Spectra Passport is another portable system. Edinger said it has already proved popular with offshore race crews and cruisers who need a watermaker for only a limited time.

Maintenance for Watermakers

Watermakers have long had a reputation for being difficult to maintain, but the equipment has improved over the years and overall, routine maintenance isn’t more challenging than with other onboard systems. “The best rule of thumb is to operate the watermaker in water that looks good,” Andrews said. “There are a few factors in the feed-water condition that come into play. Operating a watermaker in dirty harbors will most certainly result in repeated pre-filter changes and a clogged sea strainer. If you have extra filters on board, you can get by, but it’s not recommended. The environment in the open ocean and remote anchorages is much better. Also consider how shallow the water is where you’re anchored. Sometimes there can be a lot of tidal movement, which can kick up fine particulate and sediment. This too can also contribute to more frequent filter changes and even damage other components. A nice option is an automatic freshwater flush, which will rinse the watermaker’s membrane element after use. It helps keep the membrane vessel housing free of any biological growth that could foul the membrane and reduce your ability to produce fresh water.”

Whatever system you choose, with proper use and maintenance you can expect years of service from your watermaker. And plenty of hot showers.

Jen Brett is a CW associate editor. This article first appeared in the February 2015 issue of Cruising World.

Aqua Marine: www.aquamarineinc.net

Blue Water Desalination: www.bluewaterdesalination.com

Cruise RO: www.cruiserowaterandpower.com

Dometic Marine Sea Xchange: www.dometic.com

ECHOTec: www.echotecwatermakers.com

FCI Watermakers: www.filtrationconcepts.com

Horizon Reverse Osmosis (HRO): www.hrosystems.com

Katadyn: www.katadyn.com

Rainman: www.rainmandesal.com

Sea Recovery: www.searecovery.com

Schenker Watermakers: www.schenkerwatermakers.com

SK Watermakers: www.skwatermakers.net

Spectra Watermakers: www.spectrawatermakers.com

Village Marine Tec: www.villagemarine.com

Watermakers Inc.: www.watermakers.com

- More: DIY Sailboat Projects , How To , systems

- More How To

Rigging Redo: A Switch to Synthetic

Top Tools for Sailboat Cruising: Must-Have Gear for 2024

Made for Shade: Cockpit Cover Options

Blackwater Wisdom for Holding Tanks

North Sails Parent Company Buys Doyle, Quantum

For Sale: 1984 Camper & Nicholsons 58

Sailing Avocet : A New Adventure Begins

- Digital Edition

- Customer Service

- Privacy Policy

- Terms of Use

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

Home » Blog » Gear » Watermakers: a guide to marine desalinators and making water on a boat

Watermakers: a guide to marine desalinators and making water on a boat

By Author Fiona McGlynn

Posted on Last updated: March 23, 2022

There’s something magical about a watermaker—at least that’s how I felt after we installed one on our boat. That may sound overblown, but think about it: watermakers transform salt water into fresh water, providing a near-endless supply of potable water for drinking, bathing, and cleaning! THAT my friends is an amazing piece of technology!

(If you don’t share my enthusiasm, try going without a shower for a few days and you’ll begin to see my point).

Having experienced living on a boat and cruising, both with and without a marine desalinator, I can attest that it’s a game-changing piece of gear. However, you definitely don’t need one to go cruising. There are plenty of low-tech ways to collect and make water on a boat.

Marine desalinators do offer some major benefits: there’s more water for showers, it’s easier to travel farther afield, you can spend more time in a remote location. However, these benefits have to be weighed against the drawbacks: namely a hefty price tag and ongoing maintenance.

Deciding whether a watermaker is right for you will come down to the type of cruising you’re doing, how much water you need, and your budget. Read on to learn about the pros and cons, costs, and key features of marine watermakers.

How does a watermaker work?

A watermaker on a yacht converts seawater into fresh water through a process known as reverse osmosis (RO). A high-pressure pump pushes seawater through a semi-permeable membrane that filters out salt, organics, and bacteria. The fresh water is pumped into your water tanks while the remaining brine bi-product is discharged over the side of the boat, back into the ocean.

Marine watermakers: the benefits and drawbacks

Less water rationing.

When we started our 13,000 mile trip across the Pacific, we didn’t have a watermaker. We were on a tight budget and decided to prioritize other pieces of equipment like a life raft and wind vane.

As a result, we became experts in conserving water on a boat . We would carefully ration out water for washing dishes, taking showers, and even brushing our teeth!

After getting a watermaker we became far less meiserly because we knew we could always make more water if we needed to. It was a relief to not be constantly thinking about how much water we were using over the course of a day.

That being said, we couldn’t relax completely. We had to keep our tanks topped up, so as not to run the pump dry. We also always carried potable water in reserve, in case our watermaker broke in the middle of a long passage.

More luxuries

Can’t live without a proper shower? A boat water maker can make water-intensive luxuries like freshwater deck washdown, freshwater flushing heads, laundry, daily showers, and even baths, a possibility.

As great as this sounds in theory, we were surprised to find that we didn’t indulge in more showers after we got the watermaker.

We continued to use a hand pump pesticide sprayer to shower on deck despite having a watermaker and shower below. While some of this came down to habit, we also disliked running our engine (and consuming diesel) just to run the watermaker.

No hauling water

For us, this was by far the greatest benefit of having a watermaker!

While cruising in the US and Canada, we could refill our water tanks at a dock or marina. This was a minor hassle because it involved pulling up the anchor and docking the boat.

In Mexico, it was more challenging to get water. We would fill 5-gallon jugs at the local water purification plant in town and wheel them back to our boat on a collapsible dolly.

It often took a couple of trips with the dolly and dinghy to fill our water tanks. Oh, and we broke our dolly, twice!

We realized that if we wanted to spend more time exploring, and less time hauling water, we would have to invest in a watermaker. When we reached La Paz, Mexico we bought a refurbished watermaker, and we were so glad we did!

Our sailboat water maker gave us the gift of time, especially in places like Mexico and the South Pacific, where there were limited opportunities to fill water tanks up at the docks. It also saved us paying docking and water fees.

We estimate that our boat water maker saved us anywhere from four to six hours every week, time that we could spend exploring the wonderful places we were visiting.

A clean, safe water source

In places where the drinking water may be suspect, a boat water maker can be a reliable source of safe drinking water (assuming it’s in good working condition!).

More time in remote locations

A watermaker is a great tool if you’re drawn to remote locations where you might be the only boat in the anchorage.

It wasn’t until we reached Los Frailes, a secluded village on the Baja, that we really began to think about buying a watermaker.

There we were in an idyllic anchorage, surrounded by spectacular hiking and fishing. There was only one problem—every two days we had to walk 10 miles into town with our water jugs and hope that some kind samaritan would give us a lift back to our boat.

Before having a watermaker, we’d often leave a place we loved just because we needed to fill up our tanks. With a watermaker, we were more self-sufficient and could stay an extra few days, or as long as we wanted!

The number one drawback is the cost. We were able to find a refurbished water desalinator for $3,000, which was a great deal but also a considerable slice out of our cruising kitty.

How much does a watermaker cost?

Powered desalination systems for your average recreational cruising boat range from around 3,500 USD to 11,000 USD, with the more expensive options offering higher production (gallons of fresh water per hour).

Ongoing maintenance

Watermakers are yet another piece of boat equipment that needs to be maintained.

The majority of watermaker problems are caused by not using it enough or not using it properly.

If a watermaker is not used for a few weeks, the planktonic organisms in the seawater will die, rot, and clog the membrane and filters. This can eventually damage the reverse osmosis membrane in the watermaker.

For this reason, boat water makers should be used frequently and regularly flushed with fresh water.

Watermaker flushing

Check your manufacturer’s instructions on how to flush.

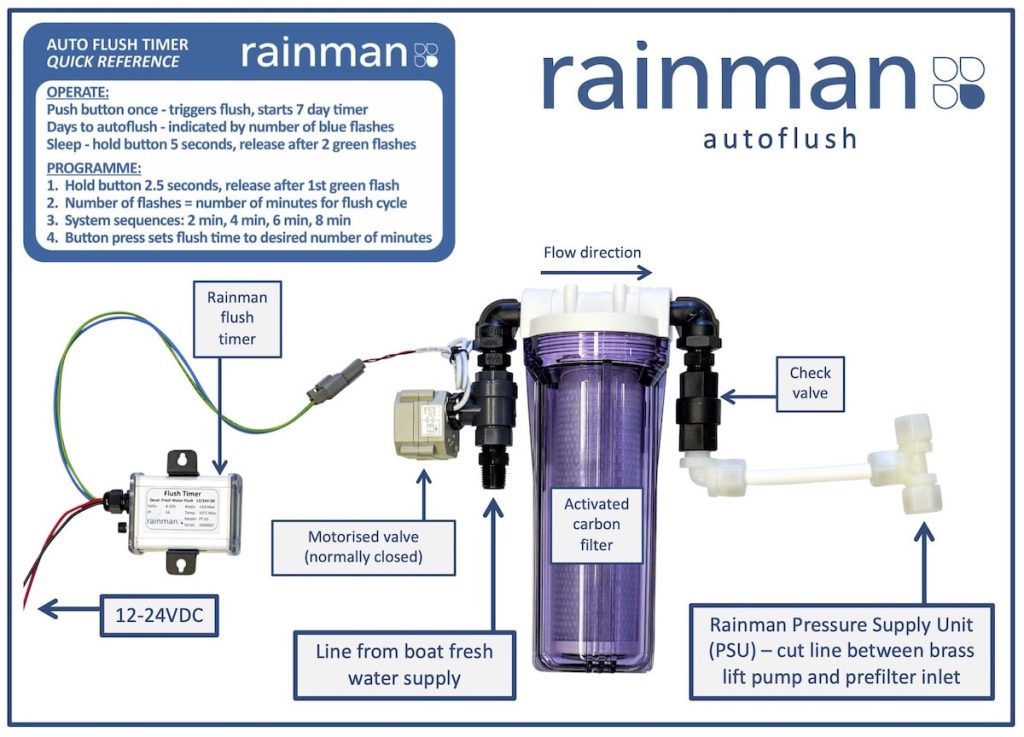

Rainman recommends flushing the seawater out of the system with fresh water if you are not using the system for more than a day or two. After another week, you need to freshwater flush the system again or pickle it for long-term storage.

Of course, it’s easy to forget, so we made it a rule to freshwater flush our watermaker after every use.

This is one good reason to choose a watermaker with an output that will meet your water consumption needs but not exceed them. If you’re using it every second day, you won’t have to try and remember whether you’ve flushed it or not.

Flushing a watermaker is relatively simple but it does involve a bit of work. We used a system with buckets of fresh water to flush our system and it generally took about 5 minutes.

You can also buy systems that automatically flush your watermaker at pre-determined times—even when you’re away from the boat (more on autoflush systems below).

Whatever you do, don’t use chlorinated water to flush as it will destroy reverse osmosis membranes. It’s possible to buy a carbon filter to remove chlorine from water sources at the dock.

Pickling a watermaker

If you don’t plan on using your watermaker for a while it needs to be “pickled” with a special biocide to prevent growth and buildup which could render your reverse osmosis membrane totally useless.

A watermaker should also be pickled every so often to chemically cleanse the membrane.

In addition to flushing and pickling, you will also need to clean out and replace the raw water pre-filters.

Operating costs

When properly cared for, a membrane should last five to ten years. If you don’t properly flush or pickle your watermaker, it can be a lot sooner and membranes aren’t cheap, generally costing in the range of 200-700 USD.

You’ll also need to purchase pre-filters and pickling solution, which are generally quite affordable. It’s also a good idea to carry spare parts

Power consumption

Watermakers can be real power hogs. When Practical Sailor tested a dozen DC watermakers they found they could draw anywhere from 12 to 48 watts per gallon, a huge range in efficiency!

According to Practical Sailor, “for maximum efficiency none of the systems drawing 15 amps or more should be operated without running the engine at the same time.”

We had to run our engine for hours to fill our tanks, which was annoying (and loud) when we were hanging out at anchor and also used up another finite resource—diesel fuel.

In our view, this was the single largest drawback to having a watermaker aboard.

Keep in mind that your power supply will determine what type of watermaker you buy. You may need to upgrade your electrical panels, get a generator or high-powered alternator, add solar panels, or increase battery capacity to supply the demand.

You can’t make water everywhere

While watermakers offer great flexibility and freedom, you can’t just make water in any old spot. If you make water in a polluted marina or anchorage, you’ll risk clogging up your filter. Most cruisers will head out to open water to ensure the saltwater they’re using is as clean as possible.

Key features to look for

Powered or handpump, handpump watermakers.

Handpump watermakers tend to be small and portable, the perfect thing to keep in your ditch bag in the event of an emergency. They’re less expensive than powered watermakers and produce far less water, usually around one gallon per hour.

Though I do know cruisers who have used a handpump watermaker for everyday use, they typically tend to be kept aboard for survival situations.

Powered watermakers

Powered watermakers run off your electrical supply or engine and can produce tens of gallons of water per hour. They tend to be a lot more expensive, but they’re productive enough to replenish your tanks.

Electric or engine drive

Powered watermakers can be electrically driven, by AC or DC, or run off the boat engine.

AC watermakers

AC models can produce in the range of 20-60 gph and are ideal for cruisers with an AC generator or alternator on board. They can also be used on boats with ample solar or wind sources and an inverter.

DC watermakers

DC watermaker systems typically produce in the range of 10-30 gph and are ideal for boats with solar power or 12V battery power.

Engine-driven watermakers

On an engine-driven watermaker, the high-pressure pump is belt-driven. These can produce a considerable amount of water, even on small engines. For instance, engine-driven units produce between 20-60gph, twice what a DC unit can produce.

Energy recovery watermaker

DC watermakers have become more efficient in recent years thanks to energy recovery systems (ERS). When the water leaves the watermaker it is still under pressure. ERS uses a set of valves to make use of this excess pressure to help drive the pump, which can reduce energy consumption by as much as 80 percent.

Modular, self-contained, and portable watermakers

Watermakers can be bought as modular, self-contained, and portable units. Choosing the right one may depend on your boat size and layout and whether you’re comfortable installing the watermaker yourself.

Modular units

Modular units come as several separate components that you can mount and connect yourself. This obviously offers a lot more flexibility and is particularly useful on smaller vessels where you may not have a lot of space. The downside is that these systems will take longer to install.

Self-contained units

Self-contained units arrive pre-assembled. While easier to install, they’re often bulkier and best suited to a bigger cruising sailboat with a large engine room.

Portable watermakers

Portable watermaker systems, like the Rainman watermakers, are entirely self-contained. Their compact design makes them easy to move and stow and you can completely avoid a permanent installation.

Simply put the intake and brine discharge hoses overboard, the freshwater hose in your water tank and you’ll be making water in no time.

If you race, have multiple boats, or plan on selling your boat, a portable watermaker is a great option because it can be easily moved from boat to boat.

If we were to buy another watermaker, we would probably opt for a portable one.

Automatic flushing systems

Automatic flushing systems use your boat’s freshwater supply to flush the watermaker for several minutes every few days. These systems require additional components (e.g., a timer, carbon filters, and a motorized valve) and installation but they take a lot of the maintenance out of having a watermaker onboard.

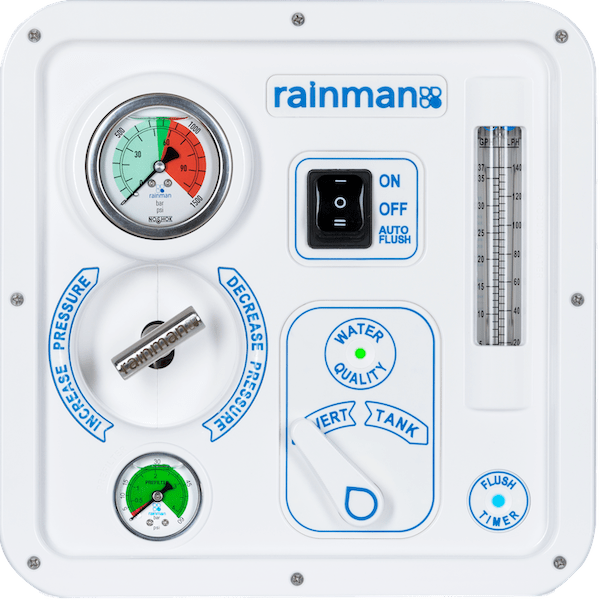

Automatic Pressure Regulation and adjustable pump speed

Your watermaker’s efficiency will be affected by the temperature and salinity of the water you’re cruising in. Cold and highly saline waters (e.g., in the high latitudes) will be more work for your watermaker, so it will take longer to purify.

Some units feature Automatic Pressure Regulation (APR) and adjustable pump speed which can help compensate for fluctuations in water temperature and salinity.

Remote control panels

Some watermakers have the option of a control panel which allows for easier access and remote control. Control panels tend to have a fairly simple interface with just a few gauges but may include a salinity sensor—so you can keep tabs on water quality—and auto-flush integration—so you can flush your watermaker with the flip of a switch.

Top watermaker brands

If you’re considering buying a watermaker for a boat, here are some of the top brands to consider.

- Cruise RO Watermaker

- Echotec watermakers

- Horizon Reverse Osmosis (HRO)

- Sea Recovery watermakers

- Schenker watermakers

- Spectra watermakers

Fiona McGlynn is an award-winning boating writer who created Waterborne as a place to learn about living aboard and traveling the world by sailboat. She has written for boating magazines including BoatUS, SAIL, Cruising World, and Good Old Boat. She’s also a contributing editor at Good Old Boat and BoatUS Magazine. In 2017, Fiona and her husband completed a 3-year, 13,000-mile voyage from Vancouver to Mexico to Australia on their 35-foot sailboat.

Terms and Conditions - Privacy Policy

Before you go, check this out!

We have lots more on the site to show you. You've only seen one page. Check out this post which is one of the most popular of all time.

Desalination Systems For Boats: 7 KEY Points To Consider

This a quote that always got me thinking, partially about the immense challenge involved with sourcing water at sea, but also the technological advances we have had in desalination and more importantly, compact desalination over the last 500 years.

“Water water everywhere and not a drop to drink “ The Rime of the Ancient Mariner – Samuel Taylor Coleridge

Being able to stay offshore for months at a time is something I was always fascinated by, the ability for ships to be largely self-sufficient and to produce fresh water. It did make me wonder though, how do they do it, what is the best option for different boats? Is there a one size fits all approach? How do you make sure the water is ok to drink? All of these questions got me thinking, what do you need to consider when installing or purchasing a desalination system for a boat? To better understand what is involved, I got researching and came up with this guide!

Compact reverse osmosis desalination systems powered manually or with varied electrical sources are suitable for most recreational boat users. For larger vessels with onboard motors, distillation becomes more viable, particularly as engine size increases and the excess heat produced can be utilized effectively.

1. The type of desalination system!

Realistically and practically speaking there are only two types of desalination systems suitable for boats, the most common being reverse osmosis and the alternative being distillation. Both options have their own advantages and disadvantages with certain boat types suited to one over the other.

Reverse osmosis (RO)

Reverse osmosis is a popular desalination technology that uses a semi-permeable membrane to remove salt and other contaminants from seawater. RO systems work by applying pressure to seawater, forcing it through a membrane that allows only freshwater molecules to pass through, leaving the salt and other impurities behind.

Advantages: RO systems are highly efficient, producing freshwater with a high salt rejection rate. They are also compact, lightweight, and relatively easy to install, making them ideal for boats with limited space. Additionally, RO systems require less energy than other desalination methods, making them more environmentally friendly and cost-effective in the long run.

Disadvantages: RO systems require regular maintenance, including membrane cleaning and replacement, to prevent fouling and other issues. They also require high-pressure pumps to operate, which can be expensive and may put a strain on the boat’s power supply. Furthermore, RO systems are sensitive to variations in water quality and temperature, which can affect their performance.

Example: Spectra Watermakers is a leading manufacturer of RO desalination systems for boats, offering a range of systems suitable for different boat sizes and water usage levels.

Best suited for .

Reverse-osmosis systems are generally the most common system utilized in marine environments due to their scalability, more compact nature and lower energy requirements. Sailing boats and vessels powered by outboard motors almost exclusively utilize reverse osmosis systems as they do not produce the excess heat required to operate distillation systems at an efficient level.

Distillation desalination systems

Distillation desalination systems use heat to evaporate seawater, leaving behind salt and other contaminants, and then condensing the steam into fresh water.

Advantages: Distillation systems produce high-quality freshwater that is free from most impurities, including bacteria, viruses, and dissolved solids. They are also relatively simple to operate and maintain, with no membranes or filters to replace. Additionally, distillation systems can be powered by a variety of heat sources, including electricity, gas, or diesel, making them suitable for different types of boats.

Disadvantages: Distillation systems are generally less efficient than other desalination methods, requiring more energy to produce the same amount of freshwater. They are also bulkier and heavier than RO systems, which can be a challenge on smaller boats with limited space. Furthermore, distillation systems are more expensive to purchase and install than other desalination methods, and may not be practical for boats with limited budgets.

Example: GEA is a manufacturer of innovative distillation desalination systems for boats where the heat produced by the engine is used in the distillation process , improving the overall efficiency of freshwater production.

Best suited for:

Distillation systems are best suited for large vessels with comprehensive onboard diesel motors. These larger vessels produce excess heat in the engine room which can be utilized in the distillation process, lowering the specific energy required to run the distillation system and thereby lowering the cost of operation.

2. The size of the desalination system.

When selecting a desalination system for a boat, size is a crucial factor to consider both the physical size of the unit and the production requirements. Factors to consider include the boat’s size, water usage, and budget.

Boat Size: This may seem obvious, but the size of the desalination system should be appropriate for the size of the boat. A large boat will require a larger desalination system to produce enough fresh water for the crew’s needs. A small boat, on the other hand, may only require a compact and lightweight system.

Water Usage: The size of the desalination system also depends on the boat’s water usage. A boat with a large crew or that spends long periods at sea will require a larger system to produce enough fresh water. A boat with a smaller crew or that spends less time at sea may only require a smaller system.

Space Constraints: The size of the desalination system should also consider the available space on the boat. Larger systems may be difficult to install on smaller boats, while smaller systems may be more practical for boats with limited space.

Budget: The size of the desalination system will also affect the cost. Larger systems will generally be more expensive than smaller systems however this is not always the case as some high-performance options can be extremely compact.

3. Testing apparatus & Quality Control.

The quality of water produced by the desalination system on a boat must be monitored to ensure that it falls within the required salinity levels prior to any potential consumption or use. Being in a space-constrained environment, practicality is key and depending on the size of the system both automatic and manual processes should be considered.

The best option for low volumes: Test Strips

Test Strips: Salinity test strips are another practical option for testing salinity levels on a boat. They are small, lightweight, and require minimal space to store. Test strips are easy to use and can produce a result in just a few minutes. They are also relatively inexpensive and can be used to measure salinity levels in both fresh and saltwater. However, test strips may not be as accurate as other testing methods and may not be suitable for scientific or research purposes.

The test strips displayed to the left are available on Amazon for $23 USD , less than 50c per test!

The best option for continuous use: Conductivity Meters.

Conductivity meters are another practical option for testing salinity levels on a boat. They are portable, easy to use, and can measure salinity levels in both fresh and saltwater. Conductivity meters are more accurate than refractometers and test strips and can be automated for continuous monitoring. However, conductivity meters can be more expensive than other testing methods and may require more maintenance.

The third option: Refractometers.

Refractometers: Refractometers are one of the most practical salinity testing methods for use on a boat. They are small, lightweight, and easy to use, requiring only a small sample of water to produce a reading. Refractometers are also relatively inexpensive and can be used to measure salinity levels in both fresh and saltwater. They are ideal for quick and accurate testing and can be easily stowed away when not in use.

For a more in-depth article specifically focussed on salinity levels testing, have a look at How To Check Water Salinity Levels: 4 Potential Methods .

4. The power requirements.

Desalination systems on boats can be powered by different energy sources, including utilizing the excess heat from the ship’s motors, solar power, wind power, and an alternator. Each energy source has unique advantages and disadvantages that make them more suitable for specific desalination systems.

Distillation systems require a significant amount of heat, and therefore utilizing the excess heat from the ship’s motors is the most practical source of energy . The heat produced by the engine can be used to evaporate and condense seawater to produce fresh water.

Reverse osmosis systems , on the other hand, require a significant amount of electrical energy, making solar power, wind power, and an alternator or generator more suitable sources of energy . Solar power, in particular, is a renewable and sustainable energy source that can be harnessed by solar panels mounted on the boat’s deck.

Wind power is another renewable and sustainable energy source that can power desalination systems on boats. The energy from the wind can be harnessed using a wind turbine and used to power the desalination system. However, the amount of energy produced by wind turbines depends on wind speed and can be expensive to install.

Alternators or generators can also be used to power desalination systems on boats, they function by converting mechanical energy into electrical energy and can be used to charge the batteries and power the desalination system. The advantage of using an alternator is its reliability, as it doesn’t depend on the weather conditions. The amount of energy produced by the alternator, however, depends on the engine’s speed and the size of the alternator.

Often, a combination of the above-mentioned energy sources is used , with an alternator or generator providing the base load power (Along with heat energy released from the ship’s motors for distillation). The remaining power demand is then sourced from small wind turbines and solar panels which fluctuate throughout the day depending on the environment. A mixed array of energy sources provides the balance between cost-effectiveness and reliability that is required to run desalination systems on board boats and ships.

5. The location of the system on the boat.

The location of a desalination system on a boat is an important factor to consider, as it can affect the efficiency and safety of the system. Here are some considerations to keep in mind when determining the optimal location for a desalination system on a boat:

- Accessibility: The desalination system should be installed in a location that is easily accessible for maintenance and repair. If the system is installed in a hard-to-reach location, it may be difficult to fix in case of a breakdown.

- Weight distribution: The weight of the desalination system can affect the boat’s balance and stability. The system should be installed in a location that balances the weight of the boat evenly. For example, if the system is heavy, installing it in the centre of the boat may be best.

- Vibration: Desalination systems can produce a significant amount of vibration, which can be uncomfortable for passengers and damage the boat’s structure. To minimize vibration, the system should be installed in a location that is isolated from other equipment and machinery.

- Water source: The location of the desalination system on the boat should be near the water source, such as the sea or a freshwater tank. This will minimize the length of the pipes and hoses required to transport water to the system, which can reduce the risk of leaks and water loss.

- Electrical connections: The desalination system requires electrical power to function, so it should be installed in a location that is close to the boat’s electrical system. This will reduce the length of the electrical cables needed, which can reduce the risk of electrical failure and improve the system’s efficiency.

- Ventilation: The desalination system generates heat and produces water vapour, so it should be installed in a well-ventilated location to prevent overheating and moisture buildup. Adequate ventilation can also prevent the accumulation of harmful fumes and gases.

- Noise: Desalination systems can produce a significant amount of noise, which can be disturbing to passengers and wildlife. To minimize noise, the system should be installed in a location that is isolated from cabins and areas where people congregate.

6. Storage requirements.

Water storage is an important consideration for any boat owner using a desalination system. Four key points to consider when it comes to water storage requirements for a desalination system on a boat are the water demand, available space, water quality and required maintenance:

- Water demand: The amount of water needed by the boat and its passengers will determine how much water storage is required. Boat owners should consider the number of people on board, the length of the trip, and the water needs for cooking, cleaning, and personal hygiene. This information will help determine the size of the water storage tank needed.

- Available space: The amount of space available on the boat will determine the size and shape of the water storage tank. Boat owners should consider the size and shape of the tank and where it can be located on the boat. This will depend on the boat’s design and layout, as well as the other equipment and storage needs on board.

- Water quality: The quality of the water produced by the desalination system will affect the storage requirements. Some systems produce water with high salt content, which can impact the taste of the water and corrode tanks and pipes over time. Boat owners should consider using tanks made from materials that are resistant to corrosion, such as stainless steel or plastic.

- Maintenance: Proper maintenance of the water storage tank is essential for ensuring the quality of the water and preventing damage to the tank and pipes. Boat owners should consider the maintenance requirements of the tank and the desalination system when selecting a storage tank. Some tanks may require frequent cleaning or flushing to prevent the buildup of bacteria or algae, while others may require regular inspection for cracks or leaks and therefore should be located in an easily accessible location.

7. The price of the system.

The financial cost of a desalination system is a critical consideration for boat owners who want to ensure a reliable source of fresh water on board. There are several costs associated with desalination systems, including the upfront cost of the system, installation costs, and ongoing maintenance costs.

The upfront cost of a desalination system can vary widely depending on the size and complexity of the system. Simple systems such as handheld or manual reverse osmosis units can be purchased for a few hundred dollars, while larger and more complex systems can cost tens of thousands of dollars. Additionally, the type of system will determine the ongoing costs of replacement filters or membranes, which can add up over time.

Installation costs for desalination systems will also vary depending on the type and size of the system, as well as the boat’s design and layout. Simple systems may require minimal installation work and can be DIY installed, while larger and more complex systems may require professional installation and plumbing work.

Ongoing maintenance costs for desalination systems include the cost of replacement filters or membranes, as well as any required maintenance or repairs. The cost of replacement filters or membranes can vary depending on the type and size of the system, as well as the frequency of use. Maintenance and repair costs may also vary depending on the complexity of the system and any required professional services.

For the average dinghy with an outboard motor, a handheld or manual reverse osmosis unit is likely the most affordable desalination system. These units can be purchased for a few hundred dollars and require no installation costs, making them an ideal option for smaller boats with limited space and budget.

For sailboats , a compact and portable reverse osmosis system that can be easily stored and transported is an excellent option. These systems are typically larger and more expensive than handheld units, but they can provide a reliable source of fresh water for longer trips.

For an extremely compact desalination system suitable as a backup water supply for recreational usage, take a look at Quenchsea , without a doubt the most lightweight manual desalination unit on the market.

For larger boats with onboard motors, a more complex and higher-capacity desalination system may be required. These systems can cost tens of thousands of dollars to purchase and install, and ongoing maintenance costs can be significant. However, they provide a reliable source of fresh water for longer trips and can be an excellent investment for boat owners who spend extended periods at sea.

https://www.spectrawatermakers.com/us/us https://www.gea.com/en/products/liquid-processing/water-treatment-systems/sea-water-distiller.jsp https://waterbornemag.com/watermaker/ https://www.saltwaterpoolandspa.com/salt-water-test-kit.html https://www.xylemanalytics.com/en/parameters/conductivity-and-salinity https://letsdowater.com/how-to-check-water-salinity-levels-4-potential-methods/ https://www.quenchsea.world/

John Wilson

Recent Posts

The Drought In Mexico: Affected Areas and Why It's an Issue

The drought in Mexico is an environmental crisis affecting over 85% of the country's land with more than 60% of the population being impacted. With over 40% of Mexico's GDP being generated in these...

Forever Chemicals In Your Water: What You NEED To Know

Forever chemicals, aka PFAS are a group of chemicals and plastics that don’t naturally break down in water and are linked to many health issues. PFAS are Utilized for their heat, water and oil...

- (954) 633-4878

- [email protected]

Compass Articles

- April 18, 2024

Deep Dive into Yacht Desalination Systems: Fresh Water from the Sea

What is desalination on yachts.

Desalination on yachts is a process that turns seawater into fresh water, making long trips on the ocean more manageable. If you’re planning to spend a lot of time at sea, having a desalination system onboard means you won’t run out of fresh water. This system can make sea water drinkable by removing the salt and other impurities. Whether you use reverse osmosis or thermal distillation, the goal is the same: to give you access to fresh water anytime during your journey.

Having this system onboard allows for longer and more flexible sea travel. It’s vital for anyone who wants to explore without the limitation of water supply, ensuring you’ve always got enough water for drinking, cooking, and cleaning.

How Do These Systems Work?

Reverse osmosis is the most common technology used in yacht desalination. It works by pushing sea water through a special filter that removes salts and dirt, leaving behind clean water. This method is popular because it’s effective and the setup doesn’t take up much space on the yacht. Another method, thermal distillation, involves heating the sea water until it turns into steam and then cooling it back into liquid water, which is salt-free and clean.

Depending on what your yacht can accommodate, you might choose one method over the other. Both have their perks, but reverse osmosis tends to be more energy-efficient and requires less room.

Why Install a Desalination System?

Installing a desalination system on your yacht adds a layer of independence and safety. It lets you travel farther from shore because you won’t need to dock just to refill your water tanks. More than convenience, it’s about making sure you always have access to safe water, which is essential for staying healthy at sea. Additionally, using your own system reduces the need for plastic water bottles, which is better for the ocean environment.

Systems nowadays are easier to manage, with many models featuring automated cleaning and maintenance alerts. They’re an environmentally friendly option that provides peace of mind, knowing that wherever you are, you can have fresh water with just the push of a button.

Picking the Right System for Your Boat

It’s important to choose a system that fits your boat and your travel habits. Think about how much water you usually need and how much space you can dedicate to the system. Getting advice from experienced professionals can make the decision easier. They can help determine the most suitable system based on your specific needs and the size and power setup of your yacht.

Remember, professional installation and regular maintenance are key. This ensures that the system works well and lasts a long time. It saves you money down the line by avoiding major repairs caused by improper use or neglect.

When it comes to staying hydrated and safe on your ocean adventures, a reliable desalination system is crucial. For expert advice on choosing and installing the right system, feel free to contact a team member from Fly Yachts, who can guide you through the process and ensure you make the best choice for your sea-going lifestyle.

Considering buying a yacht? Fly Yachts showcases a broad array of yachts for sale . For those desiring a personalized yacht, their build a yacht service allows you to tailor a yacht perfectly suited to your needs. Learn about their commitment to quality by visiting the About Us page. Adventure lovers can check out the charter destinations page for stunning places to sail. If you’re thinking about selling your yacht , they offer guidance to ensure a smooth process. Aviation buffs might be interested in aircraft for sale . Stay updated with the latest yachting news by following Gulfstream News . Any questions? The Contact page has all the information you need. For those interested in the yachting experience without the full commitment of ownership, their yachts charter options are excellent. Additionally, for more compelling stories and insights about yachting, be sure to read their Compass Articles .

About FLY Yachts

Unmatched Industry Knowledge, Paired With Brokers Who Care Equals Yachting You Love.

Recent Posts

Experience the ultimate luxury and modernity with cobalt boats r6 outboard, the cobalt boats cs23: a modern boat with ultimate luxury.

- [email protected]

- +86 180-5290-6888

A Guide to Marine Desalinations Units and Making Water on a Boat

Introduction.

Welcome to our guide on watermakers, also known as marine desalinators. If you own a boat or are planning a long voyage, access to fresh, clean water is essential. While it is possible to carry a limited supply of water with you, a watermaker allows you to produce your own water as needed, giving you greater independence and flexibility.

In this article, we will provide an overview of how watermakers work and the different types available. We will also discuss the benefits and drawbacks of using a watermaker, as well as some tips for maintaining and troubleshooting your system.

What are Watermakers?

Marine watermakers , also known as seawater desalination systems or reverse osmosis watermakers, are devices that are used to produce freshwater from seawater for use on boats and ships. These systems work by using a process called reverse osmosis to filter salt and other impurities out of seawater, producing clean, drinkable freshwater.

Marine watermakers are typically used on boats and ships that are sailing in areas where freshwater is scarce or not readily available, such as in the open ocean or in remote locations. They are an essential piece of equipment for any vessel that will be out at sea for an extended period of time, as they provide a reliable source of fresh water for drinking, cooking, and other purposes.

How do Watermakers Function?

Marine watermakers, also known as seawater desalination systems , are devices that are used to convert seawater into fresh drinking water on board ships and boats. They are particularly useful in situations where there is no access to freshwater sources, such as during long voyages or in remote locations. There are several different types of marine watermakers, but most operate using a process called reverse osmosis.

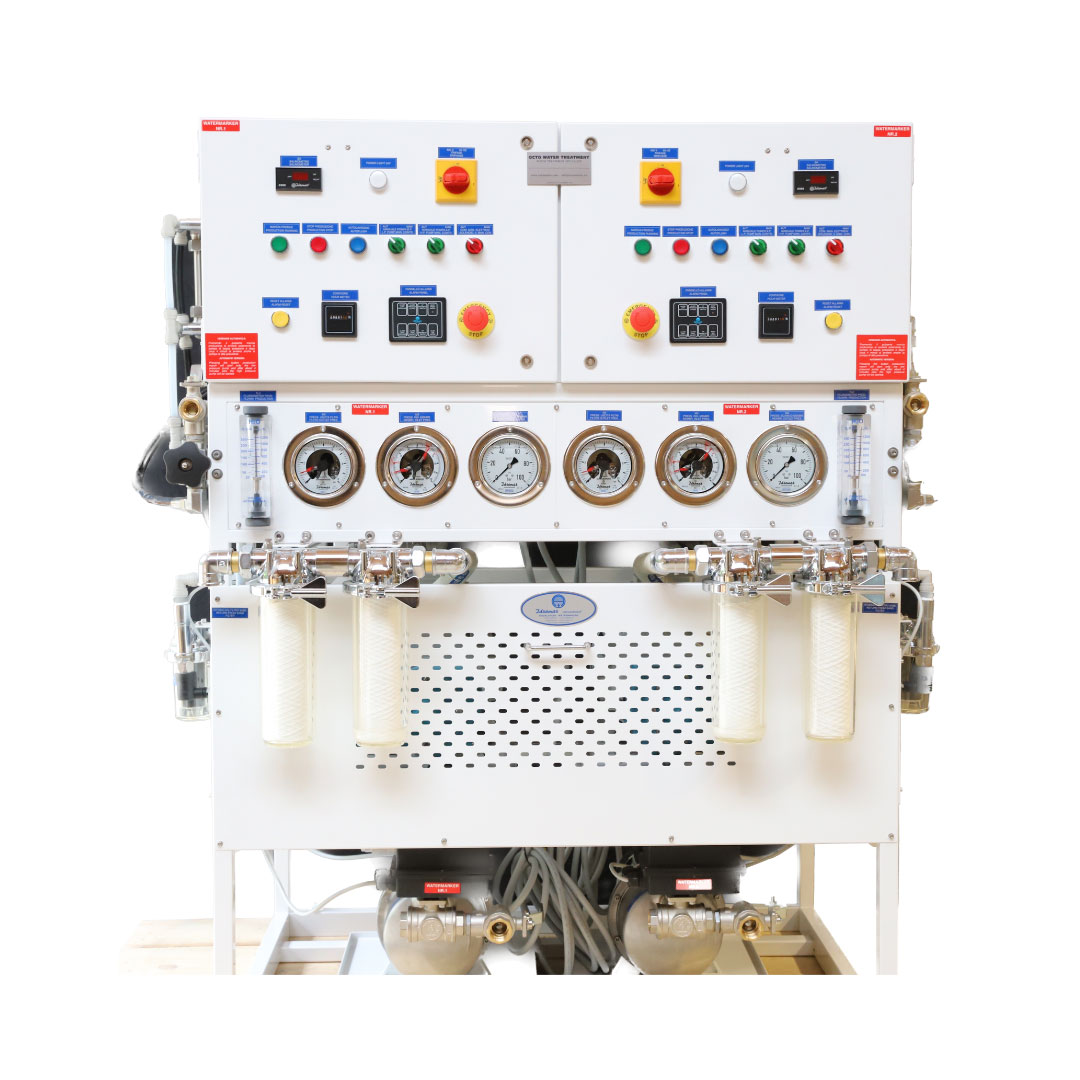

In this process, seawater is pressurized and forced through a semi-permeable membrane, which removes the salt and other impurities from the water. The resulting fresh water is then collected and stored for use on board the vessel. Marine watermakers typically consist of several main components, including a high-pressure pump, a reverse osmosis membrane, and a control system. The pump is used to pressurize the seawater, while the membrane is responsible for removing the impurities.

The control system monitors and regulates the water maker’s operation, ensuring that it is functioning properly and producing high-quality drinking water. Marine watermakers require a consistent source of electricity to operate and can be powered by the vessel’s battery system or a separate generator. They also require regular maintenance to ensure that they are operating efficiently and producing high-quality water.

Types of Marine Watermakers

There are several different types of marine watermakers available, each with its own set of features and benefits.

· Reverse Osmosis Watermakers

Reverse osmosis (RO) watermakers are the most common type of marine watermaker. These systems use a semi-permeable membrane to filter out salt and other impurities from seawater. RO watermakers are known for their high efficiency and ability to produce large quantities of fresh water. However, they require a significant amount of pressure to operate and can be quite expensive to maintain.

· Thermal Watermakers

Thermal watermakers use heat to evaporate seawater, leaving the salt and other impurities behind. The water vapor is then cooled and condensed into fresh water. Thermal watermakers are relatively simple and easy to maintain, but they are not as efficient as RO watermakers and tend to produce smaller quantities of water.

· Solar-Powered Watermakers

Solar-powered watermakers use energy from the sun to power the desalination process. These systems are environmentally friendly and can be used in areas where access to electricity is limited. However, they are not as efficient as other types of watermakers and may not produce enough water to meet the needs of larger boats or ships.

· Hand-Pump Watermakers

Hand-pump watermakers are small, portable systems that can be used to produce fresh water in emergency situations. These systems use manual labor to power the desalination process, making them suitable for use in areas where electricity is not available. However, hand-pump watermakers are not suitable for long-term use and can be quite labor-intensive.

Which is the Best Watermaker for You?

There are a few different types of boat watermakers available, including reverse osmosis systems and vacuum distillation systems. Reverse osmosis systems use a high-pressure pump to force seawater through a membrane, which removes salt and other impurities to produce fresh water. Vacuum distillation systems use heat to vaporize seawater, which is then cooled and condensed to produce fresh water. Both types of watermakers are effective at producing fresh water, but reverse osmosis systems tend to be more popular because they are generally more efficient and require less maintenance.

The Importance of Using Watermakers

Watermakers allow boaters to turn seawater into fresh, potable water, which is vital for maintaining adequate hydration and for cooking and cleaning onboard. Underneath, we’ll explore the importance of using boat watermakers and how they can benefit boaters.

· Adequate Supply of Fresh Water

One of the primary reasons for using boat watermakers is to ensure an adequate supply of fresh water. While it’s possible to carry a limited amount of fresh water onboard, it can be difficult to predict how much water you’ll need for a given voyage. Factors such as the number of people on board, the length of the trip, and the weather can all impact your water usage. A watermaker allows you to produce as much fresh water as you need, ensuring that you have enough to meet your needs while at sea.

· Self-Sufficient

Another important benefit of boat watermakers is that they allow you to be more self-sufficient while on the water. Instead of relying on shore-based sources of water, you can produce your own fresh water onboard, which can be especially useful in remote or isolated areas. This can give you greater peace of mind and allow you to explore more remote destinations without worrying about running out of water.

· Environmentally Sound

In addition to their practical benefits, boat watermakers also have environmental advantages. By producing your own fresh water onboard, you can reduce your reliance on single-use plastic water bottles, which can help to reduce plastic pollution in the oceans. Watermakers also allow you to minimize your impact on shore-based water sources, which can be especially important in areas where water is a limited resource.

Proper Maintenance Practices for Your Marine Desalinator

Marine desalinators are an important part of many boats and ships, providing a reliable source of fresh water for drinking, cooking, and other purposes. However, like any other piece of equipment, they require proper maintenance to ensure they continue to function properly and efficiently. Below, we will discuss some key maintenance practices for marine desalinators that will help keep them in good working order.

· Follow the Manufacturer’s Maintenance Schedule

Most marine desalinators come with a recommended maintenance schedule that outlines the specific tasks that need to be completed at regular intervals. This may include things like changing the filters, cleaning the membranes, and inspecting the unit for signs of wear or damage. It’s important to follow this schedule carefully to ensure that your desalinator is always in top condition.

· Change the Filters Regularly

Desalinators use filters to remove impurities from the seawater before it is processed into freshwater. These filters can become clogged over time, which can reduce the efficiency of the unit and even cause it to fail. It’s important to change the filters according to the manufacturer’s recommendations to ensure that the unit is operating at peak performance.

· Clean the Membranes Regularly

Desalinators use a special type of membrane to filter salt and other impurities from seawater. These membranes can become fouled over time, which can reduce the unit’s efficiency and lead to poor water quality. To keep your desalinator functioning properly, it’s important to clean the membranes according to the manufacturer’s recommendations. This may involve using a specialized cleaning solution or simply flushing the membrane with fresh water.

· Inspect the Unit Regularly

Regular inspections of your desalinator can help you catch small problems before they turn into bigger ones. Look for signs of wear or damage, such as leaks, cracks, or worn seals. If you notice any problems, address them as soon as possible to prevent further damage to the unit.

· Store the Unit Properly

When not in use, it’s important to store your desalinator properly to prevent damage or deterioration. Keep it in a dry, well-ventilated area, and cover it to protect it from dust and debris.

By following these maintenance practices, you can help ensure that your marine desalinator continues to provide reliable, high-quality freshwater for your boat or ship.

In conclusion, boat watermakers are an essential piece of equipment for any boat that spends extended periods of time on the water. They allow you to produce your own fresh water onboard, which is vital for maintaining adequate hydration and for cooking and cleaning.

Watermakers also allow you to be more self-sufficient while on the water and can help to reduce plastic pollution and minimize your impact on shore-based water sources. If you’re planning on taking your boat on extended voyages, a NEWater watermaker is an investment worth considering.

- Portable and Installed Watermakers

- FIND A DEALER >

- AC Electric

- Petrol (Gasoline)

- DC Electric

- Control Panel

- Autoflush System

- Plumbing Install Kit

- Hydrotester

- Prefilter Cartridge

- Pickling Solution Mix

- Lift Pump Impeller

- RO Membranes

- High Pressure Hose

- Case Studies

- Testimonials

- Applications

- Desalination Theory

- Detailed Schematic

- Dealers List

- Dealers Map

- OEM Partners

- Troubleshooting

- Installation

- Manuals + Downloads

- Sales Enquiry

- Support Request

Fresh water anywhere

AC ELECTRIC, PETROL (GASOLINE), and 12VDC ELECTRIC WATERMAKERS. PORTABLE and INSTALLED MODELS AVAILABLE.

AC ELECTRIC , PETROL (GASOLINE) , and 12VDC ELECTRIC WATERMAKERS . PORTABLE and INSTALLED MODELS AVAILABLE.

no power source required

Petrol (gasoline) watermakers.

230V/50HZ or 115v/60hz

Ac electric watermakers.

12VDC power source

12vdc watermakers, rainman watermakers, a fresh approach to saltwater desalination. .

The Rainman Advantage

VERSATILITY

Rainman watermakers can be easily transferred between boats or used in remote land based applications. Keep your watermaker when you change your boat.

RELIABILITY

Partnering with the best companies for components, Rainman watermakers have a very high quality build, ensuring reliability and longevity of your investment.

LIFE CYCLE COST

With modest initial investment and components designed for durability and easy maintenance, the overall life cycle cost of a Rainman watermaker is kept to a minimum.

Portable Watermakers

+1-954-800-8800

Welcome to SeaWater Pro

Enjoy the purest water without limitations - easy and reliable. Purchase your modular, portable, or compact boat salt water desalinator today!

Fast Express Shipping.

Industry Best Warranty!

Have a question?

14 GPH - Best for any situation or as a backup for emergencies!

Mini Portable Watermaker AC Powered

AC Watermaker Systems

Available in 17 to 40 GPH - Best for medium to large size vessels.

Watermaker: AC 110/220 Volt 970 Watts, 40 GPH Dual Membrane

DC Watermaker Systems

Available in 17 to 40 GPH - Best for small to medium size vessels.

Watermaker: DC 12 Volt, 600 Watts, 17 GPH Single Membrane

Quick assembly guide, ac powered 14 gph desalinator, customer installations gallery.

SWP Modular & Portable Watermakers

Welcome to SeaWater Pro, the premier provider of high-quality watermakers for boats and portable watermakers for all your marine adventures. Our cutting-edge technology and reliable products will ensure that you have access to clean, purified seawater wherever you go. With our easy-to-use and reliable watermakers, you can say goodbye to bulky storage tanks or worry about running out of fresh water. Our compact and efficient systems are designed specifically for marine use, making them perfect for boats of all sizes. Whether you're cruising the open seas or anchored in a secluded cove, our watermakers will provide you with a steady supply of fresh, drinkable water. At SeaWater Pro, we understand the importance of safe and clean drinking water while at sea. That's why our portable watermakers are equipped with advanced filtration systems that remove harmful contaminants and bacteria. Look no further than SeaWater Pro for your next, most reliable boating adventure investment!

Latest Articles

Watermakers vs. traditional water storage: a comparative analysis, demystify desalination, charting your course: your first steps into the exciting world of the sea industry, how do i know which seawater pro watermaker i'll need for my boat.

- Identifying which power source you'd like to run the system. AC or DC power?

- Determine how many gallons per hour will you need to maintain your lifestyle, 17 or 40 GPH.

How much does each SeaWater Pro System weigh?

Every modular watermaker system ships in 3 boxes.

- Box 1: Components (tubing, filters, boost pump, comet pump, fittings, etc.) - 40 lbs.

- Box 2: Motor - 40-48 lbs. (varies by motor option)

- Box 3: Membrane Vessels 15 lbs. per vessel, 30 lbs. each for stainless steal option.

Can I install a SeaWater Pro system myself?

Yes! We have videos and instructions for our customers on the resources page .

Do I need a control panel?

Do I need a control panel? Click to watch video

How do I rinse my system after I use it?

Rinse Timer Setup Guide Click to learn more about using your system's rinse timer!

How often do I need to pickle my watermaker?

How to pickle my SeaWater Pro system! Click to watch our short video guide.

Your Cart is Empty

But your water tank doesn't have to be :)

- Choosing a selection results in a full page refresh.

Horizontal Small Desalination Watermakers:Making Clean Water on Your Boat

Our portable and modular water generators are easily programmable and installable, converting seawater into fresh drinking water while lowering fuel consumption and maximizing energy efficiency.

NEWater: Desalination of Water Expert

Do your ships/yachts have desalination plants? If you are a sailor, working in the nautical industry, owning your own fishing boat/yacht, then you must be troubled by one thing: How to get potable water on board in an easy way? Marine desalinators can turn seawater into freshwater with one button. We have a wide range of high-quality desalination systems for boats that can support your business. Send us an inquiry today for professional desalination advice based on your vessel type and size!

NEWater Horizontal Small Desalination Watermakers

Compact and lightweight, easy to install and transport. Utilizes RO technology with 0.0001um pore size to remove 99.99% of contaminants. Features a high-quality RO membrane with a 98% desalination rate, meeting WHO drinking water standards—ideal for marine applications.

Compact, durable, and lightweight. Equipped with PLC+ relay dual-mode control for reliable operation. Features a high-quality RO membrane with a 98% desalination rate, meeting WHO drinking water standards—perfect for boat use.

Split design for easy mobility and assembly. Ideal for yachts and ships with automatic PLC control and curved panel design. Uses seawater RO membrane with over 98% desalination rate, with SS316L parts for durability and safety. Produces water that meets WHO standards.

- Fully Automated Operation : The system features fully automated operation with an automatic cleaning system, ensuring long-term performance with minimal manual intervention.

- Emergency Stop & Safety Design : Equipped with an emergency stop button and a professional electrical control cabinet, the design separates water and electricity, ensuring safe and reliable operation.

- Compact & Sturdy Design : Constructed with a fully polished stainless steel frame, the system is lightweight, space-saving, and robust, making it ideal for installation on ships or in other confined spaces.

- High-Efficiency Desalination RO Membrane : Fitted with imported high-quality RO membranes that effectively remove salts, organics, bacteria, and microorganisms, producing water that meets drinking water standards—perfect for clear seawater that doesn’t require additional filtration.

- High-Pressure Metal Components : All high-pressure metal parts are made from SS316 material, capable of withstanding pressures up to 7MPA, ensuring durability and corrosion resistance.

NEWater RO Technology

Reverse osmosis is a membrane separation technology driven by pressure difference, with high separation, no phase change, simple and efficient characteristics.NEWater adopts the world’s advanced and energy-saving and effective RO membrane separation technology, filtration precision 0.0001 microns. It can thoroughly filter out all particles of sediment, colloid, rust, bacteria and viruses, limescale, heavy metals, etc., with a removal rate of 97-98%, effectively avoiding secondary pollution. The water produced can be directly consumed, sweet and delicious.

Why You Should Invest a Marine Water Maker?

NEWater’s desalination system for boats is designed to transform seawater into clean, healthy water suitable for direct human consumption. It is used in islands, individuals, sailing, yachting, fishing, disaster relief, etc. The equipment is small, easy to carry, less weight, and at the same time less costly to invest in.

We also offer suitcase desalination units that can be customized to your needs. Solar energy supply is optional, and the equipment uses energy recovery devices to fully reduce energy consumption.

About NEWater

NEWater is a Chinese water treatment equipment company with nearly 20 years of experience, specializing in the field of seawater desalination. We have extensive technical expertise, with our engineers each having over 15 years of industry experience, understanding deeply the water treatment needs of our customers and specific usage scenarios.

All our water treatment systems, including our marine watermakers, come with a one-year quality guarantee. With our own manufacturing facility, we ensure prompt delivery and significantly shorten lead times. NEWater serves global customers, providing support even for individual marine desalination units. Our equipment conforms to ISO 9001 quality management system certification.

NEWater Desalination Machines Applications

During long-term fishing operations, brackish seawater can be troublesome. Whether for drinking, washing clothes, cooking, or bathing, the experience is subpar, and carrying large amounts of bottled water is neither economical nor convenient. A small watermaker can solve this issue with the push of a button.

Large cargo ships or logistics companies on international voyages may be at sea for several days to weeks. Without adequate fresh water supply, long-term navigation and operations are impossible. Equipping the ship with a high-capacity desalination unit ensures a plentiful supply of clean water, avoiding business interruptions.

For restaurant operations, high-quality water is necessary for cooking, beverage preparation, showers, and swimming pools. A reliable unit can convert seawater into smooth drinking water, supporting your business, maintaining brand reputation, and improving customer experience.

Whether operating a resort or owning a vacation villa, a continuous and stable supply of clean water is a worthwhile investment. Even with low usage frequency, it is more convenient than continuously purchasing bottled and mineral water.

Coastal or off-grid households surrounded by seawater often struggle to obtain potable tap water. Installing a desalination system can continuously convert seawater into clean water, enhancing household water use. The system can use solar power and diesel generators to address power supply issues.

NEWater Mission:Bring New Life for Water

- Product Parameters

- Manufacturing

- What You Care About

- Optional Components

| Model | NE-ID700 | NE-ID1400 | NE-ID3000 | NE-ID4000 | NE-ID5000 |

| Flow rate | 700L/D | 1400L/D | 3000L/D | 4000L/D | 5000L/D |

| Recovery rate | 4% | 8% | 15% | 20% | 25% |

| Power | 1.9KW | 2.6KW | |||

| Voltage | 220V 50HZ 1P(Other Vltages Customized) | ||||

| Inlet water TDS | <45000ppm | ||||

| Outlet water TDS | <600ppm | ||||

| Model | NE-SF700 | NE-SF1400 | NE-SF2000 |

| Flow rate | 29L/H | 58L/H | 83L/H |

| Voltage | 220V 50HZ 1P(Other Voltages Customized) | ||

| Power | 1.6KW | ||

| Desalination rate | ≥98% | ||

| Inlet water TDS | <45000ppm | ||

| Outlet water TDS | <600ppm | ||

| Equipment size | 84.5*47.4*43.2cm | ||

| Model | NE-PRO3000 | NE-PRO4000 |

| Flow rate | 125L/H | 167L/H |

| Voltage | 220V 50HZ 1P(Other Voltages Customized) | |

| Power | 1.9KW | |

| Inlet water TDS | <45000ppm | |

| Outlet water TDS | <600ppm | |

| Equipment size | 120*45*43cm/52*40*45cm | |

NEWater has an independent large-scale production workshop, which is convenient for the control and supervision of product production quality. Strictly abide by production standards and provide detailed guarantees for all projects.

NEWater establishes SOP standardized operation process and strictly implements the work process. The professional project installation team, implement 5S on-site management. Equipped with standard safety facilities, investigating access conditions, and short construction time.

The safe transportation process does not have to worry about product damage and extends the construction period. NEWater has provided system equipment to thousands of companies around the world, which guarantees absolute product transportation.

1)How to Install Marine Water Maker on My Boat?

NEWater’s high-capacity and low-capacity marine desalination equipment are both designed with a compact footprint and are fully tested before leaving the factory. Upon receiving the equipment, all you need to do is install it on your vessel following the provided product manual and perform simple pipeline connections. Once everything is set up, simply press a button, and the equipment will start producing pure water from the outlet. You can initially test the water quality of the produced water to ensure it meets your standards.

If there are any issues with water quality or installation, our customer support team will provide online technical guidance and assistance within one day.

2)How to Maintain My Boat Water Maker?

To minimize environmental damage to the equipment, it is recommended to place it in an area away from strong sunlight and rain exposure. When using the equipment, try to choose areas with better water quality, as the quality of raw water affects the lifespan and filtering efficiency of the RO membrane. Additionally, cleaning the RO membrane every 6 months to a year can extend its lifespan and reduce the frequency of replacements. Filters should have their cartridges replaced every 3 to 6 months to maintain system efficiency and water quality.

Marine desalination systems can be equipped with various optional components to meet the specific needs and operating conditions of different vessels.

- Transformer

- Diesel generator

- Solar panels

- Freshwater tank

- Pre-treatment filter

- Automatic cleaning system

- Control system

- Disinfection device

How Long does the General Production Cycle Need to Wait?

NEWater’s treatment types of equipment are divided into a large system and a small system according to the water volume. The equipment is divided into portable water-making equipment, small modular equipment, skid-mounted equipment, and container-type equipment. According to different water volumes and customer requirements, we provide customized services.

Conventional small equipment takes 3-7 days, and large equipment takes 2-3 months. This is based on your requirements and water volume.

If I Need to Customize Equipment, What Data Need to be Provided?

- As the voltage and frequency of different countries are different, we first need the local voltage and frequency of electricity.

- How many gallons the water requirement per hour is

- The water quality of the source water and what requirements need to be met

- If you need to provide on-site installation services

Does the Equipment Need to be Installed On-site?

- Portable and small equipment — This is plug and play, it doesn’t need to be provided installation services. According to our instructions, you can install by yourself.

- Small modular equipment, skid-mounted equipment, and container equipment-we will reserve the interface for docking. If there are installation workers, we will provide installation instructions and installation instructions. If necessary, we can also send someone to install it.

- How to provide installation instructions —— We have installation instructions and installation videos. If necessary, we can provide free remote software to help you with remote video installation instructions.

How to Charge for Installation Service ?

- We provide free installation instructions, with instruction manuals and installation videos

- Remote video installation guidance. If it is a large piece of equipment and the customer needs to install it by himself, then we will also provide free remote installation guidance service, but we need to plan a good time, within our working hours. Our working hours are from 9 o’clock to 18 o’clock Beijing time

- We send workers to install it. This needs to be based on the size of the project. If we have been designated to install it in the early stage, the installation service abroad will belong to our scope of work, and no additional charge is required.

- If we need to send someone to install it temporarily, we need to provide different charges according to different countries, installation technical requirements, and different types of technical work. Welcome to inquire.

How to Transport the Equipment?

There are several types of transportation, sea, air, and express

- If it is a small device and requires fast speed, we can provide door-to-door service by air and express, the normal transportation cycle is 5-10 days.

- If it is skid-mounted or container equipment, it is more appropriate to use the shipping method. The normal transportation cycle is 20-40 days.

What ’ s Your Payment Method ?

Small equipment needs payment to delivery

For skid-mounted equipment and container equipment, 50% is prepaid, 30% is charged after video inspection, and 20% is charged before shipment.

Of course, we provide you with flexible ways of cooperation. Become our agents, and have more flexible support. Welcome to contact us.

D o You Provide Maintenance Services ?

Absolutely.

- NEWater provides free installation guidance and a one-year product warranty service. During the warranty service period, if there is an equipment problem, we provide free equipment repair or replacement services. If it is a manual operation, a fee will be charged. We can provide the required equipment replacement.

- We provide life-long after-sales service. NEWater has a full set of equipment and accessories, which can be replaced. Don’t worry about the failure of after-sales and maintenance.

- During the warranty period, NEWater provides all kinds of professional technical support, and if necessary. We also provide remote video guidance services.

- After the warranty period, NEWater also provides life-long after-sales maintenance, which requires a certain amount of manual service. There are also many matching accessories that can be replaced, so there is no need to worry about the later operation of the equipment.

Do You Provide Design Services?

Yes, we do.

For conventional small equipment, NEWater has standardized equipment. For large-scale skid-mounted and container equipment, we can design a process that meets the needs according to different water quality requirements.

At the same time, we carry out three-dimensional drawing designs according to different requirements and then communicate with customers to confirm.

After the design confirmation is completed, we then proceed to custom processing. So you don’t have to worry about our design and production capacity. We will provide you with the most professional technical support.

“This marine desalination unit has truly resolved our water issues. Its compact and lightweight design makes installation and operation a breeze on the boat. Even in rough seas, maintenance is straightforward, and we no longer worry about water supply problems.”

“This desalination system is a fantastic addition to our yacht. Its portable design is ideal for our space, and installation is straightforward. The easy maintenance ensures we have a reliable fresh water supply while cruising.”

“We’re veed wit ry pleas h this seawater desalination device. It’s highly effective at processing seawater, and its simple installation and operation make it perfect for our needs. The portability and ease of maintenance let us focus on enjoying our time at sea.”

NEWater – Your Best Manufacturer of Desalination Systems for Boats