The Improved Outboard Well

Replacing an inboard engine with a tilt-up outboard in a custom-built well.

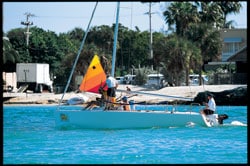

Atom’s extra-long-shaft outboard motor places the shaft nearly as low as the original prop in its aperture.

My 28-foot Pearson Triton, Atom , has undergone several extensive refits during our 40 years and two circumnavigations together. One of her major transformations included going from an inboard engine to an outboard motor well. Originally, she was equipped with a finicky Atomic 4 gasoline inboard that so disliked the salty marine environment and my inept care that it too often refused to do its job. I lived for several years with oil dripping into the bilge and the ever-present scent of gasoline permeating the cabin. The final insult came when it spit fire in my face as I knelt before its backfiring carburetor. I stubbornly refused to become a proficient mechanic, and the mulish engine made it obvious that it would accept nothing less. Being a committed engine-hater, our breakup was inevitable. My extremely limited budget at the time and my unwillingness to continue sharing my living space with any engine meant that upgrading to a more reliable diesel inboard was unthinkable. I’m glad now that my earlier poverty prevented me from making the common choice of converting to an inboard diesel because I would have remained ignorant of an auxiliary power solution that, as it turned out, better suited my needs.

After my first circumnavigation in the 1980s, I felt I had the seamanship skills needed for the challenge of sailing engineless, so I removed the burdensome beast and sailed across the Caribbean and Pacific in the rewarding pursuit of purely sail-powered passage making. Despite the successful engineless passages I made as I lived the romance of an earlier age of seafaring, I came to understand the very real limitations of engine-free pure sailing, one of which was that there were many ports that I could not safely enter or exit under sail or sculling oar alone. After a near shipwreck on a wave-lashed rocky coast when I was suddenly becalmed and then a terrifyingly close encounter with a tug and barge when becalmed one night in the Sulu Sea, I knew that the long odds of this high-risk game could catch up to me one day.

Eventually, I decided on a compromise solution by hanging a 3 hp outboard motor on an adjustable transom bracket. With the engineless sailing skills I now possessed, I used the motor sparingly, which was just as well because its limited power could only move my four-ton boat against the lightest winds and currents, and its short shaft meant the prop sucked air in even slight waves. Towards the end of my second circumnavigation, I began thinking of placing a larger motor within a well in the lazarette locker. The problem was that a larger motor just would not fit within the tight confines of the Triton’s pinched lazarette. For a few years, the optimal solution eluded me.

Years later, back in the US, I upgraded Atom with a 6 hp 4-stroke, 20-inch long shaft motor, which I used on a custom transom bracket on twin vertical tracks that permitted the motor to lift 18 inches for storage at sea. That setup gave me adequate power to stem the currents of the Intracoastal Waterway and ocean inlets, but steering the boat was awkward as I reached over the transom to operate the shifter and throttle. In its titled-up stored position it was also unsightly and placed the motor’s weight higher and farther aft than ideal for optimal sailing performance. A better solution would come a few years later as I experimented with different outboard well designs on a variety of boats.

When the motor is tilted up for drag-free sailing the sliding cover boards can be closed to restrict waves from sloshing into the well locker.

The outboard well enclosure on the Triton is raised but does not intrude on the benches.

Early versions

It has been over 20 years since I built my first seagoing outboard well in a friend’s Taipan 28 sloop while we were in Trinidad. That outboard well consisted of a circular hole in the cockpit lazarette locker—above the water on the hull’s centerline—surrounded by a plywood and fiberglass box. When not being used, the 2-stroke 5 hp motor was lifted out of the box and stored on its side in a cockpit locker, and a sealed lid secured to the box to prevent water from entering the locker. On a combination cruise and delivery trip, my wife and I successfully sailed that Taipan on an expanded Atlantic circle that took us from the Caribbean to Bermuda, Azores, Cape Verde, and Brazil. Along the way, the outboard well proved to be a workable system and a huge improvement over the transom bracket. But I felt there had to be an easier method of dealing with the motor when going from motoring to sailing.

An early version non-tilting well built into a Taipan 28. This worked OK for small, lightweight two-stroke motors but proved impractical when we switched to larger four-strokes.

This fixed well version had a fairing plug bolted to the motor skeg to reduce turbulence and water entering the well box.

At first I only built fixed (non-tilting) wells and used 6 hp motors with a long shaft. Most motors in the 4-6 hp range are the same size and weight with different carburetors so it makes sense to use the 6. In the Tohatsu/Nissan range the 8 and 9.8 are the same physical size and the 9.9 is the same as a 15 hp. The Yamaha has 8 and 9.9 of the same size. For most boats the Tohatsu 9.8 or Yamaha 9.9 is the maximum practical size and should provide acceptable performance for boats up to around 32-foot or 6 tons. I see the latest 2019 version of the Yamaha 9.9 comes with a shorter tiller handle and looks like it has a smaller lower cowling that means a smaller hole is needed in the hull. Looking at the online specs and photos it seems the extra long shaft high-thrust version weighs 115 lbs and has too large a motor mount to fit the motor well space so you’ll need to confirm the sizes before making this conversion. These motors come in three standardized shaft lengths commonly referred to as 15-inch short shaft, 20-inch long shaft, and 25-inch extra-long shaft. Those numbers are based on an old American measuring system for motorboat transom height, which does not relate directly to a sailboat installation. In practice, on a sailboat you want to use the maximum 25-inch shaft whenever possible.

Those early fixed-mount motors I built, such as on the Taipan, meant that when not being used the motors had to be lifted out and stored in a cockpit locker or on a pushpit rail mount. If left in place they added drag while sailing and risked getting corroded or fouled with growth while sitting at anchor. With the smaller and lighter 2-stroke motors it was not too difficult to lift the motors out for storage or put them back in the well when it came time to enter port. But those 2-stroke motors burned gas mixed with oil and spewed some of that oil into the air and sea. They have also become less available in recent years as environmental protection restrictions have increased. When I switched to heavier 4-stroke motors, I found it impractical to lift them in and out of the locker when underway, and they needed to be stowed carefully to prevent crankcase oil from running to places where it shouldn’t. With the longer 25” shaft lengths needed to optimize performance it was even less feasible to remove them for storage.

Before I go into the details of why and how an outboard well conversion may make sense for a particular sailor and a particular boat, it’s worth noting how today’s cruising sailboat is typically used. On nearly all large modern sailboats and even those smaller ones that are big enough to be considered comfortable and safe for coastal cruising, the inboard diesel engine is the heart of the vessel. On many cruising boats today, the sails are used as auxiliary propulsion only when conditions are ideal or the owner feels inclined to the extra labor involved. That is backwards to how I have always sailed. A couple of generations ago “auxiliary-powered sailboat” meant that the vessel had an unreliable and often underpowered engine as a secondary means of propulsion. As small diesel engine design advanced, sailing skills retreated. Admittedly, a high percentage of boat owners are satisfied with their modern inboard engines and accept their total reliance on them. I am not trying to find fault or convert them. However, I know there are many sailors out there like myself who prefer a workable alternative to the inboard engine and want something that is less costly and complex and puts them closer to the raw elemental experience of passage making under sail.

Electric propulsion (EP) is becoming more popular among do-it-yourselfers who are fed up with internal combustion engines. They have either traded off significant power and range ability or had a big enough boat to carry a large diesel generator, which partially defeats the purpose of going electric. Typical EP systems have motors that require 48 volts, while the boat’s electrical accessories and wind and solar charging are 12 volts. This configuration requires the complications of vulnerable electronic step-up and step-down voltage convertors. Even so, I remain enamored by the possibilities of EP, particularly when more efficient batteries become as safe, reliable and affordable as todays AGM batteries, or in cases where range beyond a few hours is not required.

In 2023 I had the opportunity to install dual gas/electric outboard motors on a Cape Dory 27 and on a Cape Dory 36. The owners had the choice of using the electric outboards or when they required extra range and power, switching the the gas motors. Results can be seen in the links near the bottom of the page. Perhaps a retractable electric pod with remote speed control would be possible on some boats. But because of the increased cost of electric propulsion systems with limited range, large lithium battery banks and complex dual voltage charging systems the proven modern four-stroke outboard motor is the most practical solution for most sailors.

Outboard well design elements

Over the years my outboard well designs have greatly evolved. It became obvious to me that the ideal solution was a motor that stayed permanently in the well and tilted up through a narrow slot in the transom for storage. I built these improved versions on different models of sailboats including three Pearson Tritons, a Tripp 29, an Able 32, four Alberg 30s, a Cape Dory 27 and Cape Dory 36 among others. On most of those boats and on two of the Alberg 30s I installed a SailPro 6hp Tohatsu with 25” extra-long shaft and high-thrust prop because the motor was a good compromise between weight, physical dimensions, and thrust. Most sailors who are used to having more powerful engines consider a 6 hp motor on this size boat to be underpowered. It’s true you can’t motor into strong winds and waves with 6 hp, but many sailors understand the trade-offs of going to higher horsepower and choose not to. On the third Alberg 30 I converted, the owner was keen to have more power, and I was able to make some modifications to the design to fit a Nissan 9.8. The extra thrust it provided has proved sufficient for the owner’s needs. He also appreciates the electric start, which is not available and not needed on most smaller motors. On larger boats such as the Cape Dory 36 and Able 32 you might be tempted to use a 15 hp motor. You will need to take careful measurements to confirm the fit and I would not choose the electric tilt option because it adds too much bulk and weight.

On an Alberg 30, which has a large lazarette locker and overhanging transom, the 6 or 9.8hp motors fit perfectly without the need to relocate the bulkhead.

With the motor raised for drag-free sailing or storage. If the prop ever gets fouled when motoring it’s a simple matter to tilt it up, reach over the transom, and clear it to get underway again.

Whereas the Alberg 30 has a generous lazarette of 34 inches fore and aft that can easily contain an enclosed outboard well, the Pearson Triton presented more of a challenge because of its smaller lazarette. My first outboard well in a Triton was an open-faced design, and the motor head overhung the rudder cap and tiller slightly when tilted up. Even though this design worked and was easy to construct, it did have a few drawbacks, such as the motor’s intrusion into the cockpit footwell when tilted as well as more noise and vibration to live with while seated in the cockpit. An open-faced well seemed less ideal than an enclosed well because the increased volume of the cockpit footwell combined with the open lazarette makes getting pooped by a rogue wave more of a concern. To mitigate that, the open well contains buoyancy chambers and it permits faster drainage of the footwell so I doubt it will ever be much of an issue. On later Tritons I pushed the motor aft another 1.5 inches and added structural stiffeners to what little remained of the aft deck and the transom above the motor shaft slot. This modification allowed me to enclose the front of the well while maintaining adequate structural integrity.

Because of their transom design, most boats are not suitable for an outboard well conversion. Good candidates are boats with overhanging transoms (stern counter) with 2–6 inches of clearance from where the motor skeg cutout will go in the hull and the resting waterline, and a keel-hung rudder that does not extend aft into the motor well zone. Another critical requirement is to have at least 30 inches between the transom where the motor shaft exits and the aft end of the tiller strap and rudderhead fitting. These requirements are met by some excellent classic boat designs that I have come to love. The Triton comes in at the minimum 30 inches. The Cape Dory 27 measures a slightly more manageable 31 inches. Larger boats such as the Alberg 30 and others already have ample clearance within the lazarette and do not require relocating the bulkhead. I’ve been in contact with owners of several other boats, including a Bristol 27, who have built similar tilt-up motor wells on their boats, based on my design plans. The concept and application of this modification have now been tested on many offshore passages including one of my Alberg 30 Voyager Editions that completed a circumnavigation in 2023, as well as ICW trips on several different boats. It is satisfying to know that several abandoned good old boats with blown inboard engines and other old-age issues have been resurrected and returned to service because of this cost-effective modification.

A functional outboard well design needs the following: sufficient prop depth to get a bite in moderate waves, a practical way to close off the hull and transom slot at sea, enough clearance from the hull cutout to the waterline to reduce back-flooding, and the largest possible buoyancy chambers built in to the lower portions of the well. Some builders may have produced a sensible, offshore-suitable boat with this type of enclosed tilt-up outboard well, but I am unaware of them.

Boats with fixed motor wells as options, such as the Cape Dory 25 and 26, Pearson Ariel 26, and Bristol 26 and 27, for example, were popular daysailers but were not attractive to most potential small boat voyagers partly because the motors are fixed in place, causing drag turbulence under sail, fouling, and corrosion problems. In my view, those designs are impractical, except perhaps if the boats are kept on freshwater lakes. If a slot is cut in the hull to allow the motor to tilt up and forward, and some other improved design details, most problems associated with old-style fixed outboard wells are avoided. An added benefit to having the motor shaft pivot up through a slot in the transom is that the hull shaft hole and transom slot can be surprisingly narrow and inconspicuous. The hull hole does not need to be as wide as the prop because it is taken off the motor with one nut, the motor placed in the well, tilted forward, and then the prop easily reinstalled by leaning over the transom. To remove the motor, the prop is pulled first.

In 2014, I figured out how to enclose a 6 hp Tohatsu SailPro on Atom by moving the center of the original lazarette bulkhead forward. It was considerably more work than an open well design, and it required pushing the motor mount position further aft and 1” higher than on earlier Triton conversions, resulting in a higher and more unsightly raised lid. Even so, I’m happy with the result, and the motor box lid serves as a good elevated seat or table. The motor pushes the Triton at 5.8 knots at full throttle in calm seas and is surprisingly good when punching into a light headwind and chop.

Fitting an outboard well to a Tripp 29 required modifying the aft cockpit by cutting out the lazarette locker.

The finished Tripp 29 outboard well.

Addressing the cons

Although my outboard well conversions have exceeded my initial expectations, a combination of factors have prevented outboard wells from becoming more popular. Market forces value push-button technology over age-old sailing skills. We are more inclined to power through nature’s elements than to bend to their will. The old boat restorationists are likely to cast a condemning eye on any classic boat that has had major modifications done to it, even if their authentic restorations of small to midsized production sailboats does nothing to make that boat more cruiser friendly or seaworthy. Others who have experienced the limitations of transom mounted motors or old-style fixed outboard wells as installed on small production sailboats have wrongly concluded that a better design with more care to functionality would have the same problems. Experienced sailors are by definition largely conservative and suspicious when it comes to altering their boats in a significant way. That is as it should be but if, like me, you have the sailing experience to make your own judgements on what is practical for your situation, you won’t feel constrained by the misguided opinions of those with differing views.

On many boats you have no choice other than to install a transom bracket. The disadvantages are that it is awkward to reach the shifter, throttle, and to turn it for side thrust to maneuver in a marina, it’s exposed to theft and is ugly, is more prone to getting the motor head dunked or the prop sucking air in choppy water, and the weight is farther aft than is ideal for best sailing performance. Also, if you have a centerline windvane then the motor needs to be on the corner of the transom, further degrading performance when the boat rolls or when it heels during motorsailing. On the other hand a transom bracket is a more simple installation and some boats transom design are just not suitable for an outboard well.

I have had one failed outboard well design that others can learn from. In 2008, on a friend’s Alberg 35 we replaced his very ill diesel that had been dripping oil into his bilge for years and driving him nuts with breakdowns. He did not want the diesel rebuilt or replaced: he wanted it gone forever. Because the Alberg 35 had a long and high stern counter, we felt it would be too difficult to get the motor far enough aft where the shaft could penetrate the transom when tilted up, but still be far enough forward to keep the prop in the water when in the motoring position. Our compromise experiment was to use a fixed, open-faced well kept as far forward as possible but with a 20” shaft Mercury 9.9 that could be hoisted out of the well with a tackle and laid on its side in the lazarette for storage. The result was an awkward arrangement and the shaft length proved too short to keep the prop from sucking air in anything but calm waters. The lesson there was that a fixed well for anything larger than 6 hp is unworkable and that the 25-inch extra-long shaft is the best choice. If I were to do it again I would insist on the tilt-up design and 25-inch shaft.

One of the disadvantages of outboard motors is that they are not designed for extreme long-term use, at least compared with the diesel engine. Experts have pointed out that outboard motors wear out sooner and require different, although simpler maintenance. Seawater does splash into the well in rough weather and can cause corrosion if the motor is not rinsed and lubricated occasionally. I never tried, but you probably do not want to depend on frequently running an outboard motor 24 hours a day. When I have had problems with outboards it was typically bad spark plugs or a clogged carburetor, both of which are easy to troubleshoot and fix. I now carry an entire spare carburetor to swap out in minutes if the jets become clogged. I can then go on my way and thoroughly clean out the clogged carb at my leisure. In the worst case of an unrepairable breakdown, you just buy another new or used motor, drop it in, and off you go.

The alternators available on outboard motors have very limited output so you must rely on solar or wind charging systems when away from marina shore power. Another limitation is that reverse thrust is limited on most 6 hp motor models perhaps because of the exhaust running out the center of the prop. You may have to wait for slack tide to exit your marina slip if the current is coming from astern.

Other often heard arguments are that diesel is much less explosive than gas and is more efficient for long range motoring. That is true. However, with my outboard well conversions the two portable gas tanks are stored in the vented lazarette next to the motor and sealed from the rest of the boat. Any extra gas cans carried to extend range are stored in the cockpit side lockers that are also sealed from the interior and bilge, making fire risk minimal. Typically, on a 30-foot boat you can expect roughly 10 miles per gallon with a 6–9.8 hp motor in calm conditions at three-quarters throttle. Carrying 15 gallons of gas will get you 150 miles, which is not much of a constraint for most sailors who know how to use winds and currents to their advantage.

If brute force motoring in rough seas is your primary concern, then the inboard diesel is the clear winner. In practice I have tested these motor installations in short choppy waves at an ocean inlet with up to 3-knot current against 15 knots of wind and had no problem with the prop coming out of the water. Beyond that, you may need to wait for a change in wind or tide. Most of today’s motors have an Over Rev RPM Limiter to prevent motor damage from a racing prop. I place the motors as far forward and low as possible and now only use extra-long shaft models that rarely have a problem of the prop sucking air. Even though they work much better than putting them farther aft on a transom bracket, due to the possibility of the prop coming out of the water and the relative low horsepower I do not attempt to motor in extreme wave conditions. Power, range, and keeping the prop always in the water are clear advantages of inboard diesels.

While it is possible to have stern-mounted dinghy davits that will clear the outboard motor in its tilt-up position, I don’t recommend them if there is a chance you will install windvane self-steering one day. If you already have a windvane installed, you may need to extend the mounting brackets so they do not interfere with the motor shaft. In addition, a swim ladder built into the pushpit will likely need to be relocated.

Another thing to consider is that if retaining the highest resale value of your boat is a primary concern then understand that removing the stock inboard engine will shrink the pool of prospective buyers and probably lower the boat’s resale value. On the other hand, a properly designed and built outboard well modification in conjunction with other mods and upgrades, were responsible for one of the Alberg 30s I refit in 2014 selling for a record price two years later to a sailor who appreciated the conversion.

This type of conversion may be beyond your current skills to tackle yourself. However, many people have obtained the dimensioned sketches, instructions and full size paper patterns from me in order to make the project go faster and with less errors and have either done the work themselves or hired a local boat repair person to build it for them. If you need the patterns for either the Pearson Triton or Alberg 30 you can let me know through this site’s Contact button.

The benefits

If you removed the inboard engine and all its components and laid them out on the ground you might be shocked at the amount of related gear that ran through the center of your boat and the valuable space it all consumed. The ubiquitous inboard engine’s many interconnected life support systems include cooling water plumbing and thru-hull fittings; separate engine starting battery and dual charging electronics; gauges, transmission and linkages; fuel tanks, lines, and filters that often clog or leak; a shaft penetrating the hull in an often hard to access place; and a propeller that is inaccessible and is prone to damage or fouling. Then there are all the specialized tools, maintenance materials, manuals and how-to books, and recommended spare parts to carry, particularly if you stray far from repair facilities. There is also the risk that the engine cooling water system or prop shaft stuffing box could fail one day and sink your boat.

The advantages of a properly designed tilt-up outboard well over inboards on a suitable boat include the following: 1. Less cost up front and for future maintenance. 2. Less weight and wasted space. 3. Reduced complexity, which makes for easier future motor replacement or repairs. You can take the motor to the repair shop instead of bringing a mechanic and all his tools to the boat. 4. There is no fixed prop to snag fish traps and nets under sail. 5. If the prop ever gets fouled or damaged you just tilt it up and clear it or replace it by reaching over the transom. 6. Sailing performance is noticeably improved by less drag and turbulence once you remove the inboard’s fixed prop and seal off the prop aperture between keel and rudder. The rudder will also become more efficient. 7. You have the ability to swivel the motor for side thrust when entering a tight marina slip. 8. An outboard well puts an end to inevitable diesel fuel and oil spilled into the bilge and their odors. 9. The self-contained outboard motor reduces holes underwater—no engine cooling water seacock and plumbing or prop shaft in a leaky stuffing box. 10. Because you no longer need to access a diesel exhaust and prop shaft and all the rest, you can now seal off all the cockpit lockers from the bilge, giving you the added safety of collision bulkheads and less chance of flooding. 11. There is no need for a separate engine starting battery and charging circuit. If you do want electric start, that is available on the 9.8 hp models. With pull start, a dead battery will not prevent you from starting the engine. 12. The motor does not radiate unwanted heat into the boat all night when you try to sleep in the summer or in the tropics after motoring. 13. A smaller motor has a smaller environmental impact. 14. Another benefit I recently discovered to small outboards is that if you upgrade from lead acid batteries to lithium type, it is much simpler and less costly because you don’t need a special engine starting bank, new alternator and the charging equipment modifications required for diesel alternators. The limited intermittent charging current on a small outboard alternator is not a problem for a normal sized lithium bank and you can manually turn off the switch if needed.

There are also intangible benefits to downsizing to a small self-contained motor located within an outboard well. The boat size restriction to still have adequate thrust with an outboard motor means you are compelled to have a modest sized boat instead of being lured into a bigger boat that might prove more work and expense to maintain than you want. The best boat is the smallest boat that will do what’s required of it. The more limited range and thrust of a small outboard teaches you to become a better sailor. You will find that as your sailing skills and experience in passage planning increase, there will come a corresponding decrease in the horsepower you need. After weighing the relative merits of outboards and diesels, each sailor chooses a system based his or her own needs.

Most cruising sailors are not going to switch from a diesel inboard to an outboard well conversion. However, if you don’t have unrealistic expectations and are looking for an alternative way to bring back to life a suitable older classic sailboat, the improved outboard well is worth considering. Perhaps more of those neglected but worthy old boats languishing in forgotten corners of boatyards because they have a blown or ancient inboard engine will now be rescued from the scrap yard.

This Able 32 had an open-faced outboard well added before it was brought to us. We rebuilt the well in an enclosed version.

The enclosed well we built for a 9.8hp motor in this Able 32.

Below is a list of boats that I have either confirmed to have useable lazarette lockers and transom overhangs suitable for a tilt-up outboard well or look like they will be suitable. There are many other boats such as the Taipan 28 and Cape Dory 25 and 26 that have less than 30 inches between rudder/tiller strap assembly and transom that are a bit too tight for a tilt-up well but can accommodate a fixed well. Or it may be possible to cut out and rebuild a portion of the center transom on boats that are lacking a 30-inch long lazarette.

1. Alberg 30 – Confirmed both 6 and 9.8 hp installed. This boat has the ideal combination of adequate lazarette size and overhang of transom on a boat that is large enough to be comfortable and capable offshore and small enough to be driven near hull speed with a small outboard. Contact me if you need full-size paper patterns and instructions for DIY. Video of Alberg 30 9.8 hp outboard well construction 2. Pearson Triton 28 – Confirmed 6 hp installed. This boat requires the aft cockpit bulkhead to be modified, which makes the motor well more boxy in appearance and the job more complicated than on an Alberg 30. Full-size paper patterns and instructions available for DIY. Video of Triton 6 hp outboard well construction Video of Triton 6 hp with a simpler open face design 3. Tripp 29 – Confirmed 6 hp installed and it looks like the 9.8 would also fit. This boat required extensive cockpit modifications but the results are excellent. Video of Tripp 6 hp outboard well construction 4. Able 32 – Confirmed 9.8 hp installed. This boat required the most extensive modifications but had a good result. Video of Able 32 9.8 hp outboard well construction 5. Cape Dory 27 – Confirmed 6 hp Tohatsu installed. We also fit an Epropulsion Navy EVO 3.0 electric outboard to this boat. Video of construction 6. Cape Dory 36 – Confirmed 9.8 hp Tohatsu installed. We also fit an Epropulsion Navy EVO 6.0 electric outboard to this boat. Video of outboard well construction Video of Cape Dory 36 outboard well sea trials 7. Bristol 27 – At least one tilt-up well for 6 hp has been built. 8. Pearson Vanguard 32 – At least one tilt-up well for 6 hp has been built. The following are unconfirmed but appear to be suitable: 1. Rhodes Meridian 25 – Some of these came from the factory with an outboard well. 2. Allied Luders 33 3. Bristol 32 4. Seasprite 28/29 5. Rhodes Chesapeake 32 6. Rhodes Swiftsure 33 7. Lello 34 8. Cape Dory 30 and 31 9. Cheoy Lee Clipper 33 10. Also, the Pearson 365 has been done. Here is an article on a Hybrid Gas Outboard Well / Electric Inboard in that boat.

I’m sure there are other models out there that can accommodate an outboard well so please contact me if you have additions for this list.

Part two – Adding a Tilt-up 9.8-hp Outboard Well to an Alberg 30

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Aquarius 23 Outboard In Cockpit Well

- Thread starter Capt. Seeweed

- Start date Apr 10, 2019

- Forums for All Owners

- Engines and Propulsion

Capt. Seeweed

I like the boat but the rudder engine set up is insane. The designer put the prop behind the rudder!! Putting the bow through the eye of the wind in a narrow space with only a couple of knots of head way is next to impossible. A 14 inch keel draft but the NON COLLAPSIBLE rudder draws bout 2.5 feet! And what do you do with the rudder/cassette block when lifted? It takes up the whole cockpit and leaves a huge hole in the cockpit sole. Im building a well in the cockpit for the engine and mounting a swing outboard rudder. Plus...the high topsides makes it impossible to get back aboard so the "V" in the transom for the current engine place will be an excellent boarding space.

Attachments

I had to build a little tool to construct a well for the clamping knobs and it will have a through hull drain with seacock.One of 3 thrust plates, Fore and aft running, vertical, rectangle shaped, glassed to thrust bulkhead, under cockpit and to the hull...the middle one will be fitto the underside of the clamping knob well for more center support. Im actually doing this so the boat will safely accept the forces and stresses of a 30 HP OB that will happen in the future.

Made up the walls today and cut the hull hole to size. I ordered glass and lay up resin yesterday. 1.5 oz mat for sealing and I already have plenty of nitex 1708 for tabbing. Im also eying 2 35 hp OB's... Mercy is also getting a full pilot house as well to be started in a week.

- IMG_20190411_161344288_BURST000_COVER.jpg 2.6 MB Views: 132

Project_Mayhem

You're putting a pilot house and possibly two 35hp OB's on a 23' sailboat?! You dont see that everyday. I'm definitely interested in hearing the results!

lol...no, one 35 hp ob...I want to be able to cover 100ktm during the day. The 8 hpMerc 4 stroke won't do that. Ill be west coast offshore between Washington and soCal. My swim platform is almost done. I have to mount that first before glassing in the well because access almost impossible after glassing in the well and the backing board for the platform is substantial.. Marcy is also getting bow and stern anchor platforms, hull stringers for added strength and stiffness and I Have moved the mast step further forward because now she is a ketch rig. Ill postmore pics later in the week when more progress is made.

Capt., I think you will find that the 8hp is sufficient to get you up to hull speed in most conditions. If you are concerned about extreme conditions, and getting there in the fastest time possible, no matter what, then I think a 9.9hp would do nicely. After all, she is a sailboat, and any power you carry above what gets you to hull speed is wasted. This is quite a project. Good luck.

Shes a motor sailor ketch now. 24 gal fuel in2 tanks plus jerry cans just in case. The pilot house will be framed in fur and covered with sheet frp laminate. Ill make tools to lay up glass for where the windshield turns between the pains of glass. No butting plywood together. My anchor platforms are made of teak as is the swim platform. Pics?...yes deff, as soon as I find my phone, lol.

Tom J Yeah, my 8 hp gets me to hull speed and will make, at full throttle, 6.5 kts but if a Cape Dory 28, 7000lbs displacement, can plane off with a 315 hp Yanmar, this boat, 2360 lbs dry, should plane as well.....to some degree...I hope. lol Ill be in rivers too so more hp is good for bucking a current. She should be able to make 10kts with 35 hp.

Swim platform done and attached. The motor is just sitting there for now to test and have a look. The sun lifted some mat down on the lower lip which Ill address. Im worried about how much water she'll scoop up at the aft edge of the well but I expect Ill have to make up a door in that area but all in all, I like it. I had to make up a rudder post log and am ready to glass that in. The rudder now kicks up. I am laying up a foam cored skeg and will attach it to the hull to protect the outboard and for better lateral stability too. She could use a little of that as well. Bow anchor platform done and attached. Stern anchor platform is done and ready for attaching. Because of the curve of the deck and for more strength, I cut a triangle at the bow and re-cored the area with 3/4" ply for the anchor platform to bolt through. I also had to build a mount for said platform out of mush, 1708, mat and colloidal silica then added a piece of 1" 316 ss tubing for support. The bottom end not yet bolted. Bolts in roller piece too. I know the engine sticks down a little to far but it is a long shaft. The next, larger engine will be regular length of 15" and yes, Ive got some sanding and touch up painting to do too. 6 months at Lake Havasu, anchoring every night and having to bring Abbygale to shore for pee and poop 2 times every day. 2 anchors and together about 150 feet of 5/16" chain. I switched to all chain after a beaver ate my stern anchor rode AND my brand new transom mounted sonar transducer cable. I mounted the new transducer inside. I also removed the old pivot pin in the centerboard, 3/8" and replaced it with a 7/8" bolt. Yeah...it was a lot of fun drilling that out with a hand held drill motor.

My first mate Abbygale.

Should be a fun boat for the lake. I would hesitate to bring her onto the ocean, though, with all those modifications.

Tom J said: Should be a fun boat for the lake. I would hesitate to bring her onto the ocean, though, with all those modifications. Click to expand

Capt. Seeweed said: I agree to a limit. So,what are your concerns? The A23 is hand layed up with mat and woven roving and has a rating from the manufacturer of occasional coastal cruising. At the keel, the hull is 5/8th" thick and almost 1/2" at the toerail. She is self righting even with the board up but I would feel better if she had stringers above the bunk in the first half of the boat. Thats coming. She does have a full top to bottom right to left full bulkhead, with a door, that I built and glassed in, midship. I also installed a 7 foot long counter to starboard. Shes already much stronger than stock. I am also going to install a bulkhead forward of the engine athwartship, to the seat level, with a door for the engine tiller, to keep water from entering the cockpit in rough weather. The engine will eventually be enclosed. Mercy is set up for cruising. I do cruise her. I am a full time liveaboard. Hey Tom, I lived in New Bedford for 37 years. Lol, we're homies. Click to expand

Yeah, I hear ya. Those are valid points. It will be an ongoing process. Ill have all that addressed by the time I arrive at the Great Lakes and I intend to pick my days for sailing but yeah, shit happens. Monday, Im headed to Downieville, Ca on The Middle fork of The Yuba River for a month then to Sioux City Iowa where the Salmon River becomes navigable then to the Mississippi then to Lake Michigan then?....who knows.

Capt. Seeweed said: Yeah, I hear ya. Those are valid points. It will be an ongoing process. Ill have all that addressed by the time I arrive at the Great Lakes and I intend to pick my days for sailing but yeah, shit happens. Monday, Im headed to Downieville, Ca on The Middle fork of The Yuba River for a month then to Sioux City Iowa where the Salmon River becomes navigable then to the Mississippi then to Lake Michigan then?....who knows. Click to expand

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

Backyard Dory

Backyard boatbuilding and other adventures.

I’m getting old and can only row so far for so long. My two daughters, Samantha and Allie, haven’t ever rowed anywhere before. Because of this, we decided to cut a giant hole in the bottom of our beautiful boat so we can install a small outboard. This step of the build was certainly the most nerve-racking. We put so much effort into ensuring the boat was built tight and leak-free; what sane person would cut a giant hole in a perfectly good boat?!

Alas, we were determined to have outboard power for our dory. So we schemed a way to add a motor well. Before doing so, however, I scoured the internet for the best way to install a motor well, focusing on sizes, locations, depths, etc. It was obvious from my research there are two motor well camps: those that find them useful and those that don’t. During my searches, I came across side-mount outboards, which seemed like a good idea, but I was concerned because the waters where I’m going to use the boat will get relatively rough and I didn’t want to have a 40 pound outboard hanging over the side of the boat. I liked the idea of having the boat inboard the hull, on centerline, and easily reachable.

As such, I bought an outboard. I figure this 3.5 horsepower Tohatsu will be more than enough power, and it was just a few bucks more than the 2.5 horsepower and the same engine that just rev’s higher, so I splurged. At 40 pounds, I can easily move it around, so it seemed like a fitting choice. I wanted to have an outboard with a larger external fuel tank, but seeing as I won’t have to run it at full throttle, I imagine the small internal tank will last me long enough between refueling.

The next decision was whether or not to build a motor well that allowed the outboard to kick up into the well. I toyed with the idea, but in the end, my dory just seemed too small to take up so much space with a kick-up outboard well, so I didn’t build it that way. Plus I figured my dory won’t go faster than about 4 or 5 knots, so even if I run into something submerged or hit a shallow bottom, I’m not going to break anything (other than maybe a plastic propeller that I can easily replace). So I kept the motor well simple: a squarish hole in the bottom of a perfectly good boat with raised sides that kept the water out and the outboard supported.

Having the outboard on hand really helped this process, and I pulled measurements directly from the motor as I progressed. The design plans I had did not have specific well measurements, so I was truly building from scratch at this point. Not a huge deal and it was easy to piece things together as I went along. This outboard spins 360 degrees, so I made sure that I took measurements with the outboard in a multitude of positions so that I had enough clearance to spin it in a full circle. That made for a little larger of a well than if I didn’t use a 360 degree spinning outboard (i.e. used one with reverse gear), but not too much larger.

I decided to put the outboard just behind the fourth frame of the boat. Aesthetically, it seemed like the best spot, so I went for it. Measuring carefully, I transcribed the dimensions I needed from the actual outboard onto pieces of plywood that would serve as the sides of the motor well. I decided to make the back of the motor well at an angle in order to minimize the amount of water that either splashes or plows its way up the backside of the well.

Once the two plywood side pieces were cut, I sanded them as one unit so they were exactly the same. The last step for the sides was to make sure the bottom curvature of the boat, or rocker, was accurately transcribed onto the bottom edge of these side pieces. With the rocker roughly drawn to shape, I cut and sanded the bottom portion of these side pieces so that they conformed to the rocker on the bottom and sat level and plumb at the top.

With the side pieces in position based on my end-to-end measurement of the outboard’s lower unit as it rotated through 360 degrees, I spaced the side pieces appropriately and drew the lines onto the bottom of the boat that marked the hull cut that would soon be the opening for the motor well.

I can tell you that I sat and stared at these lines for some time before I even plugged in my saw. Then I measured them again just to be sure. Then I broke out the saw. And then I measured them again!

And the moment of truth was upon me. Time to cut a giant hole in the bottom of my perfectly good dory. I utilize a jigsaw and an oscillating saw to carefully cut along my markings. Drumroll please…

With the drama of the hole being cut behind me, I pressed on with the installation of the motor well. Using spacer pieces of scrap lumber and several clamps, I positioned the motor well sides into place and made measurements for the front and the back pieces of the well. Once measured, I cut them out, sanding them to fit, and readied them for installation.

With the front and back pieces ready to be installed, I applied them, one at a time, bedding each in a solid mix of thickened epoxy. Once the epoxy set, I removed the temporary bracing and the motor well was complete!

I ended up adding a 2×4 to the front of the upper edge of the motor well so the outboard had a little more substance to bite into when I tightened down its mounting screws. You can see the addition in the pictures below when I test fit the outboard. It ended up fitting perfectly and I can only imagine the smile on my face finally having my mechanical oar in place! Yes, I did sit in the boat with the motor installed and made motorboat noises!

With a finished motor well, it was time to finish the fiberglass work and then paint the inside of the boat ! Click each area to see how Elizabeth Lynn ends up!

4 thoughts on “Motor Well”

Hi Kevin, I have a client that wants a motor well in his Nova Scotian 4.9 Grand Banks Dory I came across you building blog and you have done it successfully, I will be fitting a Suzuki 2,5 Hp Is there any possibility for you to send me your dimensions and angles of your well. I enjoyed looking at your build you have some good techniques. Kind regards Paul

Doesn’t appear to have room to tilt up the prop!

Tom – you are correct! No room to tilt up the prop; I didn’t want to take up any more space than I had to inside the boat. My solution was to get an outboard that only weighs 40 lbs. If I need to move the motor, I simply unscrew the transom clamps and pull the motor out of the well and into the boat! Pretty easy and has worked well.

Paul – I’m not sure if you will ever check this again since it has been almost 2 years since your comment, but if so, please reach out again and let me know the best way to send you the information you requested!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

- Search forums

- Practical Boat Owner's Reader to Reader

Advice on choosing outboard for sailboat with engine well

- Thread starter Samoddie

- Start date 7 Feb 2023

Hi, I am hoping to replace my existing outboard in my 22 foot Anderson. The boat has an engine well, and I am advised by a fellow Anderson owner that the width of this restricts brand choice. This directs me to Mercury Mariner. The agent I have been in touch with has suggested I buy a sail drive, but these only seem to be available in long shaft, which undermines the point of engine change (I want to be able to stow the engine in the relevant locker while sailing). Arguments for ‘saildrive’ seem to focus on 1) presence of charging coil and 2) prop/ engine/ revs/ boat speed. 1) would be nice, although it must be said I blew my solar charge controller last time connected my current engine up! 2) I don’t really understand. I can understand that there is some kind of theoretical advantage. So, my question is - how much does it matter to buy an engine configured for a sailboat? My interest is in having a way of staying safe when there is no wind, or a horrible current/ traffic etc. But I am not really buying outboard for long distance cruising under powere - that would be a bad outcome! What do people think/ know from experience? Thanks Sam

ePropulsion

Electricity very attractive, but not much mains power where I am, and I have determined that petrol better suits my purposes in this instance. Not like car…

Well-known member

An outboard gives it’s rated power at a certain rpm band, and that is usually it’s max rpm, usually described as Wide Open Throttle WoT. Different pitched propellers give different WoT rpms depending on the load. Most small short shaft outboards are sold with props suitable for tenders, and on a heavier boat they won’t achieve their best WoT hence rated power, unless you buy a shorter pitched prop which will allow the motor to rev high enough. Fairly easy to calculate on larger motors that have tachometers, but on a little 4-6hp typical, you need a strobe light to see what your WoT is compared to what it should be. Sail drive outboards typically come supplied with shorter pitched props.

Samoddie said: Hi, I am hoping to replace my existing outboard in my 22 foot Anderson. The boat has an engine well, and I am advised by a fellow Anderson owner that the width of this restricts brand choice. This directs me to Mercury Mariner. The agent I have been in touch with has suggested I buy a sail drive, but these only seem to be available in long shaft, which undermines the point of engine change (I want to be able to stow the engine in the relevant locker while sailing). Arguments for ‘saildrive’ seem to focus on 1) presence of charging coil and 2) prop/ engine/ revs/ boat speed. 1) would be nice, although it must be said I blew my solar charge controller last time connected my current engine up! 2) I don’t really understand. I can understand that there is some kind of theoretical advantage. So, my question is - how much does it matter to buy an engine configured for a sailboat? My interest is in having a way of staying safe when there is no wind, or a horrible current/ traffic etc. But I am not really buying outboard for long distance cruising under powere - that would be a bad outcome! What do people think/ know from experience? Thanks Sam Click to expand...

Fine pitch prop as in sail driver gives max thrust at low boat speeds. it should be possible to buy a fine pitch prop for standard leg length o/b. However fine pitch means higher RPM at no wind cruise speed. While in no wind a standard pitch (course) will still move the boat along nicely like 5knots at low rpm lower noise. But if you find you need to bash into strong winds and waves you might appreciate the fine pitch more thrust option. Charging coil to my thinking on a sail boat is pointless if you don't use the motor much. ol'will

LittleSister

You don't need strobes. It's a fact of life that 'regular' small outboards will have props suited to a small light high speed load and will not be able to produce anything like their rated power when driving something like an Anderson 22. You can buy (at a price) an alternative prop for some outboards which will better suit your purpose (i.e. you do not necessarily have to get a 'sailpower' one to get an appropriate prop), but the correct length (standard or long shaft) is also important, and an effective charging coil is a boon. To the OP I'd suggest he considers carefully the recommendations of experienced existing A22 owners, and whether the outboard could be accommodated: Could the locker be extended, or a hole (with lid?) made in it so that part of the outboard projects out of it.? Could an arrangement be made by which the outboard is supported above the well and out of the water? If the storage is only for when the boat is not in use, could it not go on the cockpit floor, with some means of securing it against theft (padlock & chain? bars between the cockpit seats?) and a (loose?) cover to protect it from the elements? I'm not familiar with the Anderson 22 outboard set up, but from my experience with a Hurley 22 (which I cruised extensively) with outboard in a well, I'd caution against getting an outboard so big and heavy its difficult to get into and out of the well position (I ended up leaving the outboard in position even when the boat was unattended, just lifting it now and again to clear it of fouling). In my case not only did the size of the outboard (8hp 2-stroke twin, IIRC) make it difficult and unpleasant getting the outboard in and out of position, but it prevented the outboard from being turned from once side to the other at all, which would have been useful. The prop was not suited to the boat, so I didn't even have the benefit of the power of the larger outboard. Had I had the available money I would have bought a smaller outboard for it, with a long shaft, low speed high thrust prop, and a decent charging coil (the lack of the latter was a pain in the backside for cruising). Good luck with whatever you choose.

Hello Sam, welcome to owning the best and fastest boat ever! ;-) I use a 5hp 2-stroke Mariner which will push Rum Run along at 6kn when the bottom is clean. It lifts out of the well quite easily. If I had to use a 4-stroke , I would look very carefully at the weights of 5hp and 6hp outboard and not choose a big weight penalty to gain a mostly pointless 1hp. In calm weather, the boat will move with a Seagull Featherweight pushing her - slowly. This engine is barely 1hp /45lbs of thrust. In not calm weather, you can sail! Actually going into a river entrance dead upwind against a tide sometimes needs the 5hp. I am always glad to turn the noisy object off though. Don't bother with a charging coil, they don't have enough output. Put a semi-flexible solar panel on the hatch or hatch garage or both....... I have found that if motoring up tide, pulling the keel up helps quite a lot.

All well and good ... but at end of day the real practical difference of props is academic. I have and my Father had various boats with outboards ... approx half were Saildrives .... My Alacrity 19 and Snapdragon 23 - both had 'normal' and 'saildrive' version O/bds while I owned them .... did I notice any real difference ? Actually no. My Kormoran has a Johnson 5hp 2str ..... admittedly only 17ft ... but more than enough for anything. I do say though ... the Saildrive O/bds were heavier due to different gearbox ... especially the Mercury I had on the Snapdragon. To OP ... with it being an engine that will be used for departure / return to mooring or those no wind days ... I suggest measure the leg length needed to clear hull to drive the hull and just go for a decent brand ... not worrying whether S/D or not. As Rum Run shows ... a typical 5hp does the job ... and even though a 2str may not be so economical as a 4str .. its generally lighter, smaller and easier to look after .. (means searching the 2nd hand ads of course !)

Thanks all. Storing a bigger engine is comprehensively not an option, unles inside, which defeats part of the object of new engine. 2 stroke would be ideal, but another objective is high degree of reliability, which is not something outboards are famous for in my limited experience. Sounds like non saildrive IS reasonable option. Shame about coil - I already have 60w solar on homemade fibreglass garage - which worked very well last summer. Really helpful.

I had a long shaft 5hp outboard on a bracket on my kestrel 22. It was ok in flat water but a waste of time in any chop as the prop was out of the water on every wave and we couldn't make much headway. I guess it would be ok in a well

Samoddie said: Thanks all. Storing a bigger engine is comprehensively not an option, unles inside, which defeats part of the object of new engine. 2 stroke would be ideal, but another objective is high degree of reliability, which is not something outboards are famous for in my limited experience. Sounds like non saildrive IS reasonable option. Shame about coil - I already have 60w solar on homemade fibreglass garage - which worked very well last summer. Really helpful. Click to expand...

38mess said: I had a long shaft 5hp outboard on a bracket on my kestrel 22. It was ok in flat water but a waste of time in any chop as the prop was out of the water on every wave and we couldn't make much headway. I guess it would be ok in a well Click to expand...

Praxinoscope

I know that trying to buy a new 2 stroke outboard is a bit like trying to buy alcohol in Iran, but the recommended engine for a 22 in the Anderson Association website is something like the 5hp 2 stroke mariner. The boat was designed to have a relatively lightweight engine so that is was possible to lift it out of the well and store in the transom locker when sailing, the problem now is that 4 stroke engines are heavy and not so easy to lift out of the well. With respect to Tranona, #5 saildrive is great for some boats, but not sure it’s suitable for the Anderson. Maybe best solution ix to look around for a good condition s/h 2 stroke 4 or 5hp and fit a solar panel as suggested by rum run in #8.

Praxinoscope said: I know that trying to buy a new 2 stroke outboard is a bit like trying to buy alcohol in Iran, but the recommended engine for a 22 in the Anderson Association website is something like the 5hp 2 stroke mariner. The boat was designed to have a relatively lightweight engine so that is was possible to lift it out of the well and store in the transom locker when sailing, the problem now is that 4 stroke engines are heavy and not so easy to lift out of the well. With respect to Tranona, #5 saildrive is great for some boats, but not sure it’s suitable for the Anderson. Maybe best solution ix to look around for a good condition s/h 2 stroke 4 or 5hp and fit a solar panel as suggested by rum run in #8. Click to expand...

Active member

On Achilles 24, little bigger boat, I was happy with 3.3 Mercury 2 stroke. Gave boat enough power to motor around local area, with occasional longer motoring. It is thirsty though - at least 2 liters per hour. If you really need an outboard for getting in/off mooring, I would consider 2 stroke 3.3 Mariner/Tohatsu/Mercury. Mine was properly serviced before I bought it and haven't had an issue with starting or so for 4 seasons - now I am planning to service it, although I use it only for dinghy now. It is simpler than any 4 strokes - fewer things to go wrong, lighter - so easier to take out during sailing.

I used to have a 1,500kg, 24ft boat with an O/b well. For the use of getting on/off the mooring and running for <15 mins a time a Yamaha 8hp worked well but was probably overkill. Once sailing, taking the O/b out and the well plug in gave us about an extra knot of boat speed. Nice and easy to take the o/b home to service in the comfort of the garage too. As a set up for a small boat, it is highly recommended. However, we took that boat through the forth/clyde canal once - having a 2stroke in a well in the cockpit is seriously loud when you motor for more than a few minutes at a time. Standing next to it for 6 hours and I was ready to chuck it in the canal! If you plan to motor for any more than just in/out of the harbour before getting the sails up, I'd get the quietest 4stroke it's possible to get. If however you just want to run it in/out of a harbour then if I had my time again, I would have an electric outboard and take the battery home after each day sail to charge at home...

doug748 said: My only doubt about 2 stokes, in a well (which I have used a fair amount, big and small), is the degree of smoke you have to put up with if motoring in light following winds, plus they can be noisy. Click to expand...

Surely this Tohatsu (the Maker of Mariner) is what you want: 6HP TOHATSU MFS6D Short Shaft Tiller 4 Stroke Outboard EXTRA Carry Handles 26kg! | eBay

Other threads that may be of interest

- emmanuelkatto

- 20 Aug 2024

- Yacht Racing, Tech and Design

Members online

- Laminar Flow

- usernamesteve

- rogerthebodger

- Seashoreman

- terrysquires

- Irish Rover

- Graham_Wright

- munster1967

- Slipstream 34

- double_ender

- Wandering Star

- RunAgroundHard

- madabouttheboat

- Fr J Hackett

Share this page

Log in or Sign up

You are using an out of date browser. It may not display this or other websites correctly. You should upgrade or use an alternative browser .

Outboard Well

Discussion in ' Boat Design ' started by Matthew , Mar 24, 2004 .

Matthew Junior Member

Can anyone let me know the drawbacks of an outboard well? It is on a sailboat, and only used as auxillary. Ive heard a few designers (Bolger, Dias) slate them, but not give reasons (in the text I read). Can anyone help? Matt

PAR Yacht Designer/Builder

Outboard wells on sailboats can clutter up the cockpit, If not vented well can rob the engine of good air and make for rough running and stalling, they have a great deal of drag in most designs (not good on sailing qualities) The heat can build up in the area to a surprising amount, complicated additional structure to have this feature adding weight, building time and costs. Working on the engine in this space is limited at best. Depending on power requirements, any boat needing 10 or more HP should really consider inboards, where a whole new can of worms opens up for the designer and builder, but in general a better arrangement for propulsion. They do leave the transom clear of bracket hung engines and the weight in the worst spot you'll find to hang the beast. They do operate with a much reduced noise level in a well, they are less likely to get stolen or damaged, then hanging on the transom. As with all elements of boat design, compromises are made and lived with. Wells have their place, but I don't like them much on sailboats when a trolling motor or kicker can be used then stowed. If the boat has enough displacement to want for some HP then the inboard is the way to go. I know a guy on Marco Island that uses a 24 volt electric motor out of a washing machine and a couple of batteries to run down the river to the races on the weekend. His motoring time is about an hour 'round trip and the batteries trickle charge 'till needed again the following week. The Atomic4 in this 25'er took a dump and he's saved a bunch of weight by removing it and using the electric brew of his own invention.

Thanks PAR, Its a double ended design, which is why we are doing it. She also has a small amount of overhang at the stern, which means the hole in the hull is above the waterline and so less draggy. Am a bit concerned about the overheating, as by necessity the cut out in the aft deck is a close fit. Its a 2-3HP engine, a 17foot epoxy ply daysailor - about 400lbs weight. Does anyone else have or know of problems with outboards in wells, like overheating or lack of oxygen? Cheers Matt

Robert Miller Junior Member

In general, I would choose to avoid creating a well with a resultant hole in the bottom somewhere... for all of the good reasons stated by others above.... and, it's just too complicated for my simple mind. In small sailboats with transoms, I favor a stowable small outboard in a purpose built compartment. Hang on transom when needed, and stow when under sail or oar. I've had this arrangement on a boat as large as 26 feet, and liked it well. In small double-enders, I would rather not have the weight of the engine all the way aft. Also, I don't wish to put my weight that far aft as I shift myself and the engine into position just to mount the thing on "something", - with the resultant reduced stability. There is a better solution. On such a small double ender, the engine belongs just aft of amidships. Create a dedicated stowage compartment (perhaps under a side seat, somewhere near amidships). An arrangement to extend a mounting board across the gunnels and secured in position is needed. This must be designed for the particular boat, and supported as needed. A plank for this or other mounting hardware should also have dedicated stowage arrangement when not in use. Nothing permanent is in the way of sailing or using oars at any time. When mounted, the engine's weight is where it belongs, and so is yours. Steer with the boat's usual tiller/rudder. And...(another thread at a yahoo small boat group has recently been disccussing this)... keep the engine small and light. EVERYTHING about that engine then becomes easier, and more handy. 2 HP can do most of what we need on the sort of boats we are considering. I'm afraid the power of fashion has led some of us to believe we need larger engines than can effectively be used! Carrying unused and unneeded horespower just makes stowing and using the engine more difficult, and provides no benefit in return. Robert

- Advertisement:

mike Johnson Guest

guest I agree with most of what has been said-but it is possible to have a good outboard well if it is designed in from the start - a good example is the Joker range of epoxy ply trailer sailers in NZ.the larger 24 ft model has a vertical slide -hoisted by a small block and tackle-that lifts the 10hp motor-it can then be tilted forward and a tight fitting ply "plug"inserted -held in place with turnbuckles-this keeps 99% of the water out.When raised the outboard is in its own locker,lying horizontally fore and aft. The hole for the OB is right at the stern(about3inches from the transom from memory) and is oblong-in its normal sailing mode the hole is clear of the water (just) but this depends on loading,speed of sailing etc.It is important to have an air hole(2 x3 inch) if you put the hatch cover on.The well is spacious so it does not get hot,has a big air volume and you can fiddle with the motor or lifting system without being cramped for room. This boat is intended for local cruising in reasonably sheltered waters-has a large rig(big main) a lead weighted cb(about 100lbs)plus about 700lbs of dumpable water ballast and carries a big range of cruisng essentials and toys-hence the biggish motor.The beam is 8ft 4" and about 7ft at the tuck to give more displacement for the motor et al as well as the normal 4 crew. However for a 17ft lightweight boat a 2 or 3 hp motor on the stern is a much easier option unless you have strong tidal waters or have more than 4 people onboard.I suggest mounting the ob directly on the stern using a tight fitting ,removable wooden block with rubber mounting-small engines vibrate alot and you dont have much mass to absorb the vibs.6 mm hard rubber is sufficient.Give the rudder plenty of room to swing and use the rudder to stear.If cracks show in the woodwork then you may need to put on some more glass tape and epoxy. Mike

I/O to outboard conversion on 18' Aluminum

after upgrading to a a15hp outboard my boat doesnt plane well

4 hp outboard torque

converting I/O to Outboard

Back of boat too high for outboard

Outboard brackets and displacement speed

Stagnation Point w/ trim tabs and outboard brackets

why aren't there fast planing sailing dingies able to take outboard motors?

What does an outboard cavitation plate actually do.

Help with outboard bracket design

- No, create an account now.

- Yes, my password is:

- Forgot your password?

- AROUND THE SAILING WORLD

- BOAT OF THE YEAR

- Email Newsletters

- America’s Cup

- St. Petersburg

- Caribbean Championship

- Boating Safety

- Ultimate Boating Giveaway

Lightweight and Small Outboard Motors for Sailboats

- By Ed Sherman

- Updated: April 22, 2019

When you’re facing strong winds and you need to get somewhere fast, it’s time to break out a small outboard such as an aluminum genny. A dependable outboard that has enough horsepower to get you to the racecourse and back, yet is light enough not to be a drag on your race results, is invaluable. Most racing sailors don’t need as much horsepower as they might think.

An eight-horsepower outboard, for example, will push a 30-foot, 6,000-pound boat along at 6.5 knots. Anything bigger will weigh more than 90 pounds and isn’t suitable for lifting on and off the stern. Here’s our roundup of some of the best outboard motors for sailboats, and some help in deciphering what’s right for your boat.

We focus our attention on engines available under nine different brand names. Two of the best-known names, Johnson and Evinrude, have dropped out of the small-engine end of the market as part of parent company Bombardier Corporation’s restructuring of these two companies. Currently they’re advertising the availability of six- and eight-horsepower four-stroke models in 2003. Another dropout in the mini-engine market is Suzuki. Their smallest two-stroke is a five-horsepower unit and in the four-stroke configuration, a 9.9 horsepower. Brand and corporate shuffling aside, of particular interest is whether the companies that are building nine horsepower- and-below engines have incorporated four-stroke technology into the lower horsepower range, since it’s now beginning to dominate the mid-sized and larger outboard engine market. The answer to that is yes, to a point.

Two or Four Stroke Outboards for Sailboats

Outboards are either two or four-stroke engines, and the four-strokes have definitely gained favor in recent years for several reasons: they’re quiet, they use much less fuel, and they run more cleanly. Since no oil is mixed with the fuel, the classic two-cycle smokescreen isn’t a factor. In a four-stroke, the piston reciprocates inside the cylinder four times for each power stroke (that is, each time fuel combusts). Rather than opening ports cut into the sides of the cylinder, intake and exhaust valves controlled by a camshaft allow a fuel/air mix to enter the combustion chamber with the suction created by the piston as it moves inward in its cylinder. Exhaust gases are forced out of the cylinder as the piston moves outward.

By carefully designing the camshaft, engineers minimize the amount of time that the intake and exhaust valves are both open, considerably reducing the amount of unburned fuel that exits with the exhaust stream. The end result? Fewer emissions and greater economy.

But they do have at least one distinct disadvantage for the racing sailor, and that’s weight. For example, four-stroke engines in the five-horsepower category are about 20 percent heavier than comparable two-stroke engines of the same horsepower. The good news, however, is that only amounts to between 10 and 15 pounds, depending upon the engine. Four-stroke engines cost more, also, but the improved technology may be well worth it.

If you’re totally weight and price conscious, you’ll want a two-stroke engine. But, if you think you can lose the weight elsewhere, a clean, quiet four-stroke without the hassle of mixing fuel could be the answer. In fact, Mercury/ Mariner’s newest six-horse four-stroke engines are actually 18 pounds lighter than their older two-stroke equivalents–a testament to the benefits of improved design and technology.

Environmental regulations are pushing manufacturers towards four-strokes as well. Four-strokes meet emission control standards, and US Environmental Protection Agency regulations mandate that new outboard and personal watercraft engines reduce engine hydrocarbon emissions by 75 percent by 2006. Environmentally conscious sailors should look for either a C.A.R.B. (California Air Resources Board) “very-low” or “ultra-low” designator, or a specification indicating 2006 EPA compliance.

How Much Horsepower Do You Need?

The amount of power you’ll need depends on several key factors. The first consideration is the weight of your boat. The second is the boat’s wetted surface. Full-keel boats not only weigh more but also have more surface area to push through the water. My rule of thumb here is to start with a two-horsepower engine for small centerboard and keelboats less than 1,000 pounds, and add one horsepower for every 1,000 pounds of displacement. For more exact, albeit complex formulae, I suggest The Propeller Handbook by Dave Gerr (McGraw-Hill 2001).

Compare your boat’s dimensions against what existing classes have found to work; for example, a Melges 24 at 1,650 pounds is typically rigged with a three-horsepower short-shaft engine, while a J/80 at 2,900 pounds can still squeak by with a long-shaft, three-horsepower engine. A 1,790 pound J/22, on the other hand, typically uses a four-horsepower long-shaft engine. On the larger end of boats using outboards, you’ll find the outboard version of the J/29, at 6,000 pounds, requires a 7.5-horsepower long-shaft engine.

If you are intending to do some cruising, or even long deliveries to regattas, an option that’s available on some engines is a high-thrust propeller. On larger boats, this option can save weight over a bigger engine and really make a difference when trying to punch through a strong tide or headwind. High-thrust props cost more and are less fuel efficient–but they can save weight and give you more power.

Once you’ve determined how big an engine you’ll need, the next step is to begin comparing features in the given horsepower range you’ve selected. There are nine manufacturers included in our roundup, but some of their brands are identical products with different labeling. In the smaller sizes, the Mercury and Mariner brands are identical. As for the Nissan and Tohatsu engines, Tohatsu builds them all. Yamaha, Suzuki, and Honda all offer competitive products as well, but they’re all independent brands.

What to Look For in Lightweight Outboard Motors

In the small engine sizes, specific features to look for can be reduced to several key items. For some, having an integral fuel tank will be important. The smallest engines have integral tanks that hold only a quart or two of fuel–good enough for an hour or two of operation. No manufacturer lists fuel consumption because the size boat the engine is pushing and the wind and wave conditions vary widely. Compare the size of the tanks, and whether you can attach a remote tank for longer trips. The extra weight and space of a separate fuel tank will be a burden on smaller ultra-light boats.

The availability of long- and short-shaft versions in the horsepower size you need is also important. Honda for example offers 20 and 25-inch transom height (long or short shaft) right down to their smallest BF2 (two-horsepower) model. Mercury and Mariner only offer a 15-inch short-shaft version on their 3.3- and 2.5-horsepower engines. Shaft length is measured from the top of the bracket to the tip of the shaft–make sure your shaft is long enough to position the propeller and cooling water intake deep enough below the waterline to avoid cavitation when the boat pitches through waves.

Other specifications that are worth comparing are whether the engine is equipped with a simple forward and neutral gearshift or if the unit has a full functioning forward-neutral-reverse gear unit. If you’re going to be doing long deliveries to regattas, or in the larger sizes for a racer/cruiser configuration, consider whether or not a charging system is part of the engine package, and if so, it’s output. Will it be adequate to keep your battery recharged and power things like a tiller pilot and running lights? Also, on the larger engines check to see if electric starting is available, or offered as a standard feature. Having it can be the difference between pain and pleasure.

If you are racing in a strict one-design group, check any class rules that apply to outboard engines. Issues related to brackets, storage of the engine and/or alternative weight might be issues, so be sure to check with your class before making any final decision.

Ed Sherman is the author of Outboard Engines, Maintenance, Troubleshooting and Repair, International Marine/McGraw Hill and a contributing editor to Sailing World.

- More: Accessories , clothing , Sailing Gear

Comfort Rules with Mustang’s Minimalist Buoyancy Aid

Smart Polars Are Here

Reproofing May Be Required

Wingfoiling Gear: A Beginner’s Guide

Barcelona Breeze Increase Spikes Intensity

Luna Rossa Dominant on Busy Day in Barcelona

One and Done on Drifter Day of Cup Challenger Series

Shocks and Drops At Louis Vuitton Cup Start

- Digital Edition

- Customer Service

- Privacy Policy

- Terms of Use

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

- Forum Listing

- Marketplace

- Advanced Search

- About The Boat

- Boat Review Forum

- SailNet is a forum community dedicated to Sailing enthusiasts. Come join the discussion about sailing, modifications, classifieds, troubleshooting, repairs, reviews, maintenance, and more!

Pearson 26 Ariel thoughts

- Add to quote

Hi all, just joined the forum last week and beginning my search for my first sailboat. Right now I found a freshwater 26 Ariel with a newer (at least 2013 as this was the first year the motor was produced) 9.9 evinrude 4 stroke, no trailer, has all rigging and ready to sail, not sure of the sails age, has new head system, and good bottom paint. I was originally leaning toward buying a marina repo or something of the likes and fixing it up, but i found this that I could trade a car and bike for which is about 5k in value, is that a fair price? NADA had it valued at 6 but I don't necessarily believe what it says. I read this is referred to as a "great boat for its time" how will it hold up today? My budget isn't super high, and I do want something thats at least a 26. I'm still planning to go check out what some marina's have available this next weekend, just wanting to see if this would be a good option as well. Thanks all!

I have a Bristol 27, which is almost a sister-ship to the Ariel. All the Alberg boats of this size are very similar to each other. They tend to be tender for about 15-20 degrees, then stiffen up. I liked mine. If you have a choice, get a boat with an inboard engine. Outboard engines are hard to keep in the water in a big chop. Having it in a well helps some. The value of any boat depends a lot more on condition than it does on age, or who made the boat. If it is, indeed, in sail-away condition $5k seems reasonable. I think there is another one for sale in Chicago (Nautical Donations, where I got mine) for around $3500.