- Vanquish 65

- Mini Maniac

- RG65 Appendages

- Maniac MK II

- IOM Appendages

- Marblehead Class

- Marblehead Appendages

- RT65 Ragnarok

- RT65R Armageddon

- RC65 Adrenaline

- ST65 Sowelu

- Mini40 / F48 Class

- Nightmare X

- Nightmare MK VIII

- MultiOne Class

- FireDragon 1000

- DIY Sail Winch

- Rig Building

- Fair American

- Tools and Techniques

- Kit Database

- Bluenose Canadian Schooner

Making Sails for Model Ships

December 3, 2017

On my Model Shipways Bluenose build , I debated whether or not to make the sails. Many (most?) ship models do not include full sails. The Model Shipways kit was designed with sails, and includes the sail cloth as part of the kit. The inclusion of sails was actually one of the factors that led me to select this kit for my second build.

With the booms and gaffs rigged and installed, I would basically be finished with the build if I omit the sails. The remaining rigging is all attached to sails, so I’d leave it off if I didn’t include sails. However, the sails really do add something to the model, especially for a schooner like this.

So, I decided to make sails. I’ve never made sails before, so this will be a learning experience. Here’s how I ended up doing it…

Choosing How Sails are Displayed

An important decision to make before you start is how you’ll be displaying sails. There are three different ways you can go:

- For Display

(I made those last two names up).

Furled sails are sails that are lowered. Many modelers choose to do furled sails on their ships. The advantage is that the sails don’t cover everything up and make a model look like a bunch of cloth. When doing furled sails, you typically don’t make the full sail, instead making smaller version. The sail is put in place, but is bunched up and tied to the appropriate boom or gaff.

Realistic sails try to show the sails rigged and set as they would be while the ship is actually at sea. Ships adjusted their sails depending on the situation. In most cases, some sails would be raised while others would be lowered. Some sails might be set off to one side. Realistic sails would try to show the ship in some kind of ‘real’ sailing state.

Making sails simply ‘for display’ is what I’m doing. I’m making all the sails, and installing them all in their raised state. I’m not going to set any sails off to the sides – everything is just going to be installed straight and even. You’d probably never see a ship at sea actually set like this, but I think it works well for a model.

When to Make Sails

From what I can tell, the general practice is to make the sails before rigging and installing the booms and gaffs. Several of the sails need to be laced onto the booms and gaffs, and that is nearly impossible to do directly on the ship.

The standard process seems to be:

- Build the booms and gaffs.

- Make the sails based on the plans.

- Attach sails to the booms and gaffs as appropriate.

- Install and rig the booms and gaffs.

- Add the additional rigging for each sail.

I’m not confident that all my booms and gaffs are 100% accurately sized, and I suspect that the dimensions of my sails might need to be adjusted to fit my particular ship. So, I intentionally put off making sails until I had installed all the booms and gaffs.

Once I had everything installed on the ship, I could make templates for the sails that take into account both the plans and the size/shape of my actual build.

Of course, this means that I had a bunch of rigging for the booms and gaffs that would need to be un-done so the booms and gaffs could be removed. That was fine with me, because I had avoided the use of glue when securing the rigging. Everything was either tied off (easy to un-tie), or attached with a hook or shackle (easy to remove).

So, my process is:

- Build the booms and gaffs .

- Install and rig the booms and gaffs .

- Make the sails based on the actual layout of my ship.

- De-rig the booms and gaffs, and remove them from the ship.

- Re-install the booms and gaffs, and their rigging.

For me, this approach (while more work) has several advantages:

- Initially, I’m able to focus on getting the booms and gaffs properly installed and rigged, without the sails getting in the way.

- I can start with sail templates based on the plans, and adjust as necessary to fit the exact size/shape of my ship.

- Once sails are ready to install, I can quickly get them rigged without spending any time on the other rigging for the booms and gaffs, since those runs are already done and just need to be re-tied/attached.

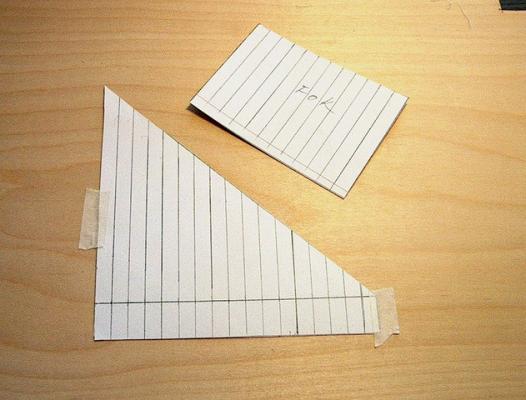

Paper Templates

Making the actual sails starts with making paper templates. Some of the sails were too big to use normal paper, so I picked up a roll of white craft paper.

For each sail, I took a piece of paper and laid it over the plans. I marked the corners of the sail, then used a ruler to draw lines between the marks, giving me the outline of the sail. Some sails have curves that I had to hand-draw.

Once the shape was laid out on the paper, I cut the paper to shape.

A paper template for the jib sail.

Next I positioned the paper template on the actual ship in the correct spot. I took note of anything that didn’t fit just right, and adjusted the template as necessary. Some sails needed to be made slightly smaller, while some had to be made slightly larger.

To help me visualize the sail, I also marked where the hems on the edges will go, along with any other key elements of the sail. For the edge hems, I’ll be folding the fabric over and sewing it. I’ll be shooting for a 1/16″ hem, so I used that size for the markings on the template.

The actual sails on the ship were made from strips of cloth, not one big piece. To simulate this, I’ll just be sewing lines onto the cloth. For some of the sails, I went ahead and marked these lines on the template since they need to be oriented correctly according to the plans.

The main and fore sails also have reef bands , which run horizontally along the lower portion of the sail. These were marked as well.

Preparing the Sail Cloth

Once I was satisfied with the template, I got out the sail cloth. Model Shipways includes sail cloth with the kit. This cloth is a medium weight cotton cloth in an off-white color. The kit includes enough to make all the sails, assuming you get everything right on the first try. I knew that wasn’t going to work, so I ordered two more packages of sail cloth from them. It was relatively inexpensive – about $7 for each package of cloth.

Sails on a ship were rarely bright white. I’ve seen that many modelers will dye their sail cloth to get a desired shade. There are many tricks for this, like dipping the material in coffee. I felt that the off-white color of the Model Shipways cloth was fine, so I didn’t dye my cloth.

If you’re wanting to use other sail cloth, look for something lightweight. Almost all fabric is going to be too thick and out of scale, so just do the best you can. I actually used some fabric from a local hobby store for a few ‘test runs’, and learned a few things. Look for fabric with a tight knit, so the fabric doesn’t start to come apart as you cut it. Also look for something without too much stretch, as stretchy fabric can distort the shape of the sails as you sew them.

Ideally, you want to wash, dry, and iron the sail cloth before you start. Most fabric will shrink a little during this process, so you want this out of the way before you start cutting things to size. Doing this will also release any wrinkles in the fabric. (I was too excited to get started, and didn’t do this.)

Once you’ve got your fabric ready and your template sized, you’re ready to cut some fabric.

I used a fabric marker to do all the markings on the fabric. I picked this up at a local hobby store in the sewing section for a couple dollars. This marker uses special ink that disappears as it evaporates. This means I can draw all over the fabric, and within a few hours the ink is gone. I found this to give much better results than using a pencil and trying to erase markings.

The paper template is used to mark up the fabric being used for the sail.

A note on marking fabric…since I’m going to be folding over the edges of the sail to create hems, one side of the sail is going to look better than the other. Often, you pick a ‘display side’ of the ship, and put ugly stuff (like the worse sail side) so it isn’t visible from the display side. I found that with the way I was marking, folding, and sewing the cloth, I wanted the markings on the display side. Making sure I marked the display side ensured that I as I worked I ended up with all the ugly stuff on the back.

First the outline of the sail is marked on the fabric. Be sure to leave extra space on all sides outside of the sail.

A second outline is made 1/16″ outside of the first outline. This is the hem that I want to end up with on the finished sail.

A third outline is made 1/2″ outside of the second outline. This one doesn’t have to be perfect…this is just a guide for cutting the fabric.

You can also mark the reef lines and strips at this point if desired. I typically didn’t mark the strips, since I was able to position those accurately using my sewing machine.

The fabric is trimmed, leaving excess material around the edges.

Once everything is marked, I cut the fabric along the outer-most outline. I used a rotary cutter (like a pizza cutter), which gave much better results than scissors.

To make sails you have to do a lot of sewing. I have no experience sewing. Doing all this by hand with a needle and thread was not practical, so I bought a cheap little ‘hobby’ sewing machine. That machine was junk, and broke within the first 20 minutes. Since I’m hoping to keep this hobby going for a few decades, I decided to go ahead and invest in a real sewing machine.

At my local hobby store, the staff helped me select a good quality machine. I got it for under $200. The advantages of a real machine include:

- It won’t jam.

- Variable speeds.

- Selectable stitch length and width (critical for trying to get the stitching remotely close to ‘scale’).

- Many different computer-controlled stitch types, so you can do more than just a simple straight stitch. This would end up making the reef bands much better.

It took me a few hours to get the hang of using the machine, but my skill level increased quickly. While I certainly couldn’t sew a shirt or a pair of pants, by the second or third sail I was flying along like a pro.

Since you’ll be sewing, you’ll need thread. There are three main considerations with the thread.

First is the color. This is a matter of personal preference. I’ve seen some models where the stitching on the sails was very high-contrast (dark brown thread on white cloth). I’ve also seen some where the thread was the same color as the cloth. I felt like the stitching shouldn’t stand out too much , and I wanted to rely on the texture of the thread to define the lines rather than the color. So, I went with a ‘natural’ color thread that ended up being really close to the color of the cloth.

The second consideration is the thread material. A hobby store will likely have hundreds of different kinds of thread. There are synthetic materials and natural materials. I went with a cotton thread. Why? No really good reason except that all my rigging lines are cotton and the sail cloth is cotton, so it seemed like a good idea.

The final consideration is quantity. I have no idea how to predict the amount of thread that will be needed (there may be some ‘trick’ to it that the pros know). Initially I bought one spool of the thread. That only made two sails. When I went back to by more, they were out of that exact thread, so I had to order more online. That caused a week delay in making sails. Obviously you wan the thread to be the same on all the sails, so buy a lot of the same thread up front. Thread is cheap, and it is better to have some leftover than to run out.

Sewing the Edges

On to sewing.

The first step is to sew the hems on the edges. I start with the longest edge first, then do the opposite edge, continuing on until all edges are sewn. The cloth is folded over at the first outline (the line that defines the actual edge of the sail) and pinned into place. The 1/16″ line that indicates the edge of the hem should be inside the sail. Since the cloth was cut 1/2″ past that line (on that third outline), there is some extra material here that makes pinning easier. I’ll cut that off later.

The edges are folded over to create a hem and pinned in place.

The hem is sewn on the edge.

The cloth then goes into the machine and gets stitched up. I used the machine’s reverse feature to double-stitch the first couple stitches to secure the thread, then just ran a straight stitch down the edge, staying between the edge of the sail and the 1/16″ hem marking. I used a small stitch length so things weren’t too out of scale.

My machine lets me set the position of the needle, allowing me to get really close to the edge.

Once the stitch was complete, the extra thread was clipped off. I used a pair of sharp scissors to carefully cut off the extra cloth along the 1/16″ hem line.

A completed edge hem, about 1/16″ wide.

This was repeated for each edge.

Two edges meet in a corner.

Adding ‘Strips’

To simulate the strips of material, some modelers simply draw lines on the cloth. I decided to run a stitch for each strip instead. It is more work, but it goes pretty fast

The ‘strips’ of sail sail cloth are simulated with stitches. Each sail has a unique strip layout shown on the plans.

The width of the strips is indicated on the plans, as well as the layout of the strips. It turned out that the width of the strips matched with space between the needle on my sewing machine and the edge of the ‘foot’. So I didn’t need to mark the strips on the fabric – I just positioned the fabric under the foot and ran the material through the machine.

Reef Bands and Points

The large lower sails (main sail and fore sail) have reef bands . These are horizontal bands across the sails. My sewing machine has a setting that creates a stitch that looks like a ladder (or railroad tracks?). I adjusted the stitch length and width to get the desired size, then ran this stitch across the sail to create the reef bands.

I ran this right over the strip lines. This is easier than doing the reef bands first and trying to start/stop the strip lines at the bands, and you can’t really tell the difference.

Reef bands were sewn in using a different stitch pattern on my machine.

At each point where a strip line crosses the reef band, there is a short rope that goes through the sail. These ropes were used to secure the sail when it was lowered and bundled up. I cut a bunch of 1″ long pieces of 0.008″ tan rigging line and punched them through at the appropriate spots. I used a small bit of fabric glue on each side to keep these ropes flat against the sail instead of sticking out.

Corner Attachment Points

The sails typically have rigging lines attached to the corners of the sails. This means you need something in each corner to attach a rigging line to. From my research, it looks like most sails had a rope that ran around the outside edge of the sail, and that rope would form an eye at the sail corners to create the attachment points.

I decided not to add this rope. I wasn’t confident I could make it look good, and I thought the tan line would stand out too much.

So, I simply sewed brass rings (made from wire) into each corner. This was done manually with a needle and thread.

Anchor points in the corners were made from brass wire and sewn in.

Finishing Up

Once everything is sewn and I’m happy with the results, there are a few final steps.

I do a final pass to trim anything that looks bad (edges of hems, loose threads, etc.).

After all my disappearing fabric markings have evaporated and disappeared, I iron the sail to flatten it out and remove any remaining wrinkles.

Finally, I use some fabric glue along any exposed fabric edges (like the hems) to keep them from fraying. I also use a little fabric glue on the ends of stitches to ensure they don’t come loose.

Then the sail is ready to install!

A few completed sails on the ship.

- Click to share on Twitter (Opens in new window)

- Click to share on Facebook (Opens in new window)

- Click to share on Reddit (Opens in new window)

- Click to share on Tumblr (Opens in new window)

- Click to share on Pinterest (Opens in new window)

- Phantom NY Pilot Boat

- Model Ship Kit Database

Copyright © 2018 SuburbanShipModeler.com The text, photos, and content are copyright of this site unless otherwise noted.

Photos were taken by the author unless otherwise noted. All brands and trademarks referenced are the property of their respective owners.

Discover more from The Suburban Ship Modeler

Subscribe now to keep reading and get access to the full archive.

Type your email…

Continue reading

Fast Shipping or local PickUp

Potter solutions, the one stop model yacht shop.

Sails, rigs, boat stands, accessories and fittings, including the new range of DF65 and DF95 complete packages.

Email Address

the history of the future

At the age of fifteen David Potter started sailing model boats at the world famous Birkenhead Model Yacht Club.

In 2012 he decided to turn his passionate hobby into a business and launched Potter Solutions.

As a qualified engineer, with a good eye for detail, he produces a range of equipment for the majority of radio controlled model yacht classes.

David has competed in this thrilling sport for over Thirty years at both national and international events and is fully aware of the need for products that can deliver in the field at a competitive price.

Whatever your requirements, including information and advice, David is always available for a chat.

featured products

Complete DF95 Package

Complete DF65 Package

DF95 Alloy Boat Stand

Pierre Gonnet Mast 11.1mm

Everything in one place.

30 Years of experience in radio sailing means we know what’s required to produce competitive and reliable parts .

Order before 3pm for UK next day delivery *

Most products can be shipped same day. Some products like sails * are made to order unless they are from our standard range. Products that can be dispatched same day will be indicated on the product description.

Secure Ordering online

You can place an order online. Once we receive the order we calculate the shipping cost and send you information on how to make payment. Your personal information is protected and encrypted by Secure Socket Layer (SSL) technology. Our website is ecommerce PCI Compliant .

Customer Service

Excellent customer service is one of the key areas where we can truly make a difference, which is why we work hard to keep our customers happy and make it easy to do business with us. A quick response matters and we aim to reply promptly and professionally.

some of our reviews

A history of trust and service.

“Fast shipping and exactly the parts I needed to complete my new IOM. Highly recommended”

“Bought a boat stand for my Marblehead. Arrived in a couple of days and very happy with the quality.”

“Bought some new sails for my DF95. Potter’s service is excellent. The sails are top quality.”

- About EH? Sails

Star 45 Class

Soling 1m class, canterbury j class, 10 rater class, 36/600 class, columbia 42 class, infinity 54 class, santa barbara class, wheeler class, vintage classes, we offer both sails and building in any class you are interested. there are too many to list them all. please visit the amya site by clicking on this link., click on the images below to enlarge view., ec12 cpm505, j class polymax.

Sail Prices All sails are designed and built to meet AMYA class specifications. Depending on class or make of model, sails are equipped with:

- Draft stripes $5

- Jib luff wire (where specified)

- Main luff slugs, tie points or jackwire

- Class insignia

- Sail numbers (main only)

- Country Designation on Main $10

- Jib numbers $10 (2 digits), add $5 per number if want 3 or 4 digit

- Colored corner patches in either Star or Oval shapes (black, white, kevlar, red, green or blue) Other colors available upon request.

Note: Sail numbers, draft stripes and class insignia - Either Insignia fabric or inked on style.

Materials available

- CPM505 - Mylar/scrim laminate

- PX75 Mylar film both sides with reinforcing threads

- 1.4 Mil Mylar

- 2.0 Mil Mylar

- 3.0 Mil Mylar

- 2.5 Polykote - PU Coated Woven Polyester Fabric (Midrange > J-Class)

- 2.1 Polymax - PU Coated Woven Polyester Fabric (Light to Midrange J-Class)

- Icarex - lightweight Polyester colored fabric.

- Other weights and materials available upon request

Sail Prices Note: Prices on the most common boats for which we have made sails. If you have other fabric suggestions you want us to consider, depending on availability, we can supply prices based on fabric cost.

- "A", "B" or "C" Suit of CPM505, PX75, or 2 mil Mylar fabric $180

- Main only 505, PX75, Mylar $120

- Jib only 505, PX75, Mylar $90

- Suit 2.1 Polymax $395

- Suit 2.5 Polykote $485

- Suit ODLO4 black Mylar $530

- Main only 2.1 Polymax $227, 2.5 Polykote $285

- Jib only 2.1 Polymax $145, 2.5 Polykote $190

- Suit Mylar dependent on choice of film discussed $???

- "B" Main for heavier winds 2.5 Polykote $285

- Note: Polymax vs Polykote - Since Polymax is not as firm as Polykote, it will respond and show wind changes along the luff line sooner than Polykote. We recommend Polykote for winds above 8 to 10 knots. Polymax can be used up to 12 to 15 knots if you want to keep that traditional look.

- CPM505 Suit $170

- PX75 "B" suit $175

- 2mil, 3mil or 1.4mil suit $140

- "B" suit PX75 $140

- "C" suit 3mil with reinforced seams $140

- Note: Rule change 6.1 - 2020, no thickness is required. Any woven polyester fabric $120

- Columbia 42 (C42) (A or B suit) Per class rules Suit $120. If only "B" main $65

© 2024 EHSails, All Rights Reserve

3 Waterside Lane, Essex, CT 06426 860-304-7007

Perfecting Your Model’s Sails: The Art of Rigging | Seacraftclassics

- September 10, 2023

- Boats and ships

Mastering the Art of Rigging: Enhancing the Authenticity of Your Model’s Sails

When it comes to creating a realistic and authentic model of a sailboat, one of the most crucial aspects is perfecting the rigging, particularly the sails. The art of rigging involves setting up the sails in a way that accurately represents the real-life counterpart, capturing the essence and beauty of sailing. In this article, we will delve into the secrets and techniques of sail rigging that will elevate the realism of your model to new heights.

Unveiling the Secrets of Rigging: Techniques to Perfect Your Model’s Sail Setup

Rigging a sailboat model requires attention to detail and a deep understanding of the principles of sailing. Here are some techniques that will help you achieve impeccable sail rigging:

1. Research and Reference

Before starting the rigging process, it is essential to conduct thorough research on the specific sailboat model you are replicating. Study photographs, blueprints, and even real-life sailboats to understand the intricacies of the rigging. Pay close attention to the arrangement of the sails, the types of rigging lines used, and the tension applied to each line.

2. Use High-Quality Materials

Investing in high-quality rigging materials is crucial for achieving a realistic look and ensuring the longevity of your model. Opt for materials such as fine thread or fishing line for the rigging lines, and choose appropriate fabrics for the sails, such as cotton or silk. These materials will provide the necessary strength and flexibility to accurately represent the tension and shape of the sails.

3. Rigging Techniques

There are several rigging techniques that can enhance the authenticity of your model’s sails:

- Running Rigging: Use thin thread or fishing line to create the running rigging, such as halyards, sheets, and control lines. Ensure that the lines are properly tensioned and secured to the appropriate points on the mast, boom, and deck.

- Standing Rigging: The standing rigging, including shrouds and stays, provides the necessary support for the mast. Use fine thread or wire to create these lines, ensuring they are accurately positioned and tensioned to maintain the correct shape of the mast.

- Sail Attachment: Attach the sails to the mast and boom using small eyelets or hooks. Pay attention to the proper alignment and tension of the sails to achieve a realistic appearance.

Elevate Your Model’s Realism: Tips and Tricks for Achieving Impeccable Sail Rigging

Here are some additional tips and tricks that will take your sail rigging to the next level:

1. Weathering and Aging

To add a touch of realism to your model, consider weathering and aging the sails. Use diluted acrylic paints or fabric dyes to create subtle discolorations and stains that mimic the effects of sun, saltwater, and time. Be sure to apply these effects sparingly and strategically to maintain a natural appearance.

2. Scale Accuracy

Pay close attention to the scale accuracy of your model’s rigging. Ensure that the size and proportions of the rigging lines and hardware are appropriate for the scale of your model. This attention to detail will greatly enhance the overall realism of your sailboat replica.

3. Practice and Patience

Perfecting the art of rigging takes practice and patience. Don’t be discouraged if your first attempts are not flawless. Take the time to learn from your mistakes, refine your techniques, and experiment with different approaches. With each model you build, your skills will improve, and your sail rigging will become more refined.

Mastering the art of rigging is essential for creating a realistic and authentic model of a sailboat. By conducting thorough research, using high-quality materials, and employing the right techniques, you can achieve impeccable sail rigging. Additionally, incorporating weathering and aging effects, ensuring scale accuracy, and practicing patience will elevate the realism of your model’s sails even further. So, set sail on your next model-building adventure and let your rigging skills shine!

Most Viewed Posts

- Talk about a venue with a view! This Quebec couple had the absolute wedding of …

- Everything You Need to Know About Trading in Your Boat

- Wishing all the IMOCA Globe Series teams and skippers competing in the Vendée-Ar…

- Happy 4th of July! Wishing you all a happy holiday weekend on the water with you…

- The training continues for Alex and the crew. In case you missed it, we won’t b…

Our latest custom models

- model 1329 1329 products

- Custom Sail boats 218 218 products

- Custom Power Boats 399 399 products

- Custom Half Models 532 532 products

- Custom Desk Models 92 92 products

- Recent Orders

Sails & Sail Cloth

Sail Cloth for Modern Yacht

Sail Cloth for Period Ships

Mantua Sail Cloth

Best sellers.

New Products

Recently Viewed

- £ 0.00 0 items

Catsails are specialist manufacturers of sails and accessories for performance radio controlled model yachts.

Proprietor Nigel Brown has been sailmaking since 1980 and has worked in some of the top sail lofts across the World including building sails for 4 America’s Cup programmes.

Years of sailmaking experience at the highest level combined with the best materials, high standards of workmanship and attention to detail have resulted in truly top quality products that are well proven on racecourses around the world. All mainsails and jibs are shaped using carefully milled moulds which ensures accurate repetition and consistency of shapes from one sail to the next.

Nigel has been building sails for the International One Metre since 2005 with sail shapes and construction techniques being continually refined ever since. IOM sails are well proven on the race circuits having won races and regattas in Spain, Italy and Malta as well as in the UK.

In 2012 the range was extended to include sails for the popular Micro Magic class that instantly received great acclaim.

When the DragonForce 65 was launched in 2013 and the DragonFlite 95 in 2016 Catsails soon became one of the leading suppliers of after market sails for these popular boats and they are now shipped all around the world and have powered boats to national titles in a number of different countries.

Catsails additionally make high performance sails for the RG65 class to fit both swing and conventional rigs.

Catsails also make custom accessories that are designed to protect boats, rigs and foils whilst the boats are out of the water.

NYLET. THE QUICK GUIDE TO SYNTHETIC SAILS & MAKING YOUR ORDER. 92 years of Sailmaking. Fine Products - Quality First. Nylet - Model sailmakers to the world ~ THE professional Master Sailmakers. Sails made by Special Commission for Collectors & Museums. Makers of model yacht sails to the National Maritime Museum Cornwall. Quick guide to ordering please scroll down. To contact us, click right link on top bar. During these times we would like to reassure our customers that we are still able to provide an uninterrupted mail order service. If you want your sails made properly, then come to us!

NYLET - International Master sailmakers - THE professional model sailmakers since 1932. We use technological advances in materials coupled with innovation, expertise and tradition during more than 90 years to bring you the very finest model sails. Plenty of photos of our sails rigged, scattered over our website (scroll down for the yellow clickable buttons). The longest established professional model sailmakers in the world ~ fine quality model yacht sails, perfect cut and finish ~ quality first; world-wide mail order since 1958. Comprehensive sailmaking service, any size sails made to your drawing/sizes. Read more about sailcloth types available in "news". A yacht's sails are its 'engine', so fit the best, don't settle for less. Improve the handling and responsiveness of your yacht with our renowned "wind catching" sails. For price list (600 items) see link/button below. For listings of other available sail designs then click on '150 sails list' below. To make an order/enquiry - phone or email us and we will be pleased to help (click on the 'contact' link on top bar). If the sails for your own yacht doesn't appear on our '150 sails' list (or our price list) then you must enclose sail dimensions for us be able to quote you - a dimensioned sketch is even better! For detailed information on racing sails and "Heritage" sewn sails click on the next yellow button under this message. Second yellow button down for our "Vintage" style cotton sails, exactly as we manufactured in the 1930's onwards. Information/quick guide on ordering IOM/racing sails, standard sails & replacement kit sails please scroll down. Makers of model sails to the National Maritime Museum Cornwall. HOW TO ORDER, SCROLL DOWN.

Read about Nylet racing sails/replacement kit sails/Heritage Dacron sails, in more detail

Read about nylet 'vintage' cotton sails in detail, download nylet order form, "how to" - submitting sail sizes, product & price list (600 items), the "150 sails" list, a few images of nylet sails.

NYLET sails, racing, cruising, Heritage, Vintage - choose your style.

View more photos of Nylet sails

Nylet sails - fit the best, don't settle for less. 92 years of sailmaking. the quick guide to nylet sails & and how to order, making fine sails.

Nylet. Using skills handed down over 6 generations and 252 years we take pride in our work.

You may be assured we use the finest materials we make sails for modern racing yachts, cruising yachts and also vintage timber yachts.

Let us have a drawing or plan, or templates so we can give you a price.

Entirely made in the finest cotton cloth, sails for museums and private collectors.

The world-wide service, mail order since 1958.

CUSTOMER COMMENTS

- Stunning sails, so well shaped and crafted and have rigged very well on my IOM. Yesterday the best results I have ever had since June when I bought the IOM. Three second places, and some praise from other club members one of which came over at the end to see what make of sails they are. Thank you for great sails that look superb. Stephen.

- The Victoria sails arrived this morning. As usual they are absolutely superb. Thank you so much. Ian, Northampton.

- The sails for my Dragon Force came today; a great product and excellent service - can't wait to try them this weekend. Bob, W.Midlands

- Sails received with thanks. You are a true craftsman. John, Glasgow

- Your sails are the icing on the cake. Carl

- The IOM sails arrived and absolutely fantastic, really pleased and more than happy to recommend your workmanship. Lee, Berkshire

- The Voyager sails arrived in perfect condition and look beautiful. Thank you very much for the nice work! Patrick, Belgium

- Just to let you know that the new IOM sails work very well, thank you. I had 2x1st, 2x2nds,2x3rds, and 1 fourth. So I came first overall after 7 races. Bob, Surrey

- I just wanted to say a really big thank you for the lovely suit of (Dacron Heritage sewn) sails you have made for my vintage 4 foot model J Class sloop. I have put the sails on the spars and they look superb! They are beautifully made as I expected them to be, but in all fairness it is actually better than I had even hoped for. John, Preston

- The Canterbury J sails have arrived in perfect condition thank you very much. Very pleased with the excellent quality you have produced. Gordon, UAE

- Just a few lines to thank you very much for the phone call and the excellent delivery, I received the sails just a few hours after your call. As for the sails, with just a few dimensions on a sketch you have produced a set of racing sails that go far beyond excellent, they are so much more than I expected, I just hope I can complete my yacht to the same standard. Thank you very much. Bob, Berkshire.

- Thank you so very much for the wonderful suit of sails, the stitching is just perfect, you are a professional (my wife commented on your work, she is a sewing machinist!). Thank you again, I am over the moon. John, Kent.

- I can confirm the sails and bag arrived safely yesterday. I am very pleased with them and must say you provide an excellent service. I will certainly come back to you for more parts and wholeheartedly recommend you to other model enthusiasts. John, Sussex.

- The (Seawind) sails have arrived, the only thing I can say is - WOW. What a difference compared with the standard sails. Andre, The Netherlands.

- At last I can thank you for the excellent suit of sails that you made for my Marblehead. She was launched yesterday and sailed beautifully - the sails set a treat and looked terrific. Your efforts are much appreciated. Ian, Dorset.

- Hi Frank, just to let you know the sails arrived in perfect condition, they are a great job. Donal, Ireland.

- Really thanks again for your great products and service! KW, Hong Kong

- I had various recommendations of who to get sails from but the other day I saw a yacht with your sails and it just shone out, the shape looked beautiful, so I decided there and then to contact you. Gordon, Sussex.

- Thank you Frank, first class service, sails arived safely this morning. John, Staffordshire.

- A big thank you for the sails you made, they were for a model I am restoring and they look great, just right for this model. I really appreciate your personal touch in contacting me by phone to discuss my order. I will send you some pictures of the completed model when it is finished and would be happy for you to use any in promotion of your business. John.

- Sails (for Katie) arrived today - they look great, much appreciated. Andy, Lancs.

- Having recently replaced the sails on my Voyager with Nylet items and experienced the jaw dropping improvement in performance, you are my first port of call for my latest project. Robert.

- I am very, very pleased with the new (One Metre) sails you supplied. Setup was very easy and the boat handles far better than before. Alan.

- Thank you Frank, the new sails arrived this morning and what a great tribute to your craftsmanship they are. Cannot wait to fit them and head off to the wide blue yonder. Thanks once again for your immaculate work. Derek.

- The Star Baby sails are a super job and the best I have seen, I am very pleased with them, well done. Jeff.

- Hi Frank, Just a quick mail to let you know the J Class is done and has hit the water here in Dubai. The sails look great and perform even better! A bit of extra ballast for trim and its done. Thanks again for the great sails. Chris.

more customer comments

- Just received my glorious suit! Magnificent! The tablings..... marvellous!!!... the stitching lines, the overall shape, every detail, all very beautiful indeed! I can't tell you how delighted I am. You must understand, the wind has always held a magical place in my heart and the thin membrane with which we apply our feeble human attempts to have it do our way over an equally mysterious sea..... alchemy indeed. I hold this suit in my hands and it all comes alive again. It occurred to me as I relished your suit the day later that one of the things I really appreciated, was that in your masterly execution, despite many years of hard learned science, though perhaps exactly because of them, you approached the design not with a mindless machine but more the inquiring instrument. You took onboard where I'd too easily lined the impossible and wasn't having any of it, discovering a way to play your sound, practical requirements for the well-made, proper sail whilst accommodating the draw perfectly. The narrow tablings, the nicely snug but slidable foot sleeves, even seeing to better sized eyelets where they would best serve tacks and clews. You sir, are a Wizard of Dacron. Thank you for your brilliant work, I raise a glass to you Sir, Roger, U.S.A.

- Absolutely magnificent (cotton) sails, the guys at the Club were amazed at the quality! Bernard, Suffolk.

- Hello Frank, the sails were waiting for me when I returned from a week away. They are in perfect condition and look superb, just like sails previously made by you. Thanks for putting them through with the others, what super service! Jeff, Staffs.

- Enjoying the new Seawind sails. Far more competitive than the stock sails. You are a star. Allan, South Africa.

- I've never won anything before with my IOM yacht but with your sails newly fitted I won the series of races. An excellent job, marvellous, thank you. Paul, Essex.

- Many thanks, sails arrived OK, great job. Ted, Cambridgeshire.

- Sails arrived this morning, superb as usual, thanks again. Ian, Nottingham.

- Sails came yesterday, great suit, can't wait to fit them probably over Easter. The KINGSWINFORD boat members highly recommend you for your sailmaking. Great, thanks again. Bob, W.Midlands.

- I received my sails today....PERFECT...arrives safely. Perfect fit and I look forward to sailing with the new sails!!!!!! THANKS, from Kjell, Norway.

- Just to let you know the sails arrived this morning safe and sound. I must thank you for such a magnificent job, they really do look the part, excellent. I just hope I can do justice to them with the rest of the boat. Many thanks again for a grand job. Chris, Somerset.

- The sail suit arrived a few days ago, and am delighted with the result. Its a real treat, in this day and age, to find something beautifully hand crafted by a true artisan. Danny, I.O.Man.

- Many thanks for the excellent sails. Jonathan, Yorkshire.

- Received the sails, many thanks - as usual, quality better than expected! Maurice, Lincs.

- Thank you for the Fairwind sails which arrived on Thursday, they are quite simply a work of art. Also thanks for your prompt and friendly service. Peter, Kent.

- The sails are wonderful, they fit like a glove! Thank you. Mark, Surrey.

- My sails arrived today. I am very pleased, they are exactly right, so neat, I just can't stop looking at them. Tom.

- The sails arrived in good order and fitted this afternoon, looking good, super quality. Will be ordering again. Robert.

- Sails arrived safely this morning, I will send some photos after we have sailed Sirius with the new suit. Thanks very much for a prompt and efficient service. Gareth.

- Hi Frank, am pleased to say the sails arrived in perfect condition earlier today. Thank you so much for the superb service. Alan, Lancs.

- If the (IOM) sails go as fast as they look, will be superb, thank you. Stephen, Huntingdon.

- Hi Frank, The One Metre sails are looking great. Andy.

- Starlet sails received and rigged - looking great. Richard.

- Hi Frank thanks for another great job (sails). Alan.

- I have now restored my 36 inch model yacht to the point where it is sailing again. Thanks to you and the VMYG for advice and Frank Parsons of Nylet for the sails and other bits and pieces. It would not have been possible without you!

Supplier of Hunter Mylar Polyester Sail Film

Inspect our site for your sail making needs, hunter mylar, 36 - 50 - 75 micron in 400mm and 600mm wide bonus 1 meter with every 10 meters ordered .

PERFORMANCE SAILS TASMANIA

DF65 - IOM - ALL MAKES

E-MAIL KYLE

Riviera Nautic

Victoria's Premier Holiday Destination

Download our press kit

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| I have rearranged the information into separate web pages. The one page was getting too large was slow to load and difficult then to navigate. Hopefully by dividing the information into separate areas navigation will be easier. There are many resources which offer all sorts of assistance to the beginner model sail maker. I have used as many as I could find including the following and would like to share some of my findings. I'm sure some will find fault with my ideas and I am only too happy to receive feedback. E-mail me on [email protected] Lester Gilbert's one metre site Larry Robinson's book on 'How To' make sails advertised in Radio Yacht Supplies Australia ; Radio Sailing Shop While not specifically for models this program the ' SailCut CAD ' program allows plotting of panels etc for sails. Its discussions and examples are very useful. This is a free download but does require some computer knowledge to set up An excellent article by Paul Bogataj on " How do sails work " - essential reading! In all of this literature there appears to be two common themes 1. To achieve a truly efficient sail it must be constructed with separate panels with built in shape or curvature. 2. Some means has to be used to hold the edges of the panels to the correct shape while joining them.

Forgot your password? Your best sail cloth and techniqueBy steven sturgis March 11, 2015 in Masting, rigging and sails

Recommended PostsSteven sturgis. Hi every one. I have been looking for the best sail cloth for my Flying Fish build. I would like to get a lot of suggestions that I can look at. Please include where the cloth can be bought. Do you change the color with dyes? do you age the cloth some how? How do you add detail to the sails? All sail makers are welcome to post their designs I know a lot of you don't put on sail because it covers the rigging so anyone that does would be a great asset to the topic. Looking forward to seeing your tricks and designs. sail techniques http://modelshipworl...-and-technique/ Link to commentShare on other sites.  Click on the Nautical Research Guild Home Page straight up to the top of the page, then, click on Ship Modeling Resources, then, click on Ship Modeling Database of Articles, Then click Rigging and Sails, then click the pdf "Making and forming sails for your model." I could have pasted the direct link, but thought it better for you to see everything that was available here on MSW. You can go to a Joanne's or any yard goods store and buy Egyptian cotton, almost silk like. Coffee and/or tea make good stains, very controllable. I'm certain there will be other suggestions to follow....

Thank you twintrow. I did look at that but some one needs to go back and up date the links. About 80% don't work any more. I was going for full rigged full sails. Can you do that in paper? 1/8 scale Im sure this is old hat to the expert modelers but passing on that knowledge is needed by the next generation of builders

I make sails for models in scale 1:75 with seams of the cloths sewing marked with single thread ( courtesy of Admiral ). For models in scale 1:100 I use computer printing of cloths lines and reef bands on thermal transferring paper for ironing on to sails fabric . Sails leech, head and foot ropes are fixed in its place with use of textile adhesive . Material for sails I prefer is old bed linen many, many times washed . Work step by step 1.Make paper stencil for each sail and check it’s dimensions on your model. 2.With soft pencil transfer all lines in to fabric – add stripe 5-7 mm around sail edges. 3.Make all necessary lines on fabric using sewing machine and thin thread with light brown or beige color. For sails with thermal transferring of line any sewing is not necessary. Cut of sail shape. 4. Fold the edges stripe to reverse side of sail and apply textile adhesive 5. Put sail on flat surface protected against glue adhesion ( wax paper ) and fix it with pins and nails for forming clews. Using textile adhesive attach thread around sail and form clews and cringles as necessary. After adhesive excess removal from sail surface and final ironing your sail is ready. Foto 1-10 Sail making Step by Step Foto 11 HMS Speedy - printed sails Foto 12 HMS Warrior - printed sails Foto 13 Patern for printing sails for S/S Savannah

I wouldn't use paper. If you don't want to use cloth, use silkspan from a hobby shop that deals with the RC guys/gals. It comes in various weights and you'd probably need to acquire small amounts of several sizes to find which one works best for you.

Mark "The shipwright is slow, but the wood is patient." - me Current Build: Past Builds: La Belle Poule 1765 - French Frigate from ANCRE plans - ON HOLD Tri ton Cross-Section NRG Hallf Hull Planking Kit HMS Sphinx 1775 - Vanguard Models - 1:64 Non-Ship Model: On hold, maybe forever: CH-53 Sikorsky - 1:48 - Revell - Completed Licorne - 1755 from Hahn Plans (Scratch) Version 2.0 (Abandoned)

Good stuff. I have seen some members using silkspan and modelspan. Any thought on this material. I'm not familiar with thermal transferring paper. can you elaborate. How do you use textile adhesive with out making a mess? Is it diluted in any way? The adhesive is not diluted , unwanted stains of adhesive on sails can be easily removed by scraping .  Thanks for outlining the step by step process you use. In my opinion, the thermal transfer is brilliant. I have been hesitating to start my sails for quite a while because I don't want to sew the seam lines (I think they would look too bulky) and I don't trust myself to be able to draw them evenly using pencil. You have certainly given me something to think about! I imagine transfer will be more durable than pencil - another plus for the technique. Current build -- MS Bluenose Future build - MS Flying Fish "A ship is safe in harbor, but that's not what ships are for." - William G. T. Shedd  Guest Tim I.Good stuff. I have seen some members using silkspan and modelspan. Any thought on this material. I'm not familiar with thermal transferring paper. can you elaborate. How do you use textile adhesive with out making a mess? Is it diluted in any way? Silk span is easy to work with. PVA glue works well and any glue that moves outside what you are trying to glue will dry clear. Also Rubber Cement works well, if applied sparingly. Here are some sails I have done using silk span. Nothing to write home about, but my first attempts at sail making. I use strips of silk span to simulate seams and sail detail and work them up in layers. You can also add bolt ropes and reef points to add more detail. I did not go into a lot of detail with these, rather kept them simple to work on my technique. Also if you use PVA a good idea is to press the sails between some parchment paper and heavy books while drying to prevent buckling or bubbling of the thin strips of silk span.  I hope this helps. I like the look of the silkspan and the layering of the cloth details. What weight silkspan do you use? Not quite sure on the weight. I just bought what my local hobby store has. This Silk Span in my pictures is the "SGM White". Hope this helps,  A question about silkspan. Can it achieve the draped and folded look of clewed up sails? Or will it be too stiff? I want to show my ship in the process of reducing to battle sail. Laissez le bon temps rouler ! Current Build: Le Soleil Royal Completed Build : Amerigo Vespucci Just saw this while looking for a source for Sig Silkspan, source of quote is the Stuntbarn an RC Forum: "Title: Silk Span Covering Post by: ericrule on October 22, 2012, 12:10:29 PM I just got off the telephone with Sig Mfg where they informed me that they will no longer have silk span available. At the present time they have only OO (Light) in stock and when that is gone they will no longer be able to obtain it. According to the person I spoke to the company that supplied the silk span is out of business and they can not find any other supplier. Mike is searching for a new source but it does not look like he is having any luck." So not sure if real or not....? But if true silkspan may not be around loong?? Just saw this while looking for a source for Sig Silkspan, source of quote is the Stuntbarn an RC Forum: "Title: Silk Span Covering Post by: ericrule on October 22, 2012, 12:10:29 PM I just got off the telephone with Sig Mfg where they informed me that they will no longer have silk span available. At the present time they have only OO (Light) in stock and when that is gone they will no longer be able to obtain it. According to the person I spoke to the company that supplied the silk span is out of business and they can not find any other supplier. Mike is searching for a new source but it does not look like he is having any luck." So not sure if real or not....? But if true silkspan may not be around loong?? Tom That is what my local hobby store told me as well. That is why I bought out everything they had, for stock. Oh noooooooooooooooooooooooooo !!!!! Say it ain't so. Thank you all this is good stuff. I hope I can still get silk span I would like to try it out.  Landlubber MikeIs there a difference between silk span and model span? I have a roll of model span, but haven't tried using it yet. Current Wooden builds: Amati/Victory Pegasus MS Charles W. Morgan Euromodel La Renommèe Plastic builds: Hs129B-2 1/48 SB2U-1 Vindicator 1/48 Five Star Yaeyama 1/700 Pit Road Asashio and Akashi 1/700 diorama Walrus 1/48 and Albatross 1/700 Special Hobby Buffalo 1/32 IJN Notoro 1/700 Akitsu Maru 1/700 Completed builds : Caldercraft Brig Badger Amati Hannah - Ship in Bottle Pit Road Hatsuzakura 1/700 Hasegawa Shimakaze 1:350 F4B-4 and P-6E 1/72 Accurate Miniatures F3F-1/F3F-2 1/48 Tamiya F4F-4 Wildcat built as FM-1 1/48 Special Hobby Buffalo 1/48 Eduard Sikorsky JRS-1 1/72 Citroen 2CV 1/24 - Airfix and Tamiya Entex Morgan 3-wheeler 1/16 Terminated build: HMS Lyme (based on Corel Unicorn) On the shelf: Euromodel Friedrich Wilhelm zu Pferde; Caldercraft Victory; too many plastic ship, plane and car kits Future potential scratch builds: HMS Lyme (from NMM plans); Le Gros Ventre (from Ancre monographs), Dutch ship from Ab Hoving book, HMS Sussex from McCardle book, Philadelphia gunboat (Smithsonian plans) I believe its just a different brand butt lets let the experts handle that question. For what it's worth I got a big roll of model span last year from CornwallModelBoats. Steven, if you're interested in furled sails, I shared my techniques that I used on my Badger in a separate thread: http://modelshipworld.com/index.php/topic/3944-landlubber-mikes-technique-for-furled-sails/

jablackwellThose looking for SilkSpan can still find it at the Guillow model airplane homepage. It can be found under the spare parts section. Each model plane has a spare parts assortment, and the wing covering is an option for most. U.S. Brig Syren - 1803 - Model Shipways - First PoB Build Sopwith Camel F.1 - 1916 - Model Airways - Not a Ship! , Completed Kate Cory - 1856 - Model Shipways - Second Build, completed Sultana - 1767 - Model Shipways - First shipbuild, completed  There's more on using SilkSpan for sails in a new booklet by SeaWatchBooks, or as a new chapter in a new edition of Swan IV.

Be sure to sign up for an epic Nelson/Trafalgar project if you would like to see it made into a TV series http://trafalgar.tv

Jolley RogerFor what it's worth I got a big roll of model span last year from CornwallModelBoats. Steven, if you're interested in furled sails, I shared my techniques that I used on my Badger in a separate thread: http://modelshipworld.com/index.php/topic/3944-landlubber-mikes-technique-for-furled-sails/ Can you recall under what product name CMB was selling the model span? I've been unable to find it on their site. Samuel Pepys notes in his diary on 19 July 1667: "the Dutch fleets being in so many places, that Sir W. Batten at table cried, By God , says he, I think the Devil shits Dutchmen." I can't find it on the website either. I'm fairly certain it was under building materials or something and listed as Modelspan. I looked at the packaging, and it had the Mantua name/emblem on it, but I don't see it under the Mantua fittings. Maybe email them and ask? Thanks Mike, i'll send them a mail. I am a passionate advocate of including sails on models so I am pleased you are making the decision to include them on your model. I had a look at your Victory build log, those sails looks fantastic! I think I will follow your method when I get to that part on my build.  Richard GriffithBluejacket Shipcrafters ran out of silkspan recently but they substituted model span which to me is the same material. I used it to added furled sails to Le Superbe. I am a very happy customer of BJ, not an employee.

I'm just using old worn bed sheets for my 1/100 scale HMS Victory. Check out my build log which is really not much at all about building the kit and mostly focussing on how I am making the sails. I bet if you searched through all my comments on MSW you would find 1/2 of all my posts are having to do with sails or rigging. I am a passionate advocate of including sails on models so I am pleased you are making the decision to include them on your model. I don't think the thickness of the material is that big a deal as long as the texture of the weave is fine enough not to draw attention to itself. Many very convincing ship model sails have actually been carved out of wood. My build log goes into a lot of detail on these points but I will just set them out here again: Don't use pure white sails, this will look too stark and in fact actual sails were cream colored or very light grey.(staining with coffee is super easy and very effective) Don't sew the boltropes on, no matter how fine a thread you use, it will look out of scale. Just glue them on. Do include sail construction details like reef bands and reinforcing patches, these give a good texture and are realistic. Look at all the photos you can find of reproduction ships that resemble your ship and try to duplicate that look. JCFrankie, thanks so much for your detailed log on your sail techniques. I went with furled sails on my Badger, but was planning on doing a mixture of furled and unfurled on my Pegasus and future builds. Your results are fantastic, and I will certainly bookmark your log for when I get to that point! I experimented with tissue and a few other materials as well, but ended up with cloth as well. Once again, a big thank you!

Hi I am making sails for a large pond yacht which will of course become very wet , if I chose a material that becomes too wet and heavy that will cause problems, what is the best material to use for a large expanse of sail. My pond yacht is 5ft long not inc bow sprit. Join the conversationYou can post now and register later. If you have an account, sign in now to post with your account.  × Pasted as rich text. Paste as plain text instead Only 75 emoji are allowed. × Your link has been automatically embedded. Display as a link instead × Your previous content has been restored. Clear editor × You cannot paste images directly. Upload or insert images from URL.

Recently Browsing 0 members

Modelshipworld - Advancing Ship Modeling through Research SSL SecuredYour security is important for us so this Website is SSL-Secured NRG Mailing AddressNautical Research Guild 237 South Lincoln Street Westmont IL, 60559-1917 Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)Helpful links.

About the NRGIf you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you. The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships. The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines. Our Emblem ®Nautical Research Guild ® and the NRG logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,999,236 & No. 6,999,237, registered March 14, 2023)

You are using an outdated browser. Upgrade your browser today or install Google Chrome Frame to better experience this site.  Sail Making ArticlesWe have several articles related to sails and sailmaking.

These articles represent the state of the art of 50 years ago or more. The modern expert on model sails, and a good source if you want to have a suit made, is Rod Carr . Rod Carr’s ObservationsAfter reading these pages, Rod offered the following observations on the difference between the freesailing designs of the 40s and the R/C sails of today: Modern panel joint tapers produce a vertical camber distribution that is the opposite of what the 1940 texts say. I do believe that it was likely that the flat headed vintage sails were the result of two requirements: a) As the cloth was asked to carry more load near the head, it would deform more, hence cutting hollow in the luff would remove some of that unwanted camber. b)The camber was defined as unwanted, because camber high in the sail can result in excessive heel, and as the boat heeled in a puff, it seems logical that the vane skipper would opt for the sail to be flatter up there to release the wind and reduce the heel. We all know that balance changes as a function of heel angle, and without a rudder to counteract things in real time like we R/C types, an automatic means of controlling heeling episodes with a flat section in the top of the sail seems sensible. The concern with heeling is reinforced by the fact that freesailing models, because they had to be able to sail anywhere in a pond, have substantially less draft than modern R/C boats, which can be steered to the deeper parts. Cotton SailclothWe have not found any cotton sailcloth completely suitable for sailing on the water. The instructions contained here are, however, suitable for constructing an accurate set of reproduction sails for display of a vintage or antique boat. The closest material we have located is called “long staple down cambric.” This is a tightly woven cotton material used in down pillows, quilts, and comforters. If you need a set of display sails made, the best approach is to locate a quilter. Quilting clubs can be found by going to your local fabric supply store such as JoAnne or Hobby Lobby. They generally have bulletin boards giving club contact information.

Enjoy fast, free delivery, exclusive deals, and award-winning movies & TV shows with Prime Try Prime and start saving today with fast, free delivery Amazon Prime includes:Fast, FREE Delivery is available to Prime members. To join, select "Try Amazon Prime and start saving today with Fast, FREE Delivery" below the Add to Cart button.

Important: Your credit card will NOT be charged when you start your free trial or if you cancel during the trial period. If you're happy with Amazon Prime, do nothing. At the end of the free trial, your membership will automatically upgrade to a monthly membership. Return this item for freeWe offer easy, convenient returns with at least one free return option: no shipping charges. All returns must comply with our returns policy.

Image Unavailable

Model Expo Sail Cloth, 18 X 36 (457 X 915MM) MS0567 Medium Weight Cotton from for Model Ship BuildingPurchase options and add-ons

Frequently bought together Similar items that ship from close to you Product information

Warranty & SupportLooking for specific info?Customer reviews.

Customer Reviews, including Product Star Ratings help customers to learn more about the product and decide whether it is the right product for them. To calculate the overall star rating and percentage breakdown by star, we don’t use a simple average. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. It also analyzed reviews to verify trustworthiness.

Top reviews from the United StatesThere was a problem filtering reviews right now. please try again later..

Join / LoginWeathering your model ship.

Weathering your model ship is the final touch that transforms a pristine replica into a lifelike miniature with a rich, nautical history. This crucial step in the model-building process adds depth, realism, and character to your creation, mimicking the effects of sun, salt, wind, and water on a vessel that’s braved the high seas. Whether you’re looking to depict a battle-worn warship, a time-tested merchant vessel, or a weather-beaten fishing boat, mastering the art of weathering will elevate your model ship from a showpiece to a storyteller. In this guide, we’ll explore various techniques and tips to help you achieve authentic weathering effects, bringing your model ship to life with the patina of adventure. Why Weather Your Model Ship?Weathering adds a layer of realism and historical context to your model. A pristine ship might look impressive, but it lacks the story and character of a vessel that has seen years of service. Weathering can:

Gathering necessary tools and materialsBefore you begin weathering, ensure you have the following tools and materials. This is everything you need in weathering kits:

Protecting areas that shouldn’t be weatheredNot every part of your ship should show the same level of weathering. To protect certain areas:

Basic Weathering TechniquesDry brushing. Dry brushing is a technique where you use a brush with very little paint to highlight raised surfaces and add texture.

This technique is excellent for bringing out wood grain on decks, for example, and highlighting details on the hull. Washes involve using thin, watery paint to add depth to recessed areas and create subtle light and colour variations.

Washes are particularly effective for adding grime to deck planking and creating shadow effects in recessed areas. Sponge paintingSponge painting creates a mottled, textured effect that’s great for simulating rust or paint chipping.

This technique works well for adding rust to metal fittings or creating a salt-spray effect on the hull. Stippling involves using the tip of a brush to create a textured, dotted effect.

Stippling is excellent for creating a worn paint effect or adding texture to large, flat surfaces. Weathering Specific Areas of Model ShipsHull and planking. The hull often shows the most weathering:

Deck and superstructuresDecks see a lot of traffic and exposure:

Metal parts (cannons, anchors, etc.)Metal parts often show the most dramatic weathering:

Sails and riggingFabric and rope elements require different weathering approaches:

Adding Environmental EffectsWater stains and tide marks. These effects can add a lot of character:

Sun bleachingSun exposure can dramatically affect a ship’s appearance:

Soot and smoke effect sFor steam-powered ships or those with galleys:

Sealing and Protecting Your Weathering WorkSealing your work protects it and enhances the overall effect:

Choosing the right sealantDifferent sealants can produce different effects:

Application techniquesProper application is crucial:

Ready to Build Your Own Model Ship?Weathering your model ship is a rewarding process that brings your creation to life. It requires patience, practice, and a good eye for detail, but the results are well worth the effort. Remember, there’s no single “right” way to weather a model – let your research, imagination, and artistic sensibility guide you. As you apply these techniques, you’ll develop your own style and preferences. Don’t be afraid to experiment, and remember that even “mistakes” can sometimes lead to interesting and realistic effects. With each model you weather, you’ll improve your skills and expand your techniques. And if you still have questions, contact our friendly team of expert modelers!  Learn The Art Of Building A Model Ship Get started in wooden model ship building today Join 18,543 other modelers to hear about specials, new products and modeling tips

Information

Copyright © 2023 Modelers Central. ABN: 31 114 830 732

Modelers Central. 2023, All rights reserved.

Get 10% offYour first order. 10% off applies only to full-price items. By providing your email address, you agree to our Terms & Privacy Policy  10% off applies only to full-price items. By providing your email address & mobile number, you agree to our Terms & Privacy Policy and consent to receive marketing messages from Modelers Central at the addresses provided. You can unsubscribe at any time by replying STOP.

[[attributes.brand]] [[description]]  Make your own sails and much more with high-performance sailcloth sold by the yard from Sailrite’s excellent selection. Choose from ripstop and Dacron® sailcloth in a variety of colors and weights. Fabric samples available. Stay in the loop! Never miss sale announcements, how-to blogs, new product launches, helpful tutorials and more! |

IMAGES

VIDEO

COMMENTS

The more experienced the sail maker gets the better the sails work. This guide is intended to help newbies to cut heir own sails and build their own rigs. Sailmaking Tips: A piece of thin melamine board about 50x200cm is very helpful to loft the outline of the sails. Use packing paper to sketch the outlines according the class rules or a ...

2023 CATALOG AND PRICE LIST. 1) Select color for corner reinforcements: (red, yellow, blue, green, day-glo orange, day-glo pink, black or white.) 2) Select mainsail to mast attachment: Mast loops, jackwire, bolt-rope. 4) If Class Insignia and racing numbers required, select color: (red, blue, green or black), (add $15.)

Batten Material - Medium. $8.38. Sail Reinforcement and Deck Patch Material 685 mm x 375 mm "White". $7.75. Sail Reinforcement and Deck Patch Material 685 mm x 375 mm "Red". $7.75. Sail Reinforcement and Deck Patch Material 685 mm x 375 mm "Blue". $7.75. Sail Reinforcement and Deck Patch Material 685 mm x 375 mm "Black".

Install and rig the booms and gaffs. Make the sails based on the actual layout of my ship. De-rig the booms and gaffs, and remove them from the ship. Attach sails to the booms and gaffs as appropriate. Re-install the booms and gaffs, and their rigging. Add the additional rigging for each sail.

Potter Solutions offers a range of sails, rigs, boat stands, accessories and fittings for various model yacht classes. Find DF65 and DF95 complete packages, custom made sails and fast shipping or local pickup options.

Using technological advances in materials coupled with innovation, expertise and tradition over 92 years to bring you the very finest model sails. ... Nylet are the longest established professional model sailmakers in the world, manufacturing full size sails from 1932 to 1965, and also model yacht sails in cotton from the early 1930's onward ...

2mil, 3mil or 1.4mil suit $140. "B" suit PX75 $140. "C" suit 3mil with reinforced seams $140. Soling 1M. Note: Rule change 6.1 - 2020, no thickness is required. Any woven polyester fabric $120. Columbia 42 (C42) (A or B suit) Per class rules Suit $120. If only "B" main $65. Competitive quality sails for J Class, Star, EC-12, IOM, One Meter ...

Larry Robinson - Making Model Yacht Sails - how to build in their shape, a master class in sail making for modern rc model yachts. Around 700 copies sold by mid 2015 and still going strong. If you want to know how to make well shaped rc model yacht sails, and make them efficiently and consistently, this contains all you need to know.

Pay close attention to the arrangement of the sails, the types of rigging lines used, and the tension applied to each line. 2. Use High-Quality Materials. Investing in high-quality rigging materials is crucial for achieving a realistic look and ensuring the longevity of your model. Opt for materials such as fine thread or fishing line for the ...

Create your own sails and sailcloth for model ships and boats with our selection of high-quality materials. Whether you're crafting a historic tall ship or a modern yacht, our sails and sailcloth options allow you to customize and personalize your models. Explore now and bring your maritime creations to life.

Catsails are specialist manufacturers of sails and accessories for performance radio controlled model yachts. Proprietor Nigel Brown has been sailmaking since 1980 and has worked in some of the top sail lofts across the World including building sails for 4 America's Cup programmes. Years of sailmaking experience at the highest level combined ...

Sail material used for premium quality Sailboat RC sails, select any thickness and colours you want, we recommend translucent for best performance.

92 years of Sailmaking. Fine Products - Quality First. Nylet - Model sailmakers to the world ~ THE professional Master Sailmakers. Sails made by Special Commission for Collectors & Museums. Makers of model yacht sails to the National Maritime Museum Cornwall. Quick guide to ordering please scroll down. To contact us, click right link on top bar.

Sail Sets. Modelers Central offers the largest range of decorative sail sets for wooden model ships & wood model boats - plus 100's of decorations, accessories & fittings available. Modelers Central is the no.1 destination for model ship builders & model boat builders worldwide.

Hobby Model Yacht Sails And Supplies. Sail Making RC Mylar Sails. Sail Makers Block Wing. Mylar Film Insignia Tape Kikusui Tapes Eyelets. ... The Preferred Construction Material . Stay On The Pace. Light Wind Medium or Heavy Wind, One Panel or 3 Panel Construction, Mylar Dose it All.

Sail Making Materials. 22 Item(s) Sort By Show per page. Eyelets - small - 100/pack. Product code: 078. £6.00. Add to Cart ... Making Model Yacht Sails - Larry Robinson's method of building in shape. Product code: BK-38. £17.00. Add to Cart. Batten material - thin. Product code: BM-T. £10.75.

The book 'Making Model Yacht Sails' by Larry Robinson is recommended reading for anyone wanting ... used by the top sailmakers and is a contemporary masterclass in its own right. It is stocked by SAILSetc, item BK-38 Sail making materials are listed in the SAILSetc catalogue and in our list of additional and surplus sail making materials ...

SAIL MAKING FOR MODEL YACHTS by Ben Morris (last edited 28/05/2024) Shape in Sails: Building Board: Making Seams: Set the Seam Curvature: Making a Sail: Sail Material: Diagonal Seams etc: Back to Intro page: Setting the Sails: The Claudio Tool: Measuring Procedures ... There are many resources which offer all sorts of assistance to the beginner ...

Work step by step. 1.Make paper stencil for each sail and check it's dimensions on your model. 2.With soft pencil transfer all lines in to fabric - add stripe 5-7 mm around. sail edges. 3.Make all necessary lines on fabric using sewing machine and thin thread with light brown or beige color.

Sail Making Articles. We have several articles related to sails and sailmaking. The first is a short discussion of theory: The Design of Model Yacht Sails by A.M.Ballantyne. We then move on to the most complete set of instructions on how to sew a set of sails from cotton: "Sails" by Walter K. Moss from The Modelmaker, 1940. The next article discusses the one thing that is possible on a ...

Amazon.com: Model Expo Sail Cloth, 18 X 36 (457 X 915MM) ... 63 inch x 2,5,10 Yards Unbleached Muslin Linen Fabric Material for Sewing Material Apparel Cloth. ... 5.0 out of 5 stars Perfect for small model boat sails. Reviewed in the United States on August 27, 2021. Verified Purchase.

Nowadays Mylar sails can be found only on relatively small boats, but Mylar film is widely used as a base for laminate sails for cruising yachts in combination with Dacron, aramids and PEN-fibers. Mylar yarns are set in the direction of expected loads and make the sail virtually unbreakable.

Weathering your model ship is the final touch that transforms a pristine replica into a lifelike miniature with a rich, nautical history. This crucial step in the model-building process adds depth, realism, and character to your creation, mimicking the effects of sun, salt, wind, and water on a vessel that's braved the high seas.

Sailcloth. Make your own sails and much more with high-performance sailcloth sold by the yard from Sailrite's excellent selection. Choose from ripstop and Dacron® sailcloth in a variety of colors and weights. Fabric samples available. Stay in the loop! Never miss sale announcements, how-to blogs, new product launches, helpful tutorials and more!