- Repair & Refit

- Localization

- Fuel Station

- Partnerships

Dry vs. Wet docking : pros and cons for your boat or yacht

- August 29, 2023

Deciding where to store your boat when you’re not using it may seem like a simple decision, but it actually has major implications for the care and durability of your boat or yacht. Two of the most common options are the dry or the wet docking, both with their advantages and disadvantages. To help you make the best decision, we are going to examine the pros and cons of each option.

Dry docking

Dry docking , often located in a slipway, involves storing your boat out of the water. This type of storage can range from simple open-air structures to enclosed, climate-controlled facilities.

Pros of Dry docking:

- Protection against the elements: One of the greatest advantages of the dry dock is that it offers excellent protection against the elements. By storing your boat out of the water, you minimize exposure to saltwater corrosion and marine organisms that can adhere to the hull. Additionally, your boat or yacht will be protected from storms and extreme weather conditions that can cause significant damage, especially during hurricane or storm seasons.

- Ease of maintenance and repair: Ship maintenance and repair tasks are more accessible in a dry marina. You can easily walk around your boat, making it easy to inspect the entire structure, including the hull and waterline. This allows easy access for cleaning, painting, applying antifouling paint, and any other work necessary to repair your boat.

- Security: Shipyards, especially those that offer indoor storage such as Barcelona Nautic Center, usually have advanced security systems, such as surveillance cameras, security fences, and security personnel. This makes it more difficult for intruders to gain access to your boat and provides an additional layer of protection.

Cons of Dry docking:

- Costs: The additional services and benefits of the dry docking can come with a higher price than wet docking. Costs can vary depending on the facility, but in general, dry docking, especially indoors and heated, tends to be more expensive.

- Water Access: Although having your boat out of the water has its advantages, it also means you can’t just hop on board and set sail at any time. You will need to plan ahead and coordinate with the shipyard staff to have your boat moved into the water.

Wet docking

As the name suggests, involves storing your boat in the water, typically at a dock or berth.

Wet docking pros:

- Convenience: The biggest advantage of the marina in water is convenience. Your boat is always ready to sail, which is ideal if you use it frequently. You won’t have to worry about moving it to and from the water every time you want to sail.

- Cost: In many cases, wet docking can be less expensive than dry docking. However, the cost may vary depending on the location of the marina and the facilities and services it offers.

Wet docking cons:

- Exposure to the Elements: By keeping your boat in the water, it is exposed to the damaging effects of salt water, which can cause corrosion and buildup of marine organisms on the hull. It is also exposed to inclement weather and sea conditions, which can accelerate wear and tear and the need for repairs.

- Maintenance and repairs: Although it is possible to perform some maintenance and repair tasks while your boat is in the water, other jobs, especially those that involve the part of the hull that is below the water line, can be more challenging. For larger jobs, such as applying antifouling paint or repairing damage to the hull, you may need to move your boat to a shipyard.

Choose the dry or wet docking?

In conclusion, both the dry and the wet docking have their advantages and disadvantages, and the choice between one or the other will depend on your individual needs and preferences. Consider factors such as cost, ease of maintenance and repair, protection from the elements, and convenience when making your decision. Whatever you choose, be sure to follow a regular maintenance and repair routine to keep your boat in the best possible condition.

And, if you have more questions, you can contact us at any time and we will advise you on the best option for your case .

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

U.S Navy Commissions USS New Jersey, First Ever Submarine For A Mixed Gender Crew

World’s Largest Hotel-Branded Superyacht Sets Sail For Maiden Voyage

India Establishes Its First Maritime Arbitration Center

Yanmar Unveils Its First Electric Propulsion Product For Emission-Free Sailing

The Ultimate Guide to Dry Docks: Types, Functions, and Essential Requirements

A dry dock is a structured area where the construction, repairs, and maintenance of merchant vessels and boats are carried out. This unique construction or arrangement allows water to be filled up in an area, also known as a lock, so vessels can be manoeuvred in and out of the area.

Once the vessel enters the dry dock, the gates are closed, and the seawater is drained out so that the hull and other parts of the ship, which have been exposed to seawater for a long time, are exposed for maintenance and repair work.

Table of Contents

Dry Dock Survey

As per SOLAS requirements, all Merchant vessels require a complete survey of the hull in a dry dock twice within a 5-year period and an intermediate survey within 36 months at the earliest.

This includes maintenance of the hull, propeller, rudder, etc. and other parts which are immersed in water and are generally inaccessible by staff when the ship is sailing

For a passenger vessel , the bottom is to be inspected annually. Two such inspections in a period of five years must be carried out in dry dock , and the maximum interval between these inspections should be three years.

Types of Dry Dock

Different types of dry docks are used for repairing and cleaning a ship. The main ones are:

- Graving dock

- Floating dock

- Marine Rail Dock

- Marine mobile lifts

Among these, the marine mobile lifts and ship lifts are mainly used for small vessels such as recreational yachts, tugs, pilot boats, etc.

Nowadays, there are mainly two types of dry dock procedures from the above list that are used for seagoing vessels:

1) Graving Dry Dock

This type of dry dock is normally constructed on land near coastal waters. It is rectangular and made of solid concrete, with blocks, walls, and gates. The vessel is shifted inside the dry dock and rested on the blocks. After the ship is in the required position, the gate is closed, and water is removed.

Related Read: Understanding Ship Stability During Dry Dock

In the past, the graving dry docks were constructed using stones and timber. Now, a steel and concrete enclosure is used, and a heavy steel gate is used to seal the dock to stop water ingress once the ship is standing on the blocks.

The gates can be in two parts, with each hinged to the sides and hydraulically operated, or one solid steel structure supported on a roller over the track, which can be retracted inside the dry dock walls when opening the gate.

Advantages of Graving Dry Dock

- It can accommodate vessels of bigger sizes when compared to other dry docking systems.

- It is cheaper to dry-docking a vessel of a similar size to other types.

- The graving dry dock can perform retrofitting, modification, etc., which is challenging in other types.

- Due to its location near the land, the graving dock is easily accessible for the supply of spares, machinery, and services.

- New advanced graving docks have welding, hot-work and other workshops inside the dock on an elevated surface (above the water surface when the dock is filled), giving quick access and workflow in the dock.

- Retractable ramps in new graving docks make it easy to supply spare machinery and save a lot of time and manpower to transfer them inside the dock.

- A bigger graving dock can be used to repair more than two ships at a time, and some modern graving docks have two gates at both ends, making it easier to repair and re-float the vessel independently.

Disadvantages of Graving Dry Dock

- When re-flooding the dry dock, all the machinery and equipment needs to be taken out from the dock, which takes time.

- The maintenance cost of the graving dock increases as per the age of the dock and becomes very high.

- Any problem with the dock gate will make the whole dock non-operational

- The docking and undocking process in the graving dock takes time compared to other types

- If the dock holds multiple ships for repair , the complete operation needs to be stopped if any one of the vessels needs to be taken out of the dry dock as it will require filling of water for refloating

2) Floating Dry Dock

A floating dock is in the form of a “U” structure, mainly used in salvage to carry ships that have met with an accident and are damaged to an extent that has made them unable to sail further to a coastal dock.

However, many regular sea-going, small, and mid-size vessels are now dry docking in floating docks. Several “U” type floating docks can be joined to carry a large vessel.

The ship is brought near the channel where the floating dry dock will partly submerge itself, and the ship slides inside the dock.

Once the ship is in position, the floating dock is de-ballasted to drain the water from its hollow floors and walls, which support the vessel on the blocks arranged on the dock’s floor.

A valve is provided that can be opened to fill up the chambers with water and immerse the dock so that the ship can sail out.

The water is pumped out of the chamber, allowing the dry dock to rise, exposing the underwater area of the ship for maintenance or carrying out the ship repairs.

Related Read: What is Ballasting and De-ballasting?

The floating dry dock is usually built using steel framing similar to that of seagoing vessels, with ballast tanks provided on the sides and bottom to raise and lower the dock.

Floating dry docks are commonly operated in sheltered harbours, where there are no waves or natural tidal activities.

Advantages of a Floating Dry Dock

- They can be propelled to the location of a salvage vessel near the harbour

- They are cheaper to maintain as compared to graving docks and can get a higher resalable return

- They can be installed near or away from the shore inside the harbour, making them a portable and space-saving structure without taking space of the shore facility

- The complete floating dry dock can be aft or forward trim by ballasting the dock, which further assists the ship or the damaged vessel which cannot be given a trim

- Additional mooring equipment is needed for the floating dry dock to make it stable

- The floating dry dock can be altered and increased in size in all dimensions by extensive retrofitting/ rebuilding

- They can also be split into two different floating docks independent of each other

Disadvantages of Floating Dock

- The supply of store, equipment, and manpower is usually done from one access point gangway, which makes the operation slow.

- The maintenance cost of a floating dry dock is similar to that of a ship, as the hull is submerged in saltwater.

- The floating dry dock operation will be affected if there are tides or during windy weather.

- When re-flooding the dock, all the machinery and equipment needs are to be removed, which takes time.

Blocks Of Dry Dock

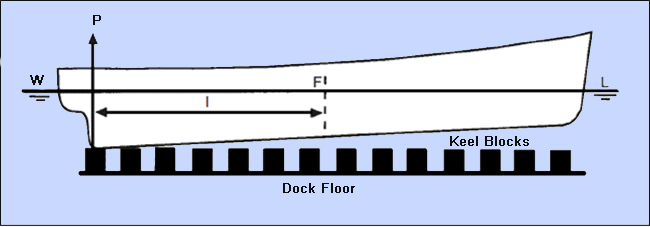

The blocks inside the dry dock play a critical role in taking the ship’s load and distributing it among the blocks placed below the keel plates. Every ship has a docking manual that will provide a guide block plan approved by the Ship Classification Society.

The shipmaster/ chief officer and the dry dock master must understand the blocking plan for the particular vessel and how the ship will behave under load when resting on the blocks, including various factors that can affect the load a block takes.

The blocks are usually constructed from one material so that their stiffness is similar. If the blocks are built from different materials, the force exerted on the blocks with a smaller elasticity module will squeeze them more than the stiffer block. This can lead to damage to the block or the ship’s hull, as the force distribution will be uneven.

The most common materials used for the blocks are:

- Concrete with steel

- Timber blocks

- Timber on top and concrete at the bottom

When a timber block is added to a keel track built of blocks with concrete or steel bases, the timber block will take a much smaller load than the others.

Apart from the keel blocks, side blocks are also arranged to support the ship. They are less stiffer than the keel blocks as a stiffer side block will overload the vessel and may damage the structure. The height of the slide blocks is usually similar or more than that of the keel blocks.

Important factors which affect the loading on the dry docking blocks are:

- The initial height of the block: The block’s height is a critical factor, as the load on the individual block will be determined by the load shared by all the other blocks. If the placement and height of the blocks are according to the ship’s hull, the load distribution will be even.

- The contact area of the block: The contact area of the block with the ship’s hull determines the load distributed on the block. If the contact area of the block is smaller in size, this means the load exerted on this block will be lesser than that with a larger contact area.

- The material of the block: As stated earlier, different materials will react differently to the load exerted by the ship. Hence, the material of the block used for the keel block and the side block plays an important role in aligning the ship in the dry dock.

- Placement of the block: The blocks in the dry dock need to be arranged according to the ship’s docking plan. Many types of equipment and parts can get damaged if the block position is not altered. For example, echo sounders, anodes, etc., the blocks need to be removed so that these equipment tools have space to settle once the ship rests on them.

Choosing A Type of Dry Dock

The criteria to select a type of dry dock for a ship depends on the following factors:

- The size of the vessel: The graving dock accommodates larger sizes than any other type. If the shipowner/ manager has to dry dock a large oil tanker, they will go to the graving dock. The Marine railway type can be used if the vessel is about 10000 tonnes. If a boat or small yacht of up to 250 tonnes needs repair in the dock, a mobile marine lift can be used.

- The condition of the vessel: If the vessel propulsion plant is not working or some damages can make a ship immobilized, floating docks are commonly used in such a condition

- Types of repair: The choice of dry dock type also depends on the type of repair the ship wants to undergo. For the regular scheduled dry dock, a floating dock can be selected; however, if there is major retrofitting or massive parts/ machine fitting is required, the graving dock is chosen as they are usually located near the shipyard and it is easy to move the material from land to dock as compare to the floating dock.

- Schedule of the Vessel: The location and the type of the dry dock will be decided as per the current schedule of the vessel and how easy it is for the ship to reach the dock after unloading all the cargo to the last port of call

- Budget: The most critical factor in selecting the type of dry dock is the budget allotted to the ship

Related Read: How Cost Estimation is done for Ship’s Dry Dock?

Requirements for Dry Docking

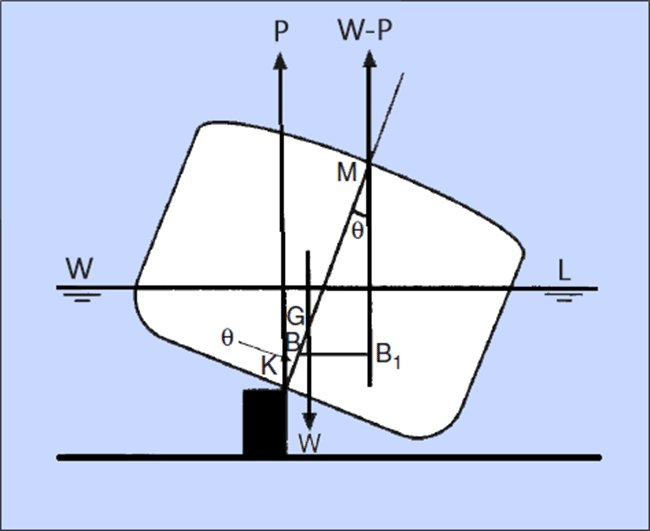

Stability is the most important requirement for getting a ship safely into a dry dock. The three important parameters which must be ensured before entering the dry dock are:

1) Adequate Initial GM:

When the ship touches the blocks, a reaction at the point of contact raises the centre of gravity “G” and reduces the metacentric height “G.M.” so that an adequate initial metacentric height is required to compensate for this.

2) Vessel to be Upright:

While entering the dock, the vessel must be upright, meaning there should be no port or starboard list when the ship touches the blocks. If the point of contact of the ship and keel blocks is outside the centre line of a vessel, it may force the ship to tip over.

3) Small or Moderate Trim Aft:

When making the ship’s keel sit on the keel block, a moderate trim aft is usually kept. As the water level in the dock lowers, the slight trim allows the stern and bow to ascend in tandem rather than simultaneously, which will reduce the load and pressure on a vessel’s hull and keel.

Related Read: 10 Types of Dry Dock Accidents That Can Occur in Ship’s Engine Room

Dry Dock Procedure

Once the ship manager selects the type of dry dock, the next step is to prepare the ship to enter the dry dock and carefully place the ship’s keel on the blocks provided on the dry dock floor. Some important points to note are:

- Make sure the ship is prepared to enter the dry dock by having the least ballast and no cargo carried on board

- If the floating dock is used, the ship’s movement will depend on the docking master’s requirements and the vessel’s condition. If the vessel is immobilized due to an accident, the floating dock will move towards it, and if the vessel is functioning correctly, it may propel inside the dock.

- Once the ship enters the dry dock, it is moored to the dock

- The docking master will inform the ship’s crew beforehand about the trim requirement they must maintain.

- Before emptying the dock, the ship and dock master must ensure that equipment like an echo-sounder or log sensor does not hit any blocks and is clear of any obstruction. For this, divers are sent to check that all such equipment is precise of the blocks

- The dock master will give the order to pump the water out from the dock, and slowly, the ship will sit on the keel blocks

- The docking master and the ship’s crew must ensure the point of contact of the ship and keel blocks does not lie outside the centre line of a vessel as it may lead to the tumbling of the ship

- Once the ship sits on the dock, the cleaning and repairing process starts

Related Read: Dry Docking of Ships – Understanding Stability And Docking Plan

Duties of Ship C rew Members During Dry Docking

While dry-docking the ship, the duty of the ship’s crew (under the guidance of the chief engineer and chief officer) will be:

- To keep the ship at minimum ballast condition

- To keep the aft trim as requested by the dockmaster

- To ensure the vessel is moored by assisting the dock crew once the ship comes inside the dry dock

- To keep a check on the stability of the ship while the water is lowered in the dock

- Once the ship is sitting on the blocks, the ship’s crew will pump out the ballast

- To prepare the vessel to connect to the shore power

- Once the dry dock water is pumped out, de-ballast tanks using gravity

- Remove the drain plugs from the bottom of the ship for various tanks

Related Read:

- Checks to Perform on Ship before Coming out of the Dry Dock

- What is Extended Dry-Docking of Ships?

Drydocking is one operation that allows the ship’s crew to learn areas that cannot be explored when the ship is sailing.

It also helps the ship manager to assess the condition of the ship’s hull and the machinery which are not accessible when the ship is in water.

Bringing the ship to the dry dock is a team effort between the ship’s crew and dry dock personnel. Proper communication is the key to safely laying the ship’s keel on the keel blocks.

Article In Pictures

Disclaimer : The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Do you have info to share with us ? Suggest a correction

About Author

Raunek Kantharia is a marine engineer turned maritime writer and entrepreneur. After a brief stint at the sea, he founded Marine Insight in 2010. Apart from managing Marine Insight, he also writes for a number of maritime magazines and websites.

Read More Articles By This Author >

Daily Maritime News, Straight To Your Inbox

Sign Up To Get Daily Newsletters

Join over 60k+ people who read our daily newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

BE THE FIRST TO COMMENT

13 comments.

We have ship repair yard and we are trying to build a graving dock of 121 metres length in to in 21metres in to in breath What are the basic standard ofvsafety required and what is the minimum thickness of concrete walls required finally will a dept of 3.5 mettres be enough to dock a vessel of 8 metres draft. In balance Thanks in antipation

Personal take on building a graving dock should come from a commercial stand point, then design according to your commercial needs, the soil condition and sea bed conditions of graving dock location.

Based on the size according to your input, my guess on your target segment are tugboats, small fishing trawlers and maybe catamaran. Look at your total geographic location and see if there are expanding business opportunities such as offshore OSV potential, OSV support base and such. Otherwise it will be costly to rebuild or modify your graving dock again just to cater for missed opportunities. Similarly there is always a question of cost when how big a size is enough? The very reason why I feel your commercial requirements rules over what size of docks to build. Generally I feel your dock should cater at least 20 years of business projection.

On the size that you mentioned, seems like this project of yours is very initial stage and you are currently working on minimum information. Your depth of graving dock should not be determined by whether you can take certain vessel draft. Instead do your seismic on the sea bed and understand what are your tide movements. I have seen shipyards building docks with more depths but needs dredging periodically more than required. I have bring vessels in on 7.5 mtrs draft although the docking draft at zero tide is 5.5 mtrs, simply because I worked on high tide window of 2 to 3 mtrs.

To me ship repair is exciting and to an extend fun because it really challenges your thinking outside the norm. Keep looking and keep understanding your area, ship repair is not just the repairs per said. You can have the best and safes dock, world class facilities and effective workforce. If the ship cannot come, is effort down the drain.

Good luck and all the best.

Regards Clement See

What are the dry dock repairs under statutory / class requirements

List any three jobs usually done on the anchoring system of a ship in a dry-dock .?

Hello, I’m trying to put together a proposal for the construction of a floating dock. Is there anyway to deduce and estimate for the construction of breakwater, with a total length of 1500m.

Good Day All,

How much power is required, on average, per dock, for a typical dry dock system

Please send me a buchture of Dry Dock

A Korean shipyard named Hanjin Heavy Industries is considered one of the biggest shipyard in Asia where there shipyard is located in Subic, Philippines (Former US naval base) .

Last month, a bad news came out that the shipyard is to shutdown and requested to the bank lenders to apply for bunctiotcy.

There are about more than 2,000 employees to be displaced. In this regards, we would like to invite any investors to save more than 2,000 employees being laid off due to mismanage of the company.

If anyone would interested to take over the shipyard. Please feel free to contact me as we have hundreds of qualified welders, naval architects to support the business.

Thanks for explaining the different types of dry docks and that you mention how it’s important to consider the current schedule of the vessel to find one that is easy to reach so the ship can be unloaded. When choosing, it would probably help to hire a local company that offers dock construction services. This would be useful to figure out the best type based on your ship, schedule, and location and could also help you get quality materials that will work properly and last a long time.

How does ECDIS System affected, when a ship is already on the blocks at Dry Dock ?

What is the maximum recommended duration of a floating dock to operate in salty water before it can undergo a major maintenance before it can continue holding vessels under dry dock.

Kind Regards

sir. we have planed to make a prototype of graving dock which having flap gate for our project. can you tell me any specified area we should follow. Thank you.

Please see below which could be added to this article.

The world’s first road-transportable floating dry dock

tugdock.com

Leave a Reply

Your email address will not be published. Required fields are marked *

Subscribe to Marine Insight Daily Newsletter

" * " indicates required fields

Marine Engineering

Marine Engine Air Compressor Marine Boiler Oily Water Separator Marine Electrical Ship Generator Ship Stabilizer

Nautical Science

Mooring Bridge Watchkeeping Ship Manoeuvring Nautical Charts Anchoring Nautical Equipment Shipboard Guidelines

Explore

Free Maritime eBooks Premium Maritime eBooks Marine Safety Financial Planning Marine Careers Maritime Law Ship Dry Dock

Shipping News Maritime Reports Videos Maritime Piracy Offshore Safety Of Life At Sea (SOLAS) MARPOL

WAIT! Did You Download 13 FREE Maritime eBooks?

Sign-up and download instantly!

We respect your privacy and take protecting it very seriously. No spam!

How Much Does It Cost To Dry Dock a Boat Exactly? (3 Types)

Are you a boat owner looking to give your vessel some much-needed maintenance? If so, you may need to dry dock your boat, which means you will remove it from the water and place it on land for repairs, cleaning, or storage. But exactly how much does it cost to dry dock a boat? Let's dive in and break down the costs of dry docking a boat and get some tips on how to save money without sacrificing quality.

A 20-foot sailboat costs around $200 to $500 for a month of dry docking. Pontoons measuring 20 feet cost between $200 and $600 to dry dock. For medium-sized boats, costs can vary from $1,000 to $2,000, while for large boats measuring over 40 ft., such as yachts, costs can run between $3,000 and $5,000.

Remember that dry docking is not the only option to store your boat, as you can also opt for wet slip, rack, and garage storage options. Let's compare the prices and characteristics of each of these storage options versus dry dock storage as you continue reading below.

- The exact cost of dry-docking a boat depends largely on the type of boat, whether it is a sailboat, a pontoon, or a yacht. It will also depend mostly on the size of the boat.

- Other factors that influence the overall costs of dry-docking include the duration of dry-docking, the location of the marina, the materials and types of services you need, the docking fee required in your chosen marina, and other additional costs for cleaning, repair, security, and moving your boat.

- There are other storage options that you may want to consider aside from dry-docking, such as wet slips, racks, or garage storage, and dry docking is the most expensive option, it is also the safest option for your boat.

On this page:

Dry docking costs by boat type, dry docking costs by boat length, understanding dry docking, cost factors of dry docking a boat, comparison of costs: dry docking vs other storage options, additional costs to consider, dry docking locations and their costs, how to save on dry docking costs.

Dry docking costs can vary depending on the type and length of the boat. Here's a table showing the costs of dry docking depending on boat type:

| $20 - $50 | |

| $50 - $100 | |

| $10 - $30 |

Cost of dry-docking a sailboat

Sailboats are typically smaller than yachts, so their dry docking costs are generally lower. The average cost to dry dock a sailboat is around $20 to $50 per foot of length. For example, if your sailboat is 30 feet long, you can expect to pay between $600 and $1,500 for dry-docking services.

Cost of dry-docking a yacht

Yachts are larger than sailboats and require more maintenance, so their dry docking costs are higher. The average cost to dry dock a yacht is around $50 to $100 per foot of length. So, if your yacht is 50 feet long, you can expect to pay between $2,500 and $5,000.

Cost of dry-docking a pontoon

Pontoons are smaller than yachts and sailboats, but they still require dry docking services. The average cost to dry dock a pontoon is around $10 to $30 per foot of length. For a pontoon that is 20 feet long, you can expect to pay between $200 and $600 for dry-docking services.

Dry docking your sailboat is necessary for maintaining its integrity and prolonging its lifespan. Aside from the type of boat, dry-docking rates can also vary depending on the size of your boat. Here's a table showing the dry-docking costs in terms of boat length:

| $200 - $500 | |

| $1,000 - $2,000 | |

| $3,000 - $5,000 |

Cost of dry-docking a small boat

Small boats, which are typically under 20 feet long, are the least expensive to dry dock. On average, you can expect to pay anywhere from $200 to $500 for dry-docking services for a small boat. However, keep in mind that prices can vary depending on the location and the specific services provided.

Cost of dry-docking a medium-sized boat

Medium boats, which are typically between 20 and 40 feet long, are more expensive to dry dock than small boats. On average, you can expect to pay anywhere from $1,000 to $2,000 for dry-docking services for a medium boat. Again, prices can vary depending on the location and the specific services provided.

Cost of dry-docking a large boat

Large boats, which are typically over 40 feet long, are the most expensive to dry dock. On average, you can expect to pay anywhere from $3,000 to $5,000 for dry-docking services for a large boat.

Dry docking is an essential part of maintaining your sailboat's hull and keeping it in good condition for years to come. It involves taking your boat out of the water and placing it on a dry dock for repairs, maintenance, or inspections.

The cost of dry-docking your sailboat depends on several factors, including the type and length of your boat, the location of the dry dock, and the scope of the work required. On average, you can expect to pay anywhere from $20 to $40 per foot of length for dry docking services.

Here's a breakdown of the average costs of dry docking for different types and lengths of sailboats:

| $20 | |

| $25 | |

| $30 | |

| $35 | |

| $40 |

When dry docking your sailboat, safety should always be a top priority. You may need to make sure that the dry dock is equipped with the proper equipment, like cranes, lifts, and straps, to safely lift and support your boat.

A good rule of thumb is to choose a dry dock that has experience working with sailboats and can provide references from previous customers. This will give you peace of mind knowing that your boat is in good hands.

In addition to safety, you might also want to have a clear understanding of the work that needs to be done on your sailboat while it's in dry dock. This can include anything from routine maintenance, like painting the hull or replacing the zincs, to major repairs, like fixing leaks or replacing damaged parts.

To ensure that you get an accurate estimate for the cost of dry-docking your sailboat, you could provide the dry dock with as much information as possible about the work that needs to be done. This will help them provide you with a more accurate quote and avoid any surprises down the line.

When it comes to dry docking your boat, the cost can vary depending on several factors, not just by boat type and length. Here are some other key cost factors to consider:

The duration of dry docking will influence the cost

The longer you need to dry dock your sailboat, the more it will cost. Some marinas charge by the day, while others offer monthly rates. Generally, the longer you stay, the lower the daily rate will be. However, you may need to keep in mind that some marinas may have a minimum stay requirement.

The location of the marina will also impact the cost of dry docking

Marinas in more popular or high-demand areas may charge more than those in less popular areas. Additionally, marinas located in areas with higher costs of living may also charge more. For example, the costs of docking in the Mediterranean are higher since it is a very popular and crowded area .

The materials and types of services you need can affect the cost of dry docking

For example, if you need your boat to be pressure washed or painted, this will add to the cost. Additionally, if you need any repairs or maintenance done while your boat is in the dry dock, this will also add to the cost.

The amount of docking fee required can add up to the costs

In addition to the cost of dry docking, you may also need to pay docking fees . These fees can vary depending on the size of your boat, the duration of your stay, and the location of the marina.

Generally, docking fees for boats under 30 feet long start at around $50 per day and $500 per month .

If you're looking for a place to store your boat, you have several options to choose from. Dry docking is one option, but there are other storage options that you may want to consider, such as the following:

Storing boat on a wet slip

A wet slip is a storage option where your boat is stored in the water. The cost of a wet slip can vary depending on the location, size of the boat, and the amenities offered by the marina.

On average, the cost of a wet slip is around $12-$15 per foot per month . So, if you have a 30-foot sailboat, you can expect to pay around $360-$450 per month for a wet slip.

Storing boat on a rack

A rack is a storage option where your boat is stored on a rack in a covered storage facility. On average, the cost of a rack is around $7-$10 per foot per month.

Storing a boat in a garage

A garage is a storage option where your boat is stored in a garage or covered storage facility. On average, the cost of a garage is around $10-$15 per foot per month.

Below is a table summarizing the costs for each storage option:

| $20-$50 | |

| $12-$15 | |

| $7-$10 | |

| $10-$15 |

As you can see, dry docking is the most expensive option, while rack storage is the least expensive option. However, each option has its own pros and cons, so you may need to consider your needs and budget when choosing a storage option for your sailboat.

Dry docking a boat is not just about the cost of the actual dry-docking process. There are additional costs that you may need to consider when planning your budget. Here are some of the additional costs that you should keep in mind:

Additional costs for cleaning

Before you take your boat out of the water and into the dry dock, you should make sure that it is clean. If your boat is not clean, it can cause problems during the dry-docking process. You may need to pay for a professional cleaning service, or you may be able to clean your boat yourself.

Additional costs for repairs

If your boat needs repairs, you should get them done before you dry dock it. If you don't, the repairs will be more difficult and expensive to do once the boat is out of the water. You should also consider the cost of any repairs that need to be done while your boat is in the dry dock.

Additional costs for security

When your boat is in the dry dock, it is vulnerable to theft and vandalism. Try considering the cost of security measures such as cameras, alarms, and security guards.

Additional costs for a lift

You will need to pay for a lift to get your boat out of the water and into the dry dock. The cost of the lift will depend on the size and weight of your boat.

Additional costs for a trailer

If you have a trailer, you may be able to avoid the cost of a lift by using it to transport your boat to and from the dry dock. However, you should keep in mind that there may be additional costs associated with using a trailer, such as the cost of a vehicle to tow the trailer.

Also, not all sailboats are trailerable. You can read this article to know the characteristics of a "trailerable sailboat".

Additional costs for mooring/berth/anchorage

While your boat is in the dry dock, you will need to find a place to store it. You may be able to store your boat on land, but you may also need to pay for a mooring, berth, or anchorage.

Additional costs to purchase a Fender

When your boat is in the dry dock, it will be resting on blocks. You may need to purchase fenders to protect your boat from damage.

Additional costs to avail of a launch service

When you are ready to take your boat out of the dry dock and back into the water, you will need a launch service. You should consider the cost of the launch service when planning your budget.

Different locations worldwide offer different dry-docking costs. Below is a table summarizing the dry docking costs in different locations around the world:

| Location | Dry-docking costs per foot of length | Popular dry-dock location |

|---|---|---|

| United States | $20 to $40 per day | Coastal areas |

| France | €30 to €80 per day | Marseille, Toulon, Antibes |

| Italy | €30 to €60 per day | Naples, Palermo, Rome |

| Greece | €20 to €60 per day | Athens, Corfu, Rhodes |

| Croatia | €20 to €60 per day | Split, Dubrovnik, Zadar |

| Monaco | €40 to €100 per day | Port de Fontvieille, Port Hercule |

Dry docking can be a costly process, but there are ways to save money without sacrificing quality. Here are some tips to help you save on dry docking costs:

Schedule your dry docking well in advance so that you can take advantage of early-bird discounts and avoid peak-season rates. You can also save money by bundling services, such as bottom painting and hull repairs, instead of doing them separately.

Consider alternative docking options

You can consider the use of an in-water dry dock system like the patented SeaPen. This system keeps your boat's hull dry while it's still in the water, reducing the need for costly maintenance. Another option is to use a boat lift, which can be less expensive than traditional dry docking.

Purchase your own dock

If you plan to keep your sailboat in the same area for an extended period, consider purchasing your own dock. This can be a cost-effective solution in the long run, as you won't have to pay transient mooring or liveaboard fees. Plus, you'll have the convenience of having your boat right at your fingertips.

Contact the marina directly

When booking your dry docking, try to contact the marina directly instead of going through a third-party booking service. This can often save you money, as the marina won't have to pay a commission to the booking service.

Park your boat off-season

If you don't plan to use your sailboat during the off-season, try storing it on land or in a covered dry stack facility. This can be significantly less expensive than keeping it in the water year-round.

Compare rates

Be sure to compare rates from different marinas and dry docking facilities. Rates can vary widely depending on the location, boat size, and duration of the dry docking. Don't be afraid to negotiate with the marina to get the best possible rate.

Leave a comment

You may also like, how much does it cost to dock a boat in california (7 types).

Boating in California is a dream come true for many enthusiasts, with miles of beautiful coastline and picturesque harbors to explore. While owning a boat can be a …

How Much Does It Cost To Dock a Boat in San Diego?

The 3 Cheapest Places to Dock a Boat (You Didn't Think Of)

How Much Does It Cost to Dock a Catamaran? (7 Locations)

The Cheapest Place To Dock a Boat in California (7 Places)

ACTIVE STORM TRACKER Hurricane and Tropical Storm Information Learn more

Service Locator

- Angler Endorsement

- Boat Towing Coverage

- Mechanical Breakdown

- Insurance Requirements in Mexico

- Agreed Hull Value

- Actual Cash Value

- Liability Only

- Insurance Payment Options

- Claims Information

- Towing Service Agreement

- Membership Plans

- Boat Show Tickets

- BoatUS Boats For Sale

- Membership Payment Options

- Consumer Affairs

- Boat Documentation Requirements

- Installation Instructions

- Shipping & Handling Information

- Contact Boat Lettering

- End User Agreement

- Frequently Asked Questions

- Vessel Documentation

- BoatUS Foundation

- Government Affairs

- Powercruisers

- Buying & Selling Advice

- Maintenance

- Tow Vehicles

- Make & Create

- Makeovers & Refitting

- Accessories

- Electronics

- Skills, Tips, Tools

- Spring Preparation

- Winterization

- Boaters’ Rights

- Environment & Clean Water

- Boat Safety

- Navigational Hazards

- Personal Safety

- Batteries & Onboard Power

- Motors, Engines, Propulsion

- Books & Movies

- Cockpit Confessions

- Communication & Etiquette

- Contests & Sweepstakes

- Colleges & Tech Schools

- Food, Drink, Entertainment

- New To Boating

- Travel & Destinations

- Watersports

- Anchors & Anchoring

- Boat Handling

- ← Lifestyle

An In-Water Dry Dock For Your Boat

Advertisement

SeaPen is an alternative to traditional docking — and boat lifts — that cuts down on boat maintenance.

Here's a riddle: How do you keep your boat's hull dry but in the water at the same time? The patented SeaPen in-water dry dock system is a new way (and place) to park your boat that does just that. SeaPen was created by the Australian manufacturer Dock Pro, and is now available in North America through Solstice Docking Solutions.

This drive-on dry dock system can be simply tied to any fixed or floating dock. A high-density polyethylene frame sits at water level. Drop the rear gate using a remote-control key fob and glide your boat onto the pliable, breathable, marine-grade rope netting. Water drains through the net onto a growth-resistant liner where the Smart-Pump System detects then automatically pumps out any water. This leaves the hull dry, but still at water level. No permanently installed boat lift needed!

This innovative floating dry dock keeps your hull free from marine growth without the need for antifouling. This allows for more time on the water and less for maintenance. In addition, the 13-inch-wide frame is sturdy enough to walk on, allowing for easy cleaning, inspections, and repairs all the way around your boat. An optional aluminum walkway can be added for convenience.

SeaPen - The Dry Docking Solution

"There's a SeaPen for every size and type of boat," says Craig Freeman, sales director, explaining that 13 model sizes create "on-water garages" for center-consoles, pontoons and jet boats, and yachts ranging from 13 to 65 feet. The manufacturer claims that the entire unit requires minimal maintenance. The cost for this system starts at $12,000. SeaPen is available for purchase direct from Solstice Docking Solutions or through its dealer network.

Related Articles

The truth about ceramic coatings for boats.

Our editor investigates the marketing claims of consumer-grade ceramic coatings.

Fine-Tune Your Side Scan Fishfinder

Take your side-scanning fishfinder off auto mode, and you’ll be spotting your prey from afar in no time

DIY Boat Foam Decking

Closed-cell foam flooring helps make boating more comfortable. Here’s how to install it on your vessel

Click to explore related articles

Contributing Editor, BoatUS Magazine

A marine surveyor and holder of RYA Yachtmaster Ocean certification, BoatUS Magazine contributing editor Mark Corke is one of our DIY gurus, creating easy-to-follow how-to articles and videos. Mark has built five boats himself (both power and sail), has been an experienced editor at several top boating magazines (including former associate editor of BoatUS Magazine), worked for the BBC, written four DIY books, skippered two round-the-world yachts, and holds the Guinness World Record for the fastest there-and-back crossing of the English Channel — in a kayak! He and his wife have a Grand Banks 32.

BoatUS Magazine Is A Benefit Of BoatUS Membership

Membership Benefits Include:

Subscription to the print version of BoatUS Magazine

4% back on purchases from West Marine stores or online at WestMarine.com

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

Deals on cruises, charters, car rentals, hotel stays and more…

All for only $25/year!

We use cookies to enhance your visit to our website and to improve your experience. By continuing to use our website, you’re agreeing to our cookie policy.

- [email protected]

- +86 18800548228

What is a Dry Dock? 8 Things You Need to Know

Regardless of the type of vessel, dry docking operation is required every few years. This is usually a complicated process, but a necessary procedure. It allows the vessel to be refurbished, thoroughly maintained and upgraded.

If you’ve ever been curious about dry docks and their significance, you’re in the right spot. In this article, we’ll provide a comprehensive breakdown of dry docks, their functions, and the associated processes. Keep reading to learn more.

What is a dry dock?

Dry docks originated in 200 BC and were used by the Greeks and Romans to build and repair warships.

Now, A dry dock is a specialized form of docking facility, usually located at harbors and shipyards, designed to allow ships to be partially or completely removed from the water for maintenance, repairs, and inspections.

The term can also refer to a verb, It means an action, which we call dry docking, it is the process of moving a ship out of the water and onto land.

And there is a difference between a dry dock and a normal dock. Docks are used for loading/unloading cargo and water transportation, while dry docks are mainly used for shipbuilding and overhauling due to their ability to drain water.

What is the purpose of a dry dock?

A dry dock allows us to fully assess and manage the hull and all mechanical equipment without the hindrance of seawater.

When a ship is at sea, we do not have access to the parts of the ship that are underwater, such as the underwater hull and areas that are often submerged. With drydocking, you can treat the hull of your vessel safely and stably.

Dry docking can also be used for shipbuilding – after all, you can’t build a ship directly in the water – At dry docks, we can launch the ship into the water after it has been built.

Finally, it ensures that the vessel remains in optimum condition and has an extended life cycle, and it is also a regulatory requirement for flag state and classification society certification.

How does a dry dock work?

A dry dock is typically a rectangular basin enclosed by left, right, and front walls, used to hold and work on boats. It can be filled and drained of water by a floodgate.

To keep a ship upright in a dry dock, dock managers arrange keel blocks on the floor ahead of time and adjust them according to the ship’s size. They also use side blocks to support the ship and prevent it from falling over.

Before a ship can enter a dry dock, the basin must be filled with water. This is done using pumps or by opening a caisson/gate until the water inside is level with the sea. Once the water level is safe, the ship can enter.

After the ship is in position, the gate is closed, and the water is drained so that workers can enter and start working.

What happens when a ship is in dry dock?

Dry docking a ship is a meticulous and costly process, requiring thorough coordination between shipowners, shipyards, and contractors. So, what exactly happens when a ship enters dry dock? Let’s learn the dry docking process:

- Inspections: Rigorous checks are conducted on the hull and machinery, including propellers and thrusters, to detect any signs of damage or corrosion.

- Cleaning: The hull undergoes meticulous cleaning to remove marine growth and biofouling, ensuring optimal performance upon return to the water.

- Maintenance: The hull is blasted to remove old paint and rust, followed by repainting to protect against corrosion. Other components may also undergo maintenance procedures.

- Repairs: Any identified damages, such as issues with sea chests, sea valves, or other underwater structures, are promptly addressed and rectified.

- Upgrades: Opportunities for improvement are seized, with the installation of new equipment or the modification of existing systems to enhance operational efficiency.

- Additional Renovations: Decks, lighting, flooring, and trim may undergo renovation, while upgrades to appliances, entertainment systems, and other amenities are also considered.

It’s important to highlight that all repairs and overhauls undergo scrutiny by Classification Society surveyors to ensure compliance with scheduled class items.

During dry docking, all non-essential personnel, including passengers, vacate the ship. Crew members who remain aboard receive basic wages and assist with tasks such as catering, cleaning, and security, ensuring the smooth progression of operations.

How often do ships dry dock?

The frequency of dry docking for ships is contingent upon various factors, primarily the vessel’s age and type. Here’s a breakdown of typical dry-docking intervals:

- Cargo Ships: Generally, cargo ships undergo dry docking every five years. However, older vessels may require dry docking every three years to ensure continued seaworthiness.

- Passenger Ships: According to SOLAS 1974 regulations, passenger ships must be dry-docked at least twice every five years, not more than 36 months apart, and optimally about every 2.5 years.

The duration of a ship’s stay in dry dock typically spans around two weeks, although this timeline is subject to the vessel’s specific needs. For instance, the world’s largest cruise ship” Oasis of the Seas “, took 63 days to update and amplify, with more than 2,700 contractors working simultaneously in the dry dock in Cadiz, Spain. In cases where extensive repairs are necessary, dry-docking periods may extend to several months.

Shipowners are mindful of the financial implications of dry docking, as docking a ship renders it non-profitable during the maintenance period. Hence, shipowners prefer to minimize both the frequency and duration of dry-docking operations.

To address these concerns, almost all the major classification societies offer an alternative known as the “Extended Dry-Docking” (EDD) scheme. Under this program, ships can undergo dry docking every 7.5 years by conducting In-Water Surveys through approved diving companies. However, it’s important to note that the EDD scheme does not apply to passenger ships, maintaining stringent safety standards for vessels carrying passengers.

Types of dry docks

Dry docks are available in various configurations to cater to different types of ships and specific dry docking requirements. Here are the common types:

- Graving Dry Dock :

Graving Dry Docks are solid, rectangular concrete structures located near coastal waters. They allow ships to be shifted onto land for maintenance or repair. This type is popular for accommodating larger vessels and more cost-effective for similar-sized ships‘ docking needs. While it enables quick access to required items and saves manpower, the water filling and draining processes are slow, and docking/undocking procedures are relatively sluggish.

- Floating Dock :

Shaped like a “U,” floating docks provide flexibility for various scenarios, including emergency repairs in open waters. They cater to damaged vessels unable to reach coastal docks and can handle small to mid-size vessels for routine maintenance. Constructed with steel framing and ballast tanks, floating docks can be propelled to salvage locations. Advantages include mobility, cost-effectiveness, and adjustable trim to match the vessel’s trim.

However, they require additional mooring equipment and face operational challenges during tides or windy weather. Maintenance is also higher due to exposure to seawater.

Slipways are inclined ramps or tracks facilitating the launching and retrieval of small ships or vessels onto land for maintenance, repair, or storage. They offer a cheaper alternative to traditional dry docking for ship upkeep. The process involves clearing the slipways, deploying airbags or wheel pallets, and using cranes, forklifts, or slip winches to pull the vessel out of the water. Once repairs are completed, vessels can be quickly undocked.

- Syncrolift :

Syncrolift represents a modern dry docking solution that serves as both a dry dock and a launching platform. It features a platform equipped with winches and anchor chains that can be raised and lowered vertically. When a vessel sails into the platform, it’s secured by various support elements, and the platform is lifted out of the water to dock level. This process ensures safety and efficiency in dry docking operations.

- Boat Lift :

Boat lifts are specialized equipment designed to elevate boats out of the water, keeping them suspended above the surface. Commonly used by marinas or individuals, they are suitable for small boats and yachts. Boat lifts prevent corrosion, prolong service life, and facilitate cleaning and maintenance. Mobile boat lifts offer flexibility with self-propelled functions, enabling easy transportation of small boats in ports.

How to choose a dry dock for your vessel?

Selecting the appropriate dry dock for your vessel is a critical decision that requires careful consideration to ensure a successful outcome. You need to be aware of this:

- Seek Professional Assistance: Engage a reputable maritime services company to manage your dry docking project. Their expertise can streamline the process and mitigate risks.

- Evaluate Key Factors: Consider crucial factors such as the budget, shipyard’s reputation, your vessel’s size & condition, repair types, and schedule.

- Book in Advance: Reserve a dock well in advance, preferably several months beforehand, to secure availability. Popular shipyards like CSBC Kaohsiung Shipyard, Gotaverken, and Gunsan Shipyard are preferred choices but may experience high demand.

- Choose the Right Type of Dock: Select the appropriate type of dock based on your vessel’s size and specific needs. Graving dry docks are suitable for larger vessels, while mobile ship lifts are ideal for smaller boats or yachts. Floating dry docks offer flexibility for sudden dry docking needs, while shore-based docks are preferable for major renovations or overhauls.

- Plan Schedule: Arrange your sailing route and timing carefully, ensuring that cargo is unloaded before entering the dock, and is not far from the scheduled dock. This minimizes docking time and cost.

Who is responsible for dry docking?

Determining responsibility in the dry docking process is crucial to mitigate risks and prevent unnecessary damage to the vessel. But who holds accountability in case of accidents—shipowner or the shipyard?

Typically, both the shipowner and the shipyard share responsibility for damages arising during dry docking. While the master assumes responsibility for the safety of the vessel and crew in their presence, in their absence, this responsibility shifts to the shipyard.

Today, shipyards often assign specific maintenance tasks to subcontractors via contractual agreements. For example, marine insurance company Gard has detailed the issue of liability allocation in a circular for your reference. Alternatively, you can choose to hire your own contractor to ensure transparency and accountability throughout the process.

Failure to establish clear delineations of responsibility in the contract can lead to significant complications. As a ship owner, it’s imperative to proactively manage these issues. Before dry docking, submit the vessel’s docking plan, negotiate and sign a comprehensive contract, and explicitly define responsibility for any damage incurred during repair or maintenance work.

To safeguard your interests, stipulate the maximum compensation amount in the contract and reach a mutual understanding with both the shipyard and contractors involved. Clear communication and meticulous contract management are essential to minimize risks and ensure a smooth dry docking process.

Above is the important knowledge about dry dock that we have introduced to you. OUCO stands as a premier manufacturer of marine equipment in China, with our port cranes widely utilized in renowned shipyards and dry docks across the Middle East, Europe, and the Asia-Pacific region. During dry docking periods, we assist our customers by installing and replacing winches, marine cranes, and other equipment for their ships.

Moreover, China boasts the world’s lowest dry docking costs, making it an attractive option for shipowners. If you’re considering dry docking in China, we offer valuable advice and access to a range of shipyard options. How can we assist you? Don’t hesitate to reach out with your inquiry!

Recommend Reading:

Heave Compensation: Explained, Principles, and Applications

What is Dredging? Everything You Need To Know

Crane Operations in 8 Extreme Weather: Safety Tips and Advice

Start typing and press enter to search

+31 621 304 650

What You Need to Know About Dry Docks: A Beginner’s Guide

Introduction to dry docking.

Dry docking is a crucial process in the maritime industry. It involves placing a vessel into a specialized facility called a dry dock for maintenance, repairs, and inspections. But why is dry docking so important?

Think of it as a trip to the mechanic for your car. Ships, like cars, need regular check-ups to ensure they operate safely and efficiently. A dry dock provides a controlled environment where ships can be thoroughly inspected and serviced without the interference of water.

Ships operate in harsh environments. The saltwater, marine organisms, and constant use can wear down even the sturdiest of vessels. Regular maintenance is essential to prevent long-term damage and ensure the ship’s safety. This is where dry docking comes into play. By removing the ship from the water, workers can access and repair parts that are usually submerged.

What Happens When a Ship is in a Dry Dock

When a ship enters a dry dock, the dock is first flooded to allow the vessel to float in. Once the ship is properly positioned, the dock is drained, leaving the vessel resting on a series of blocks. This process exposes the ship’s hull, allowing workers to perform essential tasks that can’t be done while the ship is in water.

In dry dock, the ship undergoes a thorough cleaning. Workers remove marine growth, like barnacles and algae, from the hull. This cleaning is important because it improves the ship’s performance and fuel efficiency. A clean hull reduces drag, allowing the ship to move more smoothly through the water.

Next, workers inspect the hull for damage. They look for cracks, corrosion, and other issues that could compromise the ship’s integrity. Any damage found is repaired. This step is crucial for ensuring the ship’s safety. Even small cracks can expand over time, leading to serious problems.

Frequency of Dry Docking for Ships

How often do ships need to go into dry dock? It depends on the type and usage of the vessel. Generally, commercial ships are dry docked every 2-3 years. However, some regulations might require more frequent dockings, especially for passenger ships or those carrying hazardous materials.

Regular dry docking helps prevent long-term damage and costly repairs. It allows for routine maintenance and early detection of potential problems. By addressing issues early, shipowners can avoid more extensive and expensive repairs later on. This proactive approach helps keep the ship in good working order and extends its lifespan.

Passenger ships, for example, often require more frequent dry docking. These ships carry hundreds or even thousands of people, so their safety is a top priority. Frequent inspections and maintenance ensure that any issues are promptly addressed, keeping passengers safe.

The Dry Docking Process: Step-by-Step

The dry docking process can be broken down into several key steps:

Preparation: The ship is inspected, and a plan is created for the docking process. This includes deciding on repairs and maintenance tasks. Preparations also involve coordinating with the dry dock team to ensure everything is ready for the ship’s arrival.

Entering the Dry Dock: The dock is flooded, and the ship is carefully guided into position. This step requires precision to ensure the ship is correctly aligned with the support blocks. Once the ship is in place, the dock gates are closed.

Draining the Dock: Once the ship is in position, the water is pumped out, leaving the ship dry and accessible. This step is known as dewatering. As the water level drops, the ship gradually settles onto the support blocks.

Inspection and Maintenance: Workers clean the hull, inspect for damage, perform repairs, and apply new coatings. This step can involve a variety of tasks, from welding and painting to replacing worn-out parts. The goal is to ensure the ship is in top condition.

Re-floating the Ship: After the work is completed, the dock is reflooded, and the ship is floated out of the dock. The dock gates are opened, and the ship is carefully guided out of the dock and back into the water.

Each step is critical to ensuring the ship is properly serviced and ready for its next voyage. The process requires careful planning and coordination to ensure everything goes smoothly.

Roles and Responsibilities in Dry Docking

Dry docking involves a variety of professionals, each playing a crucial role in the process. Dockmasters oversee the entire operation, ensuring safety and efficiency. They coordinate the docking and undocking of the ship, ensuring everything goes according to plan.

Marine engineers and technicians conduct inspections and perform repairs. They have the technical expertise to identify and fix issues with the ship’s hull, machinery, and other systems. Their work is essential for maintaining the ship’s safety and performance.

Painters and cleaners handle the hull’s maintenance, removing barnacles and applying fresh coats of paint. A clean, well-painted hull not only looks good but also improves the ship’s efficiency by reducing drag.

Ship owners and operators coordinate with the dry dock team to ensure all necessary tasks are completed. They are responsible for making sure the ship is ready for dry docking and for overseeing the work being done. Their involvement is key to ensuring the process is successful.

Each role is vital to the success of the dry docking process, ensuring the ship is in top condition. The collaboration between these professionals ensures that the ship receives the care it needs.

Importance of Regular Dry Docking

Regular dry docking is essential for several reasons. It ensures the safety of the vessel and its crew by allowing for thorough inspections and timely repairs. By addressing issues early, shipowners can prevent more serious problems and ensure the ship remains safe to operate.

It also helps maintain the ship’s performance, improving fuel efficiency and extending the vessel’s lifespan. A well-maintained ship operates more efficiently, using less fuel and reducing operating costs. This is especially important in today’s competitive shipping industry.

Moreover, regular dry docking helps comply with international maritime regulations, avoiding fines and operational restrictions. Many countries have strict regulations regarding ship maintenance and safety. Regular dry docking ensures compliance with these regulations, allowing the ship to operate without restrictions.

In essence, regular dry docking is an investment in the ship’s future, keeping it seaworthy and operational for years to come. It helps shipowners save money in the long run by preventing costly repairs and ensuring the ship operates efficiently.

Dry docking also plays a role in environmental protection. By maintaining the ship’s hull and machinery, shipowners can reduce the vessel’s environmental impact. For example, a clean hull reduces fuel consumption and emissions, contributing to cleaner oceans and air.

In conclusion, dry docking is a fundamental aspect of maritime operations. It involves meticulous planning, skilled professionals, and a series of well-coordinated steps to ensure a ship remains safe and efficient. By understanding and valuing the dry docking process, shipowners can ensure their vessels continue to sail smoothly across the world’s oceans. Regular dry docking is not just about maintenance; it’s about ensuring the long-term success and safety of the vessel.

ADM MARINE is your go-to expert for marine vessel maintenance, specializing in welding, engine repairs, and electrical services. Our professional welders deliver precise welding work for all your ship’s needs. We handle engine repairs to keep your vessel’s operations seamless and efficient. Our electrical services ensure all onboard systems are functioning perfectly. Count on ADM MARINE for dependable and expert maritime services. Reach out to us today for comprehensive marine maintenance solutions.

Copyright © 2024, ADM Marine, All rights Reserved

Dry Docking 101: All You Need to Know About Ship Dry Docking

Every ship demands to be dry-docked after a regular interval of time. It is vital for a ship to undergo a dry-docking procedure so that the ship can be assessed properly for repair, any outstanding construction, or maintenance. In this blog, we are going to discuss what exactly dry docking is. In simple words, dry docking is taking the ship in a structured area where the repair and maintenance work for a ship can be carried out. Sinotech Marine offers engineering, dry-docking management, and ship inspection services in Vietnam . Let us now look at an in-depth analysis of dry docking.

Common Types of Dry Docking

There are varying types of dry docks that are used for repairing and cleaning a ship. Some of them are:

- Floating Dock

- Graving Dock

- Marine Mobile Lifts

- Marine Rail Dock

How to Choose an Ideal Dry Dock?

There is a set criterion for the selection of dry dock for a ship. Listed below are some essential factors that can help in selecting a dry dock:

Condition of the Vessel

When there are damages that can possibly immobilize the ship or if the vessel propulsion plant is not working, floating docks are used.

Size of the Vessel

When a huge oil tanker has to be dry-docked, a graving dock is used. If a small boat or yacht is to be dry-docked, weighing up to 250 tonnes, a mobile marine lift is used. Marine Railway docks are used when the vessel weighs around 10,000 tonnes.

Type of Repair

Selecting the type of dry dock also depends on the types of repairs that a ship requires. While the regular scheduled dry dock can be fulfilled on a floating dock, the major retrofitting procedures can be carried out on a graving dock.

Budget for Dry Docking

Budget plays an important factor when selecting the type of dry dock. If you want to get premium ship inspection services in Vietnam, budget plays an essential role in it.

Current Schedule of Ship

The location and type of dry dock for the ship are also decided based on the current schedule of the ship. Depending upon how easily can the ship reach the dock after unloading the respective cargo or by visiting the last port.

What Can the Ship Crew Do During Dry Docking?

Given below are some of the functions of a ship’s crew when the ship undergoes dry-docking:

- Keeping the ship at minimum ballast condition

- Aft trim to be kept as directed by the dockmaster

- Ensuring the vessel is moored by the assisting dock crew after the ship reaches inside the dry dock

- Keeping the stability of the ship in check

- Preparing the ship to connect to the shore power

- De-ballasting tanks when water is pumped out of the dry dock

- Removing the drain plugs for tanks from the bottom of the ship

Not everyone is accustomed to dry-docking. This should best be done by experts who are qualified to carry out dry docking. At Sinotech Marine , dry-docking services are offered by professionals. We have diligent and highly qualified teams of experts who carry out dry docking for all kinds of ships, vessels, etc.

Connect with us to get the best dry-docking and ship inspection services in Vietnam with Sinotech Marine.

Social Share:

For more details get free Quotation.

VESSEL CONDITION ASSESSMENT

- Vessel Pre-Purchase Inspection

- Vessel Pre-Charter Assessment

- Asset Monitoring Service

- Owned Vessel Assessment

Subscribe to Newsletter

Recent news.

Click one of our representatives below to chat on WhatsApp or send us an email to [email protected]

Step-by-step: a Glimpse into the Dry-docking Process

April 18, 2016

What is Dry-docking and why do we do it?

The process of dry-docking refers to when a vessel is taken to the service yard and brought to dry land so that submerged portions of the hull can be cleaned and inspected. This work is both preventative as well as a regulatory requirement within the industry. When second-hand purchased vessels are due for dry-docking, they are rebranded and assessed to meet all Teekay standards.

At Teekay, vessels are scheduled for dry-docking once every five years, with intermediate surveys taking place in between. Once the vessels are put back into service, they are more eco-friendly and fuel-efficient. At its core, the process of dry-docking is about our commitment to Operational Leadership and our pledge to operate the best ships in the industry.

If the world of dry-docking had one moto, it would be “plan, plan, plan and plan some more.”

In 2015, the Teekay Tankers team completed the largest dry-docking program to date, successfully processing 17 vessels over the course of 382 days of service time. The process itself requires careful planning and preparation. Every minute detail needs to be taken into consideration when undertaking a major project such as the dry-docking of a vessel – and even more so when trying to coordinate 17 of them in a year.

So what does the actual dry-docking process entail? Let’s have a look:

Arrival at Yard and Entering the Dry-dock

After completing all necessary preparatory work, the vessel arrives at the shipyard. On completion of port formalities, the vessel proceeds to the dry-dock with assistance from tug boats and shipyard personnel. Prior to this, the blocks are arranged by the shipyards as per each vessel’s specific docking plan.

Pumping Down the Dock and Vessel “Taking” the Blocks

The water is drained from the dry-dock (generally overnight) over the course of about eight to ten hours, depending on the size of the vessel. Before the vessel is rested on the block, specialized dive teams ensure the block structures are in the correct location.

Ranging the Cables

The cables (or anchor chains) are ranged on the dock bottom once the dock is dry. Anchors and cables are then inspected and measured to determine the quality/ condition and defective parts are repaired or replaced as required.

Hull Painting

The hull painting consists of washing, blasting and painting of the vessel and is one of the main reasons for dry-docking, as it ensures efficient vessel operations for the next five years. After extended periods of sailing and service, it is not uncommon for marine growth such as algae or slime to build up on the sides of the vessel. This buildup has a direct impact on the efficiency of the vessel and ultimately leads to higher fuel consumption.

Shipyard personnel use (fresh water) high-pressure washers to remove marine growth and chlorides from the ship side.

Blasting is done primarily to remove rust or defective paint from the ship side. Depending on the need of each vessel, blasting may be localized or carried out along the entire side of the vessel. In this process, old paint in the defective areas is removed entirely to expose the bare steel.

Once the blasting is completed, the entire vessel is cleaned and painted to protect the integrity of the steel and prevent future corrosion. The underwater side is painted with anti-fouling paint to prevent marine growth and ensures vessel operates close to its original design speed and fuel consumption.

Opening Sea Chests and Overhaul of Sea Valves

The sea chest is a recess in the hull of the ship that provides intake of sea water for the cooling systems in the engine room. This area is opened during the dry-docking process for cleaning, inspecting and painting. At the same time, all ship-side sea valves are inspected and overhauled as required.

Necessary Repairs and Maintenance

During this period, teams take the opportunity to carry our maintenance work on engines, pumps, tanks and cargo spaces as needed. Repairs on the rudder, propeller or shafting are made if any defects are identified.

Flooding the Dock

After all planned work has been satisfactorily completed, the dock is flooded and prepared for the vessel’s departure.

Departure and Trials

The vessel is towed out of the dry-dock with the assistance of tugs and shipyard personnel. Once the vessel reaches a safe anchorage area, sea trails are carried out to confirm the operation of all ship’s machinery. On completion of sea trials, the vessel is commissioned back into service.

- Content Type

- Dry-docking

- Newbuilding

- Project Management

- Ship Management

- Ship-to-ship

- Crude Tankers

- #TeekaySPIRIT

- Market Update

- Safety & Sustainability

- Netherlands

- Philippines

- United Kingdom

- United States

- News Release

Brokerage Boats

Boat Evaluation

Misc. For Sale

Quick search, welcome to south shore dry dock marine.

We specialize in the sale of Quality Pre-Owned Vessels with the largest selection of Sportfish , Convertibles , Center Consoles , Walkarounds , Express Cruisers and Performance Boats in the Northeast. Our inventory changes daily with over 300 boats sold per year.

WE KNOW BOAT BUYERS, WE KNOW BOAT SELLERS, BUT FIRSTLY WE KNOW BOATS.

We were established in 1989 at our Marshfield, MA location. Since that time we have undergone many expansions and have diversified our business to include marina operations and boat storage. We have sales offices and storage/marina facilities throughout New England. Our Massachusetts locations include our main office in Marshfield, Bayline Boatyard in New Bedford, The Pier at Cordage Marina in N. Plymouth, Brewers Plymouth Marine in Plymouth Harbor and Our Newest location in Scituate Harbor featuring boat sales office and fully stocked Marine Supply Store .We also have sales representation in New Hampshire, Rhode Island and Connecticut.

We have placed cookies on your device to help make this website better.

You can use this tool to change your cookie settings. Otherwise, we’ll assume you’re OK to continue.

Some of the cookies we use opens in a new tab/window are essential for the site to work.

We also use some non-essential cookies to collect information for making reports and to help us improve the site. The cookies collect information in an anonymous form.

To control third party cookies, you can also adjust your browser settings opens in a new tab/window .

21st CENTURY SHIPYARD - FACILITIES

State of the Art Facilities

Our Alameda shipyard was designed and built as a state-of-the-art, 21st century ship repair facility with shops, equipment, supplies and personnel all located as close to the work site as possible. Our Syncrolift® and land based rail transfer system provide enormous flexibility by allowing ground-level 360-degree access around berthed vessels to complete all necessary work evolutions as efficiently as possible.