Welcome to Jefa Rudder

We have rudder and bearings for your boat.

Who is Jefa Rudder?

Beginning in 1980, Jefa Rudder has supplied Rudder Bearings to over 40,000 boats. Jefa was founded by Jan Faurschou. Today Jefa Rudder is steered with the second generation at its helm, by Jan’s daughter Louise.

Did you know

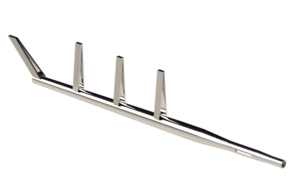

Quality roller bearings.

All Jefa rudder bearings are produces with precision machined rollers and close tolerances to provide smooth operation under load. The close tolerance allows Jefa to eliminate the roller cage needed with sloppy bearings and keep the design simple for long term reliability.

Retrofit Bearings

Jefa Rudder produces replacement rudder balls for all old JP3 and Seaway (Bavaria, Elan, Salona, etc..) rudder bearing.

Jefa Rudder produces replacements for old Harken rudder bearings which is precisely match the original outer dimensions

Standard & self-aligning bearings

Jefa produces self-aligning bearings for rudder stocks engineered to flex. Self-aligning bearings also eliminate the need for precise alignment during installation. Standard or Non Self-aligning bearings are available at a lower cost and normally have a smaller outside diameter.

My Sailing Fix

Catalina Rudder Bearing Replacement

While anchored two seasons ago, I noticed a clunk when Priorities rocked back and forth from the wakes of passing boats. The sound clearly came from the rudderpost area in the lazarette. After visually observing the rudderpost wobbling back and forth with each clunk, I figured last winter was finally time to act on a project I had been putting off for a while: replacing the top rudder bearing.

Priorities is a 1996 Catalina 400 Mark I, and like many Catalinas around her size and vintage she has rudder bearings made from a hard plastic. They are a wear item, but should last a decade or two. One symptom of excessive wear is a bunch of play in the rudder that’s noticeable when shaking the bottom of the rudder after haulout. Rudder bearing wear is a gradual process, and isn’t a crisis when first noticed. However, I can see where it might aggravate wear on steering cables and autopilot drive linkages… also items on my winter project list. It also wasn’t going to get better with time, either.

Several years ago, I hired a professional to help me replace the bottom rudder bearing. Though the job itself wasn’t that complicated, it needed to be done while the boat was out of the water and high enough above the ground to allow us to completely remove the rudder from the boat. With a rudderpost that extends 3 feet above the rudder, we needed 3 feet of clearance under the bottom of the rudder in order to remove it. I worked with the boatyard to do the project while still in the slings after haulout, but before being placed on her cradle. An alternative is to dig a hole in the ground below the rudder… but that’s not that easy in frozen Wisconsin, or for those of us that store on concrete!

I had purchased the complete set of rudder bearings from Catalina Direct when I replaced the lower bearing. It was a whopping $620! Though I initially planned on replacing the top bearing the same year I replaced the bottom, the looseness seemed much better after replacing just the bottom bearing. I put off what I saw as unnecessary work until I started hearing that clunk two seasons ago.

After haulout last winter, a quick check revealed nearly an inch of play when shaking the bottom of the rudder. The bottom bearing itself had become loose from the hull, too, which was part of the problem. It did seem, however, that most of the motion was in the top of the rudderpost, confirming my observations earlier in the season. After our steering cable failure on our trip to Pentwater that same season, a steering overhaul was big on my list of winter projects… so I replaced the top rudder bearing this same winter.

I started this project by climbing into the bottom of the lazarette and getting photos of everything. Having photos of how systems look when fully assembled helps when reassembling them later… especially if i don’t finish until spring.

Since I planned a complete steering overhaul including cable replacement, I disconnected the steering cables from the quadrant, and removed the quadrant from the rudderpost. I also removed the autopilot tiller. When I replaced the lower bearing a few years ago, I delivered the boat to the boatyard a day before haulout before disconnecting the quadrant. Some other 400 owners have used their emergency tiller for the final maneuvers to the crane… but mine didn’t fit until recently.

Since I didn’t need to replace the lower bearing this time, I didn’t need to completely remove the rudder. Therefore, I did this project out of the water in the cradle, making logistics simpler.

Before any more disassembly, I compared the new top bearing with the old top bearing. The new top bearing is a self aligning bearing, involving a partial sphere sandwiched between two plastic rings. The self aligning feature allows the bearing to “wiggle” to stay aligned while not allowing lateral movement. Apparently it helps reduce friction when underway, when the rudderpost bends with stress. Unfortunately, its overall size is larger than the original on my boat.

With some careful measurements and fussing, I figured that simply mounting the top bearing on top of the bearing box wouldn’t work due to a lack of space. Some other Catalina 400 owners, especially owners of later models, might not have this issue since I’m willing to bet each boat’s bearing box is semi custom made and has slightly different dimensions. Some boats might even use this new self aligning bearing as an OEM part.

I came up with a design that should be pretty strong: the upper bearing straddles the bottom of the bearing box, transferring any lateral loads directly into the box. The bottom flange of the bearing mounts under the box, held up by a piece of G10 fiberglass and through bolts that also hold the top flange in place. To keep the spacing right, the top flange had a ¼” piece of G10 under it as well. I used ¼” G10 under the bottom flange, but in retrospect the bottom G10 piece probably should have been ⅜” or ½” for additional stiffness.

On my boat, the packing components around the rudderpost looked like they needed attention… large amounts of caulk had been put around a joint earlier in its life. Since a new packing assembly came with the bearing assembly, I decided I would replace it, too. This meant I needed to lower the rudder a foot to give me enough clearance above the rudderpost in the lazarette to swap old with new. Lowering the rudder this amount would also give me room to make minor modifications to the bearing box to accommodate my plan.

Filled with foam, I’ve heard the rudder isn’t that heavy when in water. On the hard, however, it’s pretty heavy, and felt like it weighed 100 pounds. It’s held up by one bolt above the top bearing. Since I was working alone, I built a stand of scrap 4×4 lumber to prop up the rudder a fraction of an inch and removed the top bolt.

After triple checking my measurements, I lowered the rudder down about a foot. I widened the hole in the existing bearing box to allow the upper bearing’s lower flange to fit better, and drilled holes for the through bolts. I installed the lower section of the packing assembly with screws, sealing the edges with 4200. Then I loosely fit all the remaining components that would end up under the bearing box around the rudderpost: the rest of the new packing assembly, the lower flange’s G10 brace, and the lower flange of the upper bearing. Then, I raised the rudder to full height again.

Getting the through bolts to line up took some work… I ended up drilling out the holes in the G10 pieces one size larger and used washers. The rudder is held up by a new stainless ring (supplied with the rudder bearings) atop the upper bearing. This ring needed to be drilled out as well to fit the new 5/16” bolt that matched the existing hole in the rudderpost.

Now that the new top bearing assembly fit correctly, I felt I could reinstall the loose bottom bearing again with adhesive. The bottom bearing is not self aligning, so I waited to glue this in place until after the top bearing was installed. Lowering the rudder one last time a few inches (or all the way out if replacing the whole thing), I removed the screws holding the bottom bearing in place, and pried the bearing out of the rudder tube with a crowbar and sharp knife.

The bottom bearing is mostly held in place with 3M 5200. Some call this the “devil’s glue,” since it forms a permanent bond that’s awful to remove from most substrates. However, the bearing is plastic, and not much bonds to plastic very well. On both occasions when I’ve removed the bottom bearing it wasn’t a disaster, especially since I could use a knife to cut through the bond. To facilitate future replacement, I used 5200 only on the bottom flange, NONE on the sides that go 2 ¼” into the rudder tube.

There are screws that hold the bottom bearing in place, too. With a hull thickness of 1 to 2 inches in this area, I used 1 ¼” long screws since the bearing flange is ½” thick. When I first replaced the bottom bearing I was told these screws are mostly there to hold the bearing in place while the 5200 sets. As a result, I didn’t tighten them much. At haulout last fall I noticed they had sheared off, possibly contributing to it coming loose again. This time around, I tightened the screws more firmly.

Raising the rudder one last time while the 5200 cured to ensure it cured in alignment, I installed the retainer ring and screw at the top bearing. A few days later I wiggled the rudder back and forth to check for any binding of the bearings. Without any steering connections, the rudder moved very easily, with only a slight resistance in one direction.

New ½” flax packing was installed in the new packing assembly, and the top compression ring tightened moderately to prevent leaks. This packing is above the waterline, so the boat won’t sink at the dock if this fails, but a seal is needed in waves and maybe when motoring.

To complete the project I reinstalled the quadrant and autopilot tiller. The bearing box cover was reinstalled and resealed with silicone caulk, and the emergency tiller access port got a new O-ring purchased from McMaster-Carr .

After a season of use, including several instances of being stressed when sailing overpowered, and sailing in 6-8 foot waves, everything seems to be holding up well. Hopefully, the new bearings will last many more years. If or when they need replacement again, though, it should be easier… assuming the bearing design doesn’t change again!

Share this:

- Click to share on Twitter (Opens in new window)

- Click to share on Facebook (Opens in new window)

4 thoughts on “Catalina Rudder Bearing Replacement”

Do you spend time on the Catalina 400 Facebook page? Oh jeez, I practically live there! Sailing on hull 323, a 400 mkii and am planning a rudder bearings replacement upgrade soon/next haulout/Oct or sooner. Digging into this post as I spend time in the lazerattes and atop the aft bed with the ceiling molding pulled. If you don’t mind I’ll be sending a short video of my mid-bearing or mid-housing (remember, I’m just wrapping my head around the parts and nomenclature). More soon. Thanks. Instagram for us is beyond.the.bnb if you are curious. Cheers!

Hey Curt! Remember your MKII will likely have a significantly different steering system… probably a radial drive wheel rather than a quadrant like on my MKI. I think the bearings will work similar, though.

Great article. Any tips on how you removed the rudder bearing box cover? I removed the sealant in the gap around the cover but cannot lift or pry it out.

From what I remember, all I had to do to remove the cover was remove the sealant and unscrew the cover. There may be an extra layer of 4200 hiding deeper in the joint, so you might need a long blade or scraper to cut it.

Leave a Reply Cancel reply

My Cruiser Life Magazine

All About the Rudder on a Sailboat

The rudder on a sailboat is one of those important parts that often gets overlooked. It’s hidden underwater most of the time and usually performs as expected when we ask something of it.

But when was the last time you seriously considered your sailboat rudder? Do you have a plan if it fails? Here’s a look at various designs of sail rudder, along with the basics of how it works and why it’s there.

Table of Contents

How are sailboat rudders different than keels, how does the rudder work, wheel steering vs. tiller steering, full keel rudder sailboat, skeg-hung rudders, spade rudder, variations on designs, emergency outboard rudder options, looking to sail into the sunset grab the wheel, steer your sail boat rudder, and get out there, sail boat rudder faqs.

What Is a Boat Rudder?

The rudder is the underwater part of the boat that helps it turn and change direction. It’s mounted on the rear of the boat. When the wheel or tiller in the cockpit is turned, the rudder moves to one side or another. That, in turn, moves the boat’s bow left or right.

When it comes to sailing, rudders also offer a counterbalance to the underwater resistance caused by the keel. This enables the boat to sail in a straight line instead of just spinning around the keel.

Sailboat hull designs vary widely when you view them out of the water. But while the actual shape and sizes change, they all have two underwater features that enable them to sail–a rudder and a keel.

The rudder is mounted at the back of the boat and controls the boat’s heading or direction as indicated by the compass .

The keel is mounted around the center of the boat. Its job is to provide a counterbalance to the sails. In other words, as the wind presses on the sails, the weight of the ballast in the keel and the water pressure on the sides of the keel keeps the boat upright and stable.

When sailing, the keel makes a dynamic force as water moves over it. This force counters the leeway made by air pressure on the sails and enables the boat to sail windward instead of only blowing downwind like a leaf on the surface.

The rudder is a fundamental feature of all boats. Early sailing vessels used a simple steering oar to get the job done. Over the years, this morphed into the rudder we know today.

However, thinking about a rudder in terms of a steering oar is still useful in understanding its operation. All it is is an underwater panel that the helmsperson can control. You can maintain a course by trailing the oar behind the boat while sailing. You can also change the boat’s heading by moving it to one side or the other.

The rudders on modern sailboats are a little slicker than simple oars, of course. They are permanently mounted and designed for maximum effectiveness and efficiency.

But their operating principle is much the same. Rudders work by controlling the way water that flows over them. When they move to one side, the water’s flow rate increases on the side opposite the turn. This faster water makes less pressure and results in a lifting force. That pulls the stern in the direction opposite the turn, moving the bow into the turn.

Nearly all boats have a rudder that works exactly the same. From 1,000-foot-long oil tankers to tiny 8-foot sailing dinghies, a rudder is a rudder. The only boats that don’t need one are powered by oars or have an engine whose thrust serves the same purpose, as is the case with an outboard motor.

Operating the Rudder on a Sailboat

Rudders are operated in one of two ways–with a wheel or a tiller. The position where the rudder is operated is called the helm of a boat .

Ever wonder, “ What is the steering wheel called on a boat ?” Boat wheels come in all shapes and sizes, but they work a lot like the wheel in an automobile. Turn it one way, and the boat turns that way by turning the rudder.

A mechanically simpler method is the tiller. You’ll find tiller steering on small sailboats and dinghies. Some small outboard powerboats also have tiller steering. Instead of a wheel, the tiller is a long pole extending forward from the rudder shaft’s top. The helmsperson moves the tiller to the port or starboard, and the bow moves in the opposite direction. It sounds much more complicated on paper than it is in reality.

Even large sailboats will often be equipped with an emergency tiller. It can be attached quickly to the rudder shaft if any of the fancy linkages that make the wheel work should fail.

Various Sail Boat Rudder Designs

Now, let’s look at the various types of rudders you might see if you took a virtual walk around a boatyard. Since rudders are mostly underwater on the boat’s hull, it’s impossible to compare designs when boats are in the water.

Keep in mind that these rudders work the same way and achieve the same results. Designs may have their pluses and minuses, but from the point of view of the helmsperson, the differences are negligible. The overall controllability and stability of the boat are designed from many factors, and the type of rudder it has is only one of those.

You’ll notice that rudder design is closely tied to keel design. These two underwater features work together to give the boat the sailing characteristics the designer intended.

The classic, robust offshore sailboat is designed with a full keel that runs from stem to stern. With this sort of underwater profile, it only makes sense that the rudder would be attached to the trailing edge of that enormous keel. On inboard-powered sailboats, the propeller is usually mounted inside an opening called the aperture between the keel and rudder.

The advantages of this design are simplicity and robustness. The keel is integrated into the hull and protects the rudder’s entire length. Beyond reversing into an obstacle, anything the boat might strike would hit the keel first and would be highly unlikely to damage the rudder. Not only does the keel protect it, but it also provides a very strong connection point for it to be attached to.

Full keel boats are known for being slow, although there are modern derivatives of these designs that have no slow pokes. Their rudders are often large and effective. They may not be the most efficient design, but they are safe and full keels ride more comfortably offshore than fin-keeled boats.

Plenty of stout offshore designs sport full keel rudders. The Westsail 38s, Lord Nelsons, Cape Georges, Bristol/Falmouth Cutters, or Tayana 37s feature a full keel design.

A modified full keel, like one with a cutaway forefoot, also has a full keel-style rudder. These are more common on newer designs, like the Albergs, Bristols, Cape Dorys, Cabo Ricos, Island Packets, or the older Hallberg-Rassys.

A design progression was made from full keel boats to long-fin keelboats, and the rudder design changed with it. Designers used a skeg as the rudder became more isolated from the keel. The skeg is a fixed structure from which you can mount the rudder. This enables the rudder to look and function like a full keel rudder but is separated from the keel for better performance.

The skeg-hung rudder has a few of the same benefits as a full keel rudder. It is protected well and designed robustly. But, the cutaways in the keel provide a reduced wetted surface area and less drag underwater, resulting in improved sailing performance overall.

Larger boats featuring skeg-mounted rudders include the Valiant 40, Pacific Seacraft 34, 37, and 40, newer Hallberg-Rassys, Amels, or the Passport 40.

It’s worth noting that not all skegs protect the entire rudder. A partial skeg extends approximately half the rudder’s length, allowing designers to make a balanced rudder.

With higher-performance designs, keels have become smaller and thinner. Fin keel boats use more hydrodynamic forces instead of underwater area to counter the sail’s pressure. With the increased performance, skegs have gone the way of the dinosaurs. Nowadays, rudders are sleek, high aspect ratio spade designs that make very little drag. They can be combined with a number of different keel types, including fin, wing keels , swing keels, or bulb keels.

The common argument made against spade rudders is that they are connected to the boat by only the rudder shaft. As a result, an underwater collision can easily bend the shaft or render the rudder unusable. In addition, these rudders put a high load on the steering components, like the bearings, which are also more prone to failure than skeg or full keel designs. For these reasons, long-distance cruisers have traditionally chosen more robust designs for the best bluewater cruising sailboats .

But, on the other hand, spade rudders are very efficient. They turn the boat quickly and easily while contributing little to drag underwater.

Spade rudders are common now on any boat known for performance. All racing boats have a spade rudder, like most production boats used for club racing. Pick any modern fin keel boat from Beneteau, Jeanneau, Catalina, or Hunter, and you will find a spade rudder. Spade rudders are common on all modern cruising catamarans, from the Geminis to the Lagoons, Leopards, and Fountaine Pajots favored by cruisers and charter companies.

Here are two alternative designs you might see out on the water.

Transom-Hung or Outboard Rudders

An outboard rudder is hung off the boat’s transom and visible while the boat is in the water. Most often, this design is controlled by a tiller. They are common on small sailing dingies, where the rudder and tiller are removable for storage and transport. The rudder is mounted with a set of hardware called the pintle and gudgeon.

Most outboard rudders are found on small daysailers and dinghies. There are a few classic big-boat designs that feature a transom-hung rudder, however. For example, the Westsail 38, Alajuela, Bristol/Falmouth Cutters, Cape George 36, and some smaller Pacific Seacrafts (Dana, Flicka) have outboard rudders.

Twin Sailing Rudder Designs

A modern twist that is becoming more common on spade rudder boats is the twin sailboat rudder. Twin rudders feature two separate spade rudders mounted in a vee-shaped arrangement. So instead of having one rudder pointed down, each rudder is mounted at an angle.

Like many things that trickle down to cruising boats, the twin rudder came from high-performance racing boats. By mounting the rudders at an angle, they are more directly aligned in the water’s flow when the boat is healed over for sailing. Plus, two rudders provide some redundancy should one have a problem. The twin rudder design is favored by designers looking to make wide transom boats.

There are other, less obvious benefits of twin rudders as well. These designs are easier to control when maneuvering in reverse. They are also used on boats that can be “dried out” or left standing on their keel at low tide. These boats typically combine the twin rudders with a swing keel, like Southerly or Sirius Yachts do. Finally, twin rudders provide much better control on fast-sailing hulls when surfing downwind.

Unbalanced vs. Balanced Rudders

Rudders can be designed to be unbalanced or balanced. The difference is all in how they feel at the helm. The rudder on a bigger boat can experience a tremendous amount of force. That makes turning the wheel or tiller a big job and puts a lot of strain on the helmsperson and all of the steering components.

A balanced rudder is designed to minimize these effects and make turning easier. To accomplish this, the rudder post is mounted slightly aft of the rudder’s forward edge. As a result, when it turns, a portion of the leading edge of the rudder protrudes on the opposite side of the centerline. Water pressure on that side then helps move the rudder.

Balanced rudders are most common in spade or semi-skeg rudders.

Sail Rudder Failures

Obviously, the rudder is a pretty important part of a sailboat. Without it, the boat cannot counter the forces put into the sails and cannot steer in a straight line. It also cannot control its direction, even under power.

A rudder failure of any kind is a serious emergency at sea. Should the rudder be lost–post and all–there’s a real possibility of sinking. But assuming the leak can be stopped, coming up with a makeshift rudder is the only way you’ll be able to continue to a safe port.

Rudder preventative maintenance is some of the most important maintenance an owner can do. This includes basic things that can be done regularly, like checking for frayed wires or loose bolts in the steering linkage system. It also requires occasionally hauling the boat out of the water to inspect the rudder bearings and fiberglass structure.

Many serious offshore cruisers install systems that can work as an emergency rudder in extreme circumstances. For example, the Hydrovane wind vane system can be used as an emergency rudder. Many other wind vane systems have similar abilities. This is one reason why these systems are so popular with long-distance cruisers.

There are also many ways to jury rig a rudder. Sea stories abound with makeshift rudders from cabinet doors or chopped-up sails. Sail Magazine featured a few great ideas for rigging emergency rudders .

Understanding your sail rudder and its limitations is important in planning for serious cruising. Every experienced sailor will tell you the trick to having a good passage is anticipating problems you might have before you have them. That way, you can be prepared, take preventative measures, and hopefully never deal with those issues on the water.

What is the rudder on a sailboat?

The rudder is an underwater component that both helps the sailboat steer in a straight line when sailing and turn left or right when needed.

What is the difference between a rudder and a keel?

The rudder and the keel are parts of a sailboat mounted underwater on the hull. The rudder is used to turn the boat left or right, while the keel is fixed in place and counters the effects of the wind on the sails.

What is a rudder used for on a boat?

The rudder is the part of the boat that turns it left or right

Matt has been boating around Florida for over 25 years in everything from small powerboats to large cruising catamarans. He currently lives aboard a 38-foot Cabo Rico sailboat with his wife Lucy and adventure dog Chelsea. Together, they cruise between winters in The Bahamas and summers in the Chesapeake Bay.

Leave a comment

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

| J |

| to go to the website | to go to the website | |

| Last updated: |

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Rudder Bearing Replacement, Hunter 35.5

- Thread starter Steverhnm

- Start date Jan 19, 2014

- Hunter Owner Forums

So it looks like rudder bearing replacement is in the future for me. Has anyone done this on a 35.5?

steverhnm said: so It Looks Like Rudder Bearing Replacement Is In The Future For Me. Has Anyone Done This On A 35.5? Click to expand

Attachments

ELMAX said: As Part Of The Steering Would? The Wheel Or Shovel? Click to expand

steverhnm said: not Sure What You Meant By The Shovel... However, When The Boat Is On The Stands It Has About 3/16" Play Front/back & Side To Side. I Also Find That When Motoring The Wheel Seems To Require Constant Pressure, Like The Rudder Is Off Center. Is That Normal For These Boats To Require A Moderate Amount Of Effort To Steer In A Straight Line? If You Replaced Bearings, Where Did You Get The Material? How Did You Get The Bearings Out? What Did You Do A Install/secure The New Bearings? Did You Have To Get Them Machined With A Taper? Is There A Source For Bearings That Are A Direct Replacement? I Have Found The Drawings For The Bearings As Well As What I Might Consider Some Suitable Sources. How Long Is The Shaft, I Ask Because I Was Hoping I Could Do This On The Stands But Need To Know How Far I Need The Rudder Off The Ground To Clear The Shaft And Get The Rudder Out. Click to expand

Wow, you did quite a lot of work restoring your boat. It looks real nice. I looked at your photo albums. Thank you for sharing. I am going to use a product from this comapny Iglide. http://www.igus.com/iglide?WT.srch=1&WT.mc_id=gadUS59&c=US&L=en&gclid=CJu4vqmuta0CFUIDQAodu3GzsQ Looks like the rudder is just under 1 meter, does that make sense?

Steverhnm said: Wow, you did quite a lot of work restoring your boat. It looks real nice. I looked at your photo albums. Thank you for sharing. I am going to use a product from this comapny Iglide. http://www.igus.com/iglide?WT.srch=1&WT.mc_id=gadUS59&c=US&L=en&gclid=CJu4vqmuta0CFUIDQAodu3GzsQ Looks like the rudder is just under 1 meter, does that make sense? Click to expand

www.igus.com looks good result, if you have what you need, on Wednesday I go on the boat, I have some new pictures of the pieces, take measurements and I'll send you on Thursday. Always the same to you my helm ..... hello

bearings You are doing great. My name is Steve. I appreciate the drawing. My boat is near Guyamas, Mexico and I live in Albuquerque, New Mexico (USA) so it is a long way for me to get to my boat. I sure appreciate your help. You must really enjoy living close to your boat. Item number 3 looks like a collar of some kind, I would not think it is a bearing. It looks like a bushing or sleeve to make the collar tight on the shaft. Did you replace your bearings?

Steverhnm said: You are doing great. My name is Steve. I appreciate the drawing. My boat is near Guyamas, Mexico and I live in Albuquerque, New Mexico (USA) so it is a long way for me to get to my boat. I sure appreciate your help. You must really enjoy living close to your boat. Item number 3 looks like a collar of some kind, I would not think it is a bearing. It looks like a bushing or sleeve to make the collar tight on the shaft. Did you replace your bearings? Click to expand

ELMAX said: For me, the places you describe arouse curiosity and admiration and are famous for fishing, I live 40 kilometer from my boat. in northern Italy near Venice. but when it will be 'finished work, I keep it in Greece, where the climate and more stable. tomorrow I'll be in the boat so I send you photos and measurements more precise. I will not change because they are still good. You have to see where the control cables are attached I send you a picture. Click to expand

How long is the metal rudder post? I was wondering how high up I nee to get the rudder off the ground to be able to remove the rudder.

sorry, I measure it tomorrow afternoon and the photographer, but I warn you it is very heavy, you have to be in time to take at least two people

Shovel On first reply he spoke of a shovel which is what is done sometimes to get rudder out at yard that is if your yard is not concrete or pavement most marinas complain about but just do on weekend an put dirt and gravel back before Monday morning

by us in Italy, the blade is the final part of the rudder, but also a tool to dig the earth. writing PALA

Steverhnm said: How long is the metal rudder post? I was wondering how high up I nee to get the rudder off the ground to be able to remove the rudder. Click to expand

Thanks for the measurements. This helps me plan, look like I should be able to get the boat 80 CM off the ground so I will plan for that when I pull the rudder. That rudder sure looks heavy once its out of the boat. I looked up your Boat location on Google earth, looks like a real nice location.

Not sure of the year of the boat but you may be able to source the bearings through Foss Foam. They manufacture rudders for Hunter and supply the bearings with the rudders. You can check with Al Walker at Foss. 352-529-1104.

Thanks, I will look into that.

Steverhnm said: Thanks, I will look into that. Click to expand

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

COMMENTS

Jefa rudder bearings offer the utmost in feel and durability. Utilizing captive roller bearings in rugged aluminum housings, there is a full range of sizes and styles including self aligning bearings to suit all sizes of sailboats. Sizes are available from 30mm to 260mm for production and custom applications.

Rudders. Jefa rudder bearings offer the utmost in feel and durability. Utilizing captive roller bearings in rugged aluminum housings, there is a full range of sizes and styles including self aligning bearings to suit all sizes of sailboats. Sizes are available from 30mm to 260mm for production and custom applications.

Hey Guys!This week our friends were about to purchase new rudder bearings for HUNDREDS of dollars and lift out for a week to do a rudder bearing replacement ...

2. Jan 30, 2006. #2. Have decided it is time to replace a Harken Rudder bearing on J 120 Hull #135 (5 years old). This past season it started to vibrate a little bit at higher speeds, mostly over 10 knots. It has about 3/16 inch play at the bottom of the rudder that I did not notice previous seasons, so I suspect something needs attention.

Check out our latest Sailboat Restoration video where we complete the rudder rebuild and finally install new rudder bearings and the rebuilt rudder! Don't Li...

To facilitate future replacement, I used 5200 only on the bottom flange, NONE on the sides that go 2 ¼" into the rudder tube. There are screws that hold the bottom bearing in place, too. With a hull thickness of 1 to 2 inches in this area, I used 1 ¼" long screws since the bearing flange is ½" thick. When I first replaced the bottom ...

Check for play: Outboard rudders and rudders with a bottom bearing should be checked regularly for wear of pintles, gudgeons and other hardware by trying to rattle the rudder in its bearings. Spade rudders are supported by bearings inside the boat, so push the bottom of a spade rudder side to side to check for tube wear or other bearing problems.

Obviously, the rudder is a pretty important part of a sailboat. Without it, the boat cannot counter the forces put into the sails and cannot steer in a straight line. It also cannot control its direction, even under power. A rudder failure of any kind is a serious emergency at sea.

NEW RUDDER BEARING. Place the new rudder top rudder bearing in the top of the end of a hammer until it seats against the top of the rudder. bearing. Place the 3/8"-1/2" UHMW shim over the stainless steel rudder post before inserting the post into the rud-der tube. From under the boat put the rudder post up thru the rudder tube & bearings.

Have the boat yard lower the rudder slightly in relation to the upper bearing and check if the noise, vibration or squeak is gone. A Note About Grease - Only lubricate your rudder bearing if and where the manufacturer recommends. The rollers in a Jefa Rudder Bearing should never be greased. Self-aligning Jefa Bearings do require synthetic ...

Cue the B.O.A.T. reel! The inadequate reinforcing in the cockpit sole around the rudder bearing was plain to see. Problem No. 1: A Bad Design for the Rudder Bearing. While most of the systems on the Niagara 35 are overbuilt and well designed, for whatever reason, the rudder post bearing is simply not.

3. Hunter 28 Nashville. Jul 28, 2016. #1. I have a 1990 Hunter 28, and am considering replacing the rudder bearings. The boat is on the hard, and the rudder has been removed. The rudder post rides in a rudder tube that extends from the hull to the deck. There are two bearings made from UHMW, that are fitted in the rudder tube.

Feb 14, 2005. 4,773. Tayana 37 cutter; I20/M20 SCOWS Worton Creek, MD. Jan 26, 2012. #2. The wear on such rudder bearings is usually due to abrasion between the SS shaft and the (usually delrin/acetal) bearing material. The surface roughness of the shaft abrades away the bearing material. To reduce the bearing wear, the shaft area at the ...

A small amount of wear, maybe around 1mm at the bearing, is acceptable, but if there's significantly more than this further investigation will be needed. A 30ft (9m) boat with new Delrin bushes fitted - the black collar of the lower bush can be seen - and the rudder replaced, ready for antifouling. Photo: Rupert Holmes.

Jefa rudder and steering systems. Welcome to the Jefa brand name web portal! J efa Steering and Jefa Rudder are two independent companies sharing their web entry portal. Clicking on the below website entries will bring you to each separate website. Please make your choice! to go to the Jefa Steering website.

The Upper Rudder Bearing Standard (URB-STD) and the Upper Rudder Bearing-Low Profile (URB-LP) are both ABS and Lloyds approved, self-aligning design which accomodates up to 10 degrees of off-axis alignment between the mounting surface (rudder shelf) and the rudder stock. Tides Marine rudder bearings can be produced in custom sizes and lengths ...

Jefa rudder bearings offer the utmost in feel and durability. Utilizing captive roller bearings in rugged aluminum housings, there is a full range of sizes and styles including self aligning bearings to suit all sizes of sailboats.

Looking for some recommendations for good places to eat in Novosibirsk. Authentic food would be great. We are staying near the opera house. Last time we were there we wandered around and had a great meal with vodka and caviar that was not that...

Bavaria Ocean 38 Olympia, WA. Jul 26, 2007. #6. In response to several questions reagrding the rudder bearing problem, you all are welcome to contact me @ 360-597-4881 for a more detailed discussion.u000bAs best as I can answer the two questions.u000bFirst, I found that a replacement bearing is not necessary, as there was no wear on the teflon ...

Answer 1 of 4: Hi Tucker did you do any dog sledding at Lake Baikal , if so what company is good to go with and for how long 5, 10 , 15 km etc. any other pointers? I will be in Irkutsk mid Dec x 3 days. thanks

Novosibirsk is a city of 1.6 million people in Novosibirsk Oblast, Siberia. Novosibirsk has about 1,630,000 residents. Mapcarta, the open map.

193. Hunter 35.5 Legend 003 San Carlos, Sonora, Mexico. Jan 20, 2014. #8. bearings. You are doing great. My name is Steve. I appreciate the drawing. My boat is near Guyamas, Mexico and I live in Albuquerque, New Mexico (USA) so it is a long way for me to get to my boat.

Y. Yeltsovka (Ob) Categories: Bodies of water of Novosibirsk Oblast. Rivers of Russia by federal subject. Rivers of Siberia. Hidden category: Commons category link is on Wikidata.