Affordable Sailboats You Can Build at Home

Last Updated by

Daniel Wade

September 13, 2023

Key Takeaways

- There are many sailboats that anyone can build from home depending on tastes

- Budget will be the biggest deciding factor on a majority of the process

- Consider kits that come with most of what you need or choose ones that are all-inclusive

- Design complexities and new materials may make the building time process longer

- Plan the best you can ahead of time to save money and your working hours

Buying a sailboat can be expensive, but building your own can save you money. So what are sailboats you can build from home?

Sailboats that you can build from home will likely be a small boat under 20 feet. These could be from many different boat suppliers such as B&B Yachts, Brooks Boat Designs, and Chase Small Craft. Boat plans will vary based on your budget and how much time you have on your hands.

Based on my previous experience, building your own boat will take much longer than if a professional were to do it. You also have to be able to study plans, consider various sailboat designs, and have tons of supplies such as fiberglass tape or fiberglass cloth. On top of that, you will also have to be good with your hands.

Table of contents

Top 10 Affordable Sailboats Anyone Can Build at Home

Building your own pocket cruiser or other styles from boat plans is an impressive feat, as this will need dedicated time and money to assure your boat sails safely. Boat building takes a lot of patience as well, especially since this will not be completed in a fast manner.

Finding boat plans and materials that fit your budget will be key to being able to complete the project. The time it takes to complete these projects will vary on your overall experience and needs. Below are 10 of the most affordable sailboats that you can build in the comfort of your home.

B&B Yachts

B&B Yachts have 14 different boat plans you can choose from to find the boat of your desires. Their shop is located along the Bay River in North Carolina where they construct all of the kits and have a 100 foot dock to show off your project once you complete it.

One popular model to check out is their Core Sound 15, as it is the perfect size for those wanting to build a modest size boat for a handful of people on board. Their website features some videos of completed projects and the plans or kits for purchase.

- 14 different models to choose from plus some dinghies

- Various monohull and multihull options

- Friendly customer service with attractive prices

- Might be too many options for some that are indecisive

- Not ideal for those wanting to have a motor sailer

Brooks Boat Designs

Brooks Boat Designs has a handful of options to consider for your next sailboat building project. They are located in Brookline, Maine and give the option to buy the kits or have them build one from scratch for you. They have plenty of knowledge, so do not be shy to ask about modifications or custom features you are looking for.

Depending on your specifics, they can attempt to accommodate some of their plans to help fit your desired outcome. By checking out their site, you can see many examples of their construction in progress and what the boats will look like when completed.

- Offers a variety of kits

- Plans vary around $50 and up, while materials will obviously add more costs

- Some plans can be rowing boats that can convert to sailboats

- Might take a while to hear back from them, as their contact section is a little outdated

- Their plans may not accommodate a ton of extras for your taste

Chase Small Craft

Chase Small Craft offers a simple process for building boats. Their kits are equipped with everything you need and will help save you time than just buying the materials outright and other parts you could need. This is arguably one of the best bang for buck instances if you want to save time and money searching for pieces to your boat.

They are located in Saco, Maine and will ship everything to your home from there. All the necessary materials are included and all you need are the proper tools and working space.

- All-inclusive kits with what you need

- Tons of knowledge on their site for boat building

- Easy process to order and customize

- Complete kits can range over $20,000 for larger boats

- Kits may take up to eight weeks to ship out

Chesapeake Light Craft

You can expect high-quality boat kits from Chesapeake Light Craft . They feature 18 different sailboat kits that vary from eight to 20 feet in length. This should be more than enough to find one for you if you are newer to boat building.

They also have a wide variety of other kits in addition to the sailboat, in the event that you wanted to order a small kayak or paddleboard in addition to your sailboat. The prices vary considerably when considering a small or larger boat, so check the complete list of options to in order to potentially fit your needs.

- Plenty of sailboat offerings to choose from

- Different beautiful hull form options to consider

- Easy to build and perfect for sailing

- Only has basic materials needed for kit, so you may need to purchase other items

- Has epoxy shipping fee no matter if you pick up item

Dudley Dix Yacht Design

Dudley Dix Yacht Design has an extensive list of plywood and single skin sailing boat options. They have plenty of sail plans and kits to consider depending on your goals. These follow a classic look for sailboats, which are aesthetically pleasing.

If you are wanting one to accommodate a small family, they have more than plenty to look through. The cost is not as bad compared to others, but keep in mind that you may need to throw in your own supplies or specific tools to get the job done.

- Plans start at $30 and range up to $7,500 or more for kits

- More than enough of options to consider

- Affordable variety of sailboat offerings

- Might be too many options for those new to sailing

- Most are wood without the use of aluminum or steel

Farrier Marine

If you are in search of a multihull to build, then Farrier Marine is what you need. They offer a unique folding catamaran that is trailerable and give you the option to build it yourself. This not only makes it an appealing option, but anyone can take this multihull boat wherever they want with ease.

It features a thorough construction guide once you receive all of the materials. These also come with stainless steel fasteners and an aluminum mast for high-quality materials. Pricing will vary since you must request which model type you are considering.

- Ability to build a unique catamaran

- In-depth construction guide to help

- Easily handled and trailerable

- Price may be too high

- Limited offerings since only a few multihull options

Glen-L Marine Designs

Building a boat from Glen-L Marine Designs can save you time and money. They feature an easy system to order and receive the kits, as well as an in-depth guide to building them. This is an appealing option compared to most boat kit sellers.

The beauty about Glen-L is that anyone can build these from scratch, so you do not have to be the best boat builder in the world to get it done. They offer guides and helpful insights from their team to point you in the right direction. Plans vary around $15, while kits can range well over $1,000 depending on boat size.

- Nearly 50 designs to choose from

- Complete guide to help anyone build it

- Plenty of price points depending on size

- Might be overwhelming with the amount of options

- Could take a while to get parts since they are popular

John Welsford Boat Designs

John Welsford Boat Designs invites new and veteran boat builders that want a taste of quality small wooden boats. The boat plans are designed to meet your specifications and are catered to your desires.

There are seven sailboat designs to choose from so you do not feel overwhelmed in the process. However, they do not sell kits all the time, so you would need to have the materials or be on the lookout for the best prices when they are available.

- Seven sailboat plans with different sizes

- Quality boat builder and supporting community

- In-depth knowledge provided to you when you order

- Might be too small of boat size

- Kits are not always available

Iain Oughtred

There are plenty of options on the wooden boat store, but you should narrow down your search for Iain Oughtred’s line of sailboat kits and plans. There are 25 different plans to choose from, which should accommodate most everyone looking to build their own boat.

While they do offer some kits, they do not routinely offer sailboat kits. You would need to purchase all of the materials if you are considering one of their sail plans. Keep this in mind if you are considering, as you would need to hunt down the parts yourself.

- 25 different sailboat plans to look through

- Various sizes to contemplate for you sailing needs

- Prices will vary but are not bad compared to market

- No sailboat kits, only plans

- Newer boat builders might find too many options unappealing

Paul Gartside Boat Builder and Designer

Gartside Boats is a boat builder company based in Long Island, New York that showcases a variety of boats from traditional and newer methods of boat building. Within that variety, they have boat plans meant for six to 50 feet in length.

With an abundance of options, you will need to contact them regarding prices and any customizable options. Kits may vary as well, as they typically design in-house and build for you.

- Experienced boat designer that can accommodate with custom plans

- Many options are trailerable

- Can have plans for up to a 50 foot boat

- You will need to contact them for prices

- Customized options may make process more complicated for new boat builders

How Much Does it Cost to Build a Sailboat at Home?

As you have likely already done so, the math between building your own boat and buying one may be a huge difference. Likewise, you may even enjoy the challenge of taking an older boat that is gutted and restoring with parts from a kit to build one new again.

But how much does it cost exactly to build a boat from the comfort of your own garage or workshop? The prices are going to vary dramatically depending on your situation and material needed to get the job done. In addition, the time that it takes to complete this will also vary.

Sail plans are rather inexpensive if you are aiming to build a small boat. These plans allow you to see the workings of the boat design and what you need to build the boat.

Without these plans, you will not know the exact details of the design and it can cause major issues with the boat’s hull or other areas of the boat. Think of these as the backbone or instructions of the boat’s infancy before being built.

Price Per Square Foot

You should assume to pay anywhere between $300 to $600 per square foot if you are interested in building a boat. Buying a kit outright can be a good way to save time, but oftentimes these do not come with everything you need.

Instead, you should try to source as much of the materials at the best price as possible. Thinking ahead is part of the process and you might be able to score a deal at a lumber yard or hardware store for parts.

Boat Designs Matter

The design of the boat will be much different from one boat to the next, regardless if they are the same size in length. If you are pondering boats that range anywhere between 16 and 20 feet, you should factor in the shape of the hull, any rigging, and various appendages.

Prices tend to increase when there are more complexities within the designs. If you are considering a kit with more details than others, you will also have to pay more for the designs on that as well.

Kits Can Differ

It is important to understand that all kits are not going to be the same. As you gander at sailboat kits online to stitch together, you need to thoroughly look over to see if you have everything you need before buying.

It would also be at your advantage to ask the seller if any additional parts or supplies are needed. This may change your dynamic on the kit buying process and you may pass up one for another if it has everything you need. An all-inclusive kit may cost several hundred, if not thousands, of dollars more to have the convenience of everything in the bundle.

Construction Approaches

Some boat plans may require you to have certain tools to get the job done. This means special saws or planers, which the average person simply does not have.

Purchasing specialty tools might be expensive upfront and hard to find depending on what it is. Your best bet would be to check locally for others trying to sell their tools or consider a boat plan that does not require extensive tools to finish the job.

How Long Does it Take to Build a Sailboat?

An easy to build sailboat could take a while to build from scratch. Many different variances come into play that are difficult to pinpoint for everyone. But how long is that exactly and how will your experience play into this?

A fun project to sail in the wind could take you several months to well over a year depending on the boat plan and how big your boat is going to be. In addition, the materials all need to be accounted for prior to starting in the event a hardware store does not have them in stock.

Time Varies

The time that passes for simple boat designs on small sailing vessels can be done in a few weeks. This is assuming you have everything you need and work non-stop around the clock.

Certain complex situations may make the process long, such as the difficulty of working with some materials. If you are a skilled laborer, it may take you half the time compared to a novice. The amount of time it can take will vary on your availability and skill level.

Planning ahead will undoubtedly offer the most time-saving features. It also helps if you can tackle parts of the project at your own pace.

Complexity of Design

The design of the boat may make the construction process longer. For example, it may take you longer to build a catamaran compared to a similar lengthed monohull.

More complex designs might require more materials, therefore making the process a bit longer to complete. Furthermore, you will also need more experience working with difficult designs and that will affect you more as a newbie.

Be sure to manage your expectations well and do not allow yourself to become too stressed over this fun project. If you can, seek expert boat building advice from a local builder or the company you purchased sail plans through.

Quality Materials

The quality of the materials will matter significantly when building a boat and will greatly affect the time it takes to construct it. Handling fiberglass or carbon fiber might require specialty tools, while wood also demands a certain level of craftsmanship.

If you are not skilled at working with the material at hand, it might affect the quality of the build and you may have to go back to fix mistakes. This will definitely add more time to your project, because mistakes are bound to happen with your first project.

To save time, consider adding the tools and materials throughout the year or as often as your budget allows. You may want to try testing your skills on fiberglass or other materials to get a feel for how to work with it.

Related Articles

I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing.

by this author

Best Sailboats

Learn About Sailboats

Most Recent

Best Small Sailboat Ornaments

September 12, 2023

Best Small Sailboats With Standing Headroom

December 28, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

Discover the Magic of Hydrofoil Sailboats

December 11, 2023

Best Bluewater Sailboats Under $50K

Hunter Sailboats: Are They Built for Bluewater Cruising?

August 29, 2023

Popular Posts

Best Liveaboard Catamaran Sailboats

Can a Novice Sail Around the World?

Elizabeth O'Malley

June 15, 2022

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Get the best sailing content.

Top Rated Posts

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies. (866) 342-SAIL

© 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy

- For Sale/Wanted

- Readers Tips

- Your Yarns.

- Restoration

- Miscellaneous

- DIY Boat Yards

- Boat Building

- Cabin Cruisers

- Free Boat Plans

- Begin Boating

- Boating Terms

- Ropes and Rigs

- Just for Fun

- Celestial Navigation

- Passage Planning

- VHF Marine Radio

- Diagonal Scale

Sailboat Plans

Free Sailboat Plans

A selection of some of the Free Sailboat Plans (pdf) that were published in magazines such as “Popular Mechanics”, "Popular Science" and the "Boat Builder Handbook".

If you need help with lofting out the plans click here for an article here which should help.

- Open Dayboats/Dinghys

- Rowing Boats

Open/Dayboat, Free Sailboat Plans

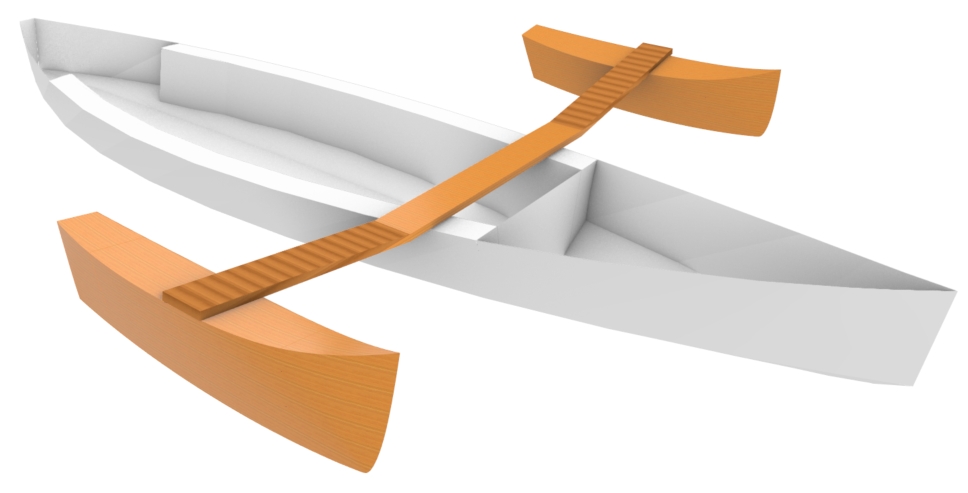

Everyone who digs boating has heard of the Hobie Cat, the sleek little catamaran that burst on the scene and captured the attention of all the fast-action sailors.

Marked by asymmetrical hulls and special trampoline supports, the Hobie can reach speeds above 20 mph and perform with a rare agility.

But it has one drawback.

It costs mucho dinero.

Thus, we introduce the Hobby Kat, sailboat plans, a build-it-yourself version of the “Hobie” that should cost from half to a third of the commercial version. If you have the moola, of course, go for a Hobie and have the time of your life on the water.

If not, try our Hobby

The homebuilt is not quite the same.

But she sails sweetly and fast—qualities which have made the “Hobie” popular

Even in a light air she’ll slip through the water at a fast clip.

She has no centreboards, leeboards or keel, and needs none.

The inside of each hull has built-in lift, like an airplane wing, so that as the boat heels and one hull digs in the boat is pulled back to windward.

Click Here for the Plans

She can run in very shallow water and the rudders kick up for beaching.

You can carry her on a trailer or even disassemble her.

Many a “stink pot” addict will take a second look at Tern because she planes in modest breezes, is easy to handle, and her streamlined prow arid pod-shaped, “inland scow” type hull offer slight water resistance. Then too, there’s a charm about the tiller of a sailer that’s not matched by the wheel of a motor-powered boat. Part of it is the challenge of making the most of nature’s free-wheeling breezes. Even with her 72sq.ft of sail, this Free Sailboat Plan is remarkably stable, and packs as many as four persons aboard

For thousands of inland lakes, Tern is the answer to sailing water sport, she is rugged and easy to launch

And she’s remarkably easy to build.

Falcon is a small, speedy, sporty sailboat which handles well. Tests on the original Falcon showed that she could easily out-distance boats of comparable size such as the one design class Snipe and Comet sailers.

And she will pace neck and neck with 18 footers with considerably greater sail spread.

This strong, beamy, eight-foot pram may be sailed either cat-rigged or sloop-rigged.

The dagger-board may be adjusted forward to balance the helm when sailing with the addition of a jib sail.

Oars or a small outboard motor may also be used to power this versatile Free Sailboat Plans.

Dart” is a small two or three person sailing craft, designed for use on protected waters such as bays. lakes, rivers or wherever sheltered waters are found. Its construction will repay the builder handsomely and provide a fast sailing craft, light in weight, easily transportable and cheap to construct with all difficult joinery eliminated

It provides thrilling and economical sport.

The 'Crescent', designed by C. T. Allen, is the ideal sailboat for day sailing on a small lake, river, or protected waters of a bay.

Centreboard design (Fig. 2) reduces Crescent's draft, so Shallow is not a problem.

Its broad beam of over 5½ft. makes it an ideal family boat because there is room for a cockpit large enough to accommodate four adults or two adults and three kids, and side and forward decks big enough to stretch out on when sun bathing.

"Jewel" is a 16' Crescent Sailboat being built by Mike Allen from the free sailboat plans by C.T .Allen in the 1958 "Boat Builders Handbook". And what a superb job Mike is doing check out his photos here .

Click Here for the Free version of the Plans

Sailing enthusiasts and backyard boat builders are not likely to find free boat plans for a sailing pram that can be built faster, lighter, stronger, or less expensively than Graefin-10. Two men can begin work on a Friday evening and have a smart, lively 10-ft. 85-pound sailboat in the water by Sunday evening (it’s been done).

Zephyr Is a refinement of a type of boat developed by the English for use in the rough open waters of the English Channel. Not only is it fast under sail, but it can stand up under punishment. And it’s light enough to be easily loaded atop an auto or light trailer.

Breeze-Baby

Skimming off a brisk wind or with the wind abeam, Breeze-Baby actually planes with one person aboard. Despite her rowboat lines that make her easy to build, she handles easily under her simple sail, an ideal first boat. Simple lines are adapted to plywood construction that’s strong, light and that keeps Breeze-Baby’s bilges dry

You can take her with you atop your car or on a lightweight trailer for summer fun wherever you vacation or get in a week-end’s sailing.

Cat’s Paw is easy to build because of the straight-sided hulls. The sheer line is flat and that simplifies building the form. Bow and stern are straight, so there’s no cockeyed bevel to fit and fuss with

She Is an Ideal boat to learn or practice sailing in because she will forgive so many mistakes.

Cabin Cruiser, Free Sailboat Plans

Previous posts

See What Others Have Posted

Recent Articles

Boat Winches

Jun 21, 24 04:18 AM

- Boat Plan Books

- Boatbuilding Tips

- Glass Cloth

- Stitch and Glue

- Strip Plank

You might like these

Knotty wood, problems with boat building timber.

Knotty wood, how to avoid structural problems with knots in lumber when using softwood timber for fitting out and boat joinery

Build a Boat, tips for the DIY Wooden Boat Builder.

How to Build a Boat, Wooden Boat Building methods for the DIY, backyard, self-builders explained, carvel, lapstrake and plywood

Wood Screws for Boat Building and Repair.

Wood Screws are the most widely used and versatile fasteners used on wooden boats. Which type to use and how to use them

Wood, Environmentally Friendly Boat Building Lumber.

Make sure that the Wood that you buy and use is sustainably grown and harvested.

Timber, Lumber for Boat Building.

A brief description of the most common Timber used for building Wooden Boats how to choose wood for your project boat

Timber Properties

A brief guide to timber properties and wood, characteristics such as strength, stiffness and elasticity for choosing lumber for wooden boat building and restoration.

Rivets and Copper Rove Wood Boat Fastenings.

How to use Copper Rivets and Roves construction guide to fasteners on your wooden boat.

Ring Nails for Marine Fastening.

Ring Nails sometimes call Gripfast or ring shank, silicon bronze boat nails are renowned for their holding power. but how to get them out?

Plywood and Veneer Guide for Marine use.

A guide to plywood for boat building and why you should use the best marine grade you can afford.

Glue for Wooden Boat Building

Which Wood Glue to use when building or restoring a wooden boat, resorcinol to epoxy.

Rowing Boat Plans

Free Rowing Boat Plans for the backyard home builder, build your own rowing boat, dory, folding dinghy or pram using these simple plywood designs.

Free Motorboat Plans

Free Motorboat Plans for the backyard home builder, build your own speed boat, cabin cruiser, runabout or utility boat using these simple plywood designs.

Wooden Boat Kits.

Wooden boat building is easy and inexpensive with wooden boat kits. From row boats and kayaks to sailing cruisers, boat to be proud of

Supplies for Wooden Boat building and Maintenance

Supplies for Wooden Boat Building and restoration, how to choose the materials and marine chandlery for your project.

Small Boats, Made of Wood

What Everybody ought to know about building Small Boats, guidance and tips for self-building or restoring.

Owens Boats

Jun 05, 24 12:14 PM

Penn Yan Boats

May 28, 24 07:51 AM

Wooden Boat Restoration, Repair and Maintainence.

Wooden boat restoration, how to fix up an old wooden boat, one of the cheapest ways to get afloat and have a boat to be proud of.

Epoxy Resin for DIY Wooden Boat Building.

A guide to the epoxy resins and sustainable enrtopy resins to use when building wooden boats with marine plywood.

Wood Rot Repair and Treatment

Wood rot in wooden boats, how to treat, repair and replace rotten timbers in a wooden boat

Privacy Policy

Advertising Policy

Cookie Policy

I am perfectly aware that the majority of Wooden Boat aficionados are sensible folk. However, I need to point out that I am an amateur wooden boat enthusiast simply writing in order to try to help other amateur wooden boat enthusiasts. And while I take every care to ensure that the information in DIY Wood Boat.com is correct, anyone acting on the information on this website does so at their own risk.

- About Modern Wooden Boats

- Tips & tricks

- What’s inside a boat plan ?

Idea 21 sportboat

The development of the family of small offshore capable sailboat plans : chined hull for the highest stability, vertical lifting keel, trailerable, suitable for club racing or cruising (two interior versions) , plywood and epoxy hull with the radius chine system, sparkling performances while sailing and reasonable interiors for coastal cruising.

| DOWNLOADS | ||

| 6,30 m | 27,5 m2 | |

| 2,50 m (trailerable) | 45-26 m2 | |

| 1,75 m – 0,50 m | outboard 2.3-5 HP on transom bracket | |

| 900 kg | ||

| 1200 kg | ||

| 1700 kg | ||

| 300 kg | ||

First boat launched : read the first impressions here

Idea 21 small sailboat plan is the latest development of my family of small plywood & epoxy sailboats plans for homebuilders : it was quite a time since i was thinking of an evolution of her smaller 19 footer sister, so i finally take the decision to publish this new plan. the goals of this plan is simple: add interior volume, simplify the work for homebuilders switching to a complete plywood & epoxy radius chine hull, enhance slightly the sparkling performances of idea 19, keeping the sailboat very balanced and suited for sailors ranging from enthusiast beginners to experienced seamen., first boat launched and several other boats in building stage make idea21 the most sparkling project on our catalogue, hull: chined hull on a small light sailboat has a simple reason to exist: it gives more stability to the sailboat when heeled, much more than a round hull similar sailboat. i managed to keep a very low wetted area of the unheeled hull, in order to achieve a good pace in light air and avoid excessive drag. stern sections are quite flat to gain speed downwind (idea 19 has been clocked with speed steadily in excess of 15 knots)., bow sections: experiences on racers showed that “knife-blade” bows may give you less resistance, but the price to pay is high in terms of buried bow sailing downwind, so i decide to provide this plan a large u-shaped section on the bow ; sails provide the sailboat plenty of power to defeat the small amount of added drag., sailplan: i have a very good starting point with idea 19, so we’re doing small adjustments and no revolutions: square top mainsail, 7/8 fractional rig , very wide single swept spreaders, no backstay, deck stepped mast with sturdy section, 110 % j jib, code zero, jennaker hoisted on swinging retractable bowsprit, and a good amount of sail area., keel and ballast: idea21 have a solid hard wood cored & unidirectional glass epoxy laminated lifting keel, with a naca optimised profile and a low resistance hydrodynamical shaped 280 kg lead bulb bolted on the keel tip; it can be made by a homebuilder, no need for professional welder; the fin area is on the low side, speed will help generating the required lift without adding too much drag. keel case is in 20 mm thickness plywood and epoxy laminated glass reinforcements, and it’s perfectly waterproof while sailing., full lifting keel version : after a request from a builder, idea 21 cruise is available in a version featuring an integral watertight keel case running form hull bottom to cabin top panels, this feature called flk (full lifting keel) will allow the boat to sail with keel partially raised or to motor with keel totally up, a good option if you sail in shallow waters frequently., cockpit: was one of the strongest point in idea19, we simply keep the same arrangement and dimensions, so we have a really huge area for the crew and a simple and sturdy building in plywood panels epoxy glued on a structure of bulkheads and stringers., interiors: here i focussed on several upgrades; i decided to split the project in two versions (so two different sets of plans, you have to specify on order), “sport cruise” or “racing” ; both versions have 4 berths, a classic v berth on bow and two quarter berth after; in the cruising version cabin is 55 cm longer, giving wider interiors, enough room for a separate toilette and more comfortable after berths ; in the racing version we have a marine toilet (there’s room for a jabsco compact one) under the bow v-berth; cabin height is 1.65 m in both versions. interiors plywood panels are detailed on plans., taking advantage form the first season of sailing, i can now say that i strongly advice the cruise version as long as you are not going to run a sailing school, thus needing extra space in the cockpit., wooden rig: starting form summer 2019 we deliver two extra drawings with the plans, both for race and cruise version, describing how to build a wooden rig suited for this boat. keep your budget low at the price of a small extra weight , how to build the boat: we chose the plywood & epoxy resin “radius chine” system, as for petrel 28 and hirundo 750, so the hull planking is in okume marine grade plywood ; planking the hull is quite fast , and the internal structure of the boat is made by plywood bulkheads, floors and solid wood longitudinal stringers, all glued with epoxy and strengthened with epoxy laminated glass tape, assembled on a cheap wood scaffold, keeping the hull light, sturdy and quite easy to build for homebuilders ; the goal is to keep the total weight of the 19 footer, raising the ballast fraction of the sailboat at the same time. here are a couple of pictures of the first planked hull perfectly showing the radius chine planking system.

a HUGE Thanks to Nils Theurer ([email protected]) for the awesome pictures taken during the first sea trials

Plans availability: Plans are available in italian and english. Plans are available in imperial units upon request (send me a mail before purchase).

Boat Reviews

- Boats Specs

- Marine Pros

- Boat Insurance

- Boat Warranties

- Boat Transport

- Boat Towing

- Marine Forecasts

Your Ultimate Boating Resource

DIY Boat Building: 8 Tips and Tricks for Building Your Own Vessel

Do you dream of your custom-built boat, but the exorbitant expenses of skilled workmanship make you feel like a fish out of water? Don’t throw in the anchor just yet! Dive into the realm of DIY boat construction and surf the waves of creativity. You may sail away on a sailboat as unique as you are with a dash of carpentry abilities, a treasure trove of tools, and a sprinkling of patience. We’ve compiled a list of must-know boat-building tips and tactics to help you succeed. Prepare to make waves and convert your dream boat into a thrilling reality!

1. Choose Your Boat Type and Design Carefully

The first step in any DIY boat-building project is deciding what vessel you want to construct. There are many different types of boats to choose from, including sailboats, powerboats, canoes, kayaks, and rowboats. Consider your budget, building space, and intended use when narrowing your options.

Next, find a suitable design for your chosen boat type. There are numerous online resources, such as forums and blogs, where DIY boat builders share their experiences and advice on specific designs. You can also purchase boat plans or check out books from the library. Remember, a simple design is essential for a successful build, especially if you have limited experience.

2. Learn the Terminology and Construction Techniques

Before diving into your project, take the time to familiarize yourself with the common terms and techniques used in boat building. Many great resources are available, ranging from books and articles to online forums and videos. Understanding the terminology will make it easier to interpret plans and follow instructions.

3. Invest in Quality Tools and Materials

You must invest in high-quality tools and materials to build a sturdy, long-lasting boat. While it can be tempting to save money by purchasing cheaper alternatives, these products may compromise the structural integrity of your vessel.

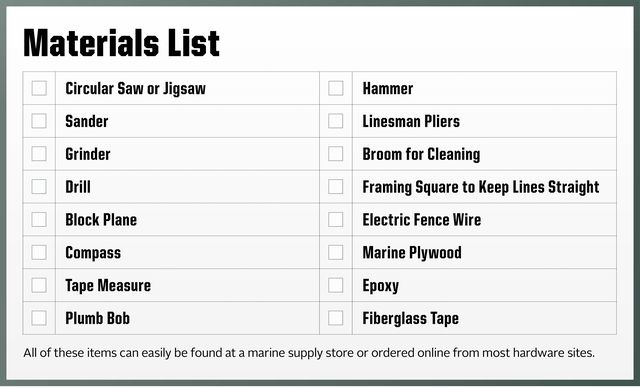

Additionally, if you don’t already own them, consider investing in some essential boat-building tools, such as:

Epoxy and Fiberglass

4. Create a Suitable Working Space

Devote an area in your home or garage to your boat-building project. Make sure the space is large enough for your boat, plus additional room for tools, materials, and mobility. This dedicated workspace allows you to keep your materials organized and reduces the risk of accidents due to clutter.

5. Develop a Project Timeline

Before beginning construction on your boat, create a project timeline that outlines each phase of the building process. This timeline should include tasks such as gathering materials, cutting and assembling parts, and applying finishes. It will help you stay on track and can provide a visual reference for what needs to be done and when.

6. Take Safety Precautions

Safety should always be a top priority when working with tools and hazardous materials like epoxy and fiberglass. To ensure your safety, be sure to:

Wear safety glasses, gloves, and dust masks when necessary

Ventilate your work area to help minimize the risk of inhaling toxic substances

Keep all tools and chemicals out of children’s reach

Store flammable materials in a safe container and away from heat sources

7. Start with a Solid Foundation

A well-built boat starts with a sturdy foundation – the boat’s backbone. Be sure to mill your timbers, beams, and ribs correctly and double-check that they align accurately. If necessary, use molds, jigs, or temporary frames to ensure the boat remains symmetrical during the assembly process.

8. Don’t Be Afraid to Ask for Help

Boat building can be a complex and challenging endeavor, but don’t be afraid to reach out for help if you’re feeling overwhelmed. Online forums, local boat clubs, and fellow DIY enthusiasts can be great sources of advice and support throughout your project. Few things are more satisfying than the sense of community and camaraderie formed with fellow boatbuilders.

Create That Beautiful Vessel

DIY boat building can be an incredibly rewarding experience, providing you with a beautiful, custom-made vessel and a sense of accomplishment once completed. By taking the time to do thorough research, plan your project carefully, invest in quality tools and materials, and adhere to safety precautions, you’ll be well on your way to building the boat of your dreams. Happy boat building!

RELATED ARTICLES

Outboard motor maintenance: tips for keeping your engine in top shape, the essential boat tool kit: tools every boater needs, the art of miniature maritime craftsmanship: ship in a bottle, antifouling paints: a guide to keeping your boat shipshape, gelcoat repair guide: everything boat owners need to know, latest posts, overview of the 2024 sea-doo rxp-x 325, overview of the 2024 parker offshore 2900 cc, what your boat’s beam is and why it matters, power cats of 2024: ultimate guide to the top power catamarans this year, don't miss, our newsletter.

Get the latest boating tips, fishing resources and featured products in your email from BoatingWorld.com!

Navigating the Heat: 10 Safety Tips for a Safe Boat Ride in the Summer Heat

What type of wood is used for pier pilings, what is the difference between a dock and a floating pier, what is the proper technique for pulling a beginner wakeboarder, what does ‘no wake’ mean on a lake, what is the difference between wash and wake, highs, lows, and tidal know-how: a deep dive into ocean currents, 10 essential tips for fishing near private property, the benefits of using a drift sock: guidance for anglers, lure fishing: secrets for imitating live bait and attracting fish, explore the untapped depths of america’s best bass fishing spots, beginner’s guide to standup paddle boarding: tips and techniques, boating for fitness: how to stay active on the water, kayak safety: how to stay safe on the water, anchoring in a kayak or canoe: how to secure your small boat, overview of the 2024 yamaha 252sd, overview of the 2024 tiara yachts 48 le, overview of the 2024 bass cat jaguar sts, 2024 pursuit os 445: an overview, 2024 aquila 47 molokai review, 2024 sea-doo switch 13 sport review, gear reviews, megabass oneten max lbo jerkbait review, fortress anchors fx-7 anchoring system review, fortress anchors fx-11 anchoring system review, fortress anchors commando anchor kit review, fortress anchors aluminum anchors review, stay in touch.

To be updated with all the latest news, offers and special announcements.

- Privacy Policy

- No products in the cart.

Build your own sail boat with Hartley Boat Plans. Hartley sail boats are the benchmark in reliable and sea worthy trailer sailers, in fact the name trailer sailer was coined by these amazing craft. Many of these build plans also have a printed study pack available to help you through your project.

Cape Bay 45

Cape Otway 37

Chuckles 18

Dateline 51

Eastcoaster 16

Easthaven 34

Hartley 16ft (5m) Trailer Sailer

Hartley 30 (Plywood Version)

Hartley 30 (Steel Version)

Royal Suva 52

Samson ‘C-Baron’ 55

Samson ‘C-Breeze’ 45

Samson ‘C-Deuce’ 45

Samson ‘C-Fever’ 62

Samson ‘C-Lord’ 53

Samson ‘C-Quence’ 36

Samson ‘C-Witch’ 63

Tahitian 27

Tahitian 33

Tahitian 38

Tahitian 45-50

Westhaven 32

DIY Boat Building Plans

Sailing Boat Plans & Blueprints

Download over 500 Boat Plans. Click on the link below.

-->click here<--.

Table of Contents

Overview of Sailing Boat Plans & Blueprints

Sailing boat plans and blueprints are essential tools for anyone looking to build their own sailing boat . These plans provide detailed instructions and diagrams that guide builders through the entire construction process. They outline the design, dimensions, and specifications of the boat, ensuring that every component is built to the correct measurements. Having a plan before building a sailing boat is crucial as it helps avoid costly mistakes and ensures that the final product meets the builder’s expectations.

Key Takeaways

- Choosing the right sailing boat plan is crucial for a successful build.

- There are various types of sailing boat plans and blueprints available to choose from.

- Understanding the key components of a sailing boat plan is important for accurate interpretation.

- Customizing sailing boat plans can help meet specific needs and preferences.

- Building your own sailing boat can be a rewarding experience with many benefits.

The Importance of Choosing the Right Sailing Boat Plan

Choosing the right sailing boat plan is of utmost importance as it can make or break the building process. Opting for the wrong plan can lead to numerous problems, such as mismatched components, structural weaknesses, or even an unseaworthy vessel. It is essential to consider factors such as skill level and intended use when selecting a plan. Novice builders may want to start with simpler designs that require less technical expertise, while experienced builders may be more inclined to tackle complex custom plans. Additionally, considering the intended use of the boat is crucial as different designs excel in various sailing conditions.

Types of Sailing Boat Plans and Blueprints Available

There are several types of sailing boat plans and blueprints available to suit different needs and preferences. Stock plans are pre-designed templates that can be purchased from professional designers or online platforms. These plans offer a range of designs suitable for various skill levels and budgets. Custom plans, on the other hand, are tailored specifically to an individual’s requirements. They allow for greater customization but often require more expertise and can be more expensive. DIY plans are another option for those who prefer a hands-on approach. These plans provide detailed instructions for building a boat from scratch, allowing builders to have complete control over every aspect of the construction process.

Understanding the Key Components of a Sailing Boat Plan

| Component | Description |

|---|---|

| The main body of the boat that sits in the water and provides buoyancy and stability. | |

| Keel | A heavy fin or bulb that extends below the hull to provide stability and prevent sideways drift. |

| Rudder | A flat, vertical blade at the stern of the boat that is used to steer the boat. |

| Sails | The fabric sheets that are attached to the mast and boom to catch the wind and propel the boat forward. |

| Mast | A tall, vertical pole that supports the sails and provides leverage for steering. |

| Boom | A horizontal pole that extends from the mast and holds the bottom of the sails in place. |

| Lines | The ropes or cables that are used to control the sails, rudder, and other parts of the boat. |

| Winches | Mechanical devices used to control the lines and adjust the sails. |

A sailing boat plan consists of several key components that are essential for understanding the construction process. The hull design is one of the most critical aspects as it determines the boat’s stability, speed, and handling characteristics. Rigging refers to the system of ropes, wires, and hardware used to control the sails and mast. A well-designed rigging plan ensures efficient sail handling and maneuverability. The sail plan outlines the size, shape, and configuration of the sails, which directly affects the boat’s performance under different wind conditions. Understanding each component is vital as it allows builders to make informed decisions during the construction process.

How to Read and Interpret Sailing Boat Blueprints

Reading and interpreting sailing boat blueprints can be daunting for beginners due to the technical language and symbols used. However, with some guidance, it becomes easier to understand these complex documents. One tip is to familiarize oneself with the technical terms commonly used in boat building . This can be done through online resources or by consulting professionals in the field. Additionally, learning to recognize common symbols and abbreviations used in blueprints is crucial for understanding the design intent. Taking the time to study and interpret blueprints accurately will ensure that builders can follow instructions correctly and avoid costly mistakes.

Factors to Consider When Choosing a Sailing Boat Plan

When choosing a sailing boat plan, several factors should be taken into consideration. Budget is an important consideration as it determines the type of plan that can be pursued. Custom plans tend to be more expensive than stock plans, so builders must assess their financial capabilities before making a decision. Skill level is another crucial factor as certain designs may require more expertise than others. It is essential to choose a plan that aligns with one’s skill set to ensure a successful build. Lastly, considering the intended use of the boat is vital as different designs excel in various sailing conditions. Researching and evaluating these factors before selecting a plan will help builders make an informed decision.

Tips for Customizing Sailing Boat Plans to Meet Your Needs

While stock plans and custom plans offer a range of options, builders may still want to make modifications to suit their specific needs or preferences. When customizing a sailing boat plan, it is important to start with a solid foundation. Making minor modifications, such as adjusting the interior layout or adding extra storage, can usually be done without major consequences. However, if considering significant changes to the hull design or rigging, it is advisable to consult with a professional designer or naval architect. They can provide guidance and ensure that the modifications do not compromise the boat’s structural integrity or performance.

Where to Find High-Quality Sailing Boat Plans and Blueprints

Finding high-quality sailing boat plans and blueprints is crucial for a successful build. There are several sources available, including online platforms, boat shows, and professional designers. Online platforms offer a wide range of plans from various designers, allowing builders to compare options and find the most suitable plan for their needs. Boat shows provide an opportunity to meet designers in person and discuss specific requirements. Professional designers are another excellent source as they can create custom plans tailored to individual preferences and provide expert advice throughout the building process. It is essential to choose a reputable source to ensure the quality and accuracy of the plans.

The Benefits of Building Your Own Sailing Boat

Building your own sailing boat offers numerous benefits that make the endeavor worthwhile. One significant advantage is cost savings. Building a boat yourself can be more affordable than purchasing a pre-built vessel, especially if you opt for stock plans or DIY plans. Additionally, building your own boat allows for customization. You have the freedom to choose the design, materials , and finishes that best suit your preferences. This level of personalization ensures that the final product is tailored to your specific needs and desires. Lastly, building a sailing boat provides a sense of accomplishment and pride. The process requires dedication, patience, and skill, and completing such a project can be incredibly rewarding.

Common Mistakes to Avoid When Building a Sailing Boat

While building a sailing boat can be a fulfilling experience, there are common mistakes that builders should be aware of and avoid. One common mistake is rushing the construction process. Building a boat requires careful attention to detail, and rushing can lead to errors that may compromise the boat’s integrity. Another mistake is neglecting proper planning and research. It is crucial to thoroughly understand the chosen plan and gather all necessary materials before starting the build. Additionally, overlooking safety precautions can have serious consequences. It is essential to prioritize safety throughout the construction process to ensure a safe and seaworthy vessel.

Conclusion – Sailing Boat Plans & Blueprints

In conclusion, sailing boat plans and blueprints are essential tools for anyone looking to build their own sailing boat. They provide detailed instructions and diagrams that guide builders through the construction process, ensuring that every component is built correctly.

Choosing the right plan is crucial as it can make or break the building process. Considering factors such as skill level and intended use is important when selecting a plan. Understanding the key components of a sailing boat plan, as well as learning how to read and interpret blueprints, is vital for successful construction. Customizing plans to meet specific needs should be done with caution, and consulting professionals is advisable for major modifications.

Finding high-quality plans from reputable sources is essential for a successful build. Building your own sailing boat offers numerous benefits, including cost savings, customization options, and a sense of accomplishment. However, it is important to avoid common mistakes such as rushing the construction process or neglecting safety precautions.

By carefully considering these factors and following best practices, builders can embark on a rewarding journey of constructing their own sailing boat.

FAQs – Sailing Boat Plans & Blueprints

What are sailing boat plans and blueprints.

Sailing boat plans and blueprints are detailed diagrams and instructions that guide boat builders in constructing a sailing boat. They include information on the boat’s dimensions, materials, and construction techniques.

Why do I need sailing boat plans and blueprints?

Sailing boat plans and blueprints are essential for anyone who wants to build a sailing boat. They provide a step-by-step guide to building a boat, ensuring that the finished product is safe, seaworthy, and meets all necessary regulations.

Where can I find sailing boat plans and blueprints?

Sailing boat plans and blueprints can be found online, in books, and from boat designers and builders. It’s important to choose plans from a reputable source to ensure that they are accurate and reliable.

What should I look for in sailing boat plans and blueprints?

When choosing sailing boat plans and blueprints, look for plans that are detailed, easy to follow, and include information on materials, tools, and construction techniques. It’s also important to choose plans that are appropriate for your skill level and the type of boat you want to build.

Can I modify sailing boat plans and blueprints?

Yes, sailing boat plans and blueprints can be modified to suit your needs and preferences. However, it’s important to ensure that any modifications you make do not compromise the safety or seaworthiness of the boat.

How long does it take to build a sailing boat using plans and blueprints?

The time it takes to build a sailing boat using plans and blueprints depends on the size and complexity of the boat, as well as your skill level and the amount of time you can dedicate to the project. It can take anywhere from a few months to several years to complete a sailing boat build.

Written by DIY Boat Building Plans

How To Build an Aluminum Boat

Aluminum Boat Maintenance Tips

Practical Boat Owner

- Digital edition

Build a boat from a kit

- Ben Meakins

- February 19, 2015

There’s a great way to own a new boat on a budget – build it yourself. You could create a unique cruising yacht to be proud of and save yourself hundreds, even thousands of pounds into the bargain, explains Ben Meakins

In the late 1960s noted author and yacht designer Maurice Griffiths wrote: ‘There is nothing like sailing the boat you have constructed with your own hands, whose every timber, screw, bolt and fastening you know intimately.’ Take a look at the pages of any early copy of PBO and you’ll find it filled with adverts for kits for home building. But times have changed.

The advent of relatively cheap, mass-produced boats, the increased size of the average yacht and, to a lesser extent, the limitations of the EU’s Recreational Craft Directive, which states that if you build a kit boat you cannot sell it on for five years, have slowed the home building flood to a mere trickle. But building a boat you can truly call your own still can’t be beaten – and there are plenty of ways of going about it.

Motivation But why bother when it’s easier to buy a boat ready made? Well, for a start, it’ll save you money – and you’ll end up with a boat that’s worth far more than the kit that it came from. Then there’s the feeling of satisfaction you’ll get from sailing a boat you’ve built yourself. If you’ve been involved in the process from start to finish, you’ll have a boat tailored perfectly to your needs.

How long will it take? You skills and spare time will influence how long a project takes to complete. On balance, it’s fair to expect to finish a small pocket cruiser within 1-2 years, working on it part time. Two owners we spoke to provide a useful contrast, taking six months and nearly six years respectively – but it all depends on time pressures and the amount of modifications and custom-building that you put in.

Do you have space? The biggest limitation to building any boat is space. It may sound obvious, but there’s many a story of a proud amateur boatbuilder realising with dismay that he’ll have to remove large bits of masonry from his house if his shiny new boat is ever going to see the water. A garage, barn or lock-up is best for the UK’s inclement weather, and will ensure the best possible conditions for your build. If you can’t manage that, a large tent will suffice.

What skills are needed? It depends on the boat you choose. Most kit boats we’ll look at use the ‘stitch and glue’ technique, where plywood panels are held together by temporary ‘stitches’, or ties, while they are glued and glassfibred together. Phil Smith of Fyne Boat Kits says: ‘If someone can follow instructions and read a manual and have the time and inclination to study a set of plans then they should consider a build.’ If you’re in doubt, it’s a good idea to build a small dinghy first, to get an idea of the skills required. You can even use the small boat as a tender to your larger boat.

‘They say you should build your first boat second,’ says one owner. ‘That way you’ll get the boat you want and have the skills to make a good job of it!’ One major advantage to building a boat from a kit, as opposed to from a set of plans, is that the building methods will have been carefully thought through for home builders. Ray Anderson was a boatbuilding novice when he started to build his Swallow Boats Storm 17. ‘The hardest part of building my boat was getting confident in using epoxy well, but luckily it was all covered in the manual.’ he says. ‘The fit of the parts was excellent and the satisfaction as you move forward through the build is incredible.’

What’s available? Some companies will create a kit for you from a set of plans. Selway Fisher and Iain Oughtred have a number of designs listed on their websites from which Jordan Boats will build a kit. Fyne Boat Kits sell a number of their own and others’ designs in kit form, and Whisper Boats sell a range of kits designed and built in Australia – and the kits include everything from hardwood trim to screws.

Alternatively, you can buy a bare GRP hull moulding from a company like Lauren Marine of Southampton, which has recently started selling the hulls of Hunter Boats for home completion.

Go to it, then There’s no doubt that building your own boat is a challenge, but, in the words of Maurice Griffiths: ‘Go to it, then, and may the winds be fair for the little ship you will build.’

JORDAN BOATS

Jordan Boats will produce a kit from any set of plans with copyright permission, supplying you with all the plywood panels precision pre-cut. They are already tooled up to produce the kits for a number of Iain Oughtred, Selway Fisher and Dudley Dix rowing boats, dayboats and small cruisers, as well as a variety of craft from the pens of other designers. We asked three customers about their chosen boats.

The Iain Oughtred-designed Wee Seal has plenty of character

Retired from the financial services sector, Gordon Simpson is excited about his project. ‘She’s finally beginning to look like a boat,’ he says. ‘I’m one plank away from finishing the hull!’ Gordon started building his 18ft (5.48m) clinker-planked, gunter-rigged Wee Seal a year ago. ‘My neighbour had recently built a rowing skiff, and I thought it looked like a great idea. I built an Iain Oughtred-designed clinker rowing boat first. I then started looking for an open boat, but my wife wanted something we could sleep on – so we settled on the Wee Seal. I wanted something with character, and she fits the bill.’ Gordon’s kit included a full set of cut plywood parts, but the solid wood – the keel, trim and framework – was down to him. ‘Having the ply ready cut on a CNC router made everything much easier for a first attempt, as it was so accurate,’ says Gordon. ‘If you’re willing to put the time and effort in, boatbuilding’s a great hobby to have!’ he continues. ‘The plans reckon it’ll take around 1,000 hours to build – and I hope to have her sailing by next summer.’

Price: £2,685. Kit includes all plywood parts and MDF moulds. Total cost will be around five times this price, for additional timber, glues, paint, fixings and rope.

‘Too enjoyable to rush’ – this Tideway 14 is a classic pocket cruiser

Graphic designer Graham Young started building his Selway-Fisher Tideway 14 pocket cruiser three-and-a-half years ago. ‘It’s been so enjoyable I haven’t rushed it!’ he says. ‘The thing I’ve enjoyed most is that there’s no time limit – unlike DIY around the house, when everything’s in a rush, I’ve been able to take my time. But I reckon three more months should see it through.’ Graham was disappointed he could find no DVD guides to building boats – so took some time off from his build to film one with Alec Jordan of Jordan Boats (see panel, page 51). Graham has just finished painting the hull and is now moving onto the rudder and rig. ‘It’s been quite a challenge,’ he says, ‘but definitely worth it. I would advise not starting too big – if you’re not sure what you’re doing, start with something small, learn the tricks and work up.’ Working from a kit also helps. ‘Having all the pieces pre-cut gave me a great kickstart,’ he says.

Price: £1,768. Kit includes all plywood parts for the boat. Total cost will be around five times this price, for all the additional timber, glues, paint, fixings, sails and rope.

Cape Henry 21

Gary Wallis finished his Cape Henry 21 gaffer in under a year

The Cape Henry 21 was developed from the well-known and successful GRP-built Cape Cutter 19. With a similar look to the Cornish Crabber, it was designed by South African designer Dudley Dix. Gary Wallis liked the look of the Cape Cutter and had built aeroplanes before he started his Cape Henry, which he built in just under a year. ‘I had to take my (now) wife to Las Vegas and marry her to keep her off my back,’ he laughs, ‘but I worked every evening until 8 and all my weekends until I’d finished.’ He says he’d highly recommend building from a kit. ‘Having the plywood panels precision pre-cut made everything so much more accurate, and improves the finished boat no end.’ Jordan Boats are also ready to tool up the plans for two more Dix designs, the Mini Didi, a Mini Transat racer, and the Dix 28, a sporty cruiser-racer.

Price: £2,536. Kit includes all plywood parts. Total cost will be around five times this price, for additional timber, glues, paint, fixings and rope.

WHISPER BOATS

If you ever built one of those wooden dinosaur skeletons as a child, you’ll know exactly how these clever kits go together. The frames, bulkheads, shelves and seats are connected to the keel and to each other by a series of precision pre-cut slots and tabs which interlock to form a rigid skeleton on a ready-made, lead-filled keel. Whisper’s kits are made by Scruffie boats in Australia, and according to Max Campbell, the UK importer, are unique. ‘We include everything down to the last bit of hardwood trim and laminated frame,’ he told PBO. ‘It’s the provision of these machined or laminated parts that makes the difference between a real kit and just having plywood sheets cut to suit plans.’ Whisper reckon it should take only three months working full-time on the build.

Chris Nunn built his Stornaway Weekender in just six months

Chris Nunn pulled out all the stops and built his 18ft (5.48m) Stornaway weekender in six months after he retired and moved to Bridport in Dorset. ‘Mooring charges were becoming extortionate,’ he says, ‘so we wanted something that would fit on the driveway. It all went to plan, I just threw it all together and in six months she was ready to sail.’ In common with all the Scruffie boats, the frame comes ready cut and ready to be assembled quickly and easily. ‘Everything came in the kit, even all the screws, so it was just a case of getting on and building it!’

Price: £8,953 complete kit

The Secret is Whisper’s best-selling model, and is a fast and capable boat

The 20ft (6.09m) Secret, described as halfway between an Essex Smack and a Sydney Harbour 18 footer, is Whisper’s most popular model. Max Campbell built one himself. ‘I was looking for a trailer-sailer to self-build, because I wanted control over the design and specification, but didn’t want the depreciation inevitable in buying a new finished boat,’ he explained. ‘My wife and I bought several sets of plans for other boats but always found a fatal flaw in their design – too ugly, or heavy, or wide, and then we came across the Secret, which fitted our bill perfectly.’ It only took a couple of weeks’ work to realise that the kit had taken most of the worry out of the build process, while leaving the satisfying building, and it still gave them plenty of scope for customisation. ‘From the first day there was no doubt that we were going to end up with a good, strong boat, and every day in the boat shed added significantly to what we’d done before. ‘The only woodwork I’d done before was building a model plane, and the process here was remarkably similar. Epoxy makes the whole process very forgiving – joints don’t lose either their strength or aesthetics if cut less than perfectly. ‘We were also grateful for the machined hardwood and laminated parts, because I don’t have a fully equipped workshop. We probably took about 1,500 hours, maybe more, and it did take longer than we’d envisaged, but in the end that didn’t matter because we enjoyed most of the actual building process, though fairing and painting did seem to go on for a long time!’

Price: £12,636 complete kit

This Scintilla has taken nearly five years to build, and is beautifully made

John Arter has been building his 24ft (7.31m) Scintilla gaffer in evenings and at weekends for five years. ‘The great thing about the kit is that it gives you a basic boat which you can personalise as much or as little as you like – I’ve put a lot of work in!’ he says. ‘I wanted a coastal cruiser, and the Scintilla has a wide hatch – so with a good awning over the cockpit, she’ll have standing headroom.’

Price: £12,352 complete kit

Contact: Whisper Boats, www.whisperboats.co.uk

FYNE BOAT KITS

The Pocket Ship: seated headroom below and a good turn of speed

Long-established Cumbrian company Fyne Boat Kits’ newest design is for the Pocket Ship, a 14ft 10in (4.52m) gaff-rigged cruiser with two berths down below and seated headroom. The kit includes all panels, and the holes for the ties are already cut. ‘She’s a fast-sailing pocket cruiser with a dry and commodious interior. It had to be quick and easy to build or the project would never get finished, so stitch-and-glue plywood construction was a given from the start. The panels are supplied ready-cut and with all ‘tie’ holes pre-drilled. The cockpit was laid out for day-sailing comfort and is large enough for sleeping on warm nights,’ explains Phil Smith.

Price: expected to be around £3,000

Contact: Fyne Boat Kits, www.fyneboatkits.com

SWALLOW BOATS

A daysailer like this Storm 17 makes a good, simple first project

Swallow Boats make a few small cuddy/cabin cruisers, such as the BayRaider (PBO February 2009), and will be releasing a kit version of the BayCruiser shortly. At present only their smaller models up to 17ft (5.18m) are available in kit form – and the Storm 17 open dayboat has found a loyal following. Ray Anderson got a kit shipped to South Africa. ‘When the idea to build a sailing boat got into my head I searched the internet for a suitable ‘old world’ type boat and eventually came across Swallow Boats,’ he says. ‘I fell in love with the looks of the Storm 17 and that was that. A lot of designs are all too much traditional building and I was put off. I wanted something that I could imagine building in a year or so. The Storm 17 has a low parts count and you have a lovely shape in a few weeks – you can pretend it’s almost finished! ‘It has been a fantastic project and totally satisfying. Every time I look at it I’m amazed at what started out as a few pieces of plywood.’ Price: £4,128 – everything included except paint and oars.

Contact: Swallow Boats, www.swallowboats.co.uk

Boatbuilding guides on DVD

This feature was originally published in PBO in 2009.

This Is the Easiest DIY Boat-Building Method We’ve Ever Seen

And the guy who discovered it is sharing all of his secrets.

In the summer of 1974, Sam Devlin was working on a tugboat in Alaska when he read the first issue of Wooden Boat Magazine . He was immediately entranced. “I couldn’t shake the image of that wooden boat from my head,” Devlin says. “I can even see it today, almost five decades later.” Devlin had loved boats from a young age and had worked on fiberglass boats in the past, but the process lacked creativity, he says, and didn’t challenge him. This wooden boat, though, was something different.

A natural craftsman, Devlin believed wooden boatbuilding was a career he could be proud of. He leaned into the idea of making vessels that were both beautiful and functional—something that would last. Physical labor suited his strong, tall frame. And as a child of the ’60s, someone who came of age post-Vietnam, he felt the freedom to draw his own roadmap and forgo a traditional career.

However, the wooden boat revival had just begun, and very few builders were sharing their processes. Devlin had to come up with his own from scratch. Starting in 1977 with hand drawings and small, to-scale models, Devlin created hull shapes that looked viable for small sail and motorboats. But one part stumped him: how to fuse the panels together.

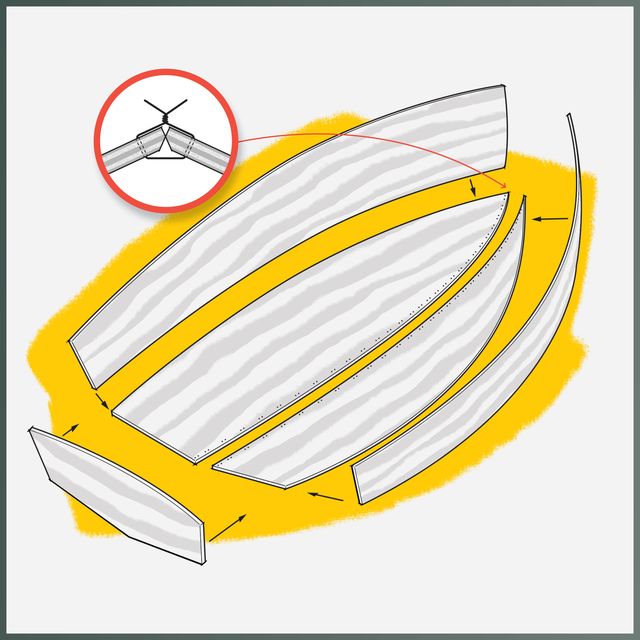

Nevertheless, he forged ahead. “My dad agreed to buy the materials if I would build him a boat,” he says. Cutting the hull panels was the easy part. But they needed a method to attach them together. “We looked around the shop and saw baling wire and pliers, and two hours later we had the boat stitched together and looking like the shape we wanted. That was the eureka moment,” Devlin says. He had stumbled upon the stitch-and-glue method.

The stitch-and-glue method is a simple boat building technique popularized in the 1960s that creates a solid, one-piece hull, unlike most other wooden boats, which start with frames and bulkheads and build the hull on top. Using marine plywood panels stitched together with electric fence wire and sealed with epoxy resin, the process eliminates the need for frames or ribs, making it a simpler, faster construction. Stitch-and-glue doesn’t require expensive molds like fiberglass, and can be maintained over the long term, perfect for DIY builders.

Devlin and his father continued to tinker with the shape and construction of their boat. A few days later they had a functional skiff. It wasn’t perfect, but it showed the stitch-and-glue process was more than viable—it had clear advantages over other boatbuilding methods.

Stitch and glue, generally speaking, has a remarkable ability to adapt. Without high tooling costs like most other boatbuilding mediums, it’s more accessible to more builders, which makes for rapid idea evolution and pervasion about the method. “With low barriers to entry from an experience side, we learned a lot quickly,” Devlin says. They learned that if they cheated on the grade of plywood, they would be sacrificing the integrity of the whole boat. They learned to use epoxy resins because they would seal stronger than more popular polyester resins. And moreover, they learned the process, the best order of operations, and how unique it was to quickly go from an idea to an actual, working boat.

Less than a year after finishing his first boat, Devlin embraced boatbuilding as a full-fledged career. Research led him to builders making small boats in England and New Zealand that used a method similar to the one he had devised with his dad, but not at the same scale or complexity he envisioned.

From there, he focused on improving the process. “We needed to nurture the method, testing the parameters and not constraining it with patents,” Devlin says. “My goal from the beginning was to proliferate the knowledge as much as possible and keep persisting and developing my own skills as a designer and builder.

“Most people didn’t see the potential for boats over 15 or 20 feet with stitch-and-glue, but I didn’t believe in that limitation. I hung my boatbuilding shingle on the door of my shop at the time in Eugene, Oregon, and I got my business started in 1978 with 25- and 30-foot boats.” Devlin’s business has grown since then, adding members to his team, expanding his shop, and refining his process. Today he works on a variety of wooden boats, and currently is putting the finishing touches on a 40-foot ocean-going catamaran.

The biggest advancement in the stitch-and-glue method in the past decades has been computers replacing hand drawings. Using 3D modeling and CNC machines to cut out shapes, the panels of the boat are more accurate and easier to work with during assembly. This also allows boat designers like Devlin to ship kits to home builders with precut panels to assemble using their own tools.

In 2012 Devlin received the Lifetime Achievement in Boatbuilding and Design award by the Wooden Boat Foundation and Wooden Boat Magazine , after designing and building over 400 boats (ranging from 7 to 65 feet) with the stitch and glue method, which he helped improve and bring to the mainstream. To this day Devlin is still building boats, from his facility in Olympia, Washington. Here are his tips for making your own.

25 Steps to Building Your Own Stitch-and-Glue Boat

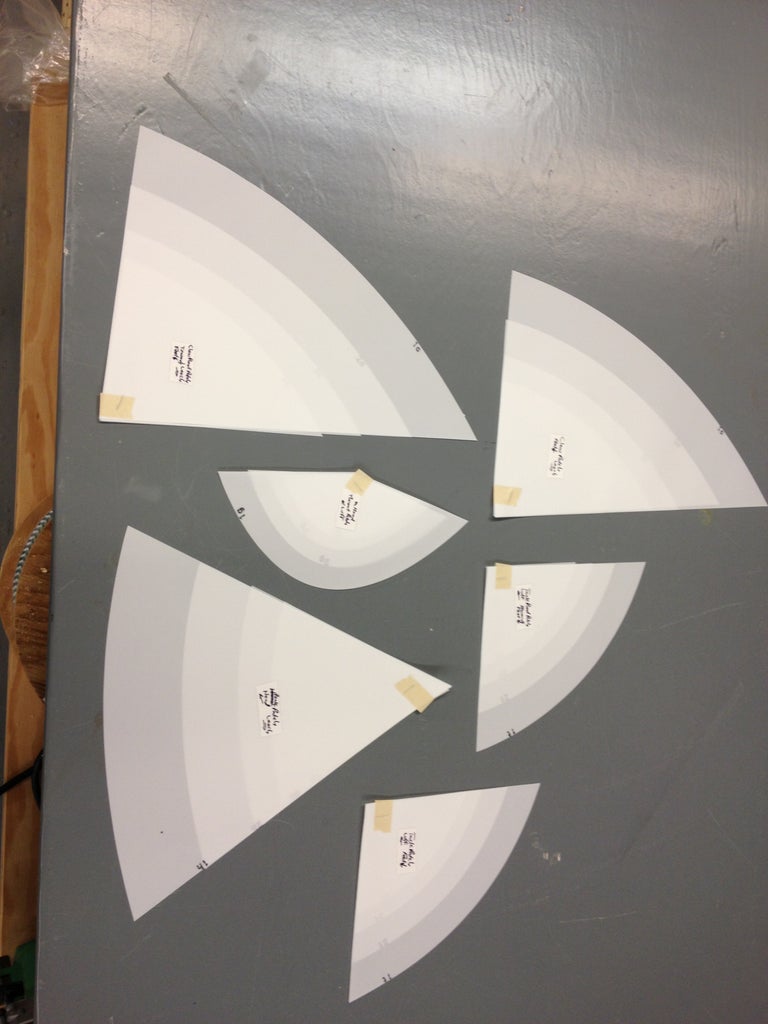

1. | Procure a set of plans, or scaled drawings of what you’re going to create. Devlin creates plans for hundreds of DIYers, detailing the peel shapes and all the materials you’ll need.

2 | If your boat is longer than 8 feet, edge-join the marine plywood panels end to end (called scarfing). If using a kit, the kit manufacturer will provide wave-to-keyhole type indexing to the ends of the panels that will help allow them to be joined.

3 | If you have a CNC router, use it to cut the panels to size (there are usually 5 to 8 for a small, simple boat). Skip to step 14.

4 | If you don’t have access to a CNC router, draw lines across the width of the panel at right angles to the long edge of the plywood, 1 foot apart.

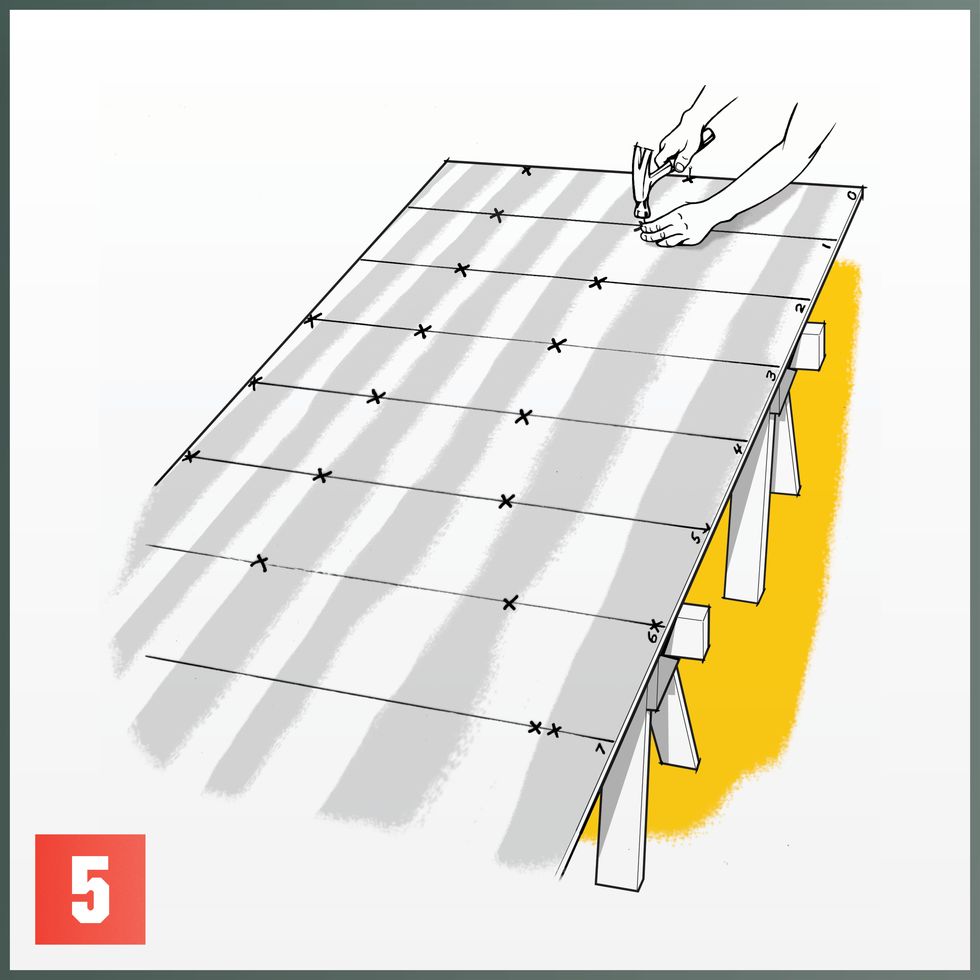

5 | Make marks at the bisects at each line, as shown on the plans, then hammer small brad-type nails (“fence posts”) partially into the plywood at each of those intersections.

6 | Draw smooth curves between these fence posts using a flexible wooden batten to span smoothly between each of the fence posts. When complete, remove the nails.

7 | Saw the panels out, leaving about 1/8 inch extra plywood overhang so you can see the line you drew.

8 | Take both pieces and use a block plane to even them out so they’re symmetrical, smoothing the cutting lines out to the pencil line marks made previously.

9 | Do this for all of the panels of the boat, which together will make up the entire hull.

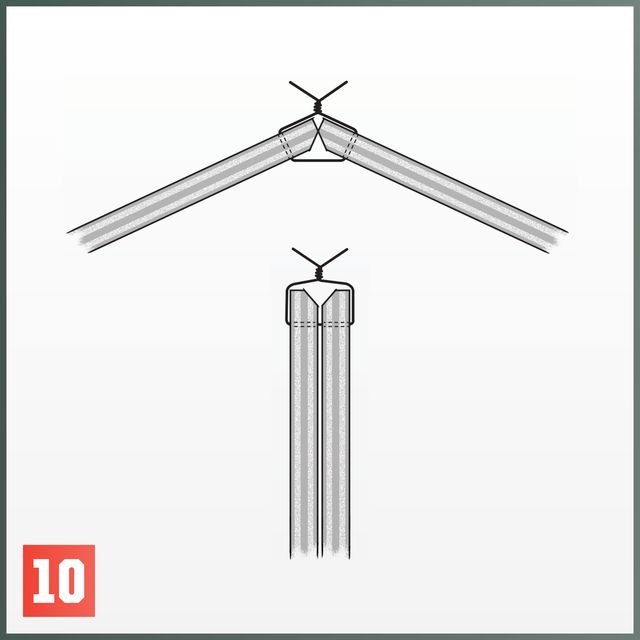

10 | Use a block plane to knock 45-degree bevels on half the thickness of the panel, on the inside surfaces (where it will mate with another panel).

11 | Scribe a stitch line, usually the thickness of the plywood plus 1/8 inch, and pre-drill small holes as marked on the designs. This works well on the bottom panels.

12 | For larger boats (those above 15 feet long), stitch upside down—it eliminates having to roll the boat over another time. A small boat can be stitched right-side up, because rolling one of these is much easier.

13 | For larger boats, set up the bulkheads, or athwartships (sideways) and longitudinal (lengthwise) structures that add structural strength and help define the architectural space of the boat. For small boats, use spreaders, which are small battens that open the top of the boat to the designed width, to stretch out the shear of the boat.

14 | Start with the two bottom panels laid one over the other (like a closed book) at the bow end and stitch the first two panels together at their keel edges. This process is similar to sewing two pieces of fabric together, but instead of a needle, you can feed the wire through the holes with your hands. It should be tight enough to keep the peels sealed together.

15 | Open the two halves of the bottom panels like opening the pages of a book and fit them over the bulkheads upside down. For small boats, use spreaders to maintain the correct shape.

16 | Repeat this process with each panel, stitching one side and then the other, from bow to stern. When all the panels are in place and the stitches are clamping the panels together into a boat shape, stitch the transom to the ends of the panels. For small boats, add spreaders to open up the top of the boat to the planned size.

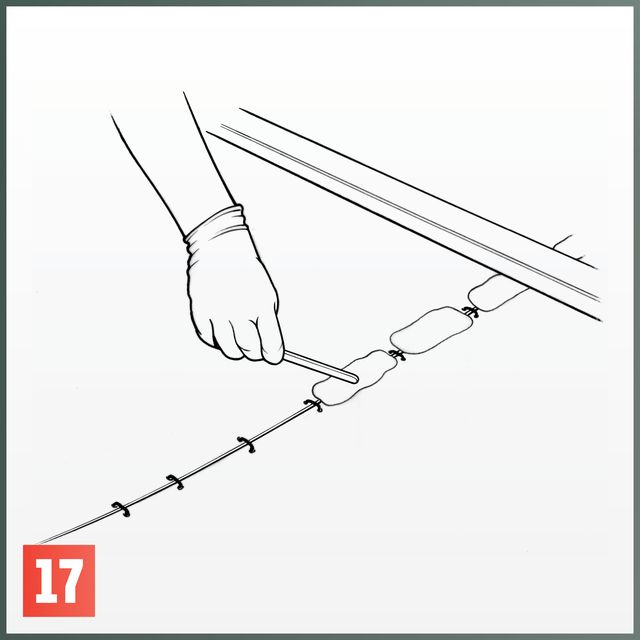

17 | Start epoxy tabbing, which is like tack welding, putting epoxy and fiberglass tabs between the wire sutures, on the interior of the hull.

18 | Once the tabs have cured solid, at least 24 hours but maybe more in humid climates, you can pull out all the wire stitches and lightly sand over the tabs to smooth things out.

19 | Finish fiberglassing the interior seams of the boat. Set several layers of fiberglass tape in epoxy resin over the top. Then fiberglass the exterior plywood panel seams.

20 | Once the hull is to the designed thickness and all seams between the panels are taped with epoxy and fiberglass cloth layers, sheath the entire exterior of the boat with epoxy and fiberglass cloth. Some builders use a final layer of peel ply to control the resin-to-cloth ratio and eliminate air bubbles.

21 | Finish fiberglassing the seams of the interior of the boat, starting with narrow tapes up to the final width of the plans designated.

22 | Sand the boat inside and out to help smooth the edges and overlaps of the fiberglassing. Reseal with epoxy resin rolled and brushed over the hull as smoothly as possible.

23 | Sand and seal one final time and roll the boat over.

24 | Install the interior, such as seats, hardware, and the engine.

25 | Paint the entire boat, inside and out. Opaque paint offers the best UV protection, which is important to shield the boat from the sun’s reflection off the water.

.css-cuqpxl:before{padding-right:0.3125rem;content:'//';display:inline;} Pop Mech Pro .css-xtujxj:before{padding-left:0.3125rem;content:'//';display:inline;}

The Day Russia's Supersonic Jet Fell From the Sky

Sub USS Idaho Joins a Slow-Growing Naval Fleet

Russian Flaunts Nuclear-Tipped Air-to-Air Missile

Chinese Missile Tech Finally Caught Up To The U.S.

China's H-6 Bomber To Play Vital Role in Air Force

The Space Force is Calling for “Fires” in Space

Did This Man Solve the Amelia Earhart Mystery?

DNA Finally Solves the 'Enigma of Kaspar Hauser'

It’s Hot Bomber Summer in Alaska

Fourth-Dimensional Aliens Could Be Spying On Us

Two Long-Lost Euripedes Works Found in Egypt

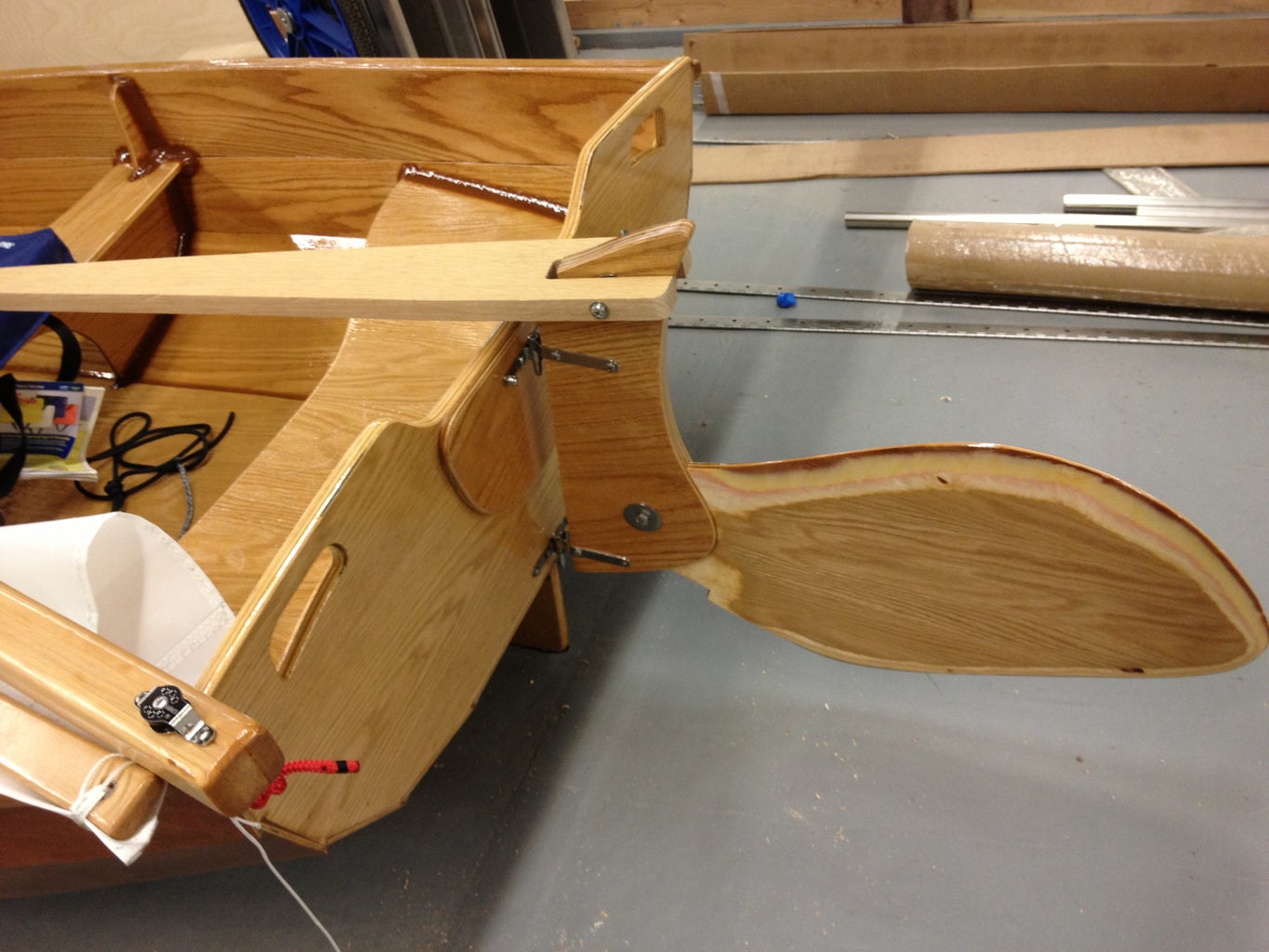

How to Build a Wood Sailboat

Introduction: How to Build a Wood Sailboat

I've been wanting to combine my two favorite hobbies - woodworking and sailing for a long time, so I thought I'd build a boat. It's got classic lines and looks so dazzling in the sunshine that people constantly stop me at the boat ramp to ask me about it. There's something unbelievably rewarding about building something like this from scratch. This is definitely a boat that is much better built than bought . Here's how I did it.

The boat takes about 100 hours to build. I did it over 3 months, working a little bit just about every day and full days when my schedule permitted.