Standing Rigging (or ‘Name That Stay’)

Published by rigworks on november 19, 2019.

Question: When your riggers talk about standing rigging, they often use terms I don’t recognize. Can you break it down for me?

From the Rigger: Let’s play ‘Name that Stay’…

Forestay (1 or HS) – The forestay, or headstay, connects the mast to the front (bow) of the boat and keeps your mast from falling aft.

- Your forestay can be full length (masthead to deck) or fractional (1/8 to 1/4 from the top of the mast to the deck).

- Inner forestays, including staysail stays, solent stays and baby stays, connect to the mast below the main forestay and to the deck aft of the main forestay. Inner forestays allow you to hoist small inner headsails and/or provide additional stability to your rig.

Backstay (2 or BS) – The backstay runs from the mast to the back of the boat (transom) and is often adjustable to control forestay tension and the shape of the sails.

- A backstay can be either continuous (direct from mast to transom) or it may split in the lower section (7) with “legs” that ‘V’ out to the edges of the transom.

- Backstays often have hydraulic or manual tensioners built into them to increase forestay tension and bend the mast, which flattens your mainsail.

- Running backstays can be removable, adjustable, and provide additional support and tuning usually on fractional rigs. They run to the outer edges of the transom and are adjusted with each tack. The windward running back is in tension and the leeward is eased so as not to interfere with the boom and sails.

- Checkstays, useful on fractional rigs with bendy masts, are attached well below the backstay and provide aft tension to the mid panels of the mast to reduce mast bend and provide stabilization to reduce the mast from pumping.

Shrouds – Shrouds support the mast from side to side. Shrouds are either continuous or discontinuous .

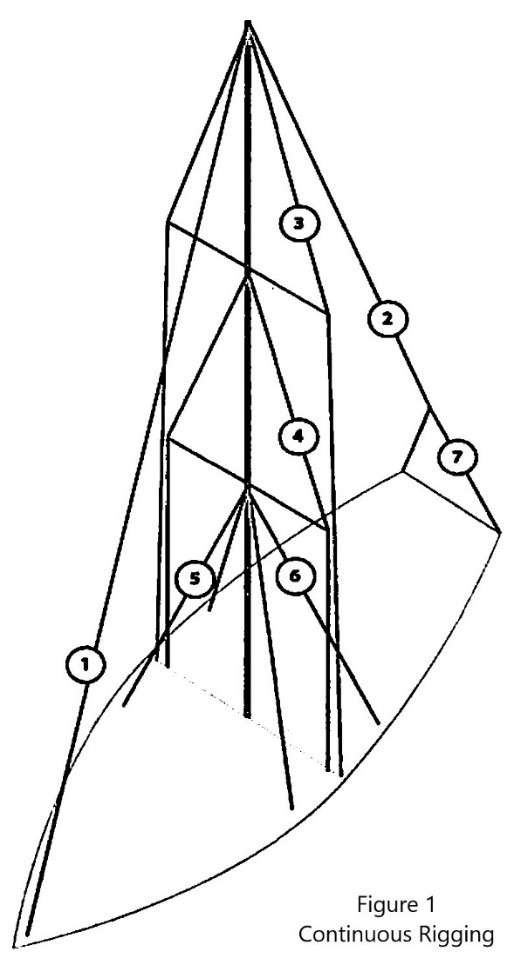

Continuous rigging, common in production sailboats, means that each shroud (except the lowers) is a continuous piece of material that connects to the mast at some point, passes through the spreaders without terminating, and continues to the deck. There may be a number of continuous shrouds on your boat ( see Figure 1 ).

- Cap shrouds (3) , sometimes called uppers, extend from masthead to the chainplates at the deck.

- Intermediate shrouds (4) extend from mid-mast panel to deck.

- Lower shrouds extend from below the spreader-base to the chainplates. Fore- (5) and Aft-Lowers (6) connect to the deck either forward or aft of the cap shroud.

Discontinuous rigging, common on high performance sailboats, is a series of shorter lengths that terminate in tip cups at each spreader. The diameter of the wire/rod can be reduced in the upper sections where loads are lighter, reducing overall weight. These independent sections are referred to as V# and D# ( see Figure 2 ). For example, V1 is the lowest vertical shroud that extends from the deck to the outer tip of the first spreader. D1 is the lowest diagonal shroud that extends from the deck to the mast at the base of the first spreader. The highest section that extends from the upper spreader to the mast head may be labeled either V# or D#.

A sailboat’s standing rigging is generally built from wire rope, rod, or occasionally a super-strong synthetic fibered rope such as Dyneema ® , carbon fiber, kevlar or PBO.

- 1×19 316 grade stainless steel Wire Rope (1 group of 19 wires, very stiff with low stretch) is standard on most sailboats. Wire rope is sized/priced by its diameter which varies from boat to boat, 3/16” through 1/2″ being the most common range.

- 1×19 Compact Strand or Dyform wire, a more expensive alternative, is used to increase strength, reduce stretch, and minimize diameter on high performance boats such as catamarans. It is also the best alternative when replacing rod with wire.

- Rod rigging offers lower stretch, longer life expectancy, and higher breaking strength than wire. Unlike wire rope, rod is defined by its breaking strength, usually ranging from -10 to -40 (approx. 10k to 40k breaking strength), rather than diameter. So, for example, we refer to 7/16” wire (diameter) vs. -10 Rod (breaking strength).

- Composite Rigging is a popular option for racing boats. It offers comparable breaking strengths to wire and rod with a significant reduction in weight and often lower stretch.

Are your eyes crossing yet? This is probably enough for now, but stay tuned for our next ‘Ask the Rigger’. We will continue this discussion with some of the fittings/connections/hardware associated with your standing rigging.

Related Posts

Ask the Rigger

Do your masthead sheaves need replacing.

Question: My halyard is binding. What’s up? From the Rigger: Most boat owners do not climb their masts regularly, but our riggers spend a lot of time up there. And they often find badly damaged Read more…

Selecting Rope – Length, Diameter, Type

Question: Do you have guidelines for selecting halyards, sheets, etc. for my sailboat? From the Rigger: First, if your old rope served its purpose but needs replacing, we recommend duplicating it as closely as possible Read more…

Spinlock Deckvest Maintenance

Question: What can I do to ensure that my Spinlock Deckvest is well-maintained and ready for the upcoming season? From the Rigger: We are so glad you asked! Deckvests need to be maintained so that Read more…

Marine Wire Rope

Strength in Challenging Environments

Our high quality marine wire rope products are engineered for strength, appearance, abrasion resistance, elongation, exceptional corrosion resistance, and performance. Applications include sailboat rigging, dock railings, winch cables, and crane ropes, all designed to stand up to the challenges of the marine environment. Whether you are refitting your sailboat or re-stocking your tow ropes, Strand Core has the marine wire rope size and construction you need.

Strand Core offers type 302 / 304 and type 316 stainless products for both fresh and salt water applications. Sizes range from 3/32" to 5/8", in 1x19, 7x7, 6x19, and 6x37 constructions. Click on a product line below for more information. Other constructions and alloys are available by request.

Marine Wire Rope Data Sheet

1x19 Stainless Steel Strand

Smooth outside and resists compressive forces. Excellent strength and appearance for sailboat stayed rigging. Used in Dockside railings and other waterfront architectural applications

7x7 Stainless Steel Aircraft Cable

Performs well when strength & moderate flexibility are concerns. Primarily used in sailboat lifeline and sailboat running rigging, boat lift winches and other single line hoisting operations.

6x19 Stainless Steel Wire Ropes

Excellent Corrosion resistance combined with flexibility and strength. Used on marine towing and marine crane operations.

Product Information

Packaging information, technical information, get a marine wire rope quote.

High School and College Sailors - 15% Off Apparel & Accessories - LEARN MORE

- Call Us +1-503-285-5536

- Sign in & Register

- Recently Viewed

West Coast Sailing offers a full selection of marine grade sailing line and rigging including One Design rigging, pre cut line, line kits, and line by the foot for halyards, sheets, control lines, and more. Shop running rigging and standing rigging today from trusted brands including Marlow, Robline, Samson, Kingfisher, New England Ropes, and more.

- Qty in Cart

Laser / ILCA 8:1 Cunningham TecPRO (Complete)

Laser / ILCA Vang Complete TecPRO (Allen Vang Block)

J/80 Main Halyard w/ Shackle

J/70 Backstay Flicker

Thistle Main Halyard Tapered (6mm Excel)

Thistle Spinsheet Continuous Tapered (6mm Excel Racing)

Melges 24 4:1 Main Halyard Vectran

Melges 24 Jib Sheet (Continuous/Tapered)

J/24 Spinnaker Sheet (Ultra Lite)

J/22 Twings (Pair) with Ring

Laser / ILCA Outhaul TecPRO 6:1 (Complete)

10mm Marlow D2 Racing

8mm Marlow D2 Racing

Laser / ILCA Vang Control PRO

Laser / ILCA 8:1 Cunningham PRO (Complete)

Laser / ILCA Outhaul PRO 6:1 (Complete)

- Total: items /

- Add all to cart

Adding your products to cart

Sailboat line & rigging - halyards, sheets, control lines & more.

Line is a critical part of any sailboat, from small dinghy to super yacht and everything in between. West Coast Sailing offers a wide variety of line and marine rope for every sailor from leading line manufacturers. Whether you're looking for a new control line for your Laser vang, jib sheet for your J24, replacement halyard for your cruising boat, or a high strength low stretch line for a high performance application, we've got what you need to get you back on the water. Shop by common application, diameter, material, and more with options available from Robline, Marlow, Alpha Ropes, and New England Ropes. All line sold by the foot with line kits for select boats and small diameter mini spools available.

Shop By Boat

West Coast Sailing offers custom rigging, line kits, and pre cut line for many popular one design dinghies and keelboats. These products make it simple to get the right line for your sailboat and you can be confident they will work great.

- Shop Line Kits

- Shop One Design Rigging

- Shop Pre Cut Line

Shop By Line Type

Line has come a long way in the past few decades, and current options offer great value and performance. We offer a variety of h igh tech Lines, which generally feature a non-stretch core for strength, durable cruising lines, which are typically polyester and less expensive but still strong and durable, or Dyneema, Spectra, & Vectran for non-stretch control line, halyard, and sheet applications. Shockcord bungee and floating Polypropylene also available. Scroll down this page for recommendations for line material based on your boat size and application.

- Shop by Line Type

Shop By Diameter

West Coast Sailing carries over 80 different lines from 6 of the best rope manufacturers in diameters ranging from 1mm all the way up to 12mm. Use our handy category filters to narrow in on the specific diameter of lines that work for your application, and then pick the one that meets your exact criteria for performance, color, or price.

- Shop by Line Diameter

Additional Line Options & Services

In addition to per foot line, pre cut line, line kits, and custom rigging, West Coast Sailing also offers mini spools, splicing equipment, and custom rigging services. If you can dream it, our team can build it!

- Shop Mini Spools

- Shop Splicing Tools

- Shop Custom Rigging

Line Fiber Type / Material Guide

| Fair | Excellent | Excellent | Poor | Poor | Poor | Fair | |

| Poor | Poor | Poor | Excellent | Excellent | Poor | Good | |

| Excellent | Poor | Fair | Excellent | Poor | Good | Good | |

| Good | Good | Good | Good | Good | Fair | Good | |

| Excellent | Fair | Fair | Poor | Poor | Excellent | Fair | |

| Good | Good | Good | Excellent | Good | Fair | Excellent | |

Line Application Guide - Dinghy

|

| | ||||||

| Good | Better | Best | |||||

| Good | Better | Best | |||||

| Good | Better | ||||||

| Good | Best | Best | |||||

| Good | Best | Best | |||||

| Good | Best | Best | |||||

| Better | Better | ||||||

Line Application Guide - Racing

|

| | ||||||

| Good | Better | Best | |||||

| Good | Better | Best | |||||

| Good | Best | ||||||

| Good | Best | Better | Good | Best | |||

| Good | Best | ||||||

| Better | Best | Good | Best | ||||

| Good | Better | Better | Good | Best |

Line Application Guide - Performance Cruising

|

|

| | |||||

| Good | Better | Better | Best | ||||

| Good | Better | Better | Best | ||||

| Good | Better | Best | |||||

| Good | Good | Better | Better | Best | |||

| Good | Good | Better | Best | ||||

| Good | Good | Better | Best | ||||

| Good | Good | Better | Better | Better | |||

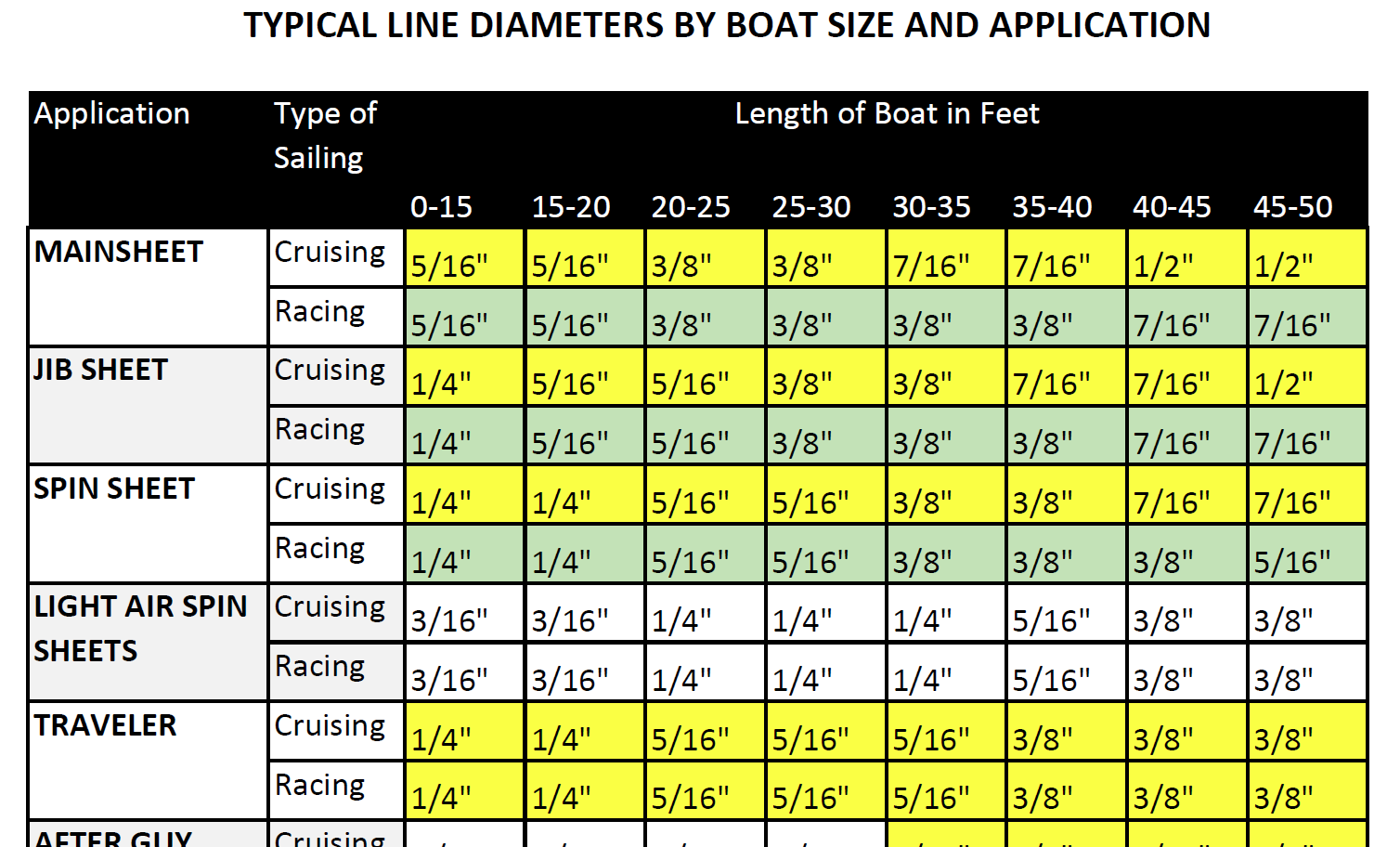

Line Diameter Guide

Recommended Diameter by Application & Boat Length

|

|

| |||||

| 6mm / 1/4 in | 6mm / 1/4 in | 8mm / 5/16 in | 8mm / 5/16 in | 9mm / 3/8 in | 11mm / 7/16 in | |

| 6mm / 1/4 in | 6mm / 1/4 in | 8mm / 5/16 in | 8mm / 5/16 in | 9mm / 3/8 in | 11mm / 7/16 in | |

| 6mm / 1/4 in | 6mm / 1/4 in | 8mm / 5/16 in | 9mm / 3/8 in | 9mm / 3/8 in | 11mm / 7/16 in | |

| 6mm / 1/4 in | 6mm / 1/4 in | 8mm / 5/16 in | 9mm / 3/8 in | 9mm / 3/8 in | 11mm / 7/16 in | |

| 8mm / 5/16 in | 9mm / 3/8 in | 9mm / 3/8 in | 9mm / 3/8 in | 11mm / 7/16 in | 12mm / 1/2 in | |

| 6mm / 1/4 in | 8mm / 5/16 in | 9mm / 3/8 in | 9mm / 3/8 in | 11mm / 7/16 in | 12mm / 1/2 in | |

| 6mm / 1/4 in | 8mm / 5/16 in | 8mm / 5/16 in | 8mm / 5/16 in | 9mm / 3/8 in | 9mm / 3/8 in | |

| 5mm / 3/16 in | 6mm / 1/4 in | 9mm / 3/8 in | 9mm / 3/8 in | 9mm / 3/8 in | 11mm / 7/16 in | |

|

| 1mm = 3/64 inch | 2mm = 5/64 inch | 3mm = 1/8 inch | 4mm = 5/32 inch | 5mm = 3/16 inch | 6mm = 1/4 inch |

| 7mm = 9/32 inch | 8mm = 5/16 inch | 9mm = 3/8 inch | 10mm = 25/64 inch | 11mm = 7/16 inch | 12mm = 1/2 inch | |

If you are replacing an existing line, the easiest way to determine what diameter you need is to match what you already have. This can be done with a caliper or by close estimation with a tape measure. For example, if you've previously used a 7mm halyard and it has performed well, another 7mm line is likely a great choice. In most applications, there is some flexibility in the exact diameter that can be used. Most blocks, for example, have an 'ideal' diameter (ie, the line diameter that runs most effectively though the block's sheave) but also have a range so that you can run a slightly thinner or slightly thicker line. If you have a halyard that is getting hung up in your rig, stepping down 1-2mm might help the halyard run more efficiently. If you have a larger boat or rig and want to run a thinner halyard, consider a double braid line that features a Dyneema or Spectra core for strength. A similar approach can be applied to replacing sheets, control lines, and other line on your sailboat.

Double Braid vs Single Braid

Two terms you will often see in line descriptions are 'double braid' and 'single braid', which refer to the way the line is constructed. At the most basic level, a double braid line has a cover and a core whereas a single braid does not, but there are other important distinctions to consider when making a line selection.

Single Braids are made up of either 8 or 12 strands that are braided into a circular pattern, half clockwise and half counter clockwise. This produces a line that is supple, absorbs twists, and tends not to kink. There are two types of single braid lines: performance single braids and polyester/blended single braids. Performance single braids are made from fibers with very low stretch and designed to handle extreme loads - think Dyneema, Spectra, or Vectran. Polyester/blended single braids, sometimes called hollow braid, are soft and easy to grip, built for sheets and hand-adjusted control lines. These are less common than performance single braid lines but recommended in a few specific applications.

Double Braids , sometimes called braid on braid, have a braided core within a braided outer jacket or cover. This creates a strong, durable, smooth-running line that is easy to handle. Double braids are used for the vast majority of all running rigging on sailboats including sheets, halyards and control lines for both cruising or racing. There are two types to consider: polyester double braids and high-tech double braids. Polyester double braids, found most commonly on recreational and cruising sailboats, have a polyester cover with polyester core. These are low maintenance, affordable, and long-lasting, while offering relatively low stretch and high working loads. For additional strength and minimal stretch, consider high-tech double braids. These lines typically feature a Dyneema or Spectra core (non-stretch) inside a polyester or polyester/dyneema blend cover for additional durability. They are more expensive but often the go to choice for high performance racing boats.

Sailing Programs & Clubs - West Coast Sailing offers special program pricing on purchases for sailing programs, yacht clubs, and community sailing organizations. Visit our YC & Program Purchasing page for more details.

Subscribe To Our Newsletter

Sign up for our newsletter to receive exclusive discounts, new product announcements, and upcoming sales.

Please verify you are a human

Access to this page has been denied because we believe you are using automation tools to browse the website.

This may happen as a result of the following:

- Javascript is disabled or blocked by an extension (ad blockers for example)

- Your browser does not support cookies

Please make sure that Javascript and cookies are enabled on your browser and that you are not blocking them from loading.

Reference ID: 5440ad75-7558-11ef-9233-5e5f8fc920ba

Powered by PerimeterX , Inc.

Yachting Monthly

- Digital edition

Rope, rigging & deck gear: how to choose the right rope

- Toby Heppell

- April 12, 2021

Rope continues to develop every year. We take a look at the plethora of options on the market

Rope is one of the most important tools for the cruising sailor

There was a time when selecting the correct boat rope for a specific task was scarcely more complicated than choosing a larger diameter for higher loads.

Choose ropes according to their role to hit the right balance between price and performance

But as new materials have been developed – offering differing characteristics, woven in different ways, with or without a jacket – deciding on which rope is right for you can be something of a minefield.

Typically, the better a rope performs in any number of areas, the higher the price tag, so for most sailors there is something of a cost-benefit analysis to be made when deciding which product to buy.

It is wise to ask yourself what specific improvement you are paying for and whether, ultimately, it is worth the additional expense.

It is also worth noting that, though we tend to equate cheaper with lower performance, that is not always the case.

Sometimes picking up a more expensive rope assuming it will behave better due to the higher price tag can leave you with an inferior product for a specific task.

On the other hand, due to the cost price of the materials they use, manufacturers don’t tend to vary hugely in terms of outright price charged for a given product.

As such, if you manage to find a rope that is significantly cheaper than everyone else online, it is worth being fairly cautious.

Rope is our most important tool and for most cruising sailors, a knowledge of the basic types established half a century ago has been enough to get by.

Traditionally, we’ve accepted what manufacturers or riggers gave us, perhaps made a decision about nylon rather than polyester for the anchor, and that’s been the end of the matter.

But progress in the past decade or so has been meteoric, driven largely by race boats. Some of these developments lie beyond the needs of cruisers, but the critical elements are right up our alley.

What’s changed and why

We’re now relatively used to seeing the term ‘high-modulus’ in reference to ropes.

English Braids’ R5 is made with yarn sourced from recycled plastic

These have been used at the highest end of sailing for well over 20 years, though until relatively recently were only available at eye-watering prices.

The term ‘high-modulus’ refers to Young’s Modulus of Elasticity.

The higher the value of this figure, the less a rope will stretch.

As it happens, most high-modulus ropes are also exceedingly strong – at least equivalent to wire – and can withstand far more load than any ropes previously.

Not only are these ropes unbelievably strong and light, they also repel water, so won’t get heavier when wet.

The same may not apply to the cover, depending on what this is made of.

The essentials remain the same as they have for a generation, though, with the high-modulus option best seen as an important bolt-on.

Polyester three-strand rope

Once the mainstay of yacht ropes, three-strand polyester is now largely used for shorelines.

Stretch is relatively low, price is not too steep and abrasion resistance is reasonable, so if that’s how you like your shorelines, it’ll do nicely.

Octo-plait gives plenty of flexibility

If you prefer more flexibility, try polyester multi-plait or ‘octo-plait.’ It seems to resist chafe better than three-strand, and if one strand does wear through, there are another seven to go.

Polypropylene three-strand rope

This is a cheap and not-too-cheerful option for shorelines.

It chafes easily, is degraded rapidly by sunlight and isn’t as strong as other rope variants.

Where polypropylene excels is in its ability to float.

As long as you have bought the best you can find (the really cheap line won’t coil at all), it will make a great heaving line as it isn’t too heavy to throw and won’t sink into your propeller.

Nylon, whether three-strand or multi-plait, is the strongest of the non-hi-tech ropes and is set aside from the others by its remarkably low elastic modulus.

This means that if it takes a snatch load, it will elongate rather than break, making it the top choice for anchor rodes and snubbers ever since it was invented.

For shorelines, many prefer polyester or really meaty polyprop because, the argument goes, you don’t want them stretching to leave the boat hanging off the dock.

Marlow’s classic braid-on-braid is very popular

However, nylon can be a better option because it soaks up any snatching and, so long as you’ve bought nylon that’s big enough for your boat, stretch won’t be an issue.

Nylon is also a very good option for gybe preventers. The less a preventer stretches, the more likely it is to damage the boom in a crash gybe .

Nylon has long been the default rope for all running rigging in cruising yachts.

Something with a bit of give is ideal for mooring

It might be ‘braid-on-braid’, with similar outer and inner parts, as sold by most manufacturers, or it could be a low-stretch polyester braidline (LSP) with a loosely laid three-strand core, such as Marlowbraid.

The stretch reduction of this can be as much as 40 per cent, which is well worth the extra you’ll pay.

Much of the braid-on-braid now sold is pre-stretched at the factory, which creates rope that’s an improvement on non pre-stretched lines, but it’s not as good as LSP, so is less than ideal for halyards on all but the smallest yachts.

With respectable strength, easy splicing and good price, braid-on-braid is the logical option for working sheets, kicker tackle, pole guys and the like.

It starts off soft to handle, but it can stiffen up over the years until the friction it creates passing round a block becomes so heavy that the boat’s winches are inadequate.

It also chafes relatively easily and it stretches a lot compared with more modern alternatives.

Buy Marlow Rope’s doublebraid rope on Amazon (UK)

Buy Kingfisher Braid on braid from Force 4

Buy Liros braid on braid from Force 4

Note: We may make a small commission on purchases made via the links on this feature. In no way does that affect our editorial independence.

Cores and modern rope.

Modern ropes are made of two components – a core that accounts for up to 95% of the rope’s strength, plus a protective outer cover (or jacket) that provides abrasion resistance, protection from sunlight and, where appropriate, improved holding in a clutch, jammer or cleat.

The cover can also be designed for better handling comfort.

Without a protective outer layer, modern rope will deteriorate in UV light

On racing boats this will usually be sacrificed in favour of a performance benefit, be it holding capability or resistance, but for the cruising sailor, striking a balance between performance and comfort is a key concern.

Broadly speaking, when talking about modern ropes, there are four or five major fibres involved – primarily Dyneema, Technora, Kevlar and polyester.

Until recently, Vectran was also used frequently, but its low resistance to ultra-violet light means there are now better fibres on the market.

These materials are blended together in different ways to produce both cores and covers that are optimised for each function on the boat.

Dyneema focus

Dyneema is perhaps the most important fibre currently used to manufacture ropes and is a proprietary brand name of DSM, which developed and sells it.

As such, brands selling Dyneema products will almost always feature the Dyneema name and/or trademark.

Dyneema is not the be all and end all of ropes but it does cover most areas and is a reliable purchase thanks to the above reasons.

All of the ‘big four’ manufacturers working in the UK – English Braids, Kingfisher, Liros, and Marlow – feature Dyneema in their performance products.

Dyneema comes in a variety of types and strengths

Dyneema lines come in different types too.

So simply specifying a Dyneema line of an appropriate size is not sufficient. Dyneema sells four different types of fibre for the marine sector: SK75, 78, 90 and 99.

SK75 has been around a while and combines strength with lightweight.

SK78 is a higher-end product with lower creep (permanent long-term elongation that arises from extended periods under load), while Dyneema SK90 has more strength, but with slightly more creep.

Continues below…

How to tie a soft shackle

Soft shackles can be used almost anywhere you currently use a conventional shackle. Look on any boat and you will…

How to make a Brummel Lock Splice for low-friction rings

Low friction rings are a robust and cost-effective addition to your boat. Graham Snook explains how to make a Brummel…

Why you should regularly check your deck fittings

What’s really going on under your deck fittings? Ben Sutcliffe-Davies investigates the hidden weaknesses

Spinnaker masterclass: tailored downwind sailing

There’s more than one way to rig, hoist, set and drop your spinnaker. Choosing the right setup and skills is…

In recent years Dyneema SK99 has been making significant inroads into the racing world and is now used by all major manufacturers.

SK99 has become one of the class leaders in the rope rigging field and offers a breaking load of almost a tonne in 3mm rope!

For most cruising sailors, however, the latter would be overkill, says Nigel Saddington of Kingfisher Rope.

‘I would say that 78 has superseded 75 and 99 has superseded 90 right now. But even then, to be honest, for most sailors and in most circumstances, I would say 78 is sufficient for almost all needs.’

Buy Marlow Excel Fusion Rope – SK75 Dyneema core – from Force 4

Buy Liros Magic Edge Rope – SK75 Dyneema – from Force 4

Effect on deck fittings

Nigel points to some concerns he has with the very top end of the Dyneema ropes being produced.

He notes that as a commercial product, its strength and stiffness are the qualities that make it a good rope but also make it a rope to be used with care.

This is because the loads that can be carried, even in a relatively small-diameter line, are high enough to warrant extra consideration with regards to which clutches and sails it is being used with.

Though super-strong modern ropes are ideal on race boats, their deck gear is set up to handle loads it will be working under

This is a theme that seems to pop-up time and again in recent years; as modern materials become stronger, so the rest of the kit on board needs to be up-spec’d in order to keep up.

Though it is impressive how much load can be carried by the highest-performing ropes, in relatively small diameters you still need something wide enough for your clutch to hold, and you will also want to ensure that your deck gear is rated high enough to deal with the loads.

Saving a halyard at the cost of losing a clutch might not be such a good idea.

That basic core of modern ropes isn’t the only area where there have been developments, however.

Here, a Dyneema mix is a popular option which has the benefit of being extremely light and, perhaps because it floats, is as resistant to water as the Dyneema inside – great for lightweight spinnaker sheets that stay light even after they’ve been dunked a few times.

The downside is that it doesn’t last very long because of the vulnerability of polypropylene to UV degradation.

The ‘entry-level’ coat is polyester of similar specification to the standard braid-on-braid most of us use.

This is relatively loosely woven, making for easy splicing.

Although the resulting rope’s performance is streets ahead of its braid-on-braid equivalent, it is prone to chafe and is more likely to slip around the core.

In other words, the clutch catches the cover but the core can slide through until equilibrium is reached.

Many modern fibres do not melt, making them fray easily when cut

Next up the scale comes Technora, a para-aramid fibre woven far more tightly.

A coat of this is a little more expensive than a basic polyester cover, but the improvement in performance and chafe-resistance is huge.

If your halyards are wearing through and need replacing, it’s a no-brainer.

Finally, if you want to see your ropes in the dark, you can specify a cover that has a light-positive strand.

This works on the same principle as those garden lights that soak up power by day then illuminate when it’s dark.

The rope won’t dazzle you, but you’ll certainly appreciate being able to see it so easily at night.

What ropes to use in running rigging

On most cruisers, sheets and other ropes that are constantly adjusted and not under tremendous load can sensibly be braid-on-braid for economy, ease of splicing and soft feel.

Lines that are set up tightly then left are a different story, however.

On a boat with pretensions to performance, high-modulus ropes can make a dramatic difference.

A clutch needs to be closely matched with a rope’s breaking strain and diameter

Reef pennants are a case in point.

A Dyneema pennant can be a size or two smaller than the standard braidline item, yet will be just as strong and will stay tight once set up.

Main halyards should definitely be made out of some variety of Dyneema, ideally with a Technora coat or its equivalent.

Wire halyards are a thing of the past now, particularly when rope can cope with almost the same loads for its size, with few of the drawbacks.

Headsail halyards should also ideally be top-quality rope, but on roller forestays it can be easier to maintain luff tension than on a mainsail.

So, if funds are tight, upgrade the main halyard first and see how you get on.

Creep stretch and elasticity definitions

Initial loading will result in elastic extension.

This happens upon loading and is immediately recoverable upon release of the load (elastic contraction).

After the elastic extension of the initial loading, the rope will experience what is known as viscoelastic extension.

This is further extension over time and is fairly limited.

It’s not a question of ‘best’ or ‘cheapest’, but buying rope with the right properties for the task

Unlike elastic stretch, viscoelastic stretch will only recover slowly over time once the load is released.

Finally there is creep, which is permanent, non-recoverable and time-dependent.

Creep occurs at the yarn molecular level when the rope is under constant load.

Once the load is released and elastic and viscoelastic extension recovered, the rope will ultimately have experienced an element of permanent extension.

This is a factor of both creep and ‘bedding in’, which is when individual fibre components in the rope and/or splice settle into their preferred position when under load.

Enjoyed reading Rope, rigging & deck gear: how to choose the right rope?

A subscription to Yachting Monthly magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

YM is packed with information to help you get the most from your time on the water.

- Take your seamanship to the next level with tips, advice and skills from our experts

- Impartial in-depth reviews of the latest yachts and equipment

- Cruising guides to help you reach those dream destinations

Follow us on Facebook , Twitter and Instagram.

standing rigging

- rope and line

- cams, cleats and clutches

- head sail gear

- roller furling

- main sail control

- mast hardware

- eye straps and pad eyes

- fairleads and bulls eyes

- anchor and docking

- miscellaneous hardware

- Alexander Roberts

- My Wishlist

- Customer Service

- Order Tracking

- Your Account

- Store Policies & Info

- Privacy Policy

- Helpful Links

- Payment Methods

Shopping Cart: 0 Items

Logging Supplies,Rigging Supplies, Black Diamond Chokers, Dyneema, Xtremaline, Skidder Chains, Logging Chokers, Crosby, CM, Peerless

WHEN YOU DRAG IT

It doesn't matter if you drag logs, move earth, or lay pipeline, o ur full line of wire rope products ensure that you get the most out of your winch and o ur traction control products will keep the job moving in the worst of conditions

We Deliver...

Materials you need to get the job done.

What Do You Do?

Industrial supply built on , what you need,, when you need it, when you lift it.

With over 30 years of experience, Redwing combines the quality of brands you trust with a team of experienced riggers to give you what you need to get the job done.

Quality You Can Depend On

WHEN YOU TIE IT DOWN

After 30 years of running the roads, we know that it's not enough to get it on the trailer, you have to keep it there. From binders to corner protectors, we have what you need to keep the load in place and deliver.

Reliability From Start To Finish

WHEN YOU CLIMB IT

It doesn't matter if you climb trees, towers, or wind mills. Redwing has the gear to help you reach new heights. Our selection of gear comes from industry leading manufacturers so you can work at height with peace of mind.

Security To Get The Job Done

Succesfully added to Request List!

- Search for:

- BSI Fiber Rigging

- BSI Rod Rigging

- Compact Strand Dyform Wire

- OS Wire Equipment

- Accessories

- Deck Filler

- Kick service

- Main Sheet – Easymatic

- Flush Hatches

- Lowline Hatches

- Offshore Hatches

- Flush Portlight

- Spare Parts

- Rigging service programme

- Certified Service Centres

- Dealer and service

BSI service

BSI’s service and refit program is based upon a worldwide network of highly respected and experienced rigging companies and service technicians.

REPLACE THE OLD, Leaky deck hatch

SPECIALIst Equipment For your yacht

BSI Group provides you with a unique selection of specialist equipment for cruising, racing, and super yachts from the most dedicated brands in the business.

BSI rigging

Made by sailors, for sailors.

Trusting Mother Nature to carry you safely across the seven seas is a lot easier with top of the line components on board.

Specialist maritime equipment We design, manufacture and market specialist equipment for cruising, racing, and super yachts. Our goal is, and has always been, best-in-class products with the strength to handle anything a raging sea can throw at them, without compromising control or speed.

EXCELLENCE ONBOARD

BSI Group provides you with Specialist Equipment for Cruising, Racing, and Super Yachts from some of the business’ most dedicated brands – all under one sail.

REFIT AND REPAIR

Refit BSI’s service and refit program is based upon a worldwide network of highly respected and experienced rigging companies and service technicians.

Repair Replace the old leaky deck hatch with a new, tight and modern one. Wear, sand and water have left their mark on the old deck hatch so now is the time to change it.

- BSI Rigging

BSI Rigging is a leading player in the yacht rigging industry supplying to OEM yards, private superyacht customers and leading mast manufacturers. The rod, wire and fibre range and associated hardware offer customers a broad range of solutions to meet their standing rigging needs. Our rigging range includes the following products.

The best-in-class rod rigging products with the strength to handle all a ranging sea and the elements can throw at them. BSI standing rod rigging and fittings are designed and manufactured in house on BSI’s own CNC machines.

BSI fibre rigging is a high-performance solution for standing rigging saving weight aloft whilst providing s sound solution, available in a number of materials made to the highest grade suitable for the specific yacht and mast.

OS high quality wire rigging, and fittings for privately owned boats in addition to supplying to many leading production boat yards. BSI offer full traceability and strict quality control on all products with guaranteed value for money.

BSI offer a service programme backed by a global network of dealers and service agents. All boats rigged by BSI have a history log to enable refit plans to fit within a yachts schedule.

news & events

Stay updated.

BSI at St Barths Bucket 2024

METS 2023 – 12.540

Beagle V #FollowTheRig 20+ Year Service

Back-to-Back Regatta Wins for BSI Rigged Nakupenda

- OYS Rigging

- Gori Propeller

- Easy products

- Moonlight products

- Jefa Steering

- Hundested Propeller

- OMS – Ocean Marine Systems

- Fjordagervej 34-36 DK-6100 Haderslev T: +45 7322 2222 E: [email protected]

Username or email address *

Password *

Remember me Log in

Lost your password?

Currency: GBP

- Worldwide Delivery

Mooring Warps and Mooring Lines

- LIROS 3 Strand Polyester Mooring Warps

- LIROS Green Wave 3 Strand Mooring Warps

- LIROS Braided Dockline Mooring Warps

- LIROS Handy Elastic Mooring Warps

- Marlow Blue Ocean Dockline

- LIROS Super Yacht Mooring Polyester Docklines

- 50 metre / 100 metre Rates - Mooring

Mooring Accessories

- Mooring Compensators

Mooring Strops and Bridles

- V shape Mooring Bridles

- Y shape Mooring Bridles

- Small Boat and RIB Mooring Strops

- Mooring Strops

- Mooring Strops with Chain Centre Section

Mooring Assistance

- Coastline Bow Thruster Accessories

- Max Power Bow Thrusters

- Bonomi Mooring Cleats

- Majoni Fenders

- Polyform Norway Fenders

- Ocean Inflatable Fenders

- Dock Fenders

- Fender Ropes and Accessories

Mooring Components

- Mooring Swivels

- Mooring Shackles

- Mooring Cleats and Fairleads

- Mooring Buoys

Mooring Information

- Mooring Warps Size Guide

- Mooring Lines - LIROS Recommended Diameters

- Mooring Rope Selection Guide

- Mooring Warp Length and Configuration Guide

- How to estimate the length of a single line Mooring Strop

- Mooring Ropes - Break Load Chart

- Mooring Compensator Advisory

- Rope Cockling Information

- Fender Size Guide

- Majoni Fender Guide

- Polyform Norway Fender Inflation Guide

- More Article and Guides >

Anchor Warps Spliced to Chain

- LIROS 3 Strand Nylon Spliced to Chain

- LIROS Anchorplait Nylon Spliced to Chain

Anchor Warps

- LIROS Anchorplait Nylon Anchor Warps

- LIROS 3 Strand Nylon Anchor Warps

- Leaded Anchor Warp

- Drogue Warps and Bridles

- 50 / 100 metre Rates - Anchoring

- Aluminium Anchors

- Galvanised Anchors

- Stainless Steel Anchors

Calibrated Anchor Chain

- Cromox G6 Stainless Steel Chain

- G4 Calibrated Stainless Steel Anchor Chain

- Lofrans Grade 40

- MF DAMS Grade 70

- MF Grade 40

- Titan Grade 43

- Lewmar Windlasses

- Lofrans Windlasses

- Maxwell Windlasses

- Quick Windlasses

- Windlass Accessories and Spares

Chain Snubbers

- Chain Hooks, Grabs and Grippers

- Chain Snubbing Bridles

- Chain Snubbing Strops

Anchoring Accessories

- Anchor Connectors

- Anchor Trip Hooks and Rings

- Anchoring Shackles

- Bow Rollers and Fittings

- Chain and Anchor Stoppers

- Chain Links and Markers

Anchoring Information

- How To Choose A Main Anchor

- Anchoring System Assessment

- Anchor Chain and Rope Size Guide

- The Jimmy Green Guide to the Best Anchor Ropes

- What Size Anchor Do I Need?

- Anchor to Chain Connection Guide

- How to Choose Your Anchor Chain

- How to Establish the Correct Anchor Chain Calibration?

- Calibrated Anchor Chain - General Information

- Calibrated Anchor Chain Quality Control

- Calibrated Chain - Break Load and Weight Guide

- Galvanising - Managing Performance and Endurance expectation

- Can Galvanised Steel be used with Stainless Steel?

- Windlass Selection Guide

- More Articles and Guides

Stainless Steel Wire Rigging and Wire Rope

- 1x19 Wire Rigging

- 50 / 100 metre Rates - Wire and Fibre

- 7x19 Flexible Wire Rigging

- Compacted Strand Wire Rigging

Dinghy Rigging

- Stainless Steel Dinghy Rigging

- Dinghy Rigging Fittings

Fibre Rigging

- LIROS D-Pro Static Rigging

- LIROS D-Pro-XTR Fibre Rigging

- DynIce Dux Fibre Rigging

- Fibre Rigging Fittings

Wire Terminals

- Cones, Formers, Wedges, Ferrules, Rigging Spares

- Hi-Mod Swageless Terminals

- Sta-Lok Swageless Terminals

- Swage Terminals

Wire Rigging Fittings

- Turnbuckle Components

Rigging Accessories

- Rigging Chafe Protection

- Headsail Reefing Furlers

- Plastimo Jib Reefing

- Selden Furlex Reefing Gear

Furling Systems

- Anti-torsion Stays

- Straight Luff Furlers

- Top Down Furlers

Guard Wires, Rails and Fittings

- Guard Rail Fittings

- Guard Rails in Fibre and Webbing

- Guard Wire Accessories

- Guard Wires

Standing Rigging Assistance

- Replacing your Furling Line

- Fibre Rigging Break Load Comparison Guide

- More Articles and Guides >

- Cruising Halyards

- Performance Halyards

- Dinghy Halyards

Rigging Shackles

- Captive and Key Pin Shackles

- hamma™ Snap Shackles

- Soft Shackles

- Standard Snap Shackles

- Wichard Snap Shackles

Classic Ropes

- Classic Control Lines

- Classic Halyards

- Classic Sheets

- Cruising Sheets

- Performance Sheets

- Dinghy Sheets

Sail Handling

- Boom Brakes and Preventers

- Lazy Jack Sail Handling

- Rodkickers, Boomstruts

- Sail Handling Accessories

50 / 100 metre Rates - Running Rigging

- 50 / 100 metres - Cruising Ropes

- 50 / 100 metres - Dinghy Ropes

- 50 / 100 metres - Performance Ropes

Control Lines

- Cruising Control Lines

- Performance Control Lines

- Dinghy Control Lines

- Continuous Control Lines

Running Rigging Accessories

- Anti-Chafe Rope Protection

- Lashing, Lacing and Lanyards

- Mast and Boom Fittings

- Rope Stowage

- Sail Ties and Sail Stowage

- Shock Cord and Fittings

- LIROS Ropes

- Marlow Ropes

Running Rigging Resources

- Running Rigging Rope Fibres and Construction Explained

- How to Select a Suitable Halyard Rope

- How to select Sheets and Guys

- Dyneema Rope - Cruising and Racing Comparison

- Dinghy Rope Selection Guide

- Rope Measurement Information

- Running Rigging - LIROS Recommended Line Diameters

- Running Rigging Break Load Comparison Chart

- Colour Coding for Running Rigging

- Selecting the right type of block, plain, roller or ball bearing

- Recycling Rope

- Running Rigging Glossary

Plain Bearing Blocks

- Barton Blocks

- Harken Element Blocks

- Low Friction Rings

- Selden Yacht Blocks

- Wichard MXEvo Blocks

- Wooden Yacht Blocks

Control Systems

- Ratchet Blocks

- Stanchion Blocks and Fairleads

- Snatch Blocks

- Genoa Car Systems

- Traveller Systems

- Block and Tackle Purchase Systems

Ball Bearing Blocks

- Harken Ball Bearing Blocks

- Selden Ball Bearing Blocks

Roller Bearing Blocks

- Harken Black Magic Blocks

- Selden Roller Bearing Blocks

Deck Fittings

- Bungs and Hatches

- Bushes and Fairleads

- Deck Eyes, Straps and Hooks

- Pad Eyes, U Bolts and Eye Bolts

- Pintles and Gudgeons

- Tiller Extensions and Joints

- Harken Winches, Handles and Accessories

- Barton Winches, Snubbers and Winchers

- Lewmar Winches, Handles and Accessories

- Winch Servicing and Accessories

Clutches and Organisers

- Barton Clutches and Organisers

- Spinlock Clutches and Organisers

- Lewmar Clutches

- Harken Ball Bearing Cam Cleats

- Barton K Cam Cleats

Deck Hardware Support

- Blocks and Pulleys Selection Guide

- Barton High Load Eyes

- Dyneema Low Friction Rings Comparison

- Seldén Block Selection Guide

- Barton Track Selection Guide

- Barton Traveller Systems Selection Guide

- Harken Winch Selection Guide

- Karver Winch Comparison Chart

- Lewmar Winch Selection Guide - PDF

- Winch Servicing Guide

Sailing Flags

- Courtesy Flags

- Red Ensigns

- Blue Ensigns

- Signal Code Flags

- Flag Staffs and Sockets

- Flag Accessories

- Flag Making and Repair

- Webbing only

- Webbing Soft Shackles

- Webbing Restraint Straps

- Webbing Sail Ties

- Sail Sewing

- PROtect Tape

Fixings and Fastenings

- Screws, Bolts, Nuts and Washers

- Monel Rivets

Hatches and Portlights

- Lewmar Hatches

- Lewmar Portlights

- Fids and Tools

- Knives and Scissors

General Chandlery

- Carabiners and Hooks

- Antifouling

Flag Articles

- Flag Size Guide

- Bending and Hoisting Methods for Sailing Flags

- Courtesy Flags Identification, Labelling and Stowage

- Courtesy Flag Map

- Flag Etiquette and Information

- Glossary of Flag Terms and Parts of a Flag

- Making and Repairing Flags

- Signal Code Message Definitions

Other Chandlery Articles

- Anchorplait Splicing Instructions

- Antifoul Coverage Information

- Hawk Wind Indicator Selection Guide

- Petersen Stainless - Upset Forging Information

- Speedy Stitcher Sewing Instructions

- Thimble Dimensions and Compatible Shackles

Jackstays and Jacklines

- Webbing Jackstays

- Stainless Steel Wire Jackstay Lifelines

- Fibre Jackstay Lifelines

- Jackstay and Lifeline Accessories

Lifejackets

- Crewsaver Lifejackets

- Seago Lifejackets

- Spinlock Lifejackets

- Children's Life Jackets

- Buoyancy Aids

Floating Rope

- LIROS Multifilament Polypropylene

- LIROS Yellow Floating Safety Rope

Guard Wires, Guardrails and Guardrail Webbing

Lifejacket accessories.

- Lifejacket Lights

- Lifejacket Rearming Kits

- Lifejacket Spray Hoods

- Safety Lines

Seago Liferafts

- Grab Bag Contents

- Grab Bags and Polybottles

- Liferaft Accessories

- Danbuoy Accessories

- Jimmy Green Danbuoys

- Jonbuoy Danbuoys

- Seago Danbuoys

Overboard Recovery

- Lifebuoy Accessories

- Purchase Systems

- Slings and Throwlines

Safety Accessories

- Fire Safety

- Sea Anchors and Drogues

Safety Resources

- Guard Wires - Inspection and Replacement Guidance

- Guard Wire Stud Terminal Dimensions

- Webbing Jackstays Guidance

- Webbing Jackstays - Custom Build Instructions

- Danbuoy Selection Guide

- Danbuoy Instructions - 3 piece Telescopic - Offshore

- Liferaft Selection Guide

- Liferaft Servicing

- Man Overboard Equipment - World Sailing Compliance

- Marine Safety Information Links

- Safety Marine Equipment List for UK Pleasure Vessels

Sailing Clothing

- Sailing Jackets

- Sailing Trousers

- Thermal Layers

Leisure Wear

- Accessories

- Rain Jackets

- Sweatshirts

Sailing Footwear

- Dinghy Boots and Shoes

- Sailing Wellies

Leisure Footwear

- Walking Shoes

Sailing Accessories

- Sailing Bags and Holdalls

- Sailing Gloves

- Sailing Kneepads

Clothing Clearance

Clothing guide.

- What to wear Sailing

- Helly Hansen Mens Jacket and Pant Size Guide

- Helly Hansen Womens Sailing Jacket and Pant Size Guide

- Lazy Jacks Mens and Womens Size Charts

- Musto Men's and Women's Size Charts

- Old Guys Rule Size Guide

- Sailing Gloves Size Guides

- Weird Fish Clothing Size Charts

The Jimmy Green Clothing Store

Lower Fore St, Beer, East Devon, EX12 3EG

- Adria Bandiere

- Anchor Marine

- Anchor Right

- August Race

- Barton Marine

- Blue Performance

- Brierley Lifting

- Brook International

- Brookes & Adams

- Captain Currey

- Chaineries Limousines

- Coastline Technology

- Colligo Marine

- Cyclops Marine

- Douglas Marine

- Ecoworks Marine

- Exposure OLAS

- Fire Safety Stick

- Fortress Marine Anchors

- Hawk Marine Products

- Helly Hansen

- International

- Jimmy Green Marine

- Maillon Rapide

- Mantus Marine

- Marling Leek

- Meridian Zero

- MF Catenificio

- Ocean Fenders

- Ocean Safety

- Old Guys Rule

- Petersen Stainless

- Polyform Norway

- PSP Marine Tape

- Sidermarine

- Stewart Manufacturing Inc

- Team McLube

- Technical Marine Supplies

- Titan Marine (CMP)

- Ultramarine

- Waterline Design

- William Hackett

Clearance LIROS Racer Dyneema £55.08

Clearance Folding Stock Anchor £123.25

Clearance Sarca Excel Anchors £294.00

Clearance LIROS Herkules £0.00

Clearance Barton Size 0 Ball Bearing Blocks - 5mm £0.00

Clearance Marlow Blue Ocean® Doublebraid £18.48

Mooring Clearance

Anchoring clearance, standing rigging clearance, running rigging clearance, deck hardware clearance, chandlery clearance, safety clearance, guide to tackling a complete re-rig.

30 Oct 2018

Replacing your Standing Rigging with Jimmy Green Marine

The task of replacing the standing rigging on a sailing yacht may seem daunting but there is a procedure to follow that can make it a relatively straight forward process for anyone who is reasonably practical.

The first decision is whether to tackle the job with the mast up or down.

If you have enough time together with the availability of a mast lift, then mast down is by far the easier option. The whole project will be much easier with the mast horizontal and chocked up on firm ground and accessible to work. You may even elect to carry out the upper mast inspection after lowering the mast to save going aloft in a bosuns chair. You will be able to purchase each wire with swaged terminals at both ends finished and ready to fit. You can order yourself online or with help from the Jimmy Green Rigging Team.

You can take confidence from the fact there is a good deal of adjustment on the rigging screws to allow for any minor errors in measurement. It’s worth noting that Team Jimmy Green set the turnbuckles at 2/3 open unless otherwise requested and undertake to produce the finished wires accurately to within plus or minus the diameter of the wire.

If the mast has to remain stepped, you need a slightly different approach, generally involving the purchase of each wire over long with the top terminal swaged. The bottom end will need to be finished in situ by cutting to the exact length and fitting a DIY swageless (mechanical) terminal. Modern Swageless terminals from Sta-Lok or Petersen are fairly simple to fit so you can be confident of success.

Rigging Checklist

- Rig Tune and Tension check on existing rigging

- Consider any design or specification alterations

- Close inspection of all components including measuring diameters

- Take photos

- Mark all tension settings (with tape above and/or below the rigging screw)

- Determine any possible improvements

- Order process for mast unstepped

- Order process for mast remaining stepped

Each step is explained more fully below:

1. Rig Tune and Tension check on existing rigging

Begin by checking that your current rigging is set up and tuned correctly. This need not be as technical as it sounds - you just need to be sure that you are copying a rig that works well. The essentials are mast rake and bend, athwartship vertical alignment and correct tensioning. You may want to elicit some professional advice but if your current set up performs satisfactorily upwind and downwind on both tacks/gybes, it may be best not to interfere with the current settings. The aim of the game is to replicate the old rig with a new one within parameters that allow for adjustment and tuning.

Look for extra unnecessary shackles or toggles which may have been added to compensate for the wire being too short and determine whether they can be omitted from the new rig.

2. Consider any design or specification alterations

The next step is to survey all aspects of the rigging including an assessment of whether the existing is the right design and specification for your anticipated purposes e.g Coastal, Offshore or Ocean Cruising, occasional or hard core racing.

3. Close inspection of all components

Carry out a thorough inspection of the rigging including all the wire, terminals and clevis pins. Establish the size of every component and make notes. A good quality pair of callipers is an invaluable investment for producing accurate results.

Once you have confirmed the wire diameter, the approximate length and identified the terminals top and bottom, it is a simple online exercise to get an accurate estimate of the replacement cost on JimmyGreen.com/standing rigging . Alternatively, Team Jimmy Green can readily produce a costing based on the same information.

4. Take photos

Take photos of everything including zoomed in detail of anything you are not sure about and any others that will serve as a reminder when fitting the new shrouds and stays.

Check for any signs of wear or structural damage and identify the probable cause. Problems can occur for many reasons e.g. misalignment leading to stress at an odd angle, fittings that allow unnecessary movement, lack of articulation due to missing toggles, undersize clevis pins or oversize clevis pin holes. Some of these may be part of the reason that you are replacing the rig so it is best to avoid repeating the issue on the new set up.

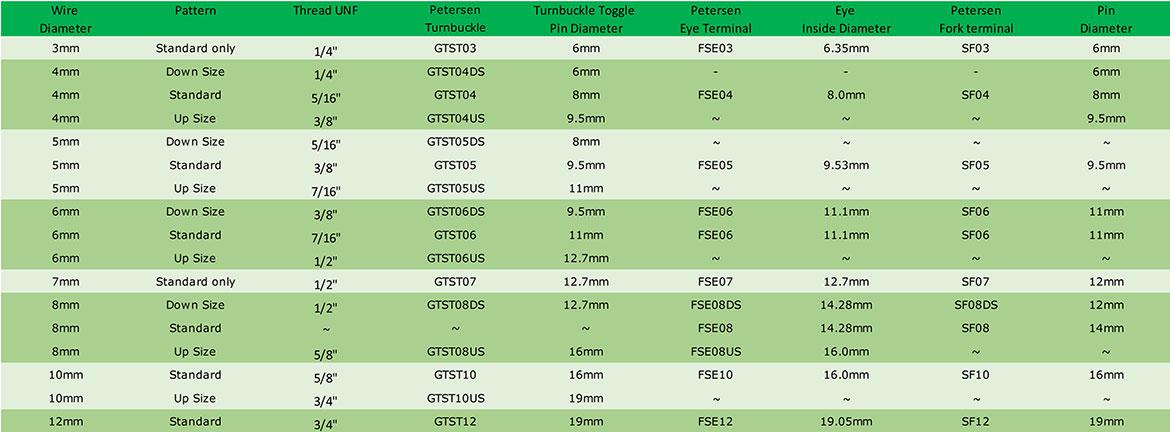

There are standard pin and hole diameters that correspond with the thread size of the studs in the turnbuckles. There is a varied choice of stud/turnbuckle sizes on each wire diameter. Components either side of the normal sizing ared enotes as Down Size and Up Size by Petersen Stainless Rigging. Threads are generally UNF or possibly the Metric equivalent. The table below sets out all the relevant sizes for standard, down size and up size components. If your rigging has special non standard characteristics, the Jimmy Green Rigging Team can source bespoke replacements or suggest suitable alternatives.

This chart is a guide only. Please check all dimensions before ordering your rigging.

5. Mark all tension settings

Make a note of all the turnbuckle settings before you disconnect any shrouds or stays by marking them with tape or taking photos. You will need to loosen all the turnbuckles to disconnect them at deck level.

Remember to return them to their noted settings before measuring. The new rigging can then be made to the required length with the optimum adjustment, normally 2/3 open.

6. Determine any possible improvements

One last check to ensure that there isn’t a change of fitting or a tweak in the set up that will make the new rig an improvement on the old one.

7. Order Process for Mast Unstepped.

Dependent on the time factor there are two main options to consider:

Determine the terminals required, measure the wires, make any adjustments and place your order either online or by emailing your requirements for Team Jimmy Green to load the order for you.

N.B. The old wires should be removed from the mast, pulled out taut with a little tension if possible to ensure that they are straight in readiness for measuring.

Measurements are from bearing edge to bearing edge of the pins or eyes.

For T terminals and studs, refer to our Standing Rigging Custom Build Instructions .

Label the individual stays. You may need them as an aide memoire when you come to fit the new standing rigging.

Check and double check your measurements and terminal fittings before ordering. Remember the old adage: “Measure twice, cut once”.

Remove the old stays, labelling them carefully as you go and noting any amendments required to length or fittings.

Coil the wires as neatly as possible.

Send them or bring them to Jimmy Green Marine for assessment and a quote.

This option puts the onus on the Jimmy Green Rigging Team to replicate your rigging accurately.

8. Order Process for mast remaining stepped

Establish the length of the existing shrouds and stays.

Order new wires with the required top terminals swaged on and the wire length appropriately over length for cutting and fitting in situ.

Order DIY swageless terminals for the bottom end.

The wire should be long enough so that it can be cut and fitted with the new swageless terminal to finish at the desired length.

N.B. Replacing the forestay will be tricky if it is fitted with a headsail furler and you may need professional help.

Standing Rigging Assistance Shop for Standing Rigging

Related products

Spinlock rig-sense tension gauge, 5mm 1x19 stainless steel wire standing rigging, sta-lok stud, petersen stainless insulators - compression and compression, 100 metre reel - 1x19 stainless steel wire, author: jimmy green, you may also like.

Carrying replacement rigging for emergency use

Keyboard_arrow_left sea anchors and yacht drogues, sheets and halyards selection guide keyboard_arrow_right.

We've detected unusual activity from your computer network

To continue, please click the box below to let us know you're not a robot.

Why did this happen?

Please make sure your browser supports JavaScript and cookies and that you are not blocking them from loading. For more information you can review our Terms of Service and Cookie Policy .

For inquiries related to this message please contact our support team and provide the reference ID below.

IMAGES

VIDEO

COMMENTS

A sailboat's standing rigging is generally built from wire rope, rod, or occasionally a super-strong synthetic fibered rope such as Dyneema ®, carbon fiber, kevlar or PBO. 1×19 316 grade stainless steel Wire Rope (1 group of 19 wires, very stiff with low stretch) is standard on most sailboats. Wire rope is sized/priced by its diameter which ...

Marine Grade 316 stainless steel 1x19 wire is generally the wire rope of choice for Yacht Rigging on Cruising Yachts. Compact Stranded stainless steel wire offers enhanced performance for racing or extended cruising. Marine Grade stainless steel 7x19 wire offers a flexible option for running rigging. Break Load Comparison Chart by Wire ...

Expert Advice: Our representatives are always ready to help you choose the right rigging lines for your boat. Shop now and save, or browse accessories like. Can't find what you're looking for? Let us help. 206-632-4462. For durable sailboat rigging rope, rely on the experts at Fisheries Supply.

Fisheries Supply carries essential parts like wire rope assemblies, spreader boots, sheaves, and halyards required to preserve the integrity of your sailboat's complex rigging system. Update your boat's reliability by selecting high-quality stainless steel boat rigging hardware and sailboat running rigging gear designed expressly for the harsh ...

Standing Rigging for cruising yachts is mainly produced from a smooth, stiff and strong 1 x 19 construction. Compacted Strand 1 x 7 and 1 x 19 are used for enhanced performance. 7 x 19 is a flexible wire construction for use where the wire needs to turn corners e.g. around a block or sheave. Jimmy Green Marine offer a comprehensive range of ...

Whether you are refitting your sailboat or re-stocking your tow ropes, Strand Core has the marine wire rope size and construction you need. Strand Core offers type 302 / 304 and type 316 stainless products for both fresh and salt water applications. Sizes range from 3/32" to 5/8", in 1x19, 7x7, 6x19, and 6x37 constructions.

Premium UK Manufacturer of Marine Cable Rigging Assemblies for Sailboats & Yachts. With more than 50 years of supplying the global marine industry, we offer an extensive range of stainless steel marine fittings, turnbuckles, and terminals for Marine wire rope rigging. Sta-Lok is the preferred choice for professionals and sailboat owners.

Rigging Only is dedicated to providing quality sailboat hardware and sailboat rigging at affordable prices to sailors through out the world ... View Cart (0) (508) 992-0434. Toggle navigation. Shop All . standing rigging; life lines; rope and line; blocks; cams, cleats and clutches; head sail gear; roller furling ... either from measurements or ...

Sailboat Line & Rigging - Halyards, Sheets, Control Lines & More. Line is a critical part of any sailboat, from small dinghy to super yacht and everything in between. West Coast Sailing offers a wide variety of line and marine rope for every sailor from leading line manufacturers.

Standing rigging supports your boat's mast. If your standing rigging is old and corroded, consider replacing it. We offer a complete selection of standing rigging, including standard 1 x 19 stainless steel and Dyform wire. Do-it-yourselfers can take advantage of West Marine's complete selection of standing rigging hardware.

Nylon has long been the default rope for all running rigging in cruising yachts. Something with a bit of give is ideal for mooring. It might be 'braid-on-braid', with similar outer and inner . parts, as sold by most manufacturers, . or it could be a low-stretch polyester braidline (LSP) with a loosely laid .

The best place to buy ropes and rigging for your sailing boat. Ropes and steel wire ropes for industry and architecture. Menu. Search. Account. ... +31 20 419 64 12. Compare Products Premiumropes Lijnenspecialist Deutsch; The best place to buy ropes and rigging for your sailing boat. Ropes and steel wire ropes for industry and architecture. Menu.

The strength, minimal elongation, excellent corrosion resistance and general performance of KOS 1x19 construction stainless steel wire are suitable for most sailing yachts. High Performance Compact strand Wire is also available to custom build online. Jimmy Green Marine source stainless steel 1x19 wire rope up to and including 12mm diameter ...

Sailboat and yacht standing rigging of the highest quality, swage and mechanical terminals, rigging supplies and cable. Checkout View Cart (0) (508) 992-0434. Toggle navigation. Shop All ... (or your safety) to save a few pennies. All rigging components leaving our shop are to manufacturer's specification; we will not alter or customize them. ...

Our 1x19 wire from KOS is a high quality 316 stainless steel wire rope most commonly used for standing rigging, although becoming more and more popular for lifelines as well. Features. 316 Stainless Steel. Stiff and Low Stretch. Highly Polished for Marine Use. One Strand Consisting of 19 Wires. WS02. 1/16" Wire Dia, 1 x 19 Wire.

Choosing the Right Rope for Your Sailboat. By The Rigging Company February 27, 2014. Deciding what rope to buy for a specific application can be a bit complicated. Only because there are so many different manufacturers, products, and not to mention the vast array of terms associated with rope. Let's try and simplify this process a bit.

Installing Synthetic Standing Rigging. It was blowing 25 knots when the inner forestay let go. Eclipse, my 1984 Tayana 42, was screaming along on a broad reach just south of Saint Thomas. I had gone to raise the staysail, and upon putting a slight strain on the hanks, the stainless wire separated from its swagged fitting at the deck.

Redwing Company & Logging Supplies: 800-766-0285 We Deliver all your lifting & rigging supplies. Xtrema Line, Wire Rope Slings, and Chain lifting slings.

BSI Rigging is a leading player in the yacht rigging industry supplying to OEM yards, private superyacht customers and leading mast manufacturers. The rod, wire and fibre range and associated hardware offer customers a broad range of solutions to meet their standing rigging needs. Our rigging range includes the following products.

Bradley's third challenge was finding the Soviet cable in over 600,000 square miles (over 1.55 million square kilometers) of water. The answer came to him while he was remembering his boyhood on ...

The task of replacing the standing rigging on a sailing yacht may seem daunting but there is a procedure to follow that can make it a relatively straight forward process for anyone who is reasonably practical. ... Carry out a thorough inspection of the rigging including all the wire, terminals and clevis pins. ...

But one ship, a 197-foot-long, Russian-flagged trawler called the Saami, had behaved differently. Traveling at about 10 knots, it had passed back and forth over the LoVe cable at least four times ...